Cup rim processing technology and assembly line

A processing technology and assembly line technology, applied in metal processing equipment, metal processing mechanical parts, manufacturing tools, etc., can solve the problem of high cost of manipulators, achieve high work efficiency, good benefits, and increase the effect of daily output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

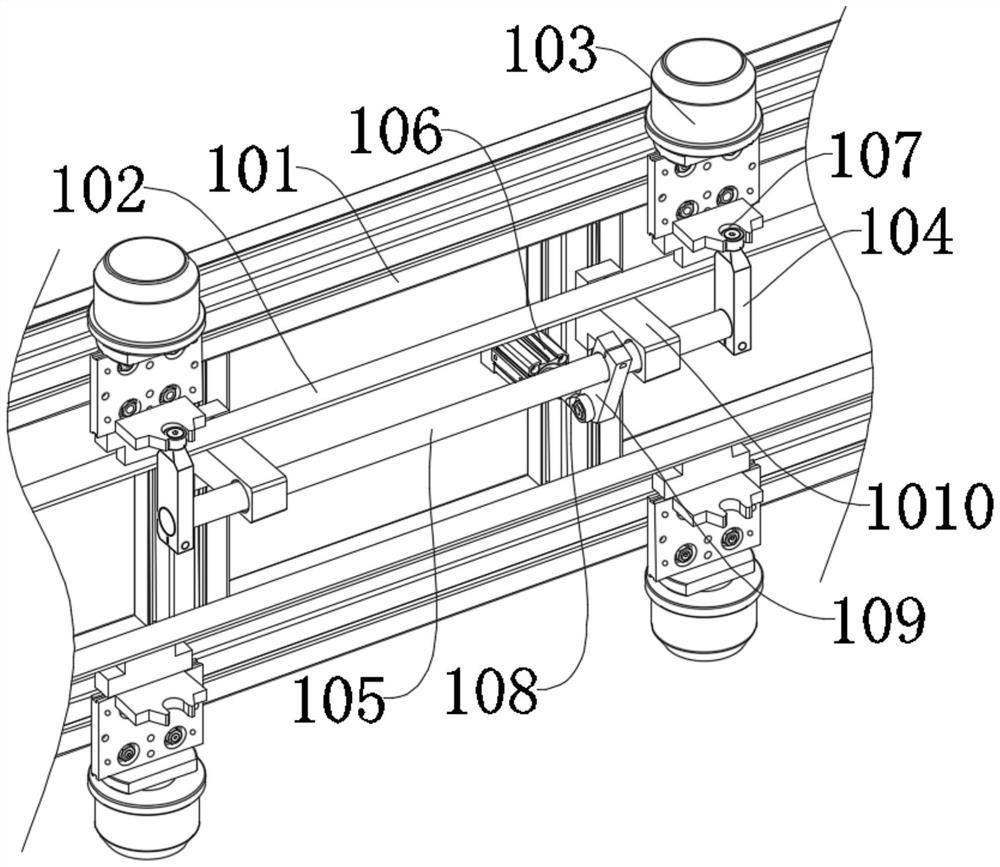

[0035] Cup mouth processing line, see first figure 1 and figure 2 , including an assembly line 1 for conveying cups, a feeding device 3 for placing cups to be processed on the assembly line 1, a necking device 4 arranged on one side of the assembly line 1, a cup mouth cutting device 5 and a loading and unloading device 2 , the feeding device 3 adopts a manipulator, and the cups to be processed in the rough shape are placed on the assembly line 1 by the manipulator, and the cups are transported through the assembly line 1. The loading and unloading device 2 matched with the mouth device 4 can simultaneously exchange the unprocessed cups on the assembly line 1 with the cups processed in the necking device 4, and the necking device 4 can shrink the mouth of the cup Processing, the assembly line 1 can move the cups that have been shrunk to the cup cutting device 5, and the cups that have been shrunk on the assembly line 1 and the cups are cut by the loading and unloading device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com