Chestnut shelling device

A technique for placing chestnuts and placing boards, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of low safety factor and low chestnut shelling efficiency, and achieve the effect of improving safety factor and improving shelling efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in further detail below by means of specific embodiments:

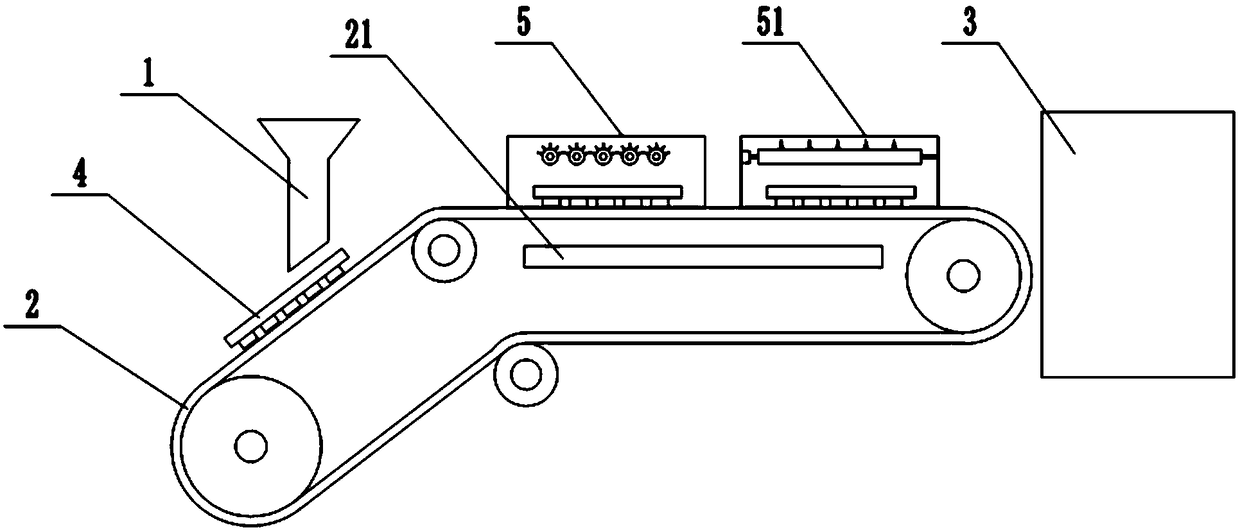

[0023] The reference signs in the accompanying drawings of the description include: hopper 1, conveyor belt 2, first magnet 21, separation mechanism 3, heating table 31, second magnet 32, receiving tray 4, holding box 41, partition plate 42, second A slide bar 43, a placement plate 44, a third spring 45, a horizontal scribing mechanism 5, a longitudinal scribing mechanism 51, a driving motor 52, a rotating roller 53, a scribing knife 54, an L-shaped bar 6, and an arc clamping plate 61 , protrusion 62, second slide bar 63, reclaimer 7, first cylinder 71, fixed plate 72, second cylinder 73, conical round platform 74, elastic pull cord 75, annular round platform 8, notch 81, second Spring 82, arc jaw 83, arc portion 84, first spring 85, chestnut 9.

[0024] The embodiment is basically as attached Figures 1 to 9 Shown: a device for shelling chestnuts, including a frame in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com