Semi-automatic cutting and rounding device for glass teapot body

A semi-automatic and teapot technology, which is applied to household containers and other directions, can solve the problems of high labor intensity, low efficiency, and waste of time for operators, so as to improve the cutting quality and the quality rate, improve the processing efficiency, and reduce the waiting time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

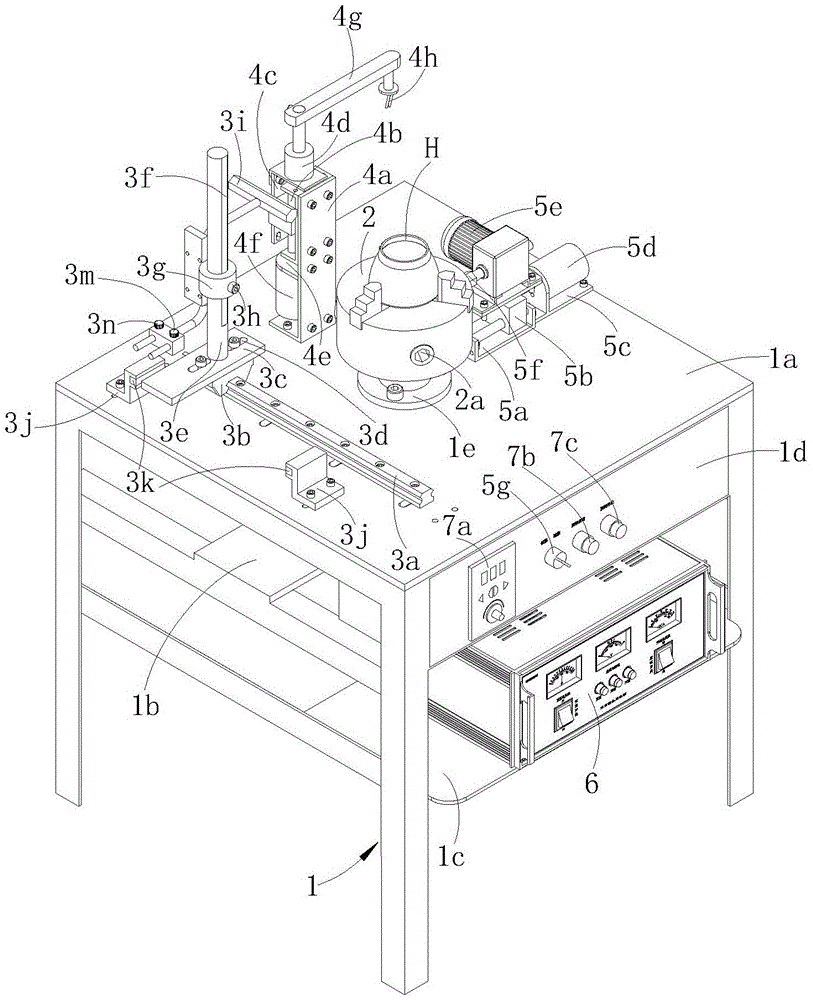

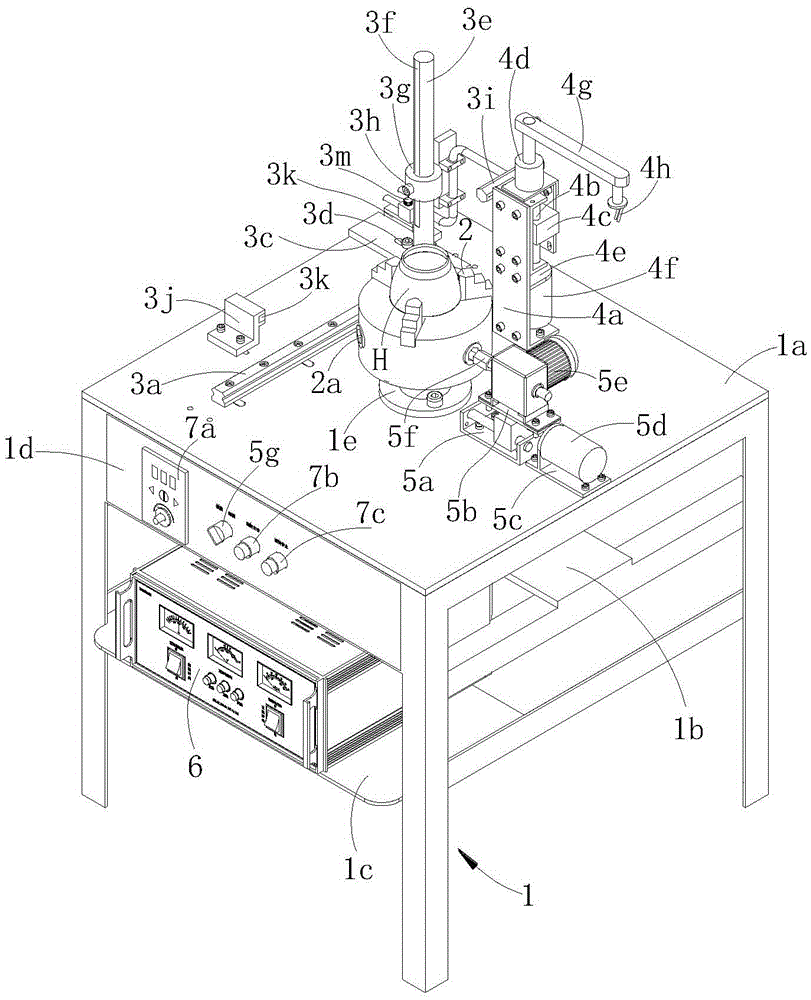

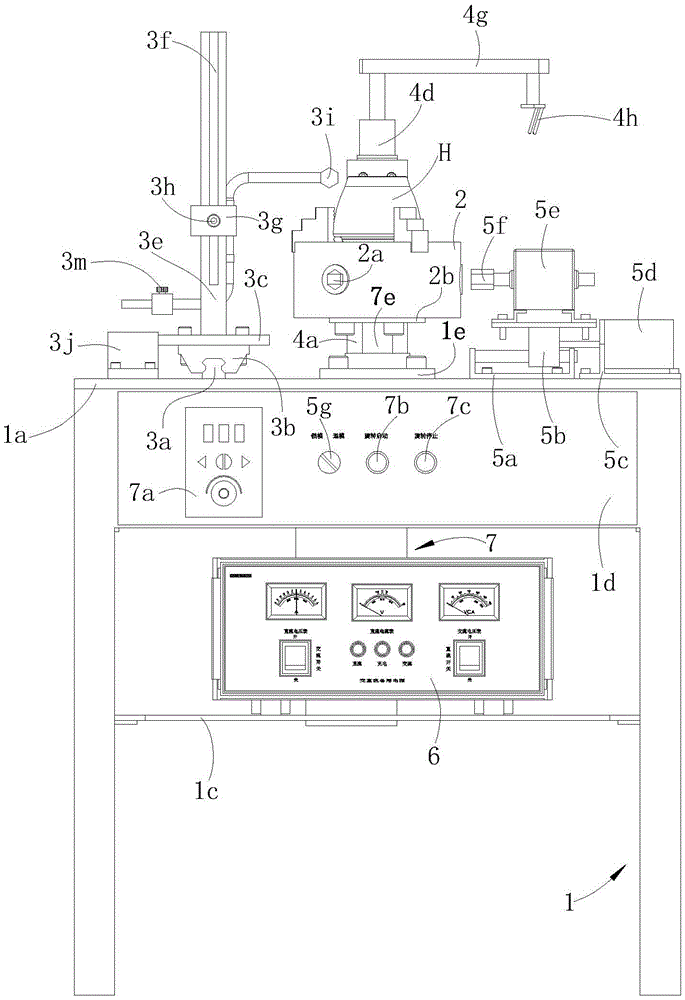

[0038] see figure 1 — Figure 5 :

[0039] The device includes a bracket 1, a chuck 2 for installing the kettle body H, a chuck motor 7, a chuck key 5f, a gun 3i, and a round rod 4h. , Chuck key 5f, musket 3i, round mouth rod 4h are higher than base plate 1a.

[0040] The chuck 2 is located at the middle area of the base plate 1a, the lower side of the chuck 2 is connected with the chuck flange 2b by bolts, there is a rotation gap between the chuck flange 2b of the chuck 2 and the base plate 1a, and the chuck flange 2b of the chuck 2 The axis is perpendicular to the bottom plate 1a, and the bayonet of the chuck 2 faces upward and away from the bottom plate 1a. The circumferential direction of the chuck 2 is evenly distributed with three key holes 2a of the same specification and shape, the center lines of the three key holes 2a are copla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com