Multangular cutter mechanism

A multi-angular and knife-cutting technology, applied in the textile field, can solve the problems of automatic sharpening, inability to cut, loud noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific content of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

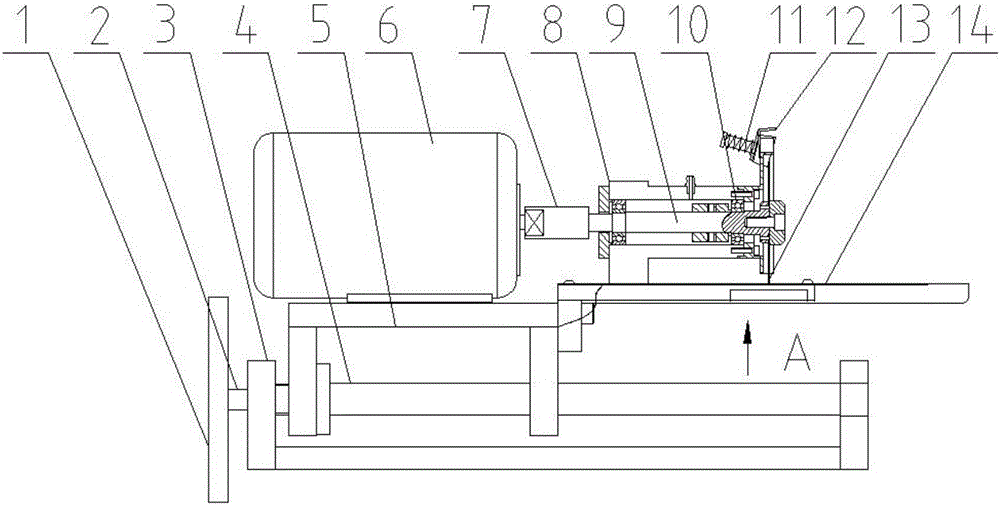

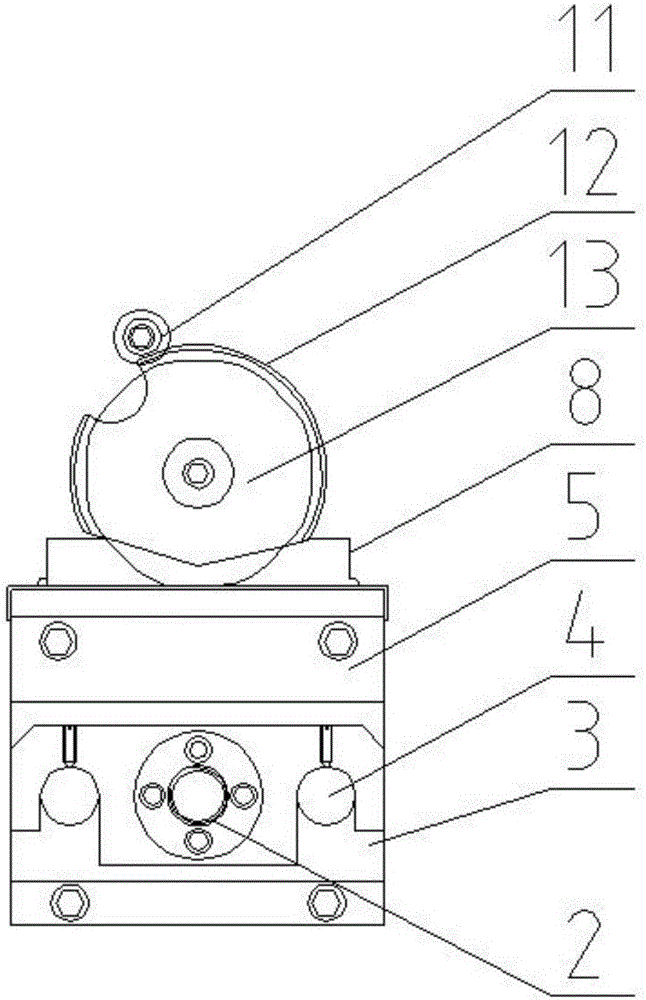

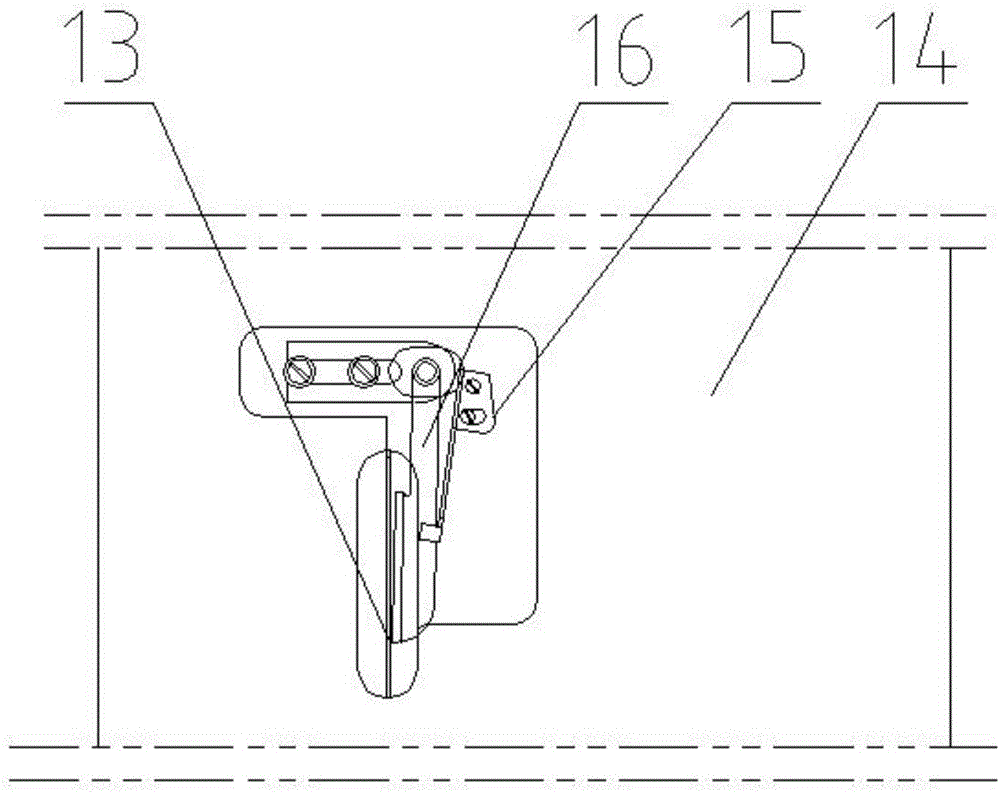

[0014] Such as figure 1 , figure 2 and image 3 As shown, a multi-angle cutter mechanism includes a hand wheel 1, an adjusting screw rod 2, a fixed seat 3, a guide rod 4, a moving seat 5, a motor 6, a coupling 7, a knife shaft seat 8, a knife shaft 9, Cutter shaft bearing 10, knife sharpening emery wheel 11, blade cover 12, multi-angular blade 13, workbench 14, leaf spring 15, knife edge pressing plate 16.

[0015] The motor 6 is installed on the moving seat 5, the hand wheel 1 is connected with the screw mandrel 2, and the hand wheel 1 is rotated, and the moving seat 5 translates left and right on the fixed seat 3 through the screw mandrel 2 and the guide rod 4. Motor 6 links to each other with cutter shaft 9 by shaft coupling 7, and multi-edged blade 13 is fixed on the cutter shaft 9, and cutter shaft 9 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com