Wire bending fatigue test device

A bending fatigue and testing device technology, applied in the direction of applying repetitive force/pulse force to test the strength of materials, etc., can solve the problems of reducing the bending fatigue life of the cord, the large diameter of the bending pulley, and the low running speed of the whole machine, so as to improve the test Efficiency, reduced size, fast rotation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

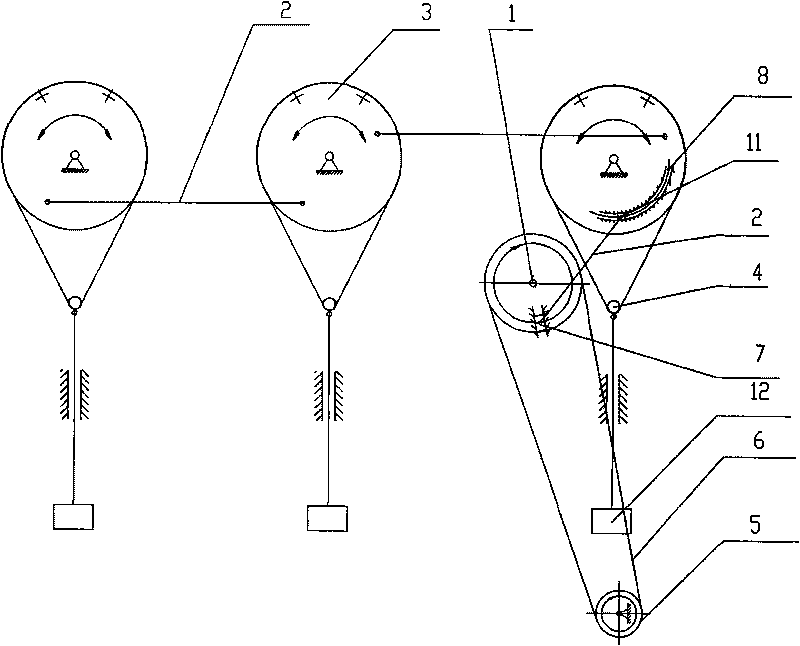

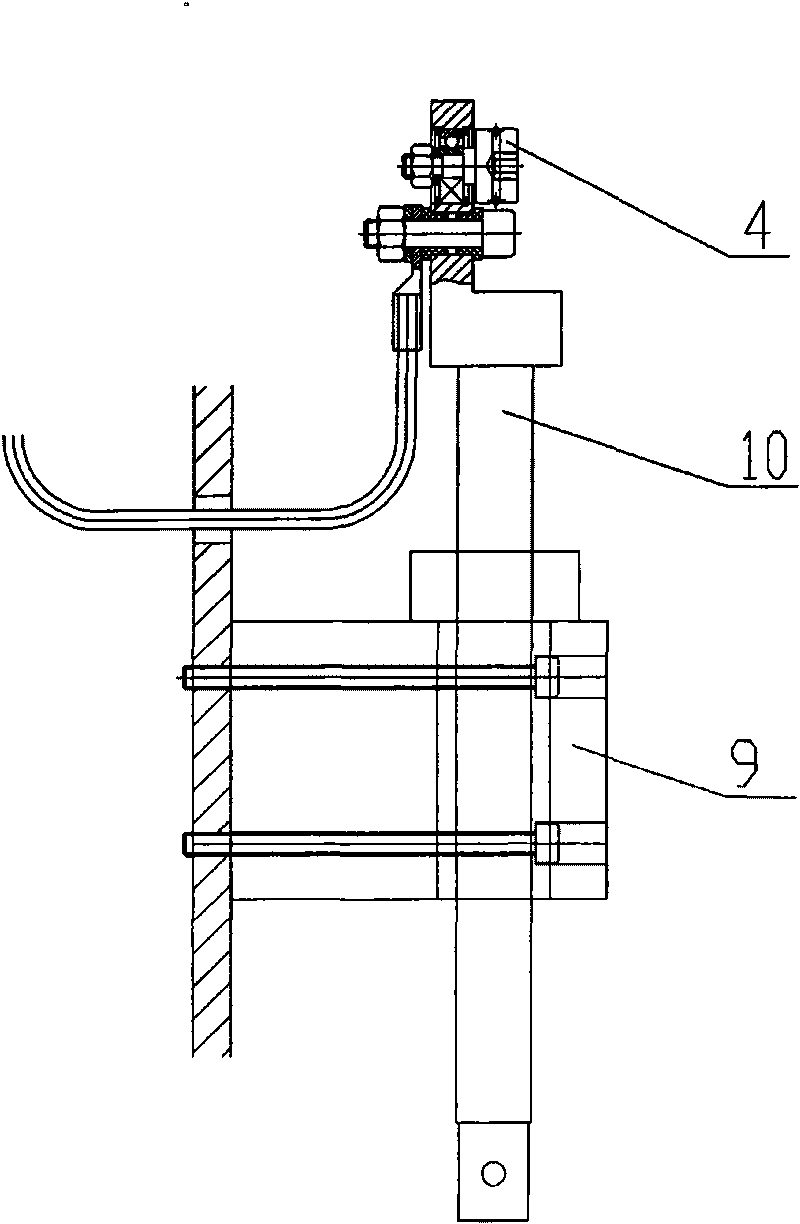

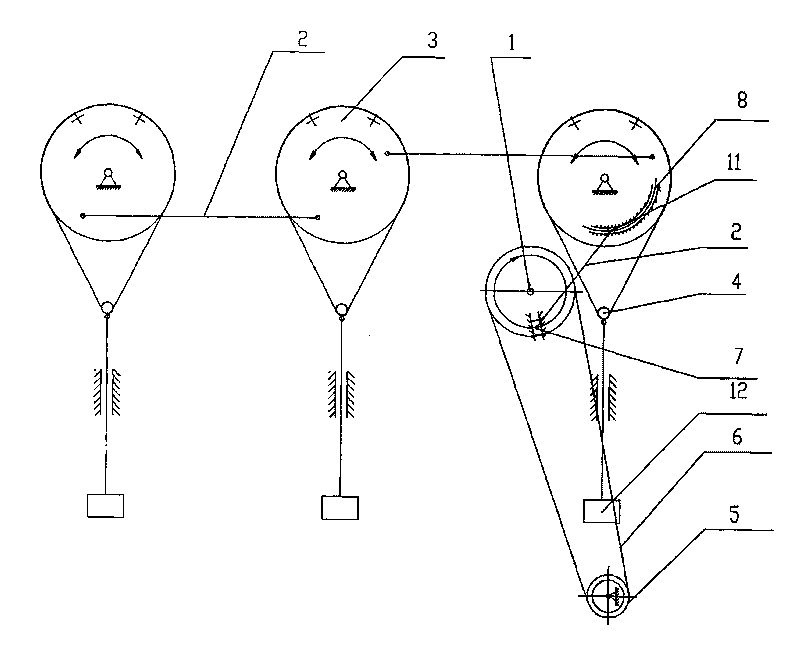

[0009] according to figure 1 and figure 2 As shown, a wire bending fatigue testing device of the present invention is mainly composed of a frame, a motor, an input shaft 1, a traction connecting rod 2, a balance wheel 3 and a roller 4, and the transmission device includes a reducer, a pulley 5 And transmission belt 6, motor drives speed reducer to carry out transmission, and speed reducer drives input shaft 1 to rotate by pulley 5, transmission belt 6. The end surface of the input shaft 1 is provided with a guide slider 7, and the guide slider 7 is provided with a long installation groove, and the bolt passes through the installation long groove to fix the guide slider 7 on the end surface of the input shaft 1. The driving end pin shaft of the traction link 2 is connected with the guide slider 7, the driven end pin shaft 11 of the traction link 2 is connected with the balance wheel 3, and the driven end pin shaft 11 is located in the arc groove 8 of the frame and can be move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com