Circulation flowing pulsating heat pipe for cooling electronic device

A technology for pulsating heat pipes and electronic devices, which is applied to electric solid devices, cooling/ventilation/heating renovation, electrical components, etc., can solve the problem of not being able to supply liquid to the heating section, and achieve convenient processing, low thermal resistance, and noiseless operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

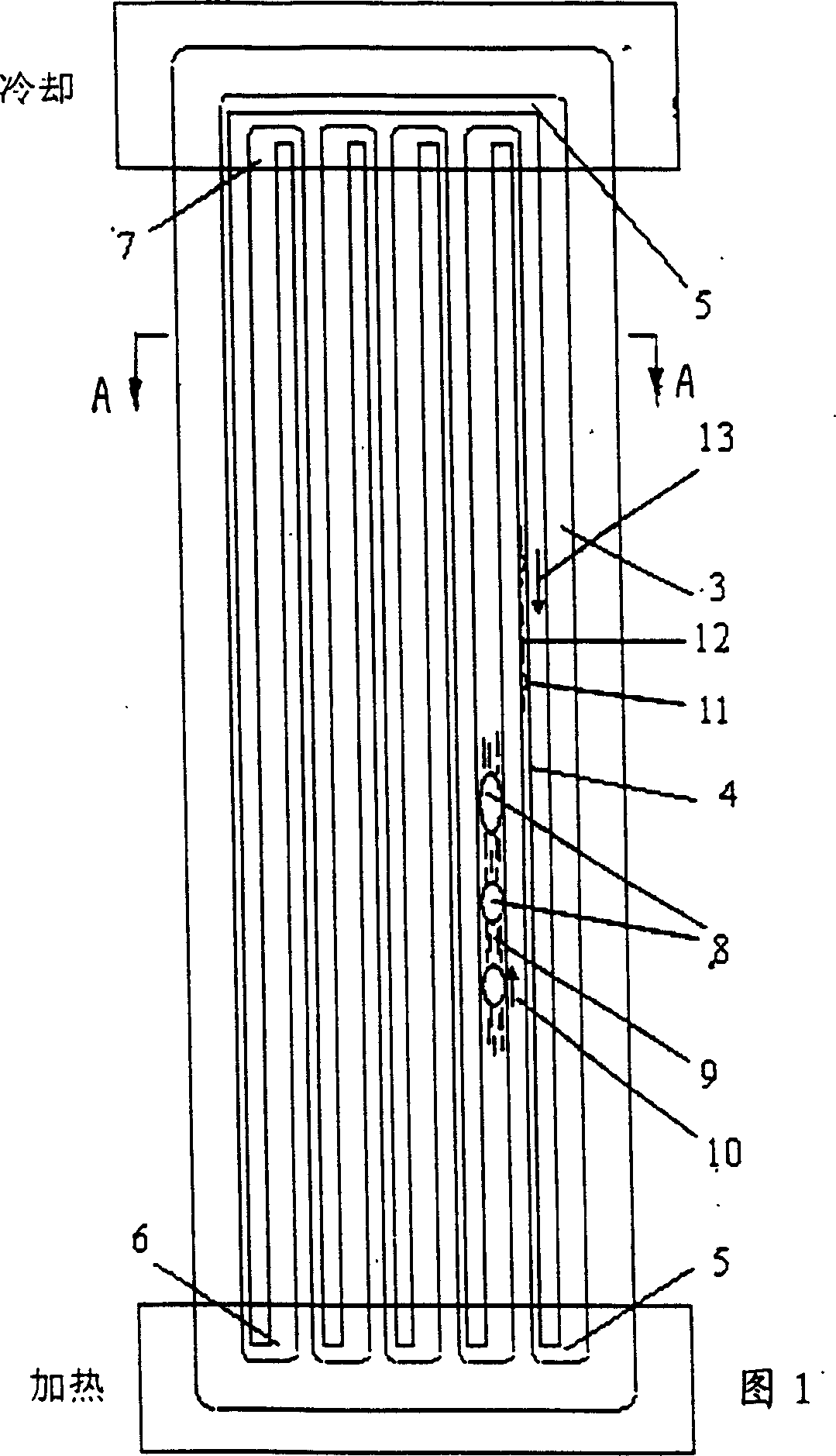

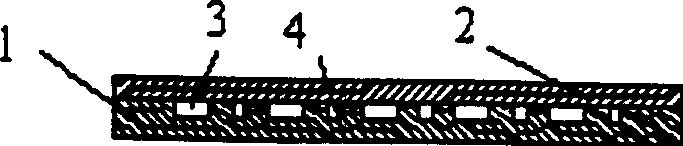

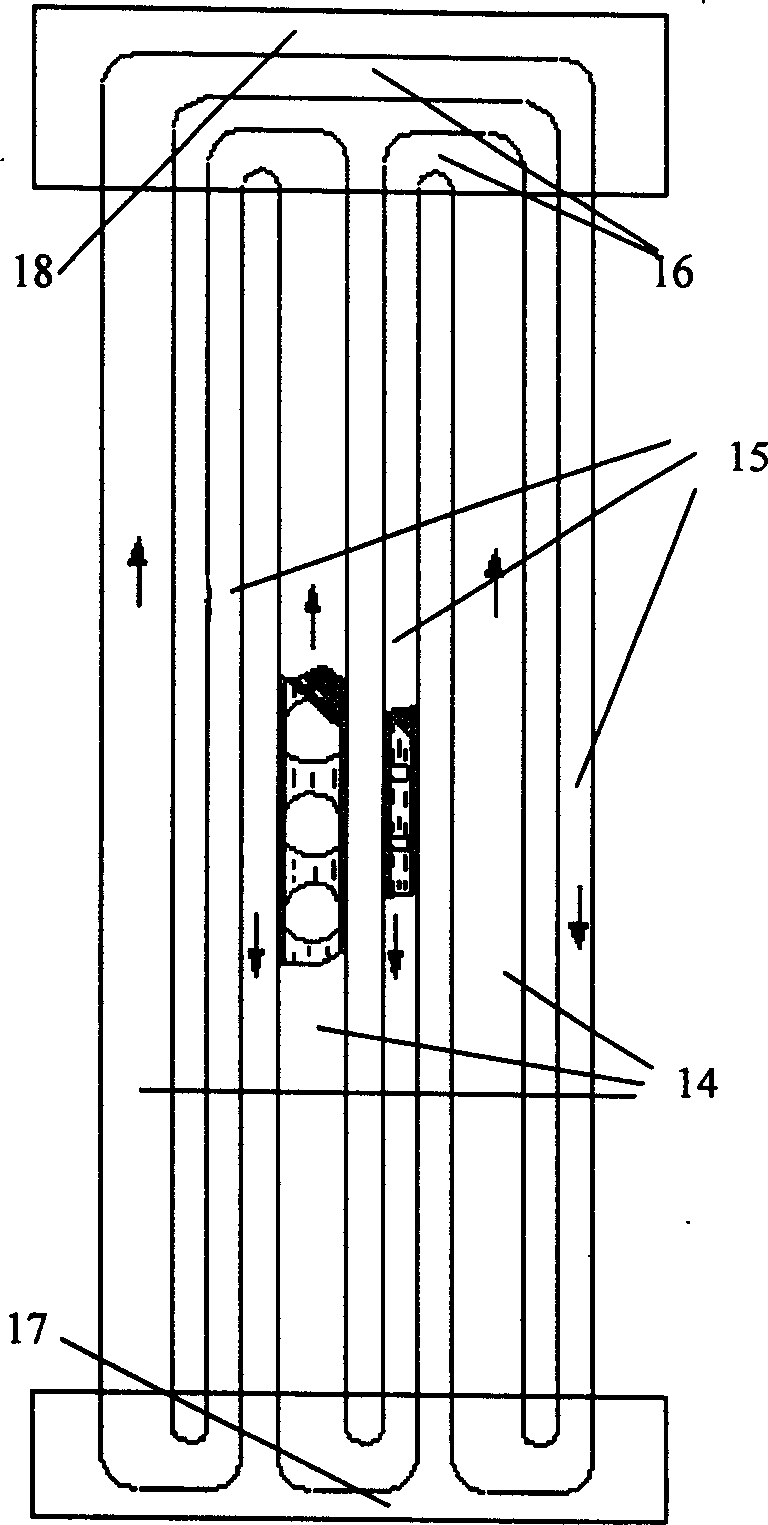

[0016] figure 1, figure 2 The structure of the pulsating heat pipe of the present invention is described. The pulsating heat pipe is composed of an aluminum unit plate 1 and a flat plate 2; one side of the aluminum unit plate 1 is milled with a group of thick straight tubes 3 arranged parallel to each other, a group of thin straight tubes 4 and a group of connecting curved channels 5. Capillary groove; the flat plate 2 covers the unit plate 1, and thus the capillary groove forms a closed cavity; the closed cavity is filled with 30% to 70% of the working fluid; the curved channel 5 at one end serves as the heating section 6 of the heat pipe, and the curved channel 5 at the other end The curved passage 5 serves as the heat dissipation section 7 of the heat pipe; the passage between the heating section 6 and the heat dissipation section 6 serves as the heat insulation section of the heat pipe.

[0017] When the pulsating heat pipe of the present invention is in operation, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com