A 3D fast positioning tool for casting pouring riser cutting and its operation method

A technology for positioning tooling and pouring risers, which is applied in the field of valve body positioning and cutting devices, and can solve the problems that the workpiece to be cut cannot be positioned accurately, the cutting accuracy cannot be guaranteed, and the identification is affected

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

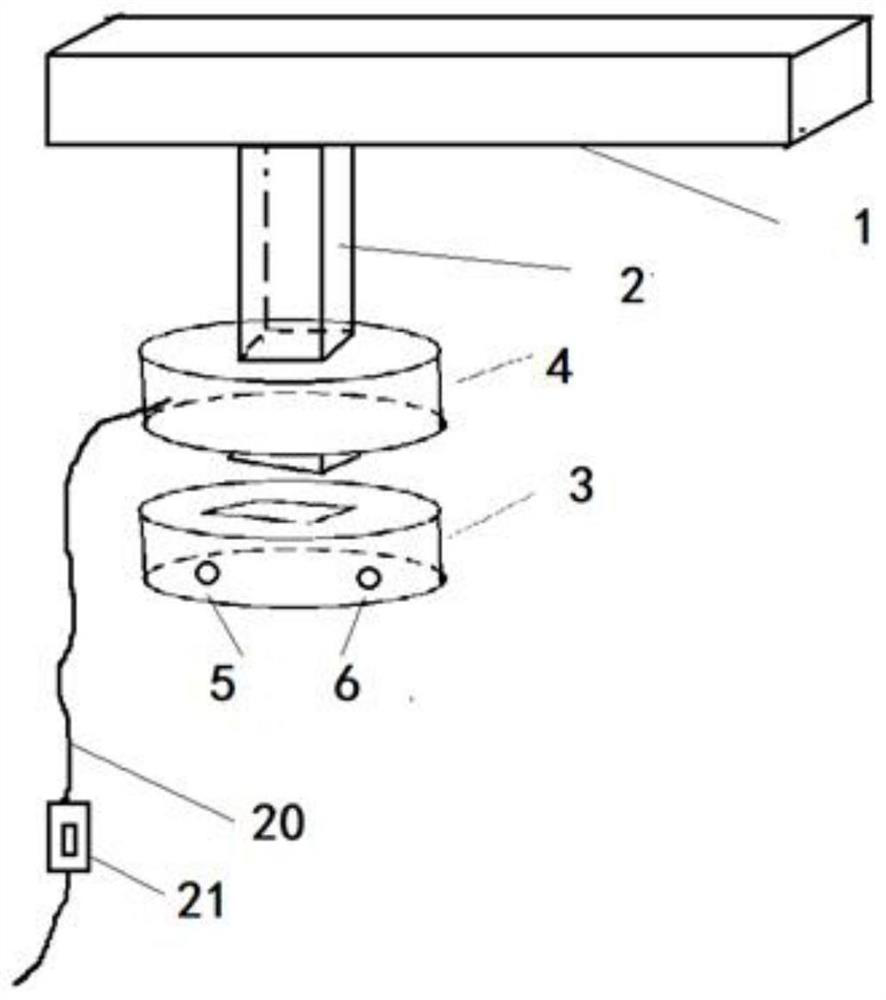

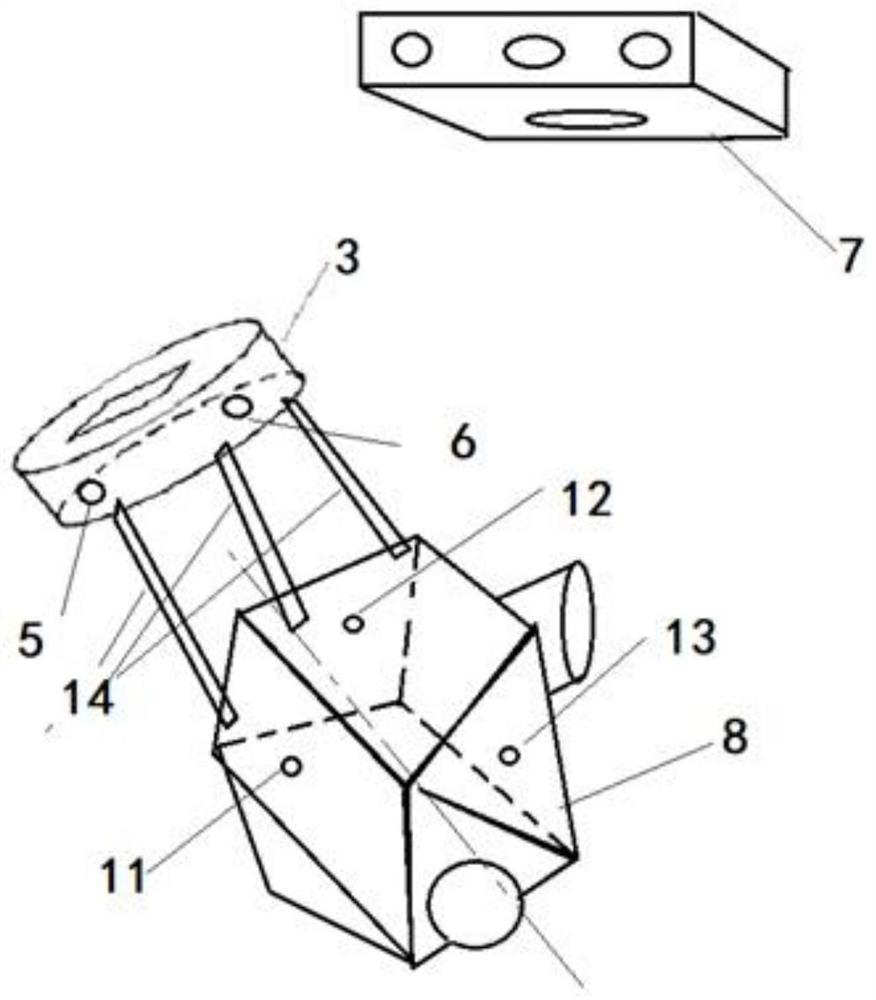

[0019] The present invention is described in further detail now in conjunction with accompanying drawing. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

[0020] Such as Figure 1-2 Shown, at first be the accurate positioning of valve body; Valve body 8 is because its own shape is more complicated, and heavier, have what have ten kilograms or even hundreds of kilograms, so it is very difficult to operate it. Now add a connector in the middle, the connector should be divided into two upper and lower suction cups (positive suction cup 4 and reverse suction cup 3), the positive suction cup 4 and the reverse suction cup 3 are only a few kilograms, and there are two first positioning on the reverse suction cup Points 5 and 6 adopt patch-type positioning points; three second positioning points are reserved on the sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com