Inspection well mouth cutting device and inspection well mouth construction method

A cutting device and inspection well head technology, which is applied in the field of engineering construction, can solve the problems that the advantages of prefabricated inspection well cover module assembly cannot be fully utilized, the bottom of the hole cannot be guaranteed to be flat, and the road takes a long time to improve cutting efficiency. High dimensional accuracy and hole quality, short cutting period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

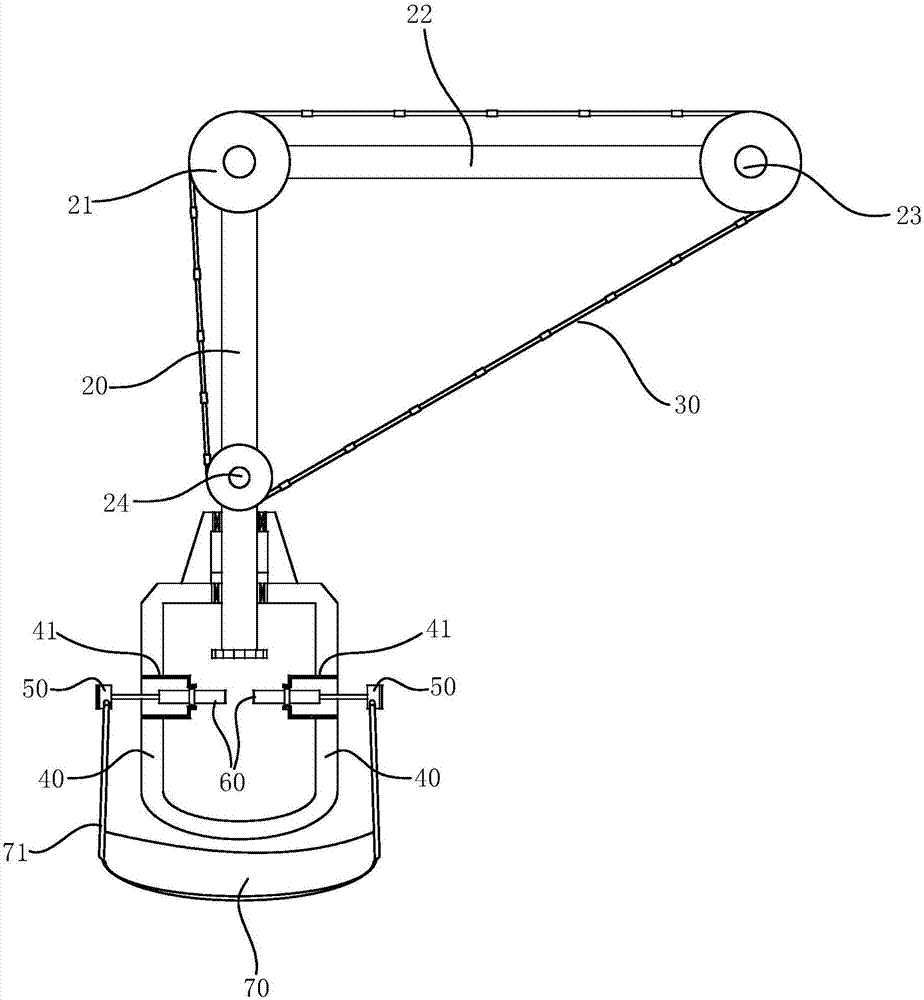

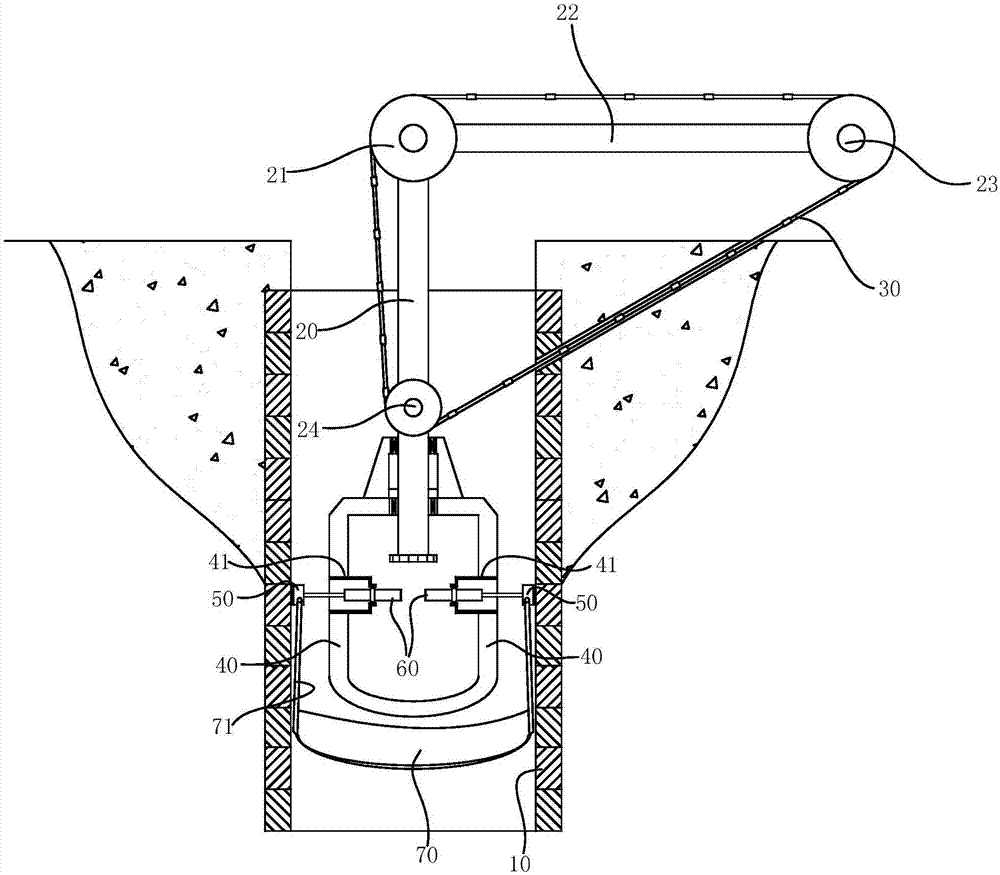

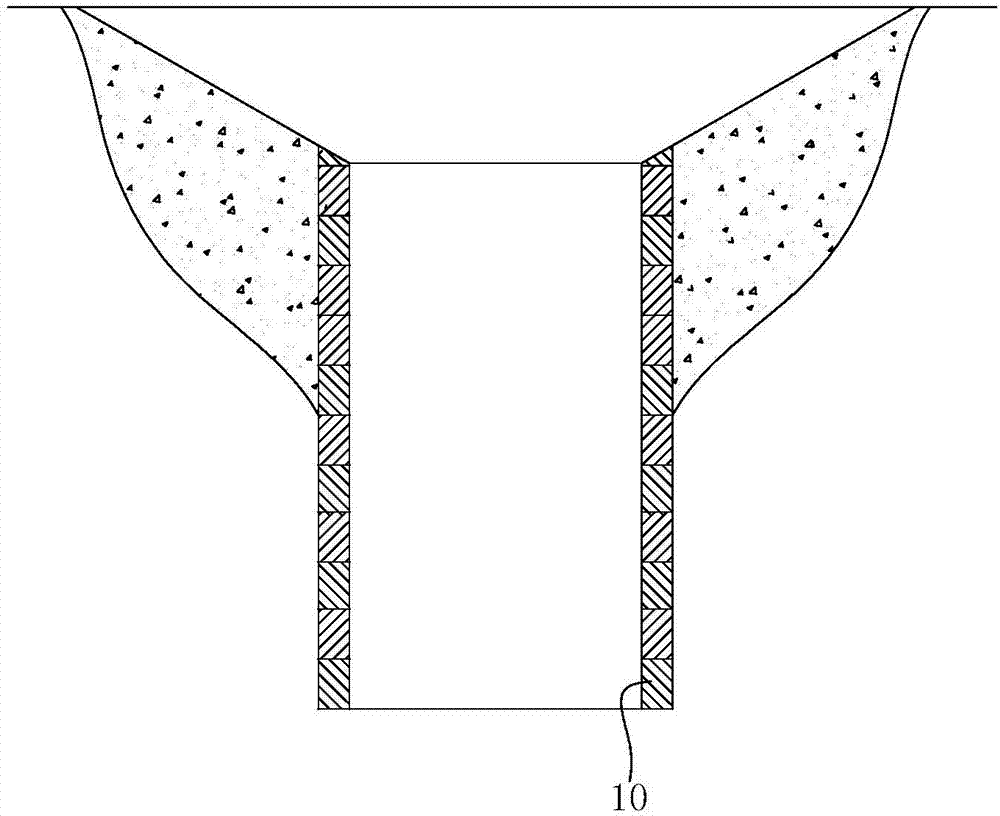

[0031] combine Figure 1 to Figure 4 , the present invention is further described:

[0032] A cutting device for the wellhead of the inspection well, comprising a positioning mechanism extending into the wellhead of the inspection well 10, a support rod 20 is arranged vertically on the positioning mechanism, the rod core of the support rod 20 is the same core as the inspection well 10, and the driving mechanism drives the support The rod 20 rotates, the upper end of the support rod 20 is provided with a wire saw 30, and the wire saw 30 passes through the well wall of the inspection shaft 10 and extends obliquely upward;

[0033] combine figure 1 with figure 2 As shown, the above-mentioned wire saw 30 arranged obliquely facilitates the construction of the wellhead of the inspection shaft 10, and starts the driving mechanism so that the support rod 20 rotates in the well hole of the inspection shaft 10, thereby realizing the cutting operation of the wellhead of the inspection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com