A rotary knife pelletizer

The technology of a pelletizer and a cutting mechanism is applied in the field of plastic "waste pipe" pelletizing and recycling equipment, which can solve the problems of oxidative deterioration, high production difficulty and unqualified quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The following is an embodiment of a rotary knife pelletizer of the present invention, which is only a preferred example and is not a limitation of the content of the present invention, and is now further described in conjunction with the accompanying drawings:

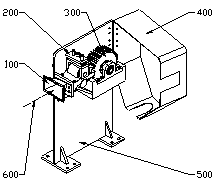

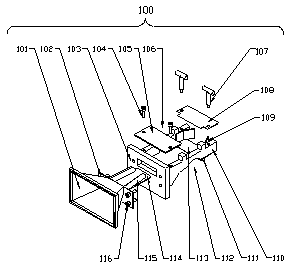

[0045] figure 1 and figure 2As shown, the rotary knife type granulator of the present invention includes a tube delivery limit mechanism 100, a pressure tube delivery mechanism 200, an olecranon cutting mechanism 300, a safety cover 400 and a support frame 500, wherein: the tube delivery limit mechanism 100 and The olecranon cutting mechanism 300 forms a butt joint relationship between the upstream and downstream of the cut pipeline flow direction 600, and the upper roller and the lower roller of the pressure pipe pulling mechanism 200 are located in the middle section of the end-to-end line of the pipe delivery limit mechanism 100, perpendicular to the flow direction of the cut pipeline 600. The pair clamps a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com