Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

174 results about "Liquefaction of gases" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquefaction of gases is physical conversion of a gas into a liquid state (condensation).

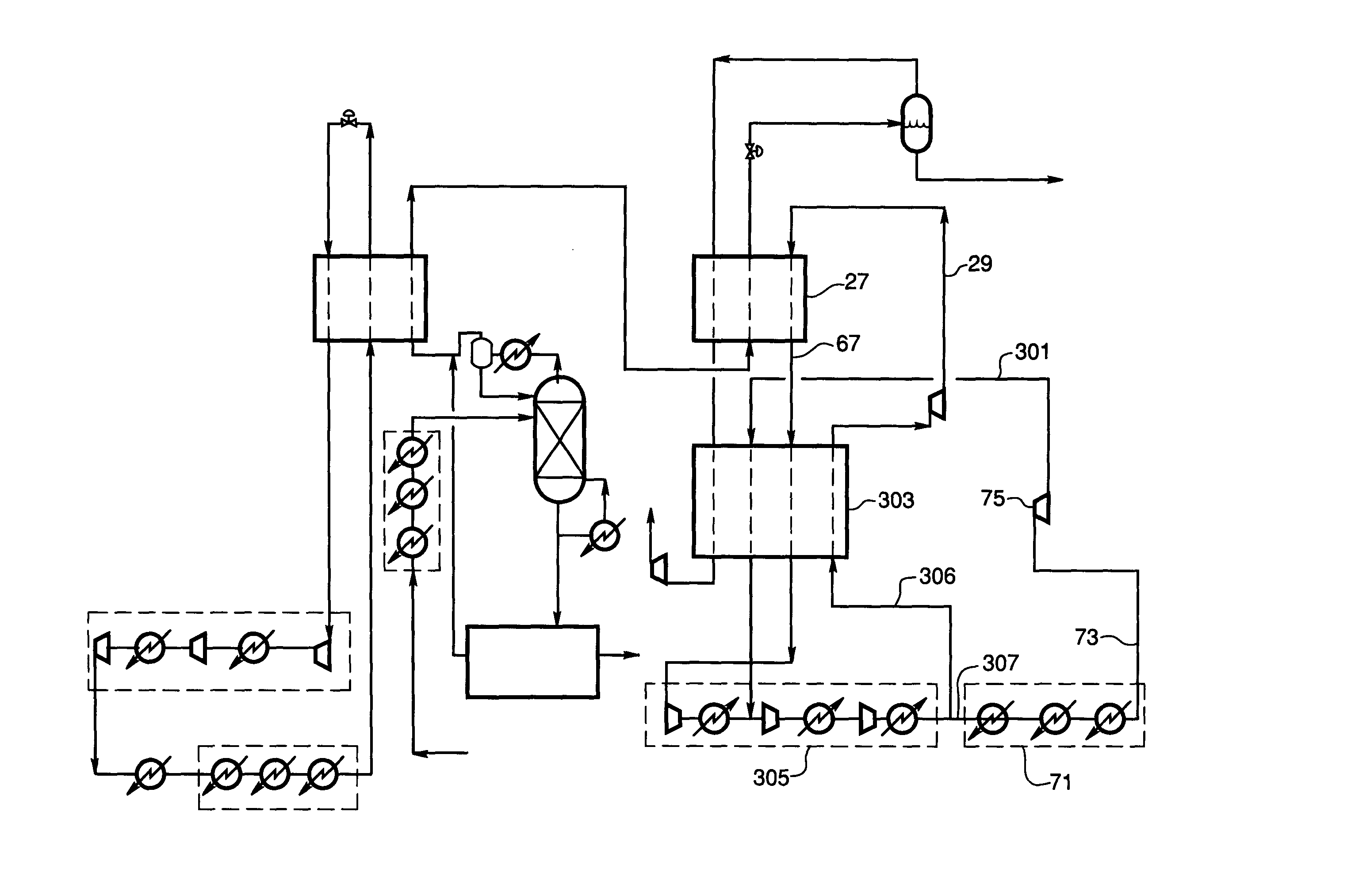

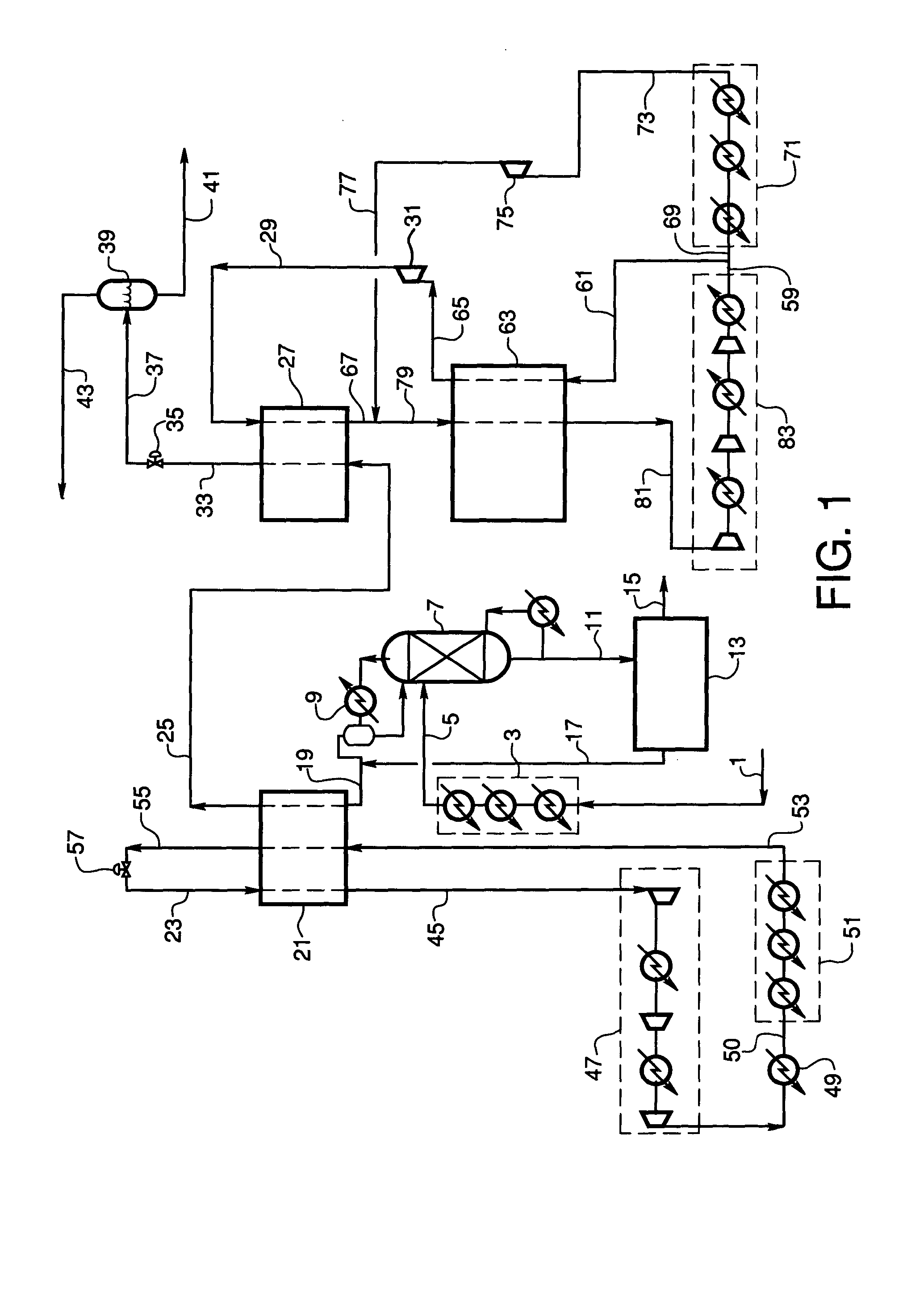

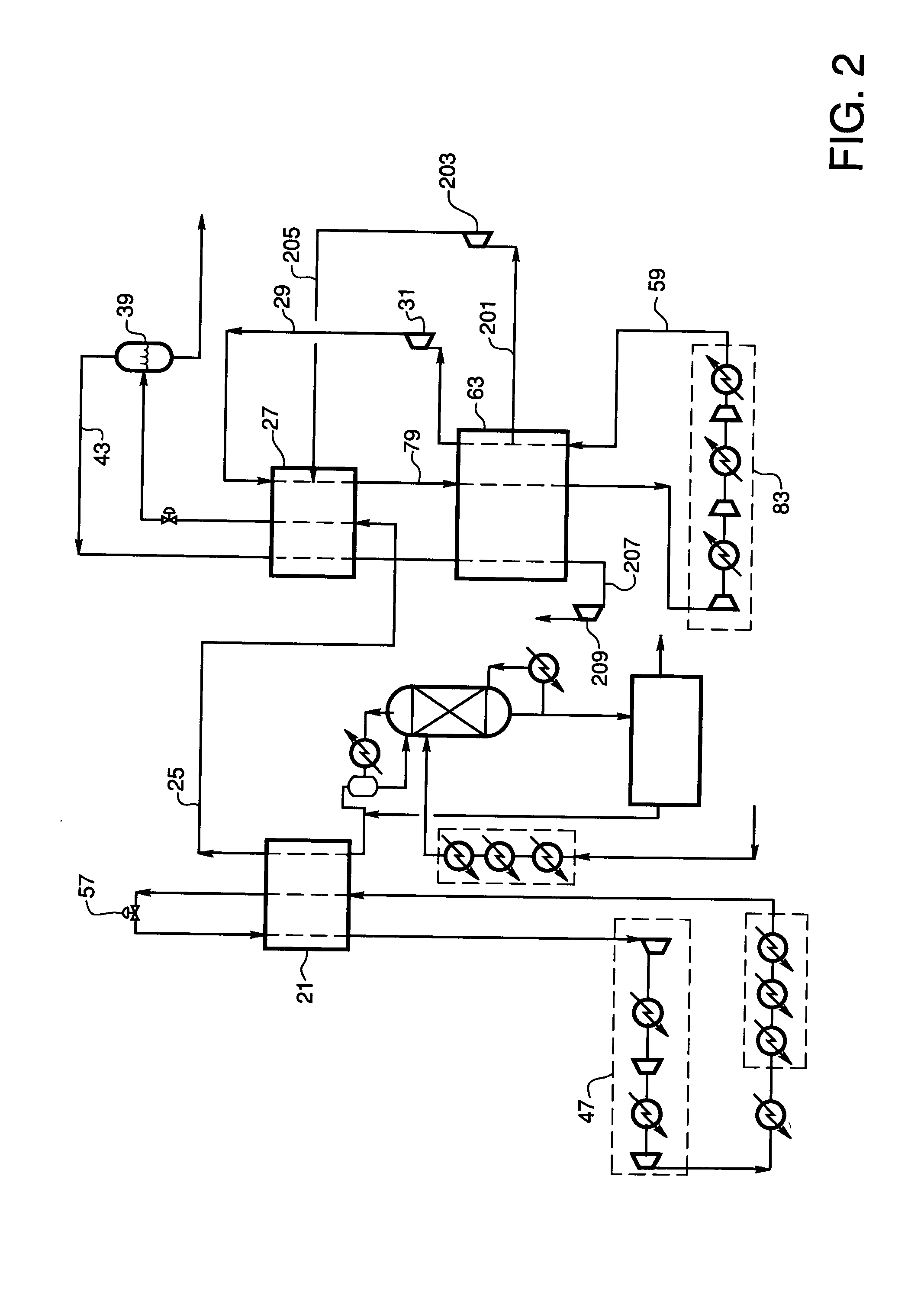

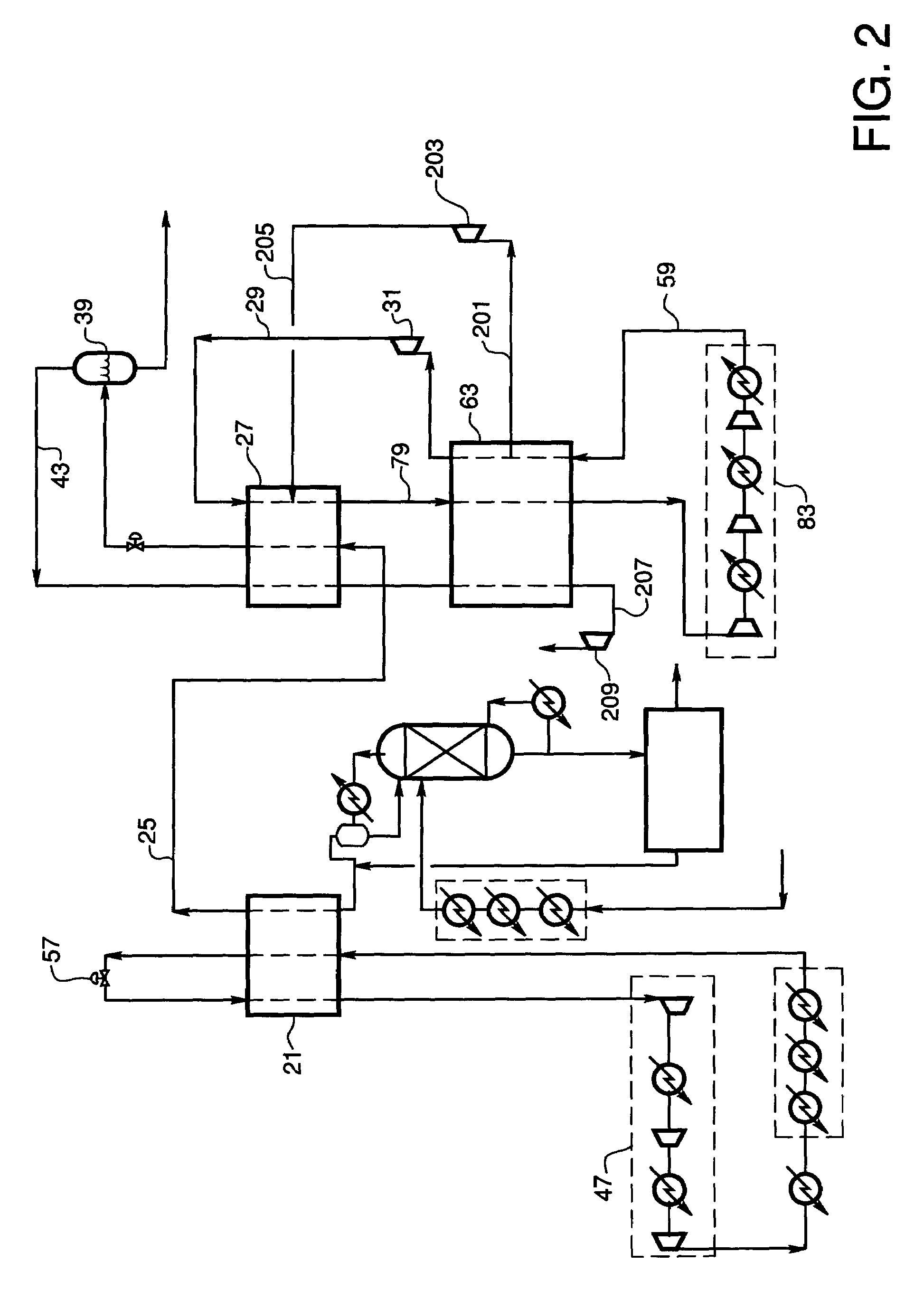

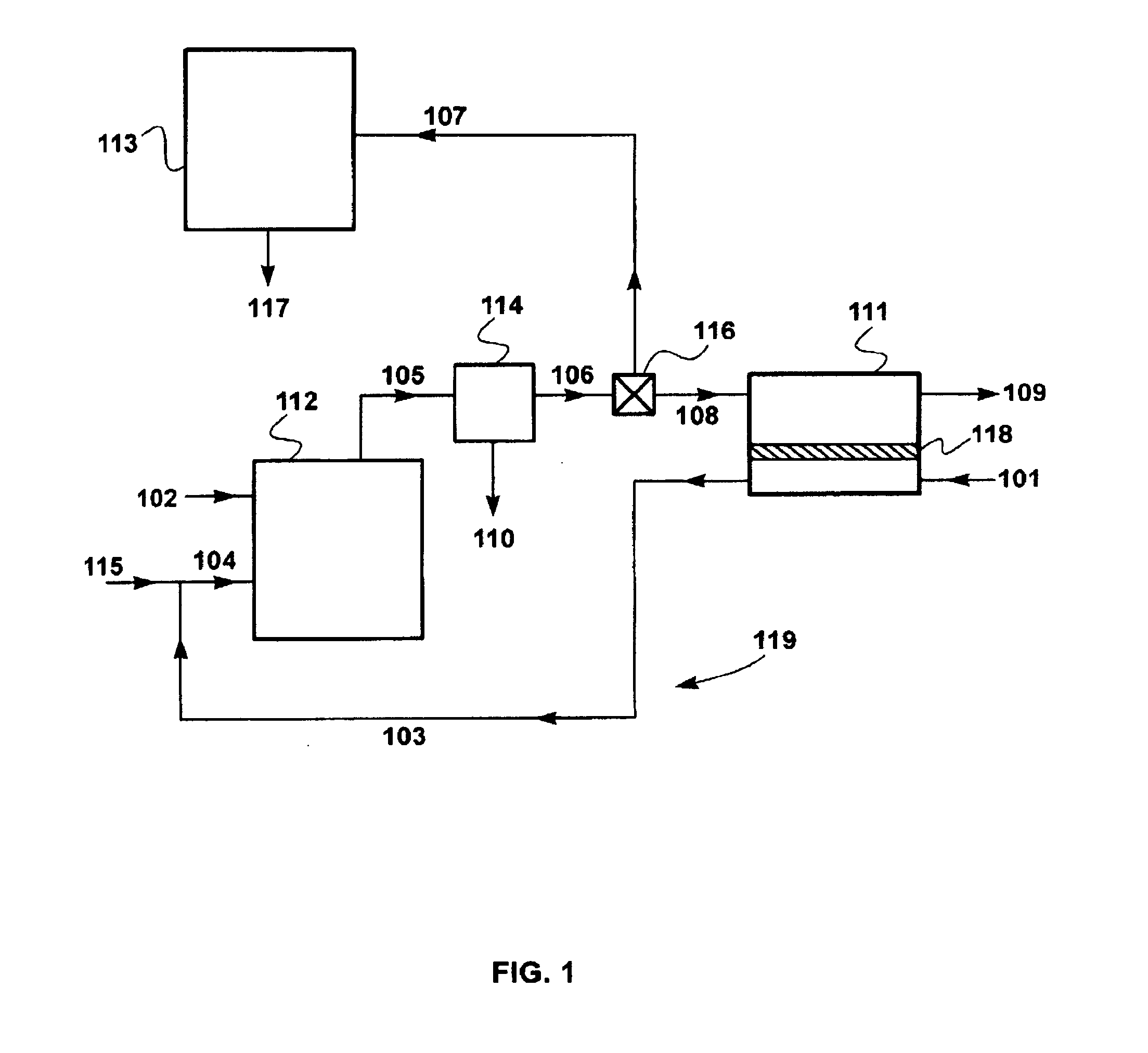

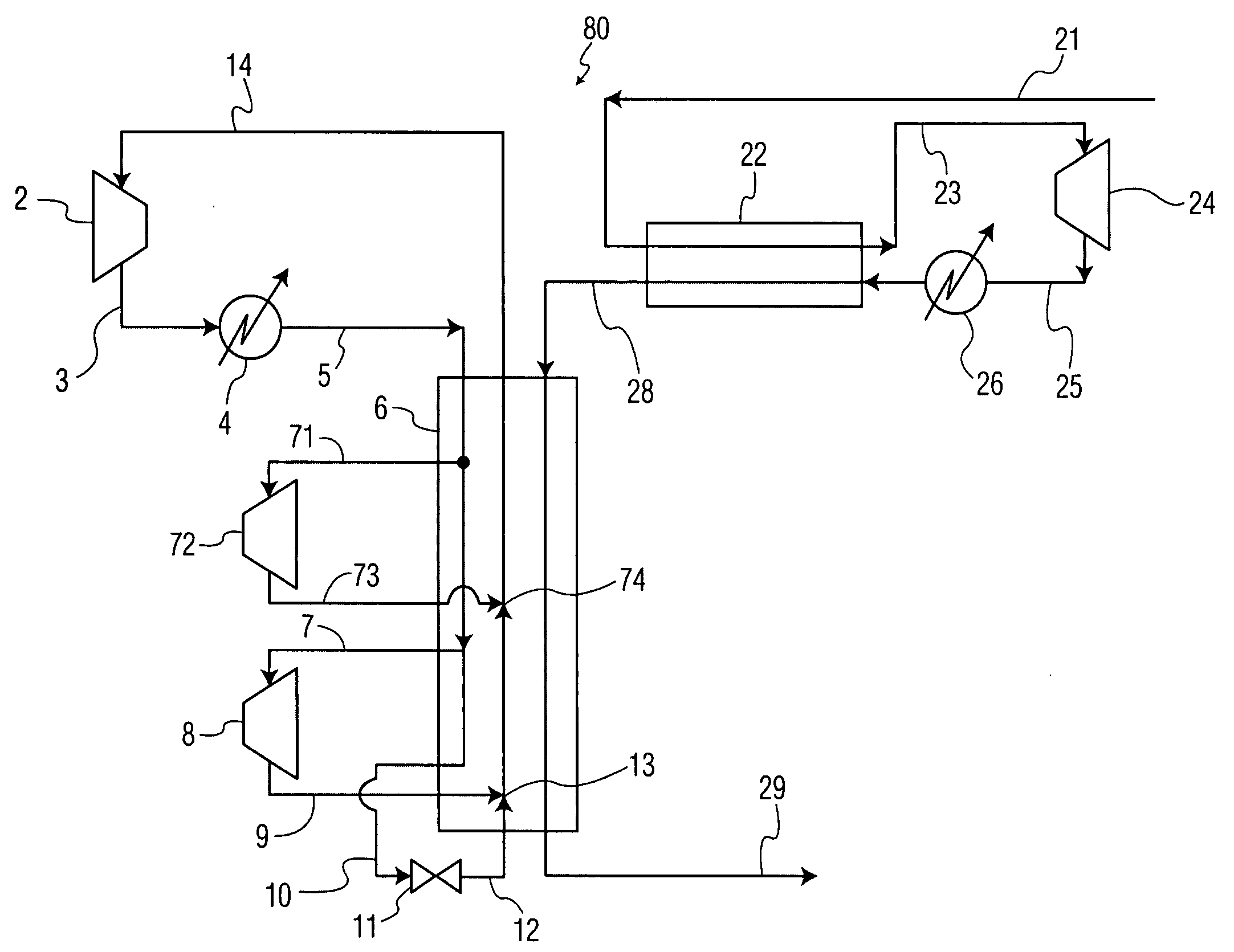

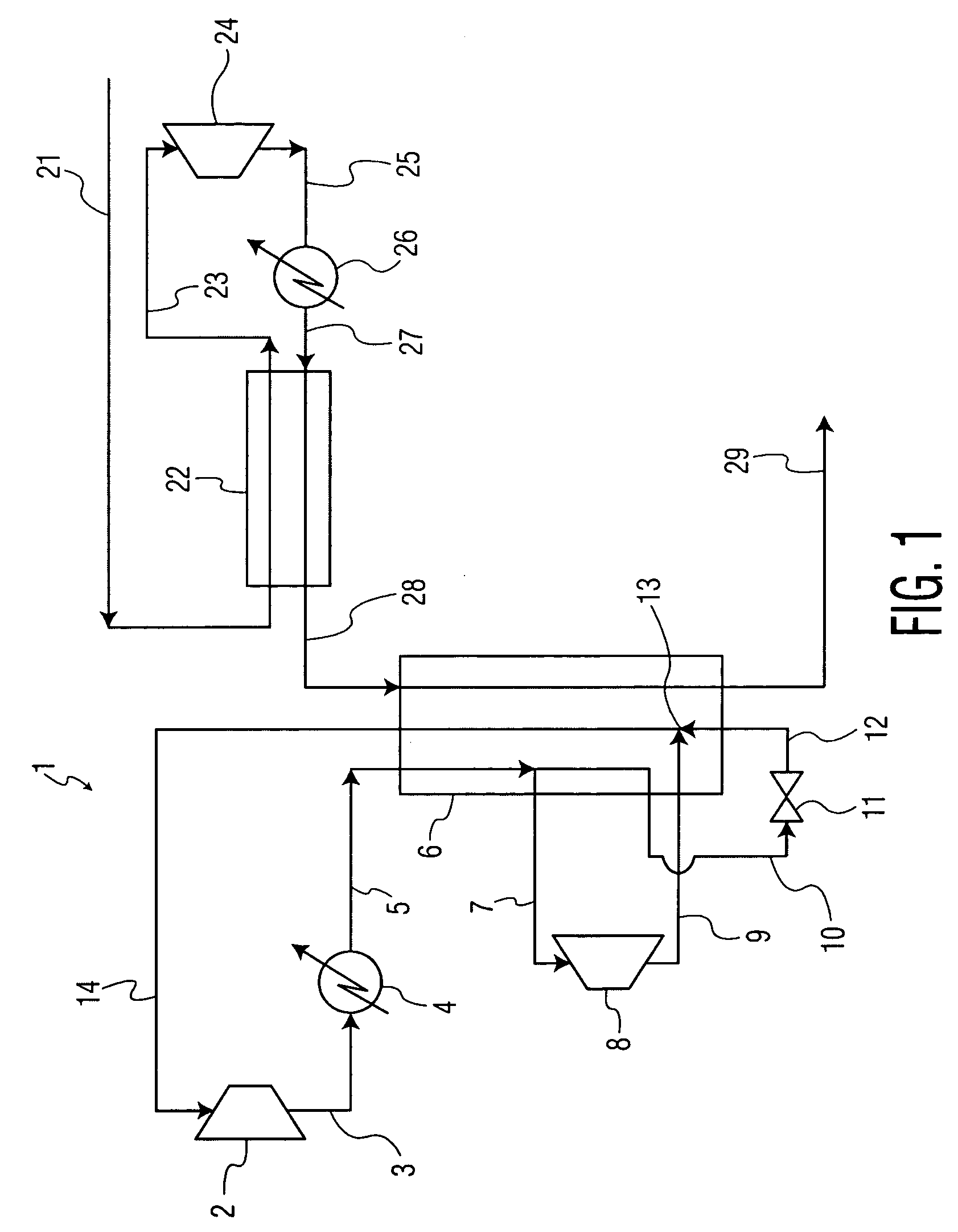

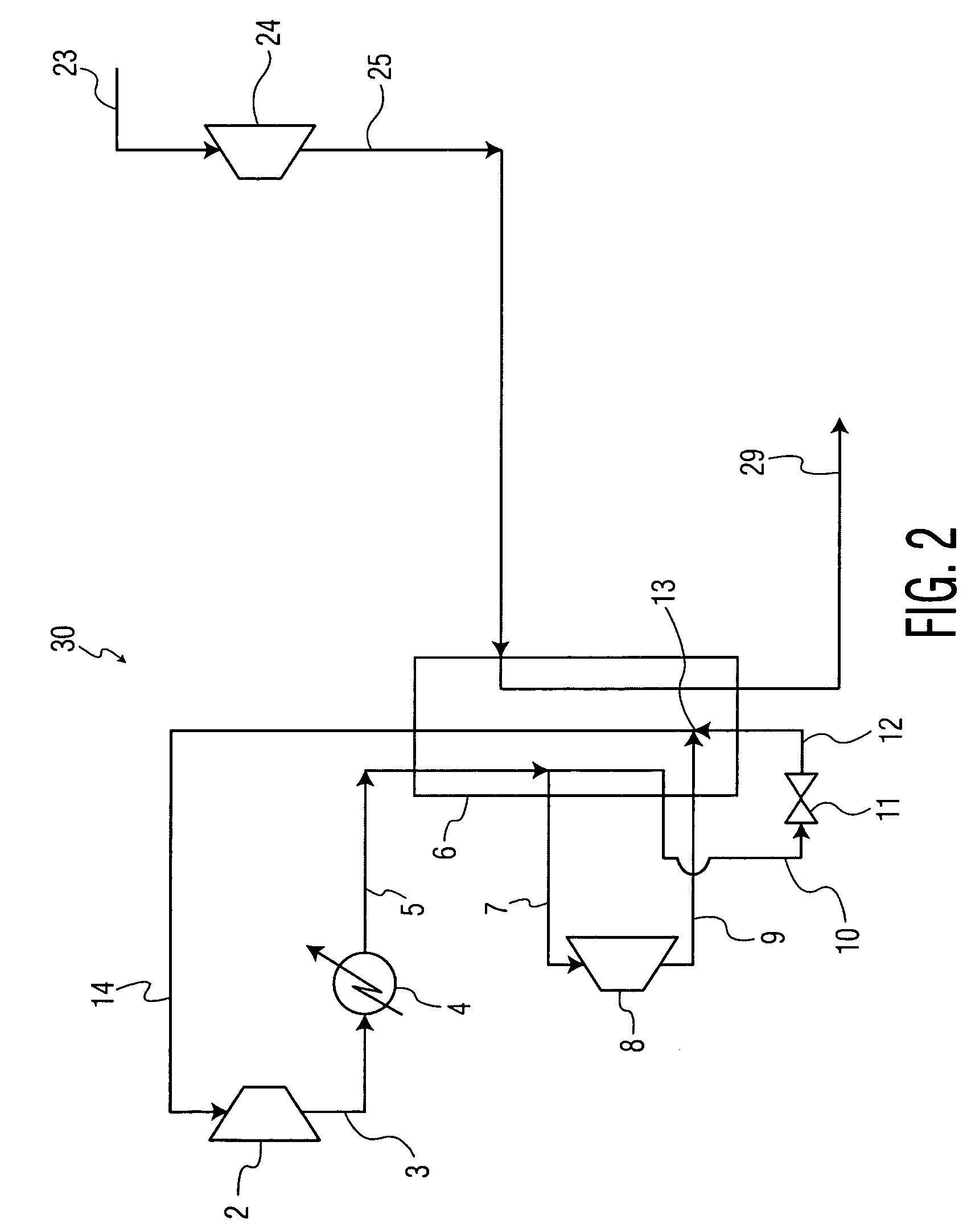

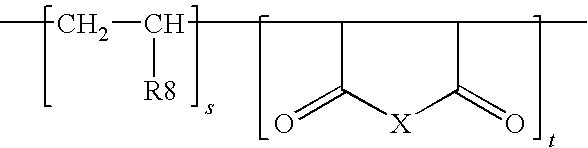

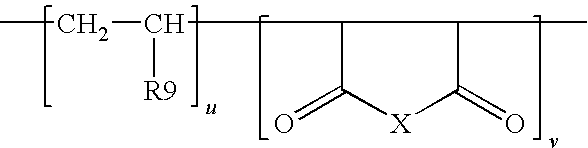

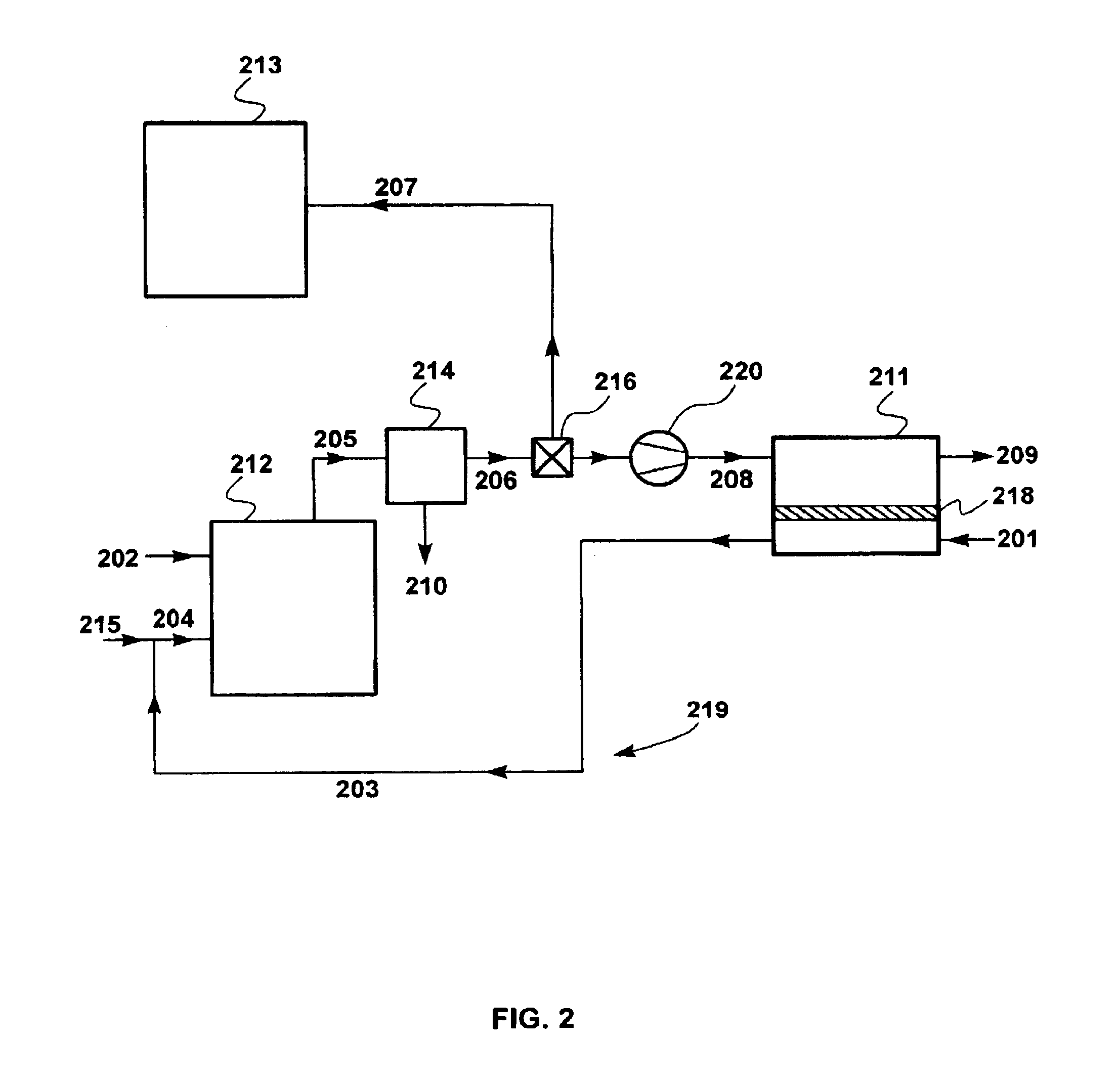

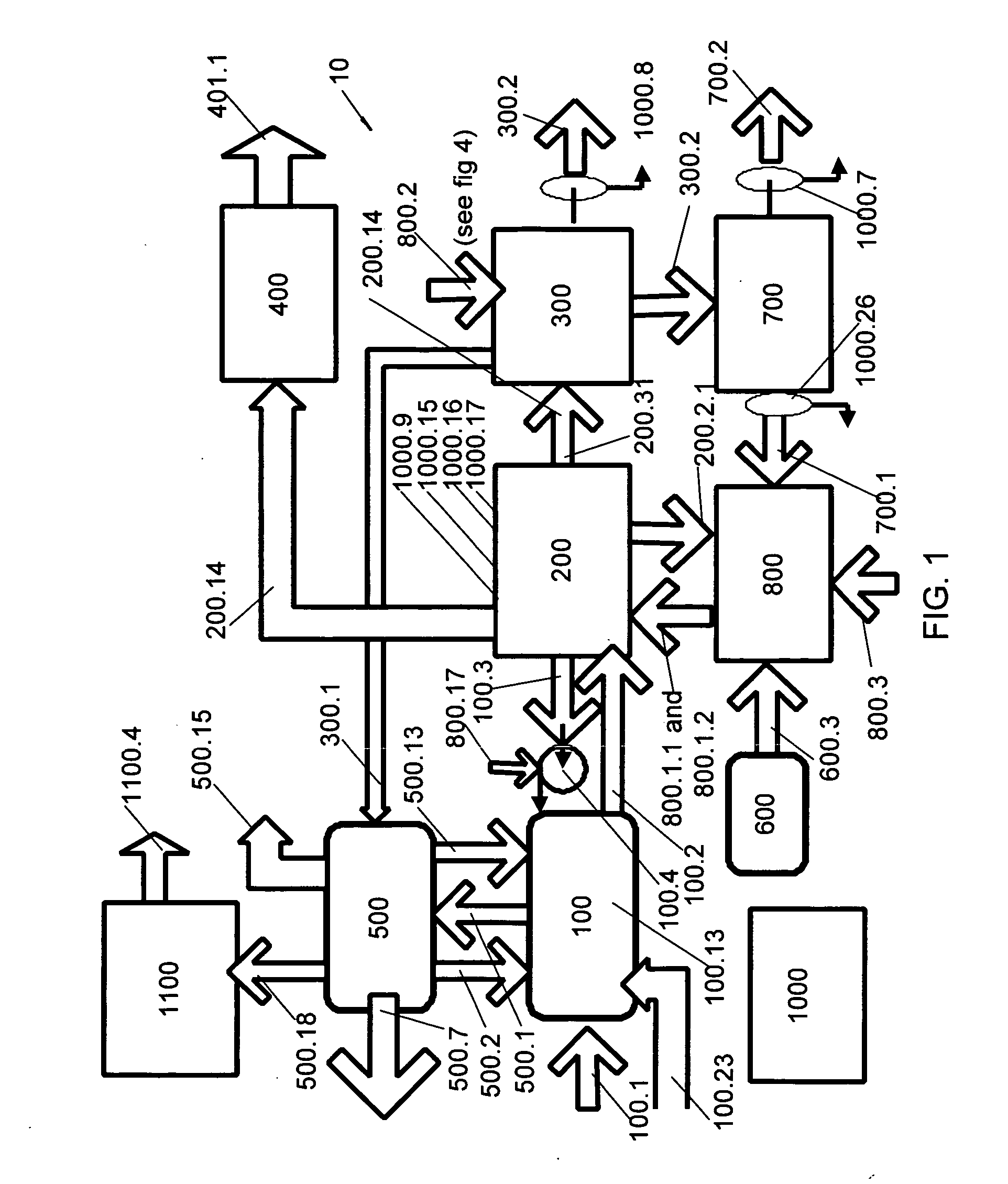

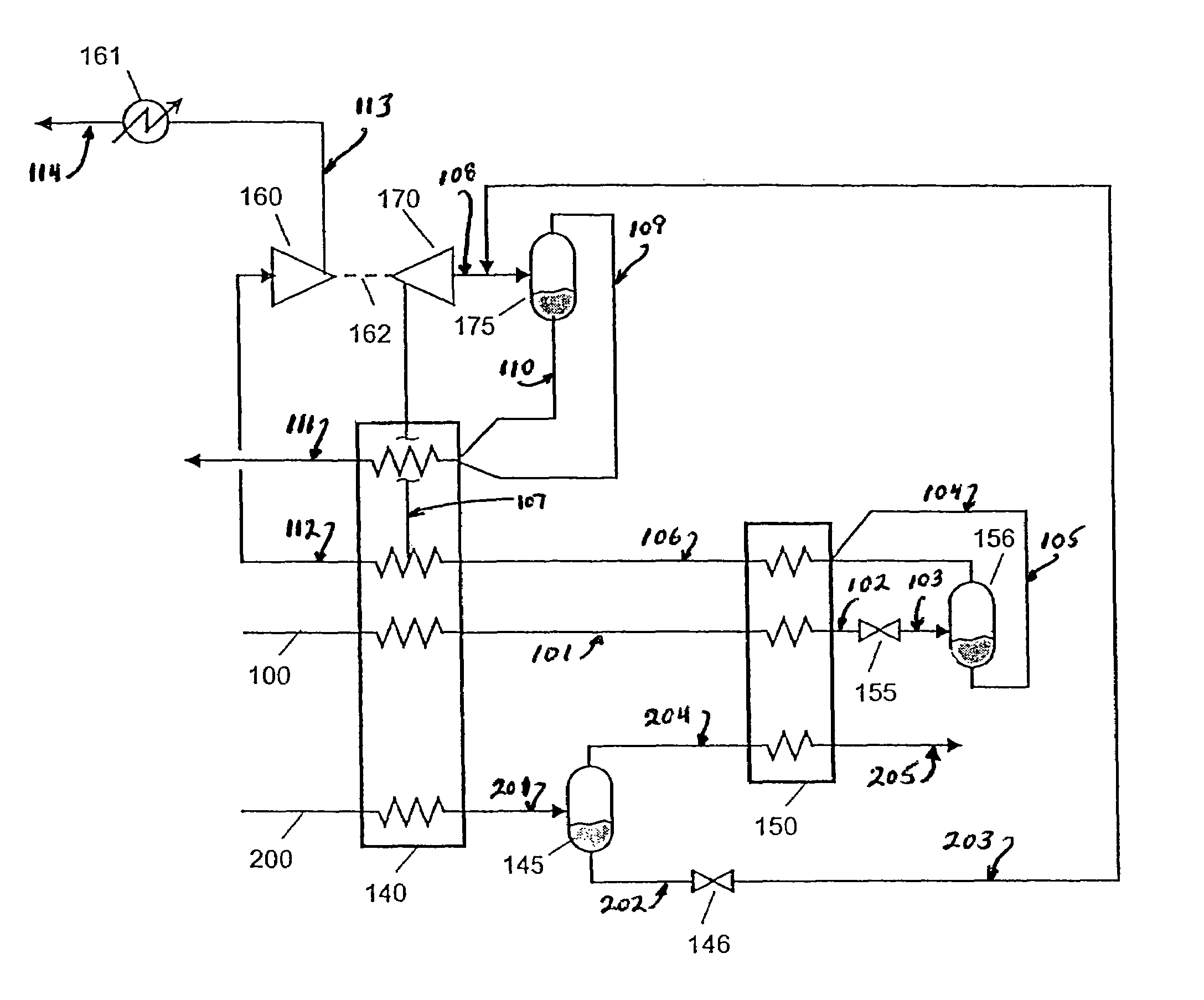

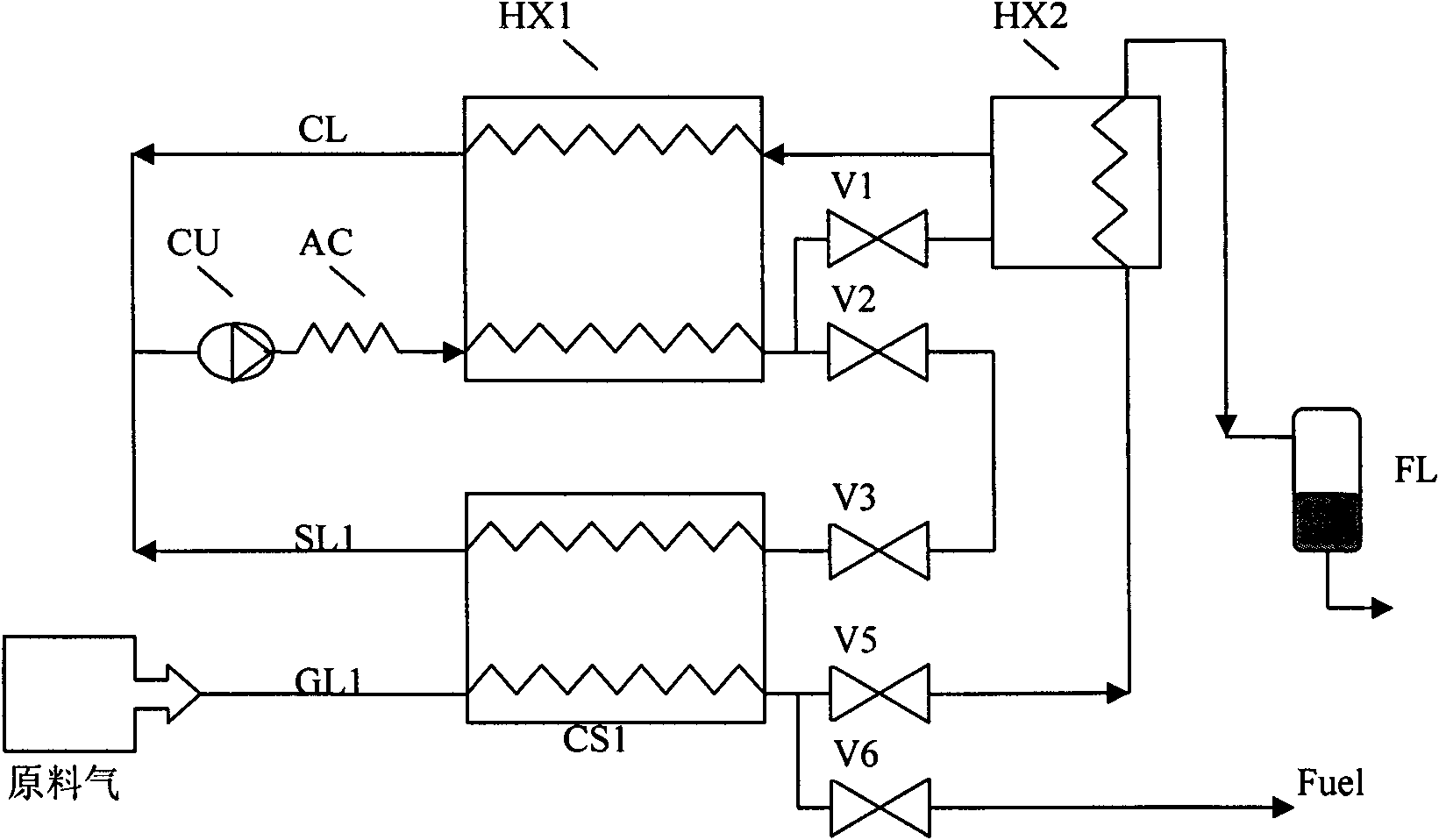

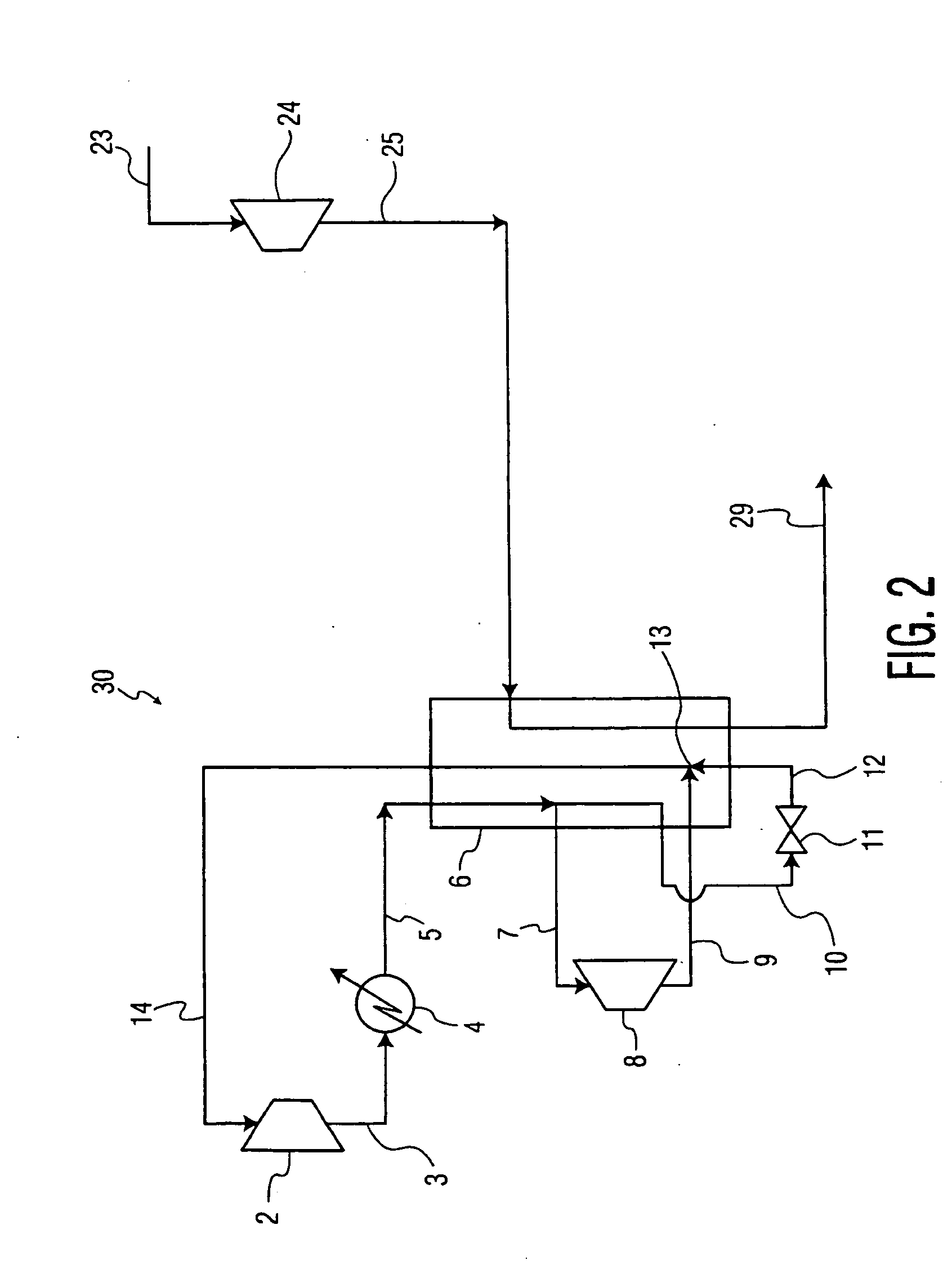

Hybrid gas liquefaction cycle with multiple expanders

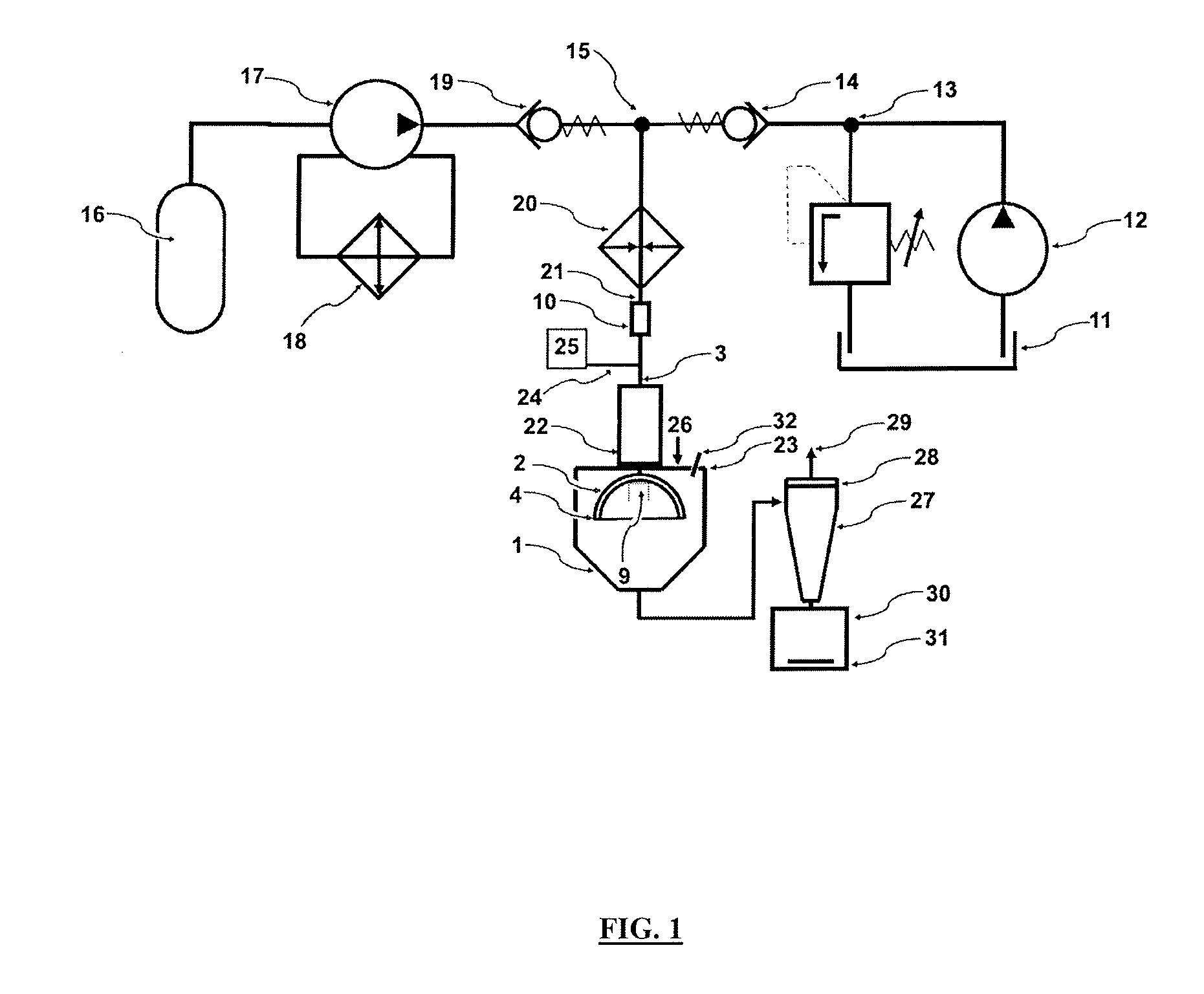

Method for gas liquefaction comprising cooling a feed gas by a first refrigeration system in a first heat exchange zone and withdrawing a substantially liquefied stream therefrom, further cooling the substantially liquefied stream by indirect heat exchange with one or more work-expanded refrigerant streams in a second heat exchange zone, and withdrawing therefrom a further cooled, substantially liquefied stream. At least one of the one or more work-expanded refrigerant streams is provided by compressing one or more refrigerant gases to provide a compressed refrigerant stream, cooling all or a portion of the compressed refrigerant stream in a third heat exchange zone to provide a cooled, compressed refrigerant stream, and work expanding the cooled, compressed refrigerant stream to provide one of the one or more work-expanded refrigerant streams. The flow rate of a work-expanded refrigerant stream in the second heat exchange zone typically is less than the total flow rate of one or more work-expanded refrigerant streams in the third heat exchange zone.

Owner:AIR PROD & CHEM INC

Hybrid gas liquefaction cycle with multiple expanders

ActiveUS7127914B2Reduce pressureReducing and eliminating needSolidificationLiquefactionEngineeringProduct gas

Method for gas liquefaction comprising cooling a feed gas by a first refrigeration system in a first heat exchange zone and withdrawing a substantially liquefied stream therefrom, further cooling the substantially liquefied stream by indirect heat exchange with one or more work-expanded refrigerant streams in a second heat exchange zone, and withdrawing therefrom a further cooled, substantially liquefied stream. At least one of the one or more work-expanded refrigerant streams is provided by compressing one or more refrigerant gases to provide a compressed refrigerant stream, cooling all or a portion of the compressed refrigerant stream in a third heat exchange zone to provide a cooled, compressed refrigerant stream, and work expanding the cooled, compressed refrigerant stream to provide one of the one or more work-expanded refrigerant streams. The flow rate of a work-expanded refrigerant stream in the second heat exchange zone typically is less than the total flow rate of one or more work-expanded refrigerant streams in the third heat exchange zone.

Owner:AIR PROD & CHEM INC

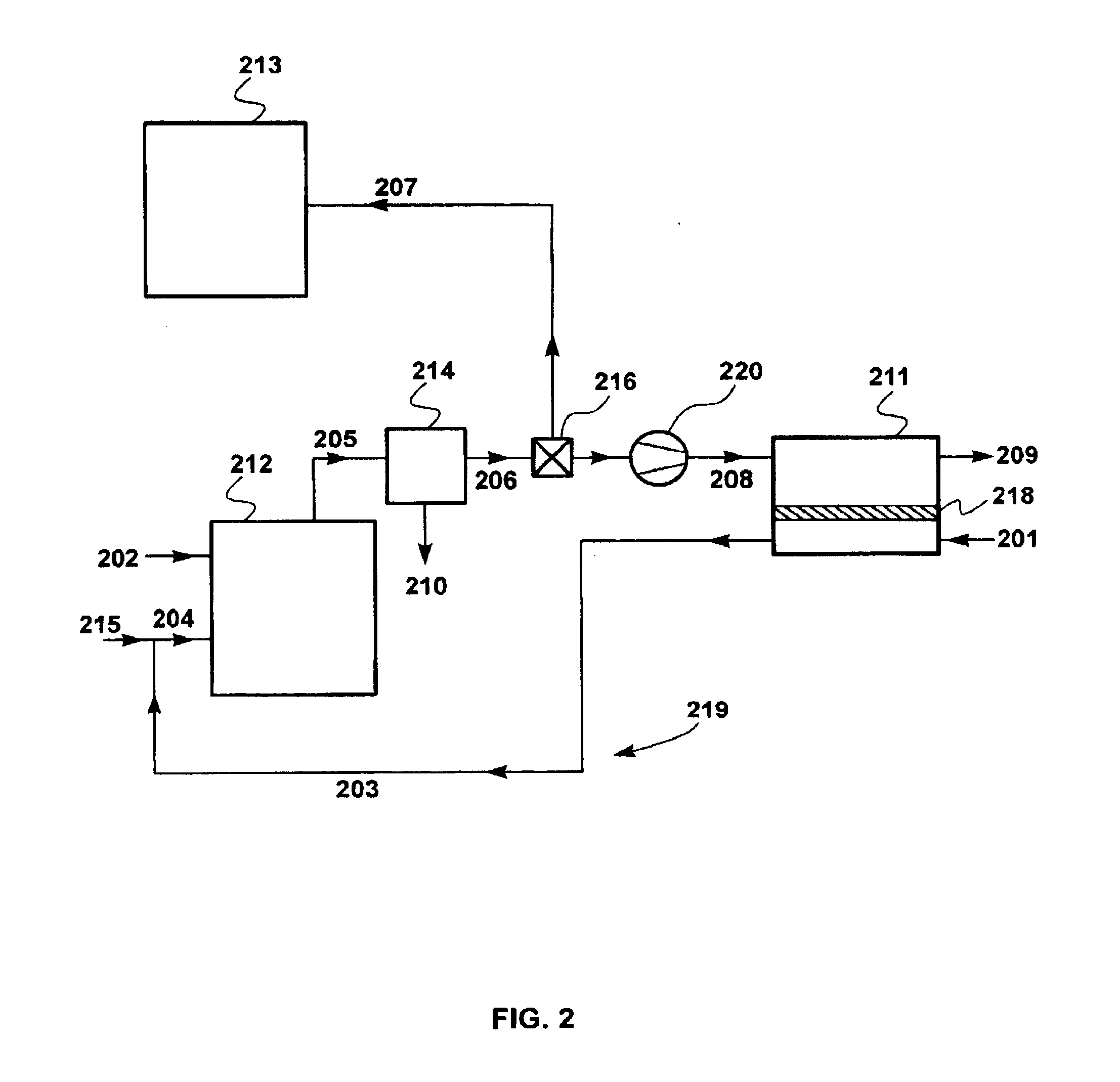

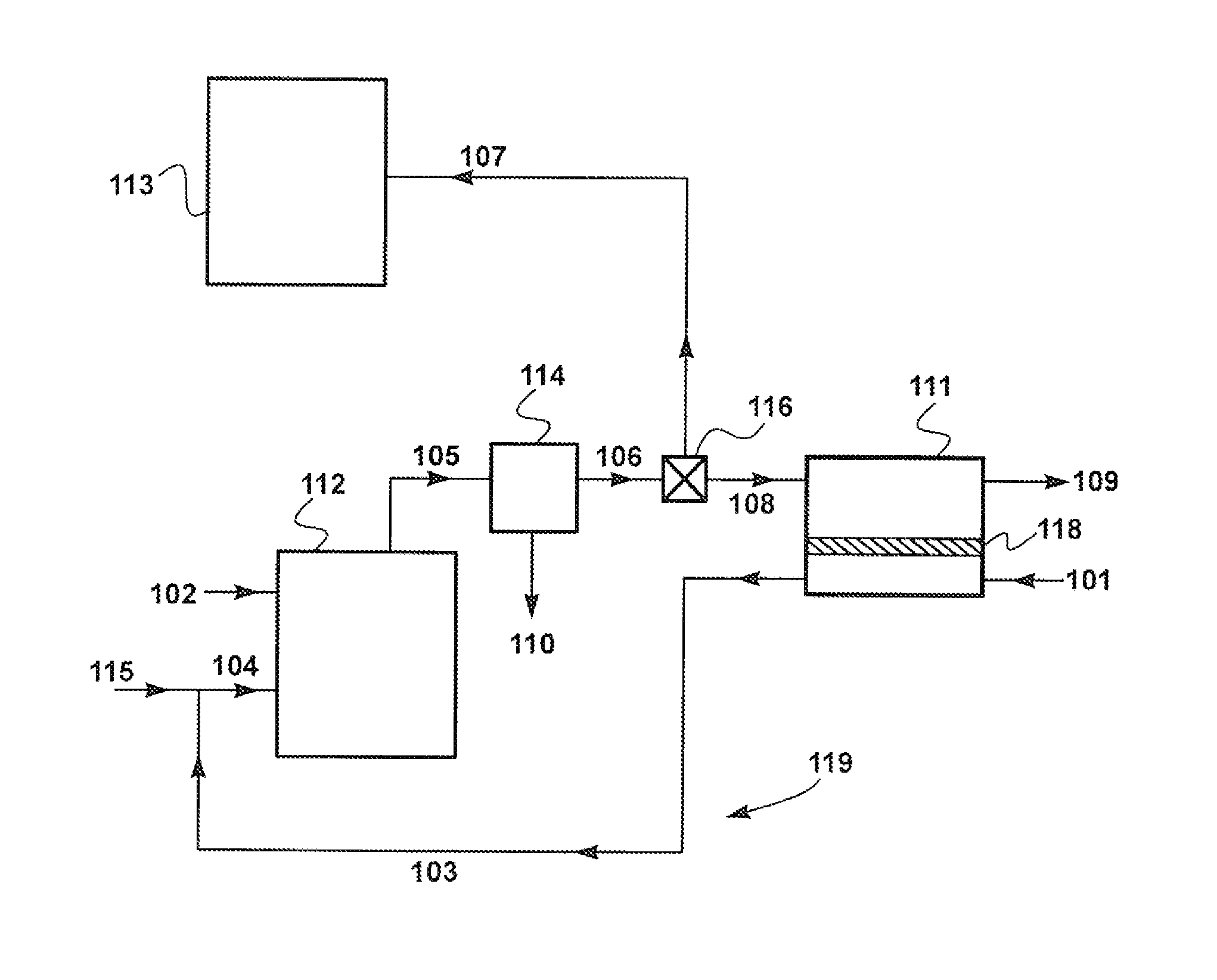

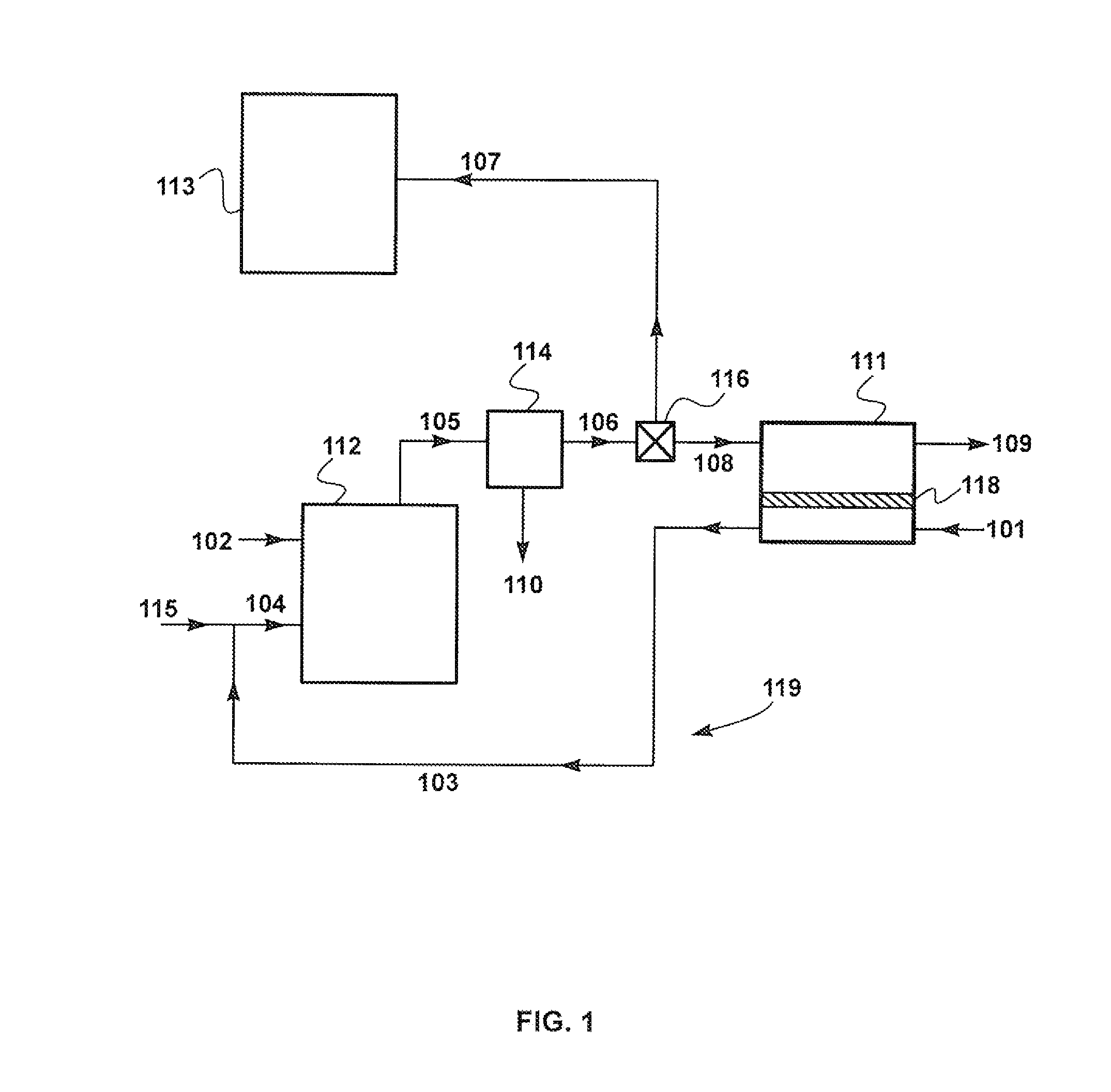

Membrane loop process for separating carbon dioxide for use in gaseous form from flue gas

ActiveUS20110260112A1Lower carbon dioxide levelsReduce harmMethane captureCarbon compoundsFlue gasProduct gas

The invention is a process involving membrane-based gas separation for separating and recovering carbon dioxide emissions from combustion processes in partially concentrated form, and then transporting the carbon dioxide and using or storing it in a confined manner without concentrating it to high purity. The process of the invention involves building up the concentration of carbon dioxide in a gas flow loop between the combustion step and a membrane separation step. A portion of the carbon dioxide-enriched gas can then be withdrawn from this loop and transported, without the need to liquefy the gas or otherwise create a high-purity stream, to a destination where it is used or confined, preferably in an environmentally benign manner.

Owner:MEMBRANE TECH & RES

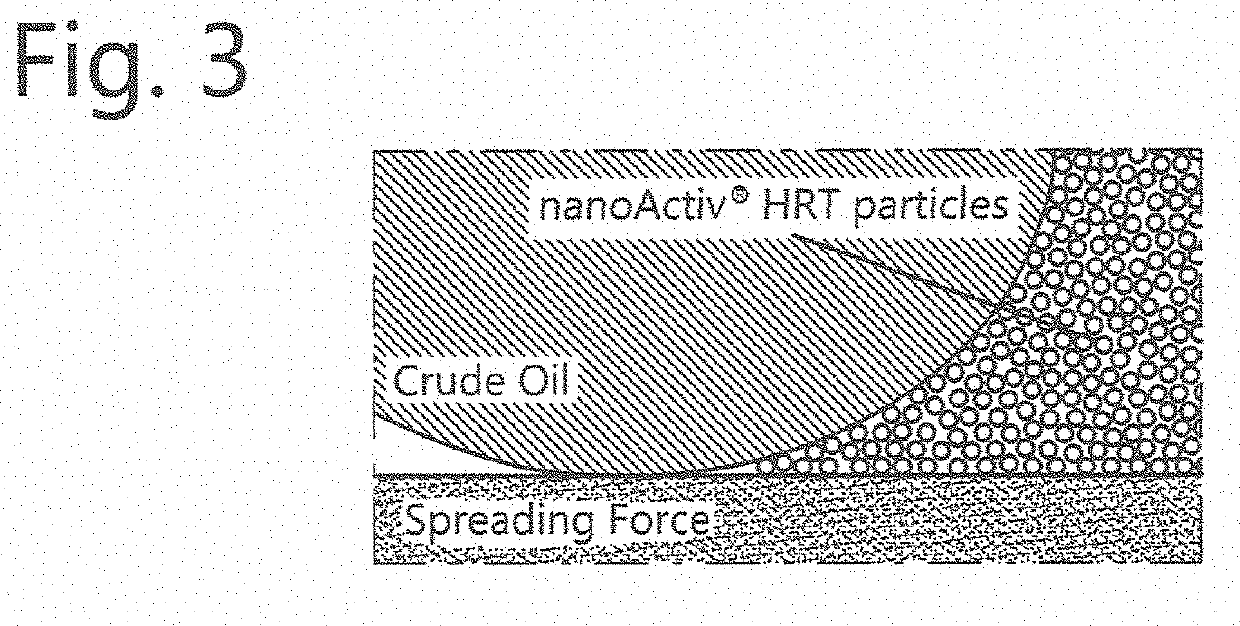

Using gases and hydrocarbon recovery fluids containing nanoparticles to enhance hydrocarbon recovery

A process of stimulating hydrocarbon recovery is described and claimed. This process includes introducing a gas, a liquified gas or a vaporized liquified gas, into an underground formation containing hydrocarbons such as crude oil and gas, permitting said gas to be absorbed by said hydrocarbons, and withdrawing said hydrocarbons containing the gas therein, wherein a pill of Hydrocarbon Recovery Fluid comprising surface functionalized nanoparticles is inserted into the underground formation containing hydrocarbons before, during or after the introduction of the gas, liquified gas or a vaporized liquified gas.

Owner:MESSER IND USA INC +1

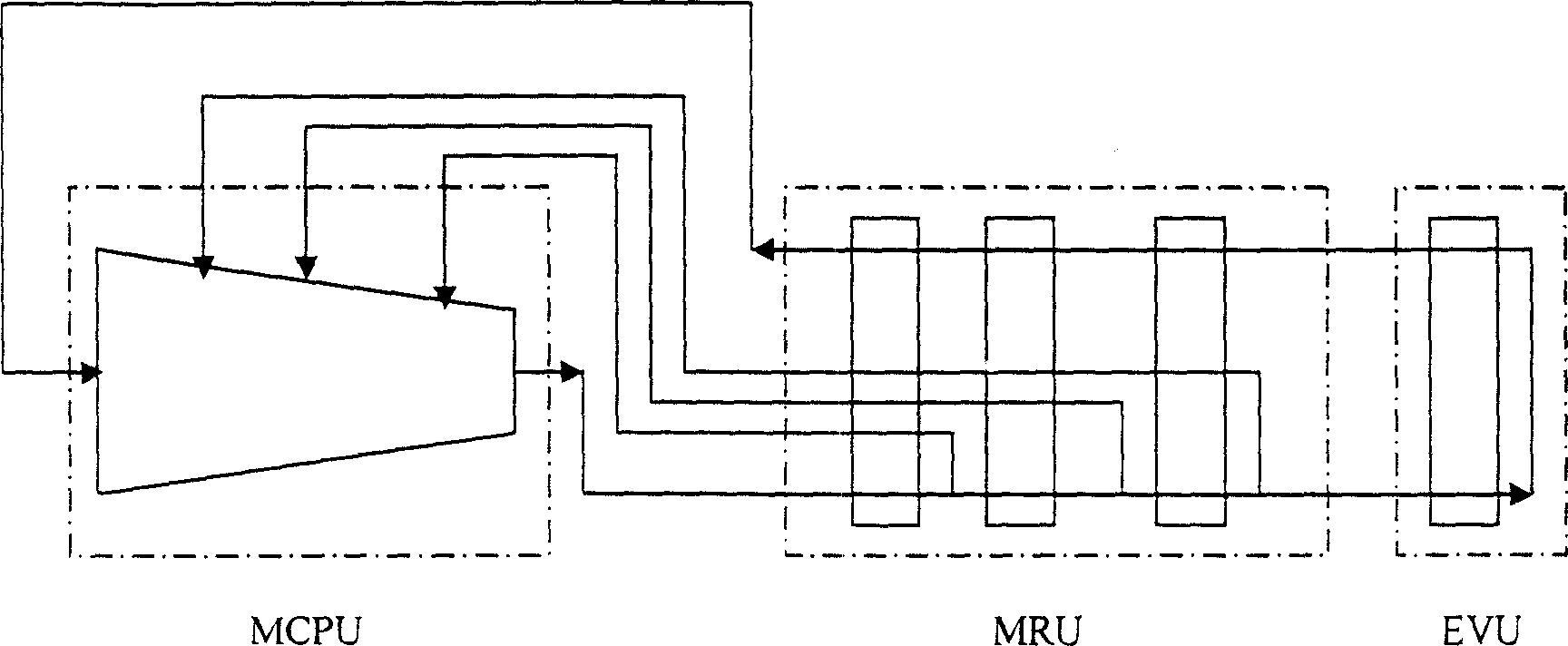

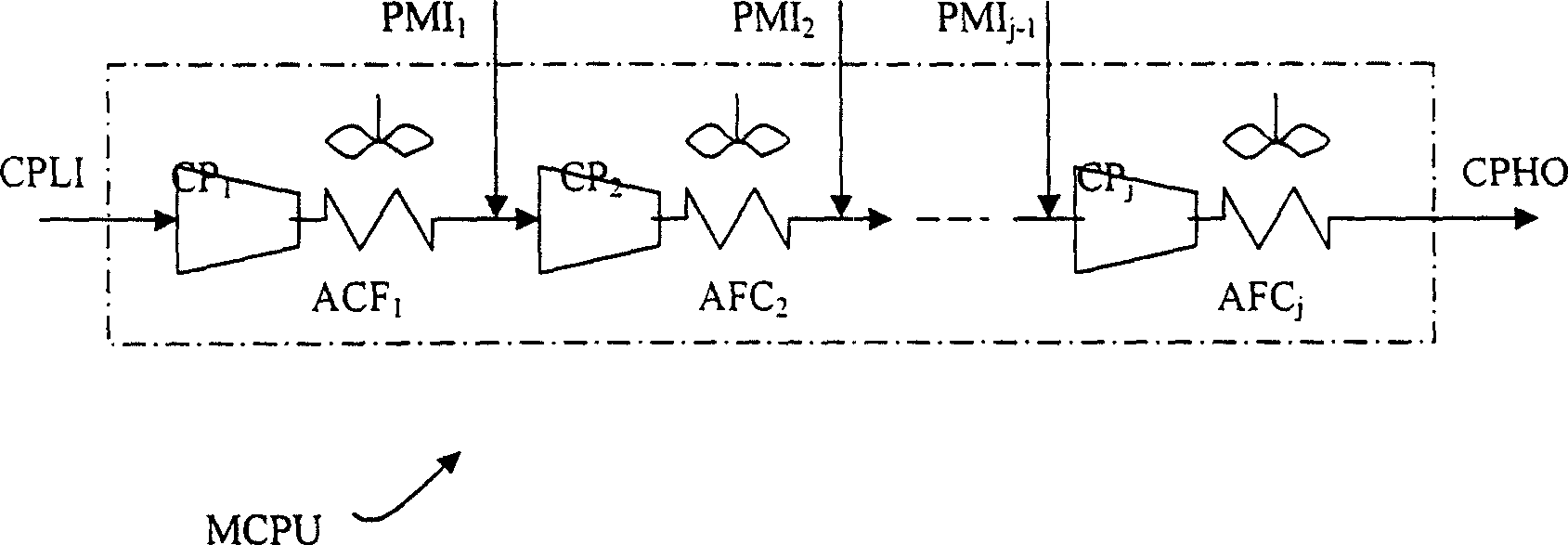

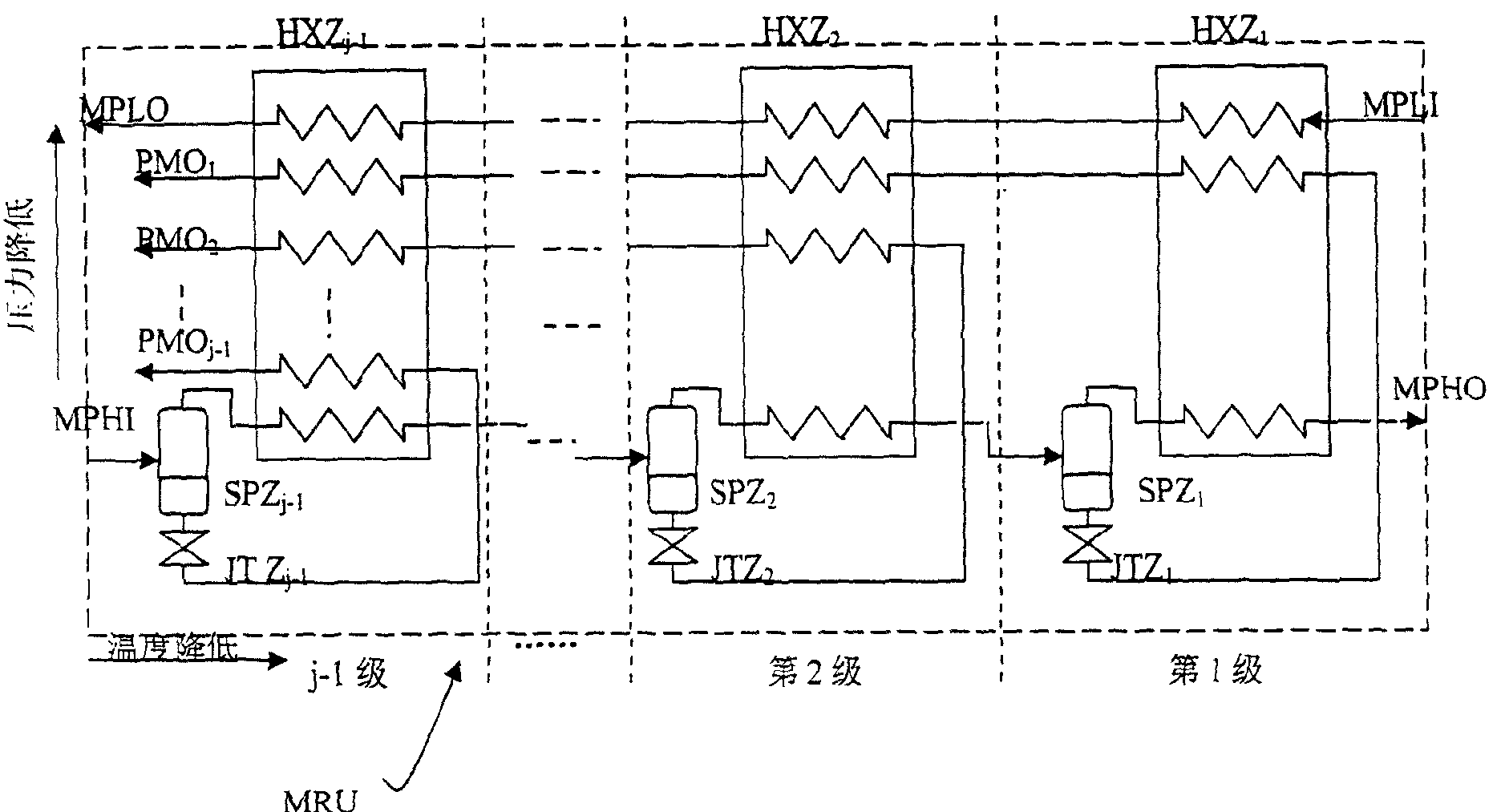

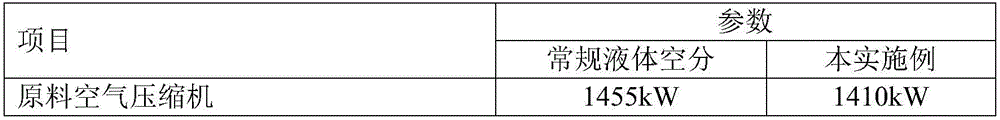

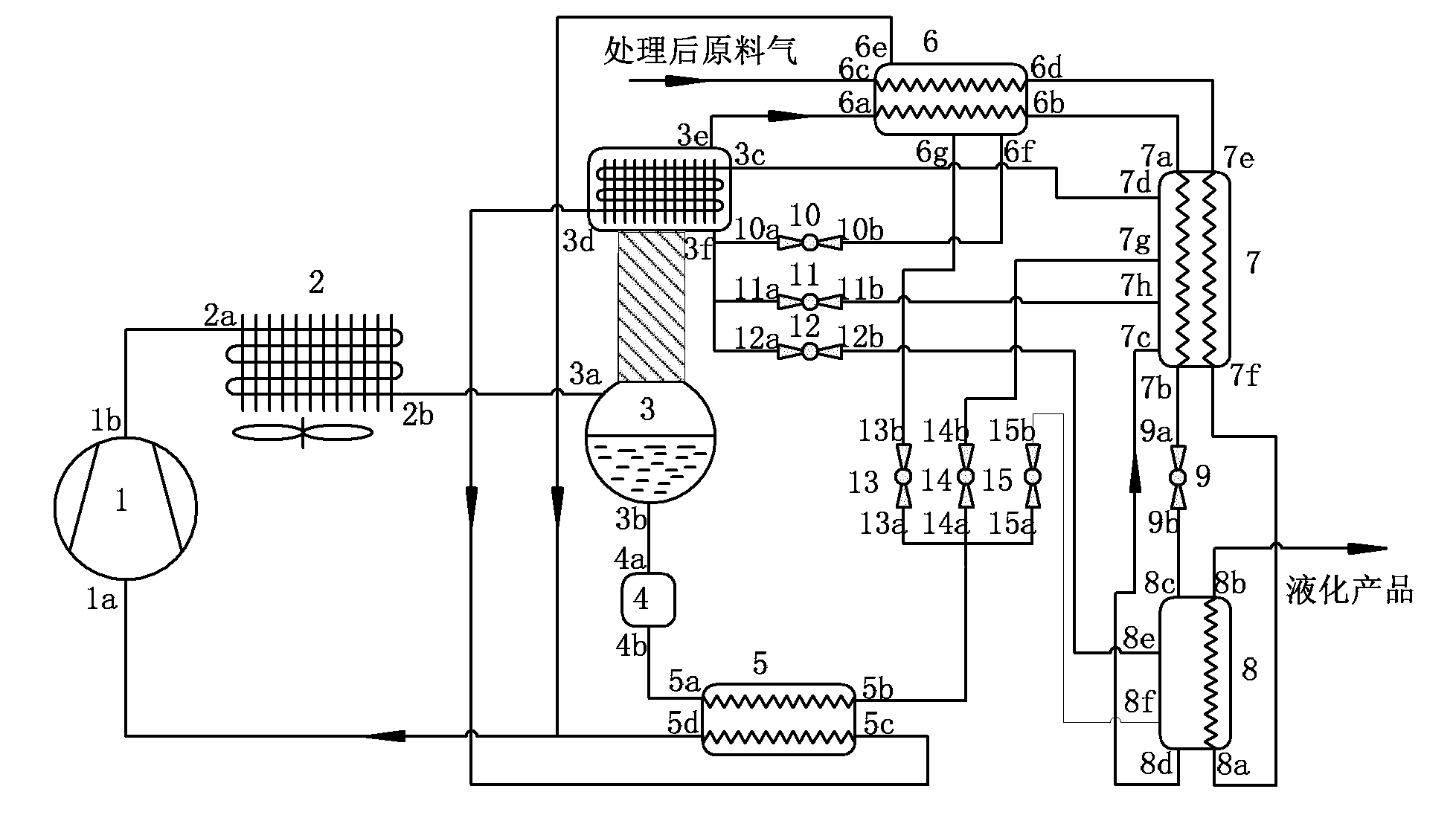

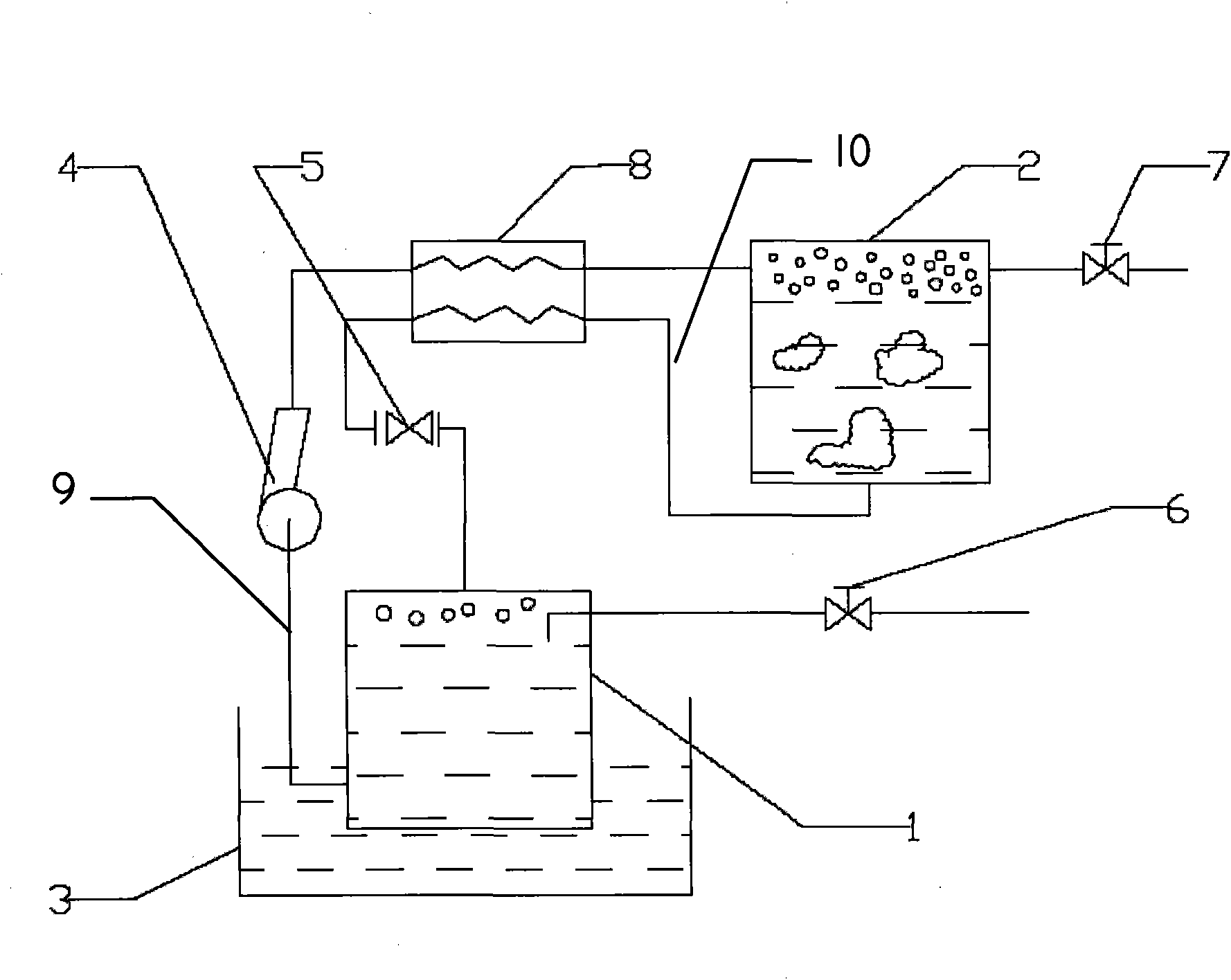

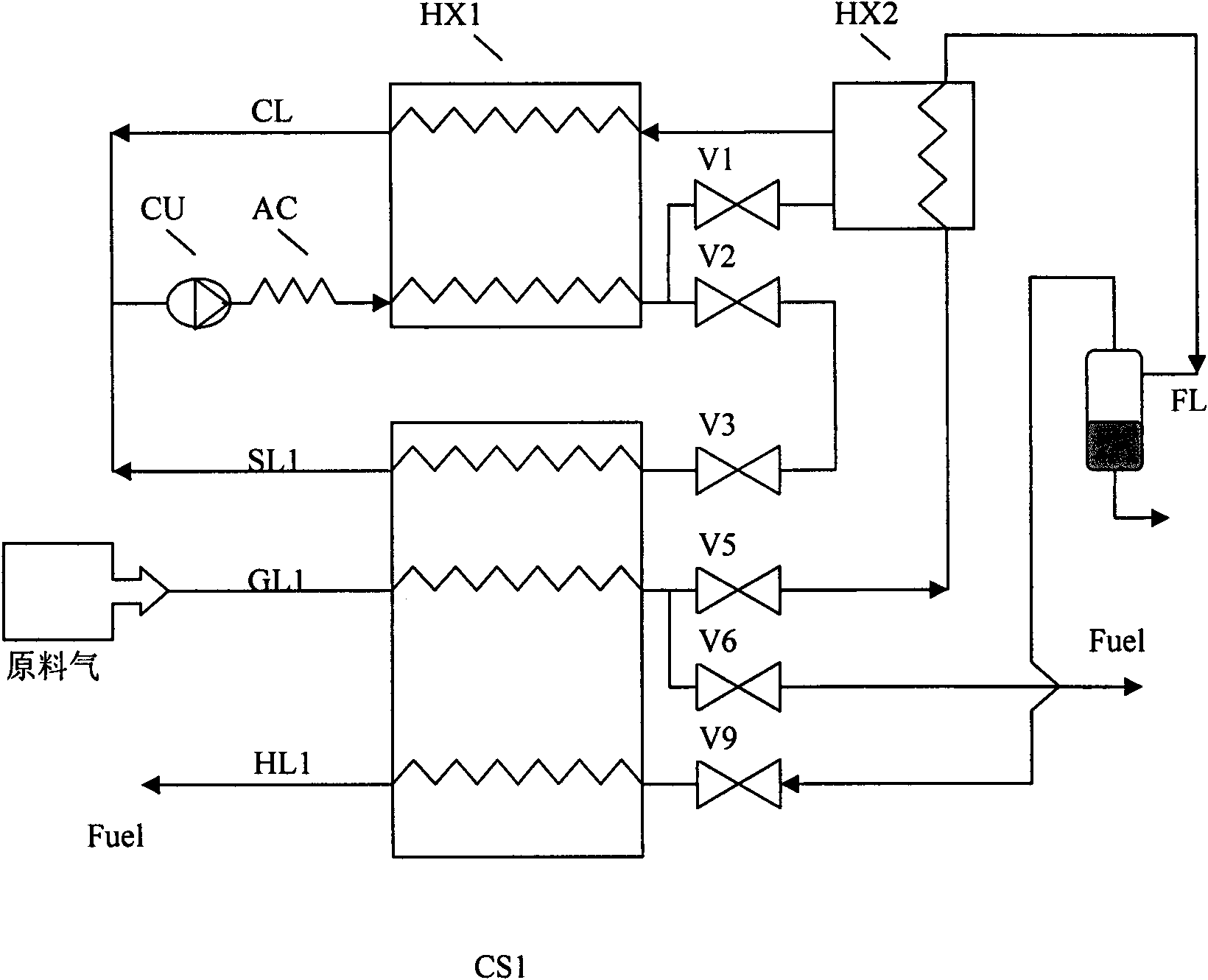

Multiple pressure grade mixed working medium cryogenic throttling refrigeration system

ActiveCN1683844AHigh thermal efficiencyGood throttling effectSolidificationLiquefactionProduct gasEngineering

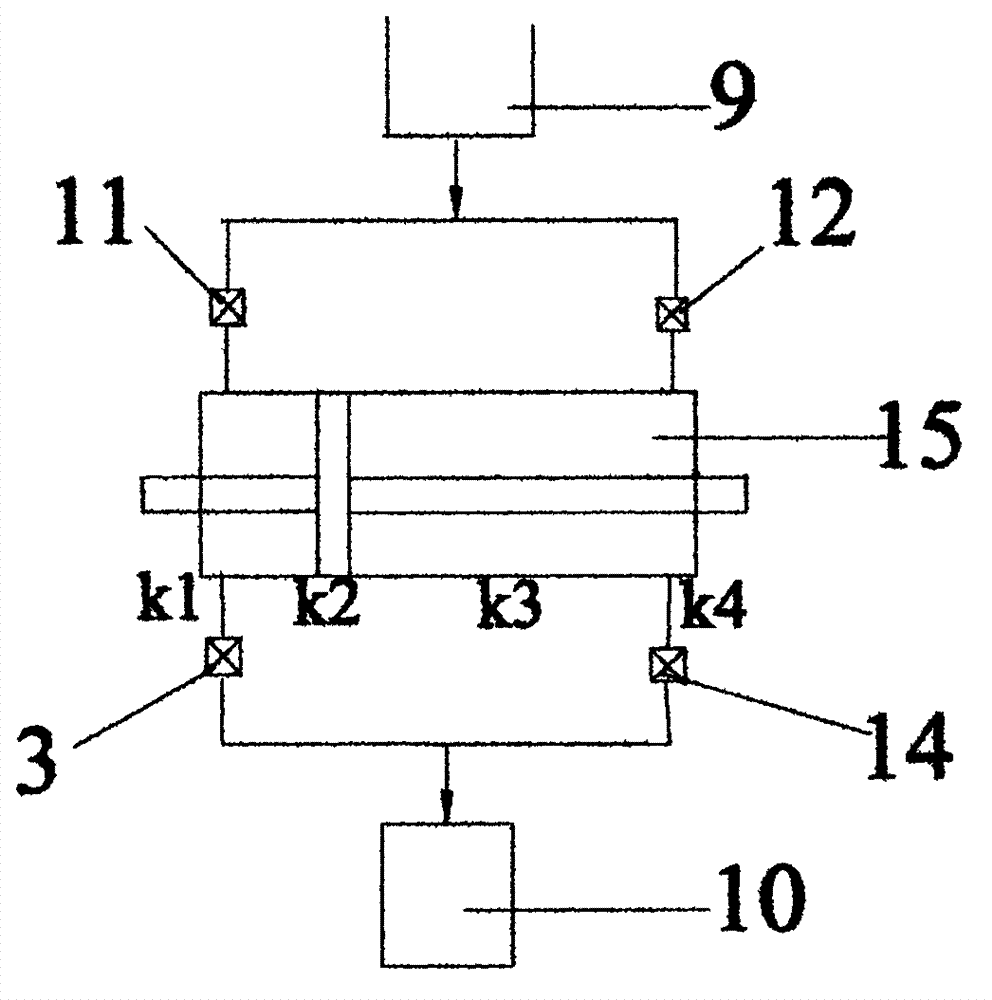

The multiple pressure stage mixed work medium cryogenic throttling refrigeration system consists of several stages of compressor set unit MCPU, back heating pre-cooling unit MRU and evaporator unit EVU. The connection mode includes connecting the high pressure outlet of MCPU to the high pressure inlet of MRU, connecting the low pressure inlet of MCPU to the low pressure outlet one MRU, connecting the high pressure outlet operate MRU to the inlet of EVU, and connecting the outlet of EVU to the low pressure inlet of MRU. The present invention adopts high efficiency multiple-element mixed work medium. The refrigeration system has lowered irreversible loss of compression and back heating process thermodynamically, reduced loss in the practical flow and heat exchange process, and thus high thermodynamic efficiency, and is especially suitable for large and middle scale low temperature refrigerating and gas liquefying fields.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

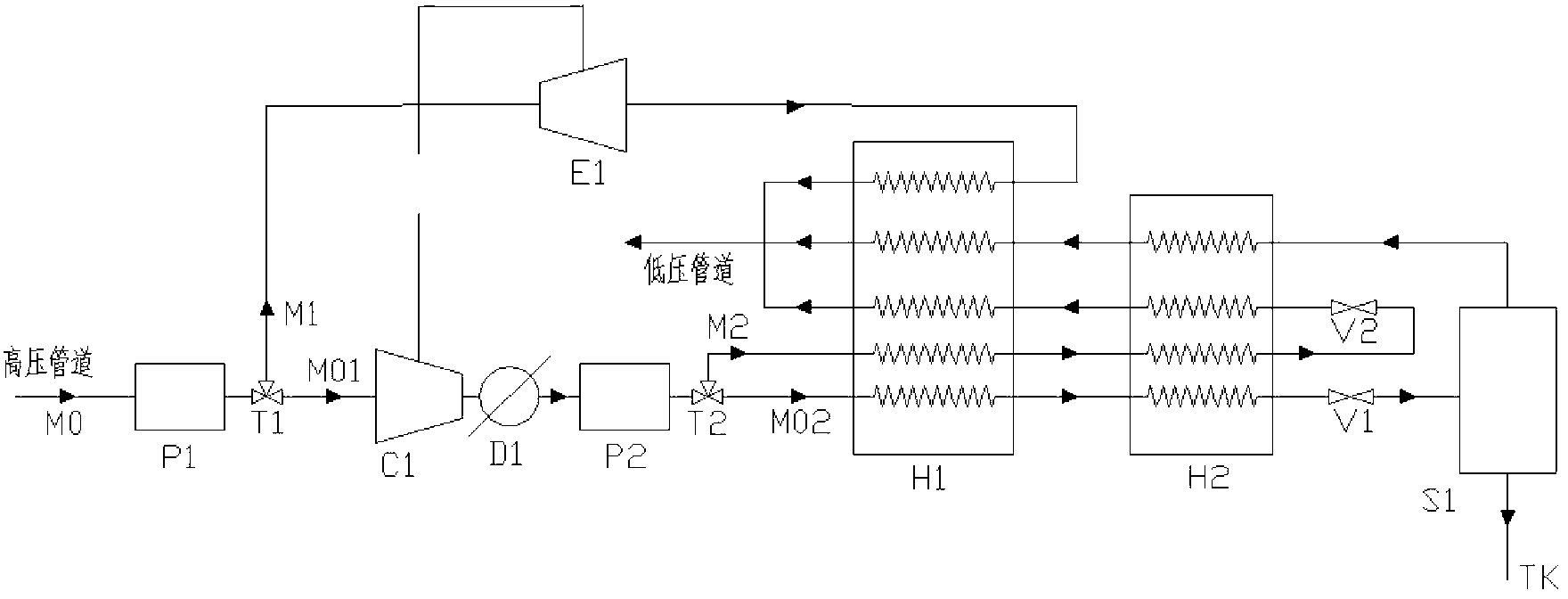

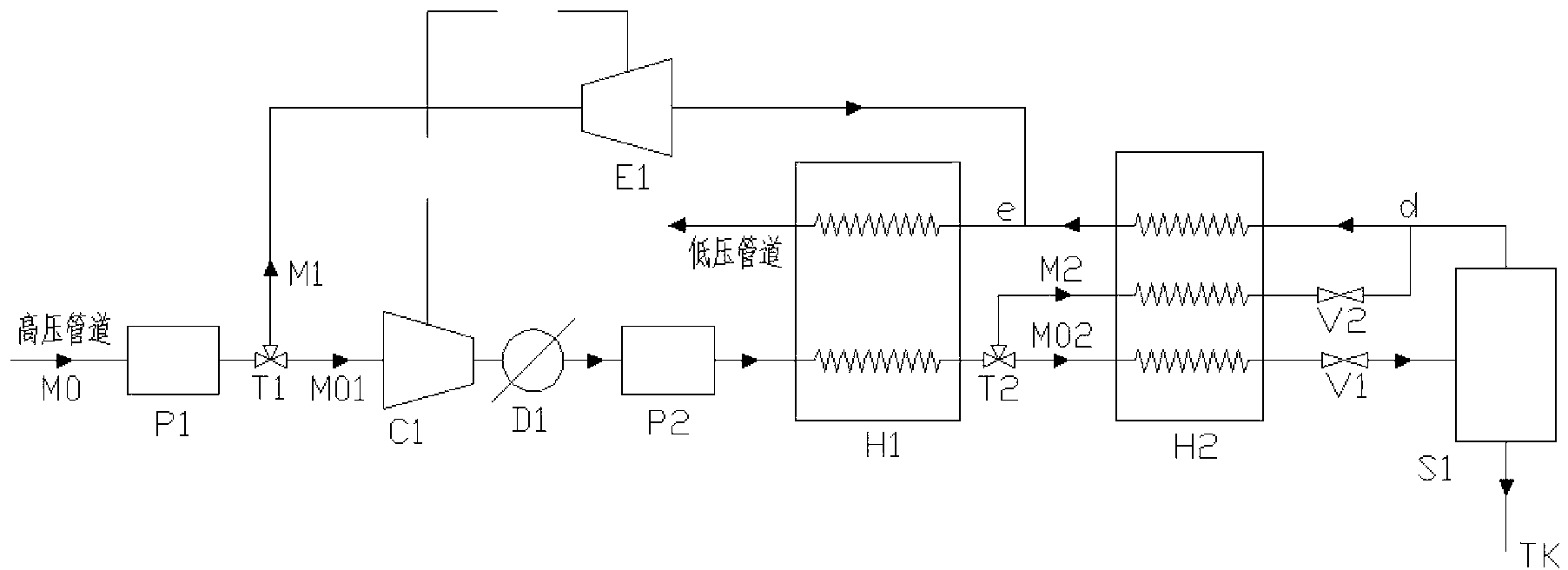

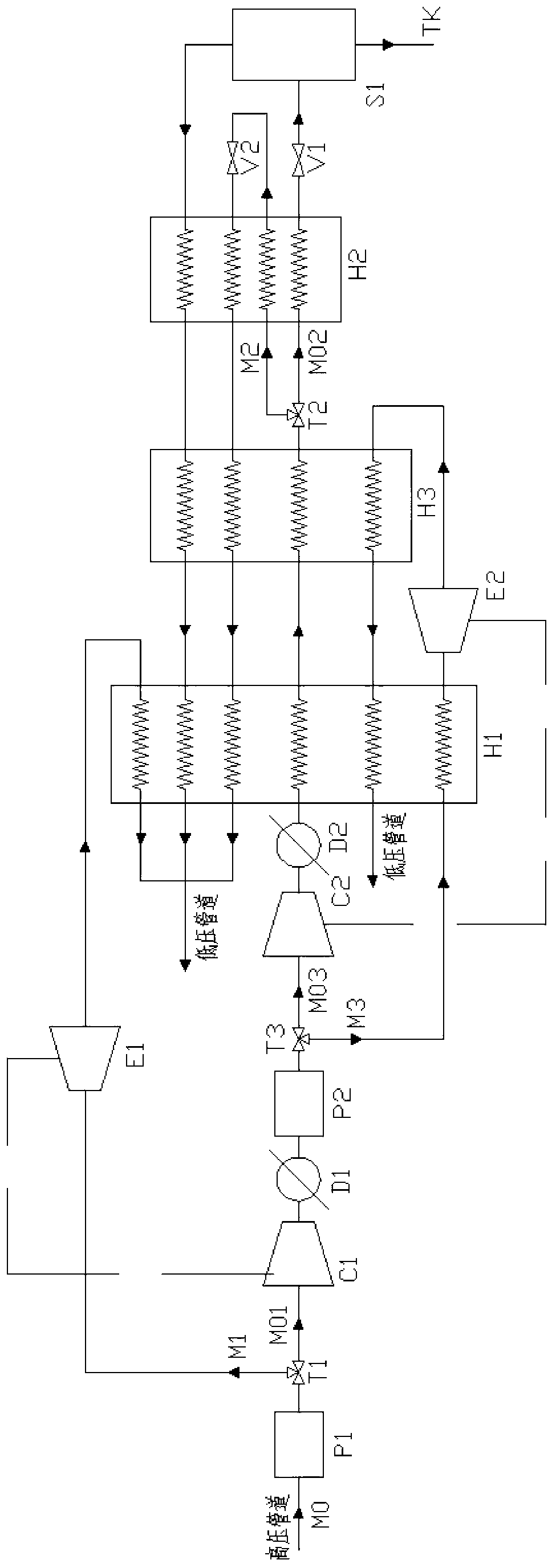

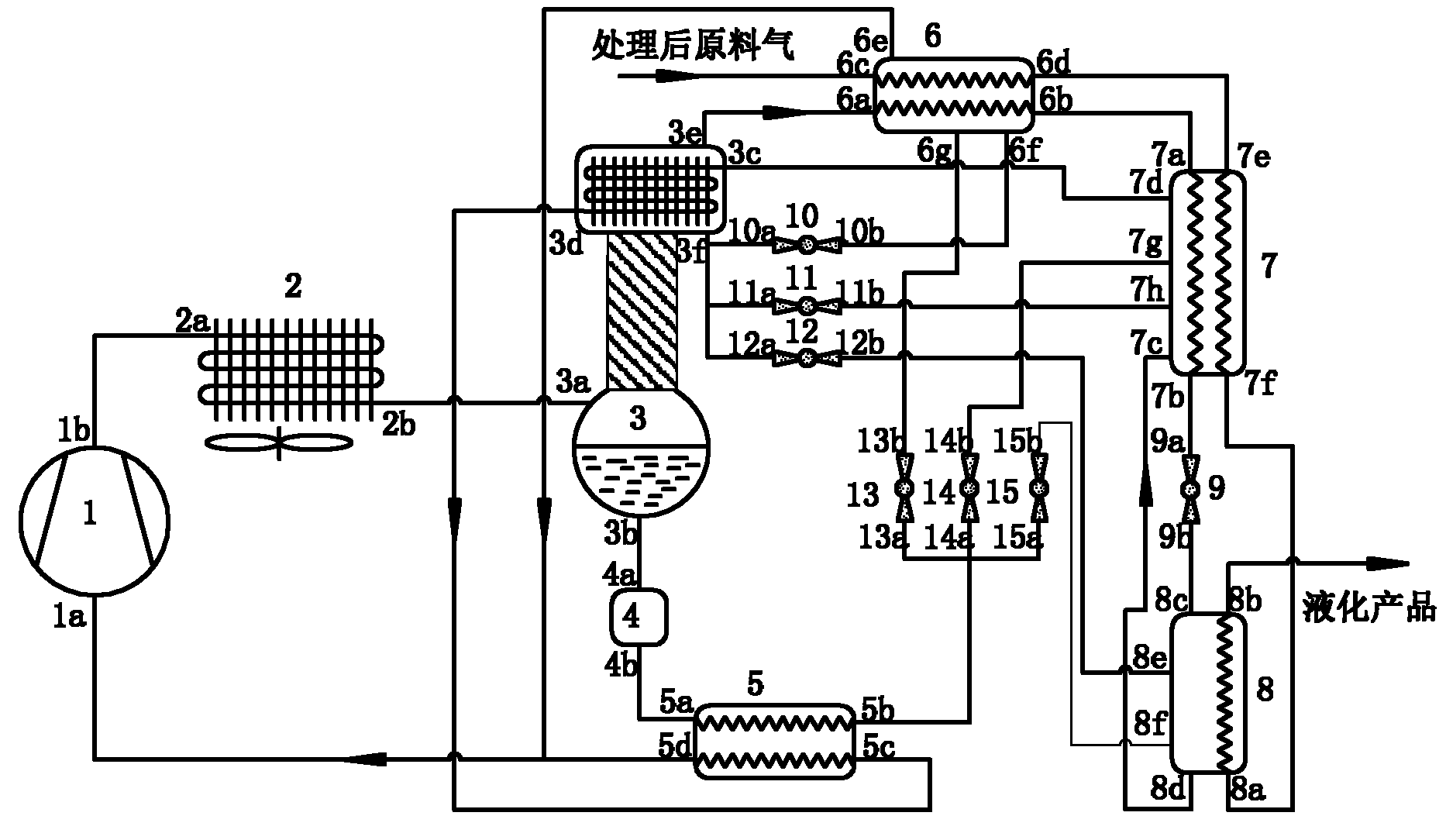

Liquefaction system for producing LNG (Liquefied Natural Gas) by using pressure energy of pipeline

ActiveCN103017480ALiquefaction achievedReduce the pressure of purificationSolidificationLiquefactionVapor–liquid separatorGas phase

The invention relates to a gas liquefaction system, and particularly relates to a liquefaction system for producing LNG (Liquefied Natural Gas) by using pressure energy of a pipeline. Natural gas from a high-pressure pipe is divided into natural gas in a liquefaction branch, natural gas in a first pre-cooling branch and natural gas in a main cooling branch, wherein the natural gas in the liquefaction branch is from the high-pressure pipeline, is sequentially compressed and cooled, then obtains heat in a backheating heat exchanger, and enters a gas-liquid separator after being throttled; a separated liquid phase is produced LNG; a gas phase enters a low-pressure pipeline after the cold energy is recycled by the backheating heat exchanger; the natural gas in the first pre-cooling branch enters the low-pressure pipeline after being expanded by an expanding machine after the cold energy is recycled in a heat regenerator; and the natural gas in the main cooling branch and the natural gas in the liquefaction branch are separated behind a cooler, the natural gas in the main cooling branch is cooled by the backheating heat exchanger and then throttled and expanded, and finally enters the low-pressure pipeline after the cold energy is recycled by the backheating heat exchanger. According to the liquefaction system, the LNG can be produced by using the pressure of the pipelines, compressors are driven by output works of the expanding machine without additional energy consumption.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

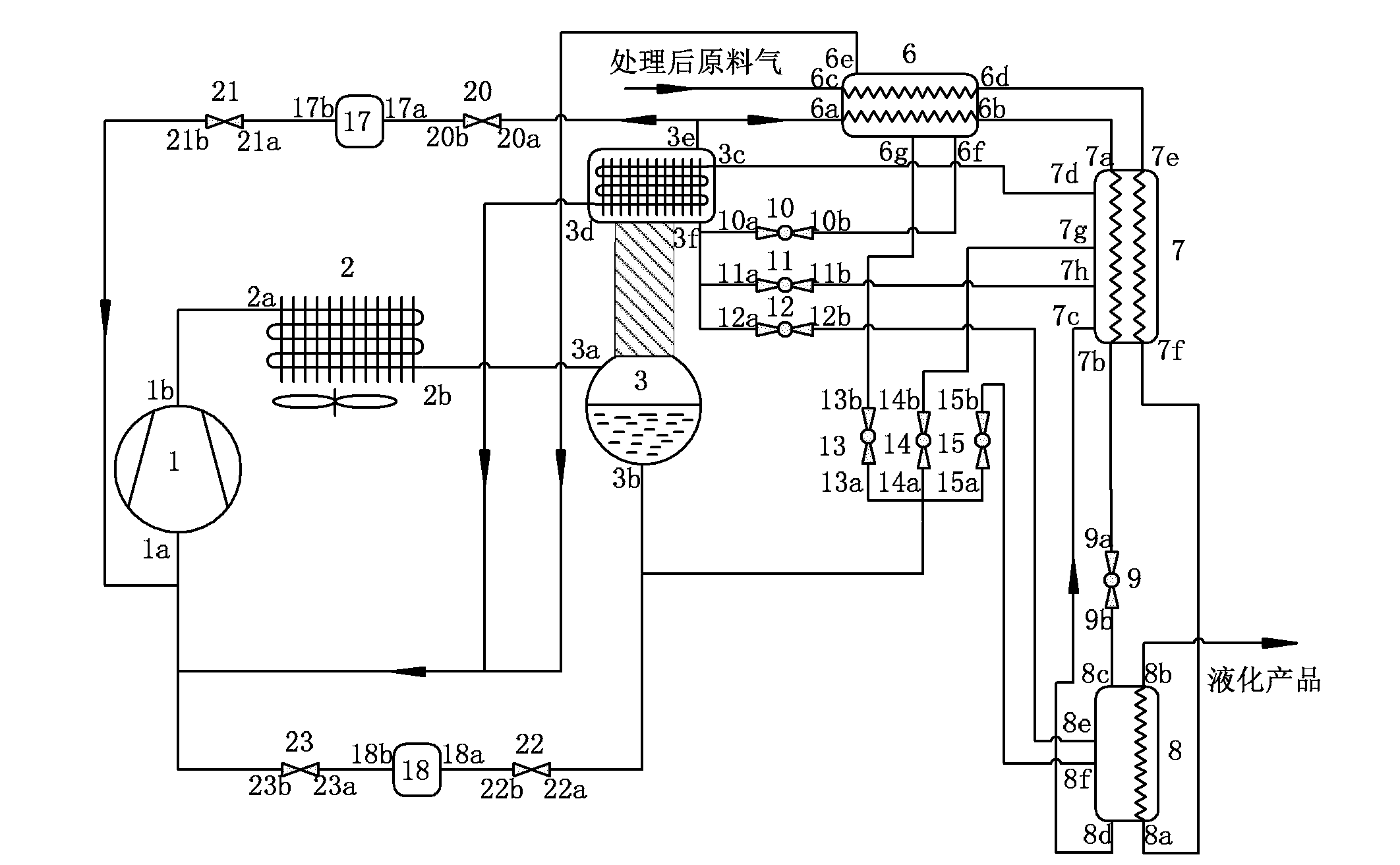

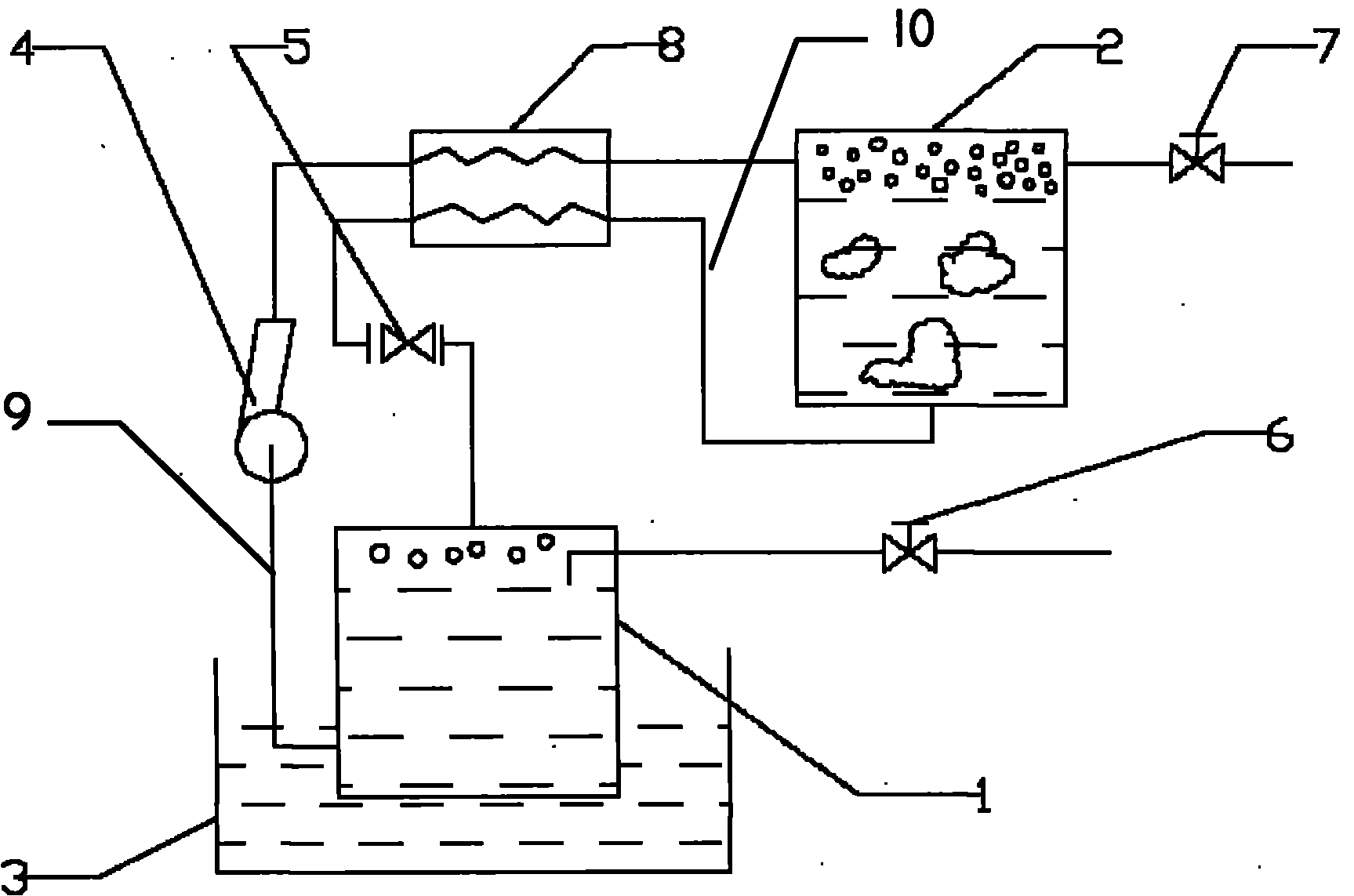

Rectification type mixed working substance self-stacking gas liquefaction system

InactiveCN101275798ASimple structureEfficient removalSolidificationLiquefactionVapor–liquid separatorProduct gas

The invention discloses a rectified mixed working medium auto-overlapping gas liquefying system, having orderly a compressor, a condenser, a device for drying and filtering, a rectifying device, a first heat interchanger, a second heat interchanger, a first throttle valve, a third heat interchanger and a gas-liquid separator connected. The invention replaces 2-5 level separating process of the conventional mixed working medium gas liquefying system by the rectifying device, cools the raw material gas section by section by three heat interchangers with different temperature, which simplifies the structure of the liquefying system, and removes the lubricating oil entering to the refrigerant in a low pressure portion to guarantee high efficiency and reliable operation of the refrigerator. The system is appropriate for occasions where small and micro-gas liquefying devices are required.

Owner:ZHEJIANG UNIV

Gas liquefying process for mixed refrigerant and mixed refrigerant

The invention relates to a gas liquefying process for mixed refrigerant, which comprises the following steps: providing the mixed refrigerant which comprises the following components in percentage by mole: 5 to 10 percent of nitrogen, 30 to 40 percent of methane, 5 to 10 percent of ethylene, and 45 to 60 percent of propane; feeding the mixed refrigerant to a single refrigerant circulating system to carry out closed cycle to produce cold energy required by cooling gas; and exchanging heat of the gas needing to be liquefied and the refrigerant circulating system through a gas liquefying system so that the gas is cooled and liquefied. The process flow is simple, the components of the refrigerant are reasonable, and a liquefying device has the advantages of safe and reliable operation, simple work, flexible load adjustment and low energy consumption.

Owner:LIAONING CIMC HASHENLENG GAS LIQUEFACTION EQUIP CO LTD

Equipment and process for liquefaction of LNG boiloff gas

ActiveUS20070256450A1Reduce compressionReduce pressureSolidificationLiquefactionSingle stageProduct gas

A design for equipment and process for reliquefaction of LNG boiloff gas, primarily for shipboard installation, has high thermodynamic efficiency and lower capital cost, smaller size (volume, footprint), lower weight, and less need for maintenance than systems utilizing the prior art. The main refrigerant gas compressor is reduced to a single stage turbocompressor. Optional elements include: compression of boiloff gas at ambient temperature; compression of boiloff gas in one or two stages; turboexpansion of refrigerant gas incorporating one or two turboexpanders; turboexpander energy recovery by mechanical loading, compressor drive, or electric generator; refrigerant sidestream for cooling at the lowest temperatures.

Owner:AIR WATER GAS SOLUTIONS INC

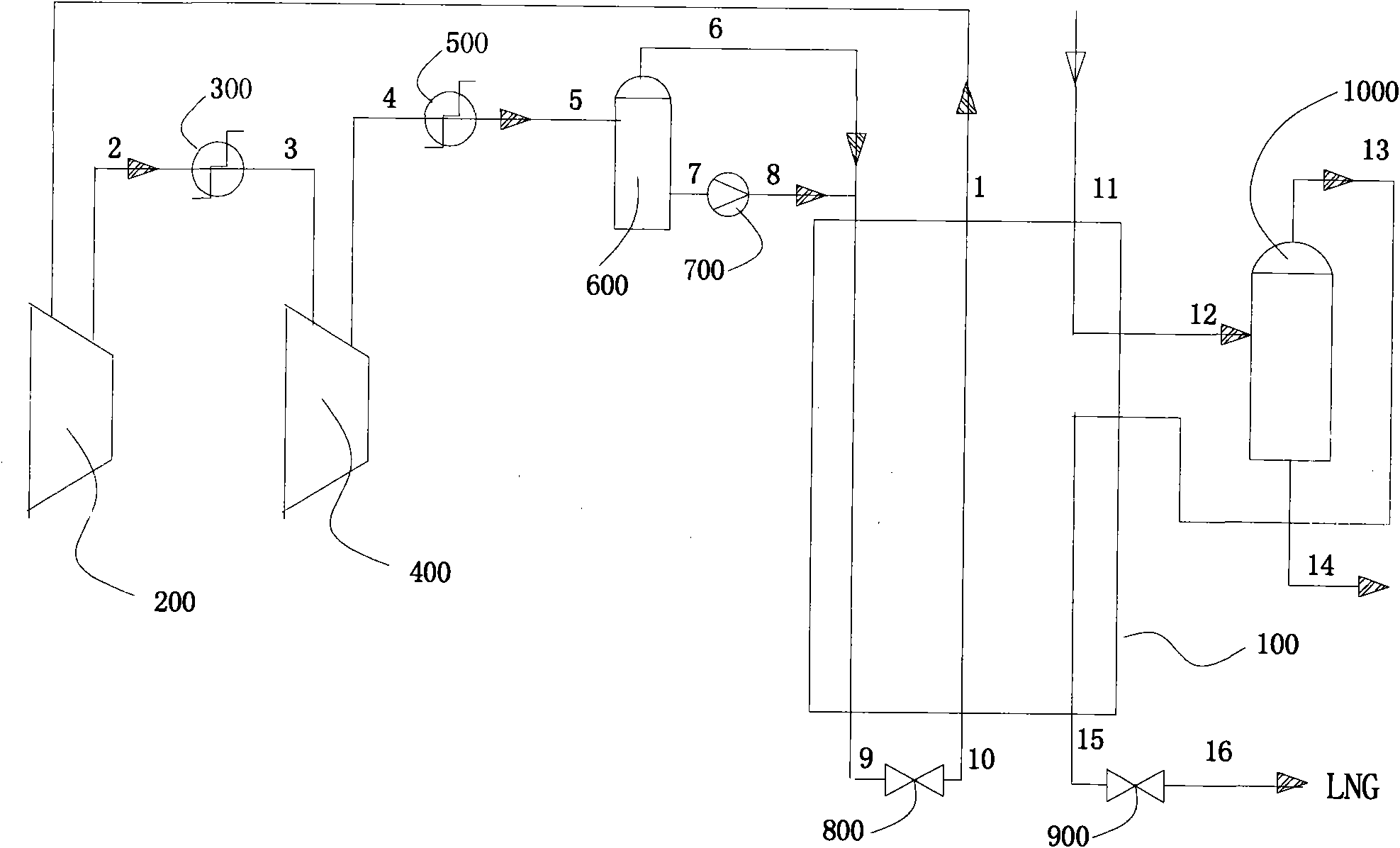

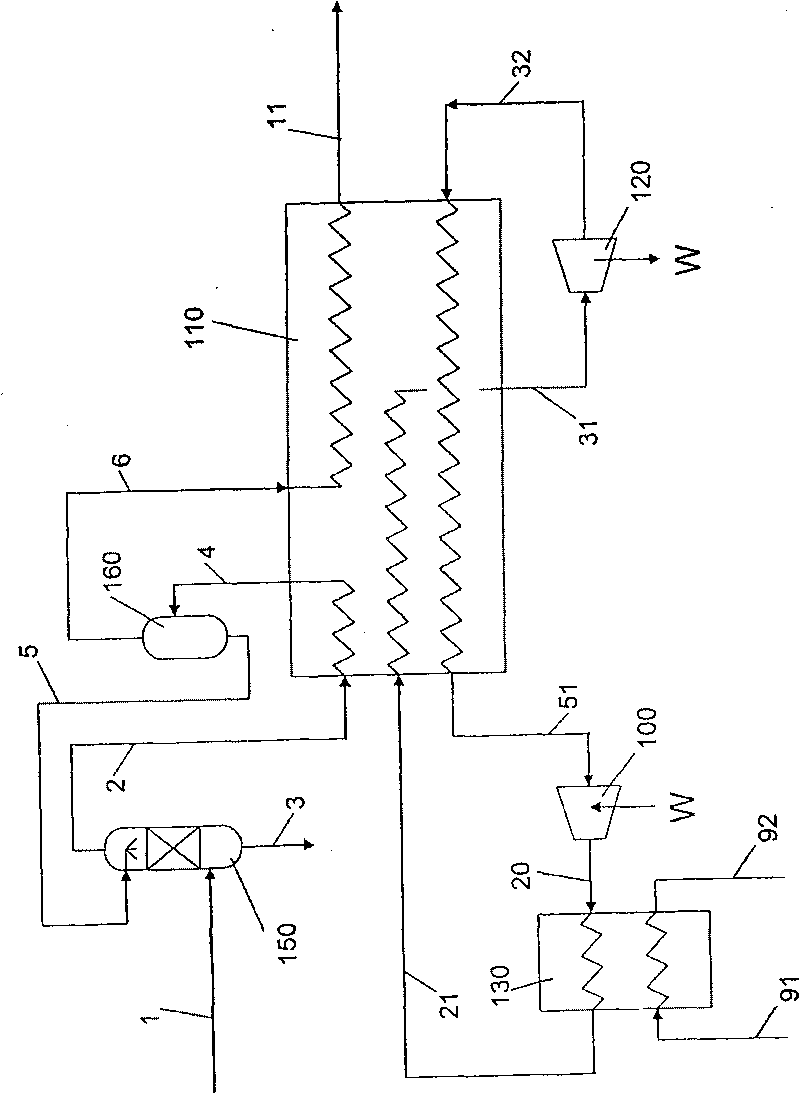

Method and system for producing LNG

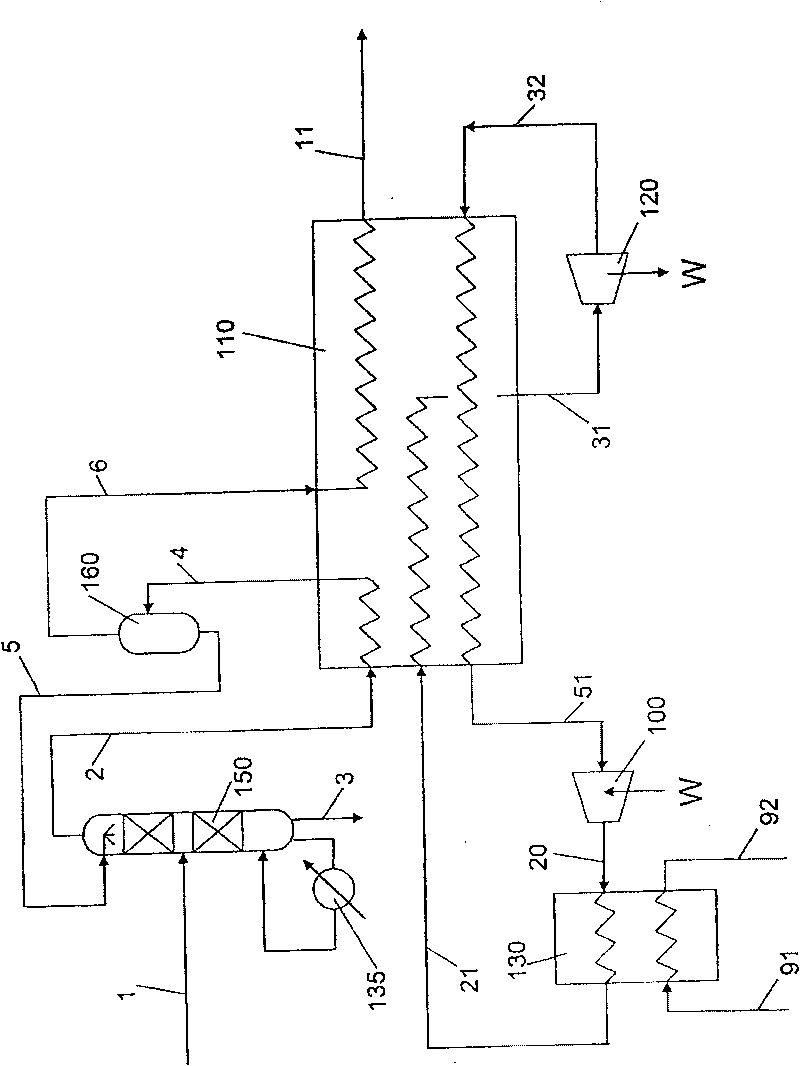

A method is described for production of LNG from an incoming feed gas (1 ) on an onshore or offshore installation, and it is characterised by the following steps: 1 ) the feed gas is led through a fractionation column (150) where it is cooled and separated in an overhead fraction with a reduced content of pentane (C5) and heavier components, and a bottom fraction enriched with heavier hydrocarbons, 2) the overhead fraction from the fractionation column is fed to a heat exchanger system (110) and is subjected to a partial condensation to form a two-phase fluid, and the two-phase fluid is separated in a suitable separator (160) into a liquid (5) rich in LPG and pentane (C3-C5) which is re-circulated as cold reflux to the fractionation column (150), while the gas (6) containing lower amounts of C5 hydrocarbons and hydrocarbons heavier than C5 is exported for further processing in the heat exchanger system (110) for liquefaction to LNG with a maximum content of ethane and LPG 3) the cooling circuit for liquefaction of gas in the heat exchanger system comprises an open or closed gas expansion process with at least one gas expansion step. A system for carrying out the method is also described.

Owner:阿拉贡股份有限公司

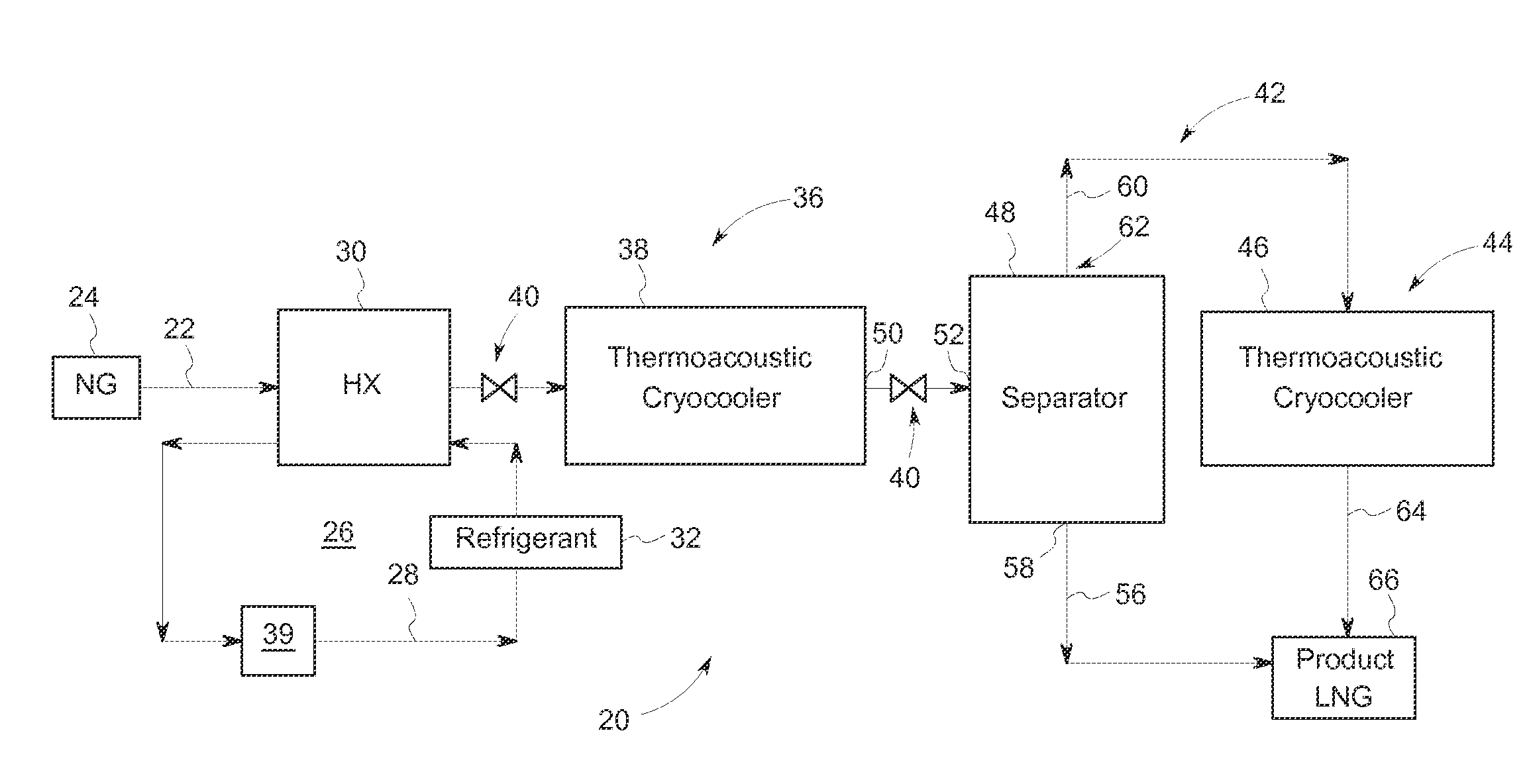

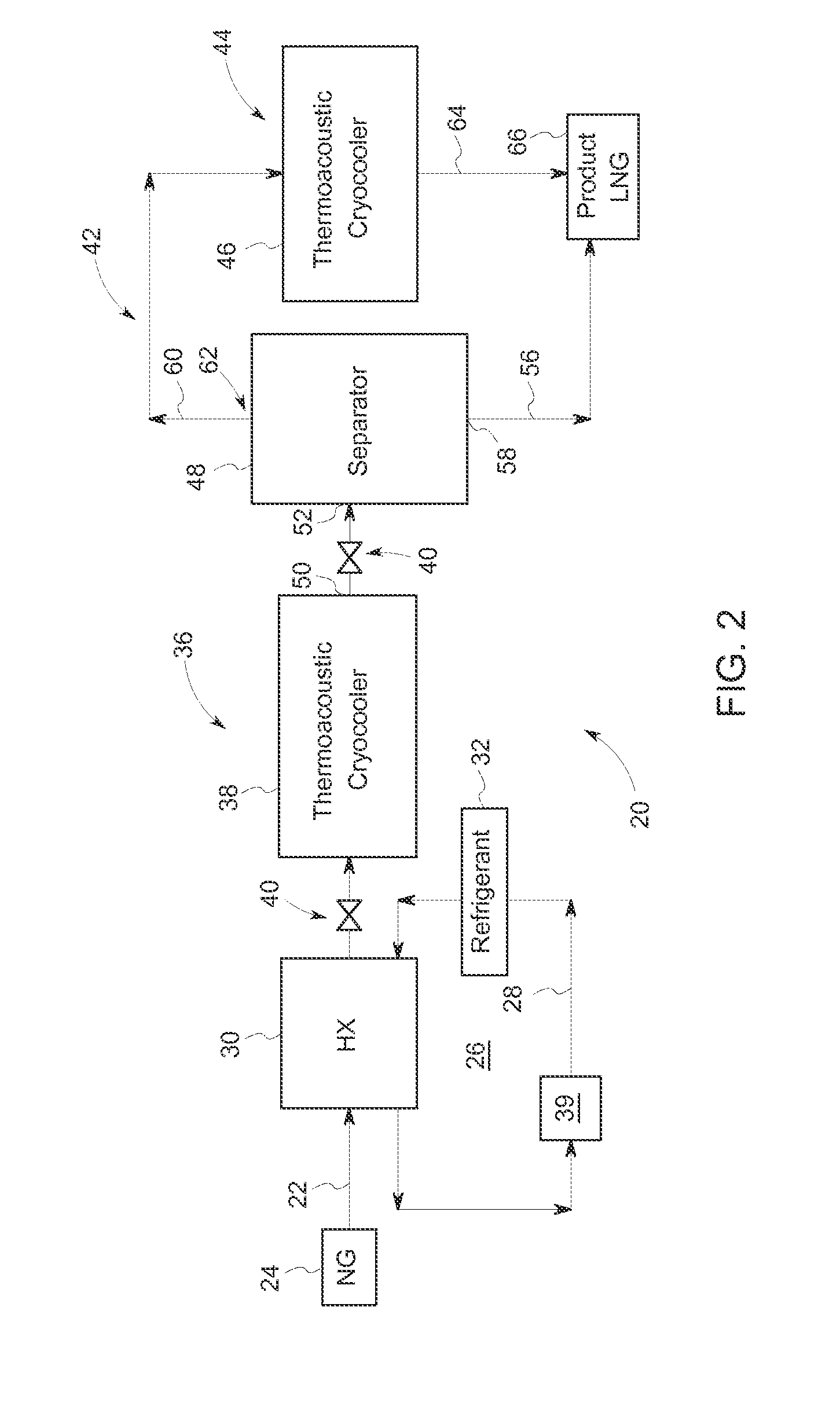

System and method for hybrid refrigeration gas liquefaction

In an embodiment, a method includes cooling a fluid along a fluid path using a vapor compression refrigeration cycle; cooling the fluid along the fluid path using at least one cryocooler of a cryogenic cooling phase; expanding the fluid during cooling within the cryogenic cooling phase, after cooling in the cryogenic cooling phase, or a combination thereof, such that a temperature and pressure of the fluid are reduced to generate a fluid stream having both a vapor phase and a liquid phase; and condensing the vapor phase. The fluid may be a natural gas.

Owner:AIR PROD & CHEM INC

Method for haze mitigation and filterability improvement for gas-to-liquid hydroisomerized base stocks

Haze formation in heavy Gas-to-Liquids (GTL) base stock is mitigated by the addition to said GTL base stock of one or more particular additives.

Owner:EXXON RES & ENG CO

Membrane loop process for separating carbon dioxide for use in gaseous form from flue gas

ActiveUS8852319B2Promote recoveryEnhanced overall recoveryMethane captureCarbon compoundsFlue gasProduct gas

The invention is a process involving membrane-based gas separation for separating and recovering carbon dioxide emissions from combustion processes in partially concentrated form, and then transporting the carbon dioxide and using or storing it in a confined manner without concentrating it to high purity. The process of the invention involves building up the concentration of carbon dioxide in a gas flow loop between the combustion step and a membrane separation step. A portion of the carbon dioxide-enriched gas can then be withdrawn from this loop and transported, without the need to liquefy the gas or otherwise create a high-purity stream, to a destination where it is used or confined, preferably in an environmentally benign manner.

Owner:MEMBRANE TECH & RES

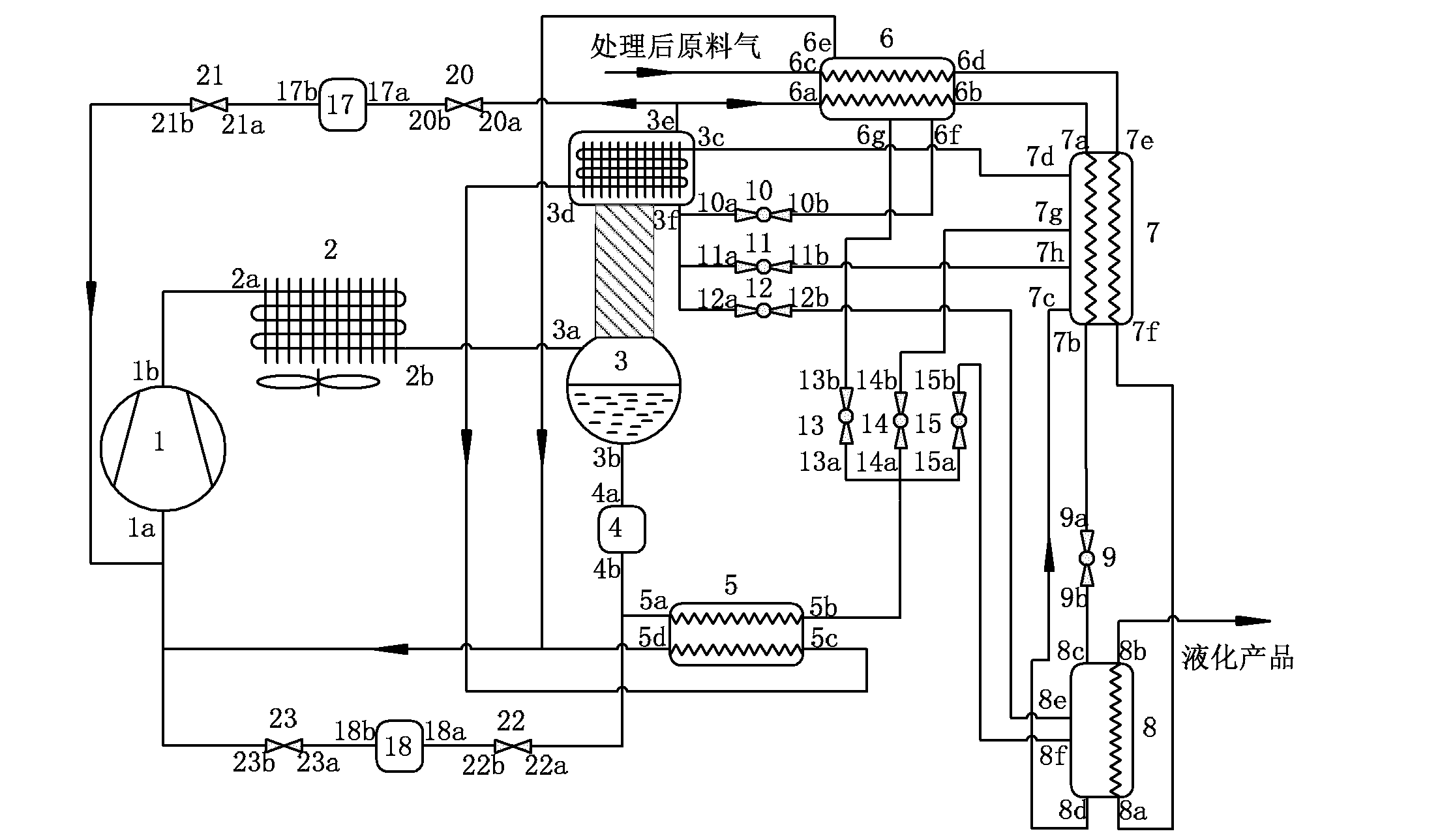

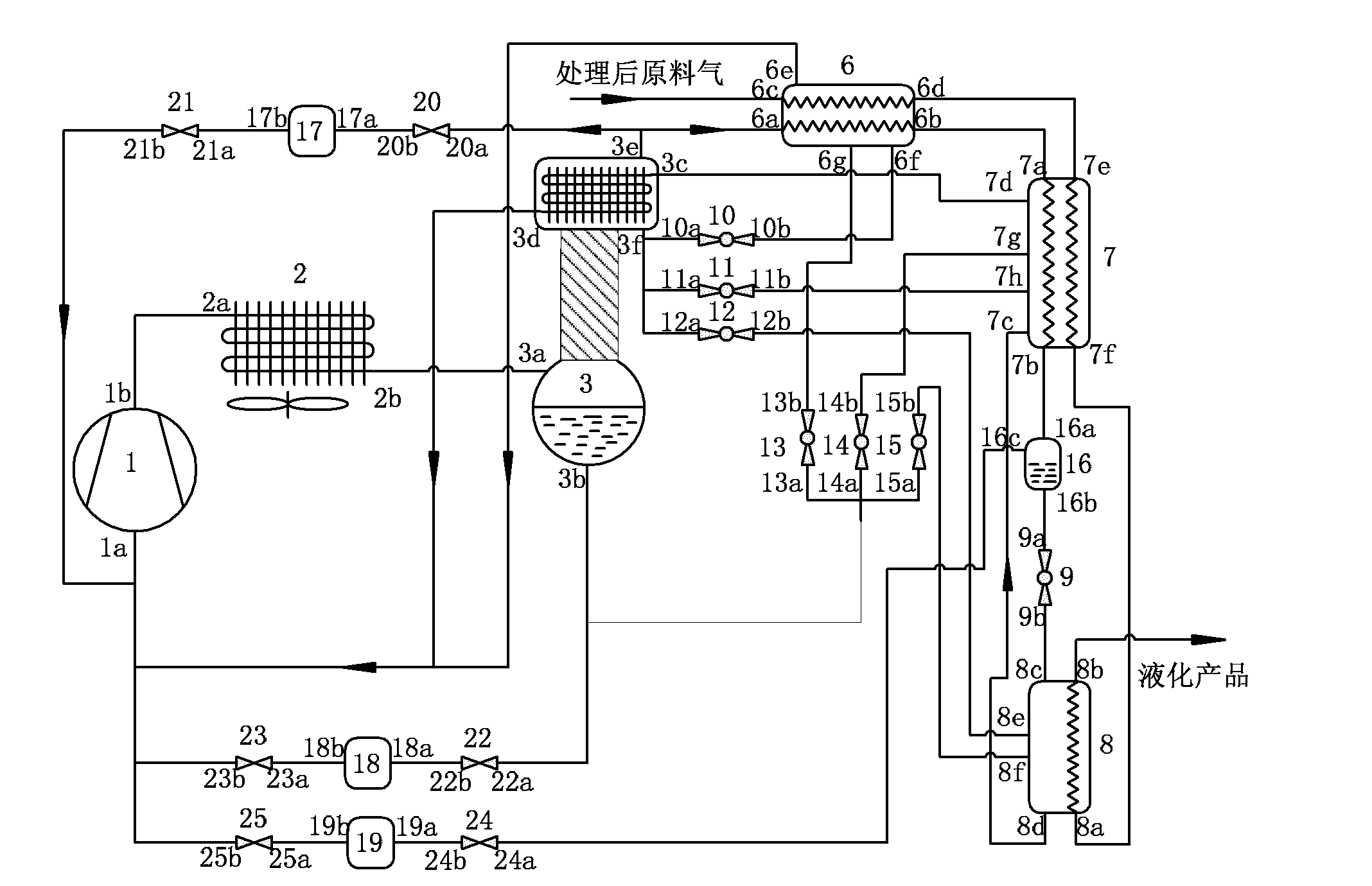

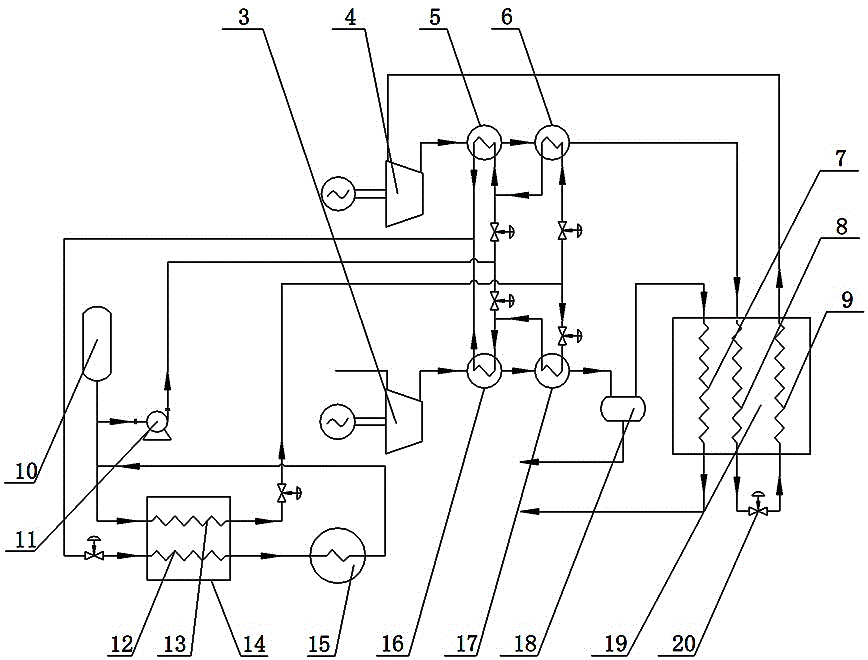

Rectifying type variation-concentration self-overlaying gas liquefaction system

ActiveCN102147162ASmall heat transfer temperature differenceReduce unit liquefaction workCompression machines with non-reversible cycleFluid circulation arrangementProcess engineeringProduct gas

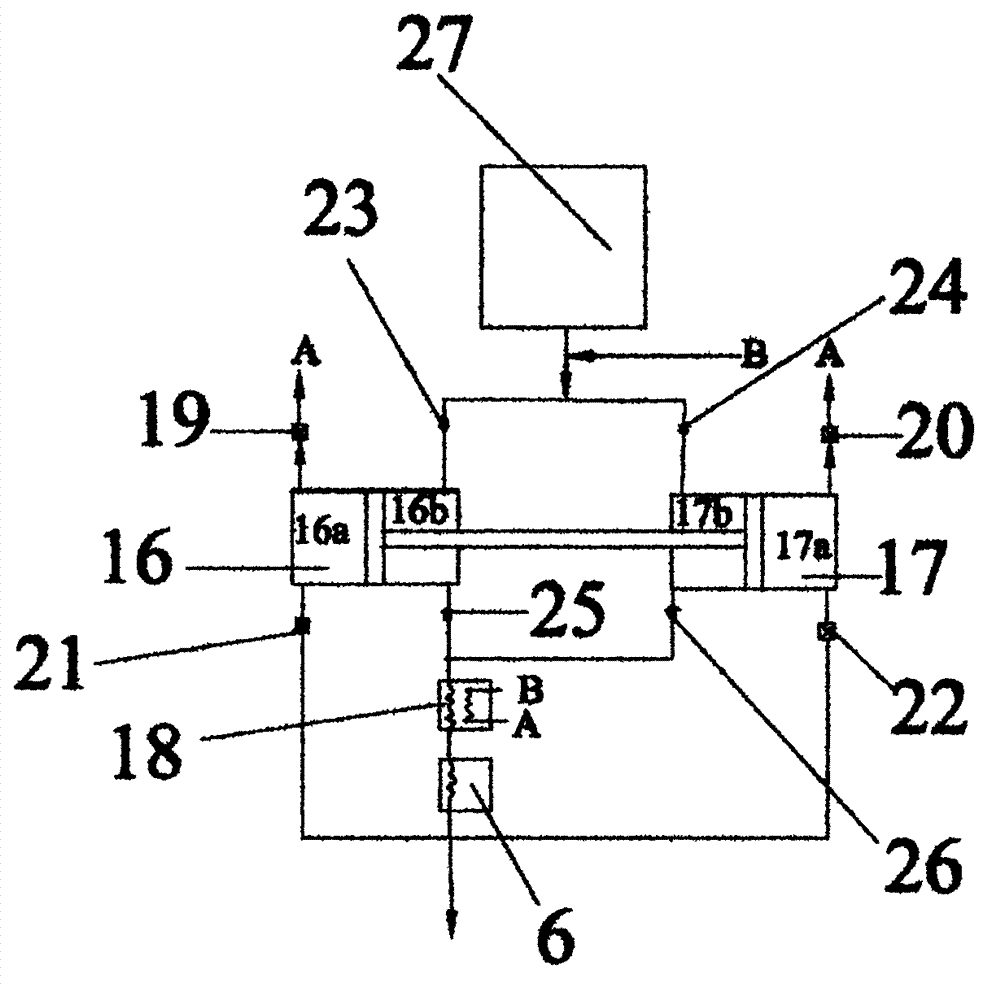

The invention discloses a rectifying type variation-concentration self-overlaying gas liquefaction system which comprises a compressor, a condenser, a rectifying device and a feed gas liquefaction loop, wherein the feed gas liquefaction loop comprises a first heat exchanger group, a second heat exchanger group and a first throttle valve arranged between the first heat exchanger group and the second heat exchanger group; and two parallel arranged first variable concentration loop and second variable concentration loop are arranged between the rectifying device and an air suction hole of the compressor. The rectifying device is used for replacing a multistage separation process of the traditional mixed refrigerant gas liquefaction system, and different components of high-pressure liquids are led from the bottom and the top of the rectifying device and are respectively subjected to pressure reduction and then enter the two heat exchanger groups, water equivalent change of a feed gas cooling and liquefaction process is optimized and matched, and variable working condition regulating capacity of the liquefaction system is improved by adopting the variable concentration loops. The invention has the advantages of simple structure, operation reliability, high system liquefaction efficiency and the like, and is suitable for various small and minitype gas liquefaction systems with high performance requirements on variable working conditions.

Owner:ZHEJIANG UNIV

Controlling Liquefaction of Natural Gas

InactiveUS20090025422A1Avoid the needInhibit thermal stressSolidificationLiquefactionProcess engineeringRefrigeration

A gas liquefaction process, especially for producing LNG, maintains product flow rate and temperature by controlling the refrigeration so that variation to reduce any difference between actual and required product temperatures is initiated before variation of the product flow rate to reduce any difference between actual and required flow rates.

Owner:AIR PROD & CHEM INC

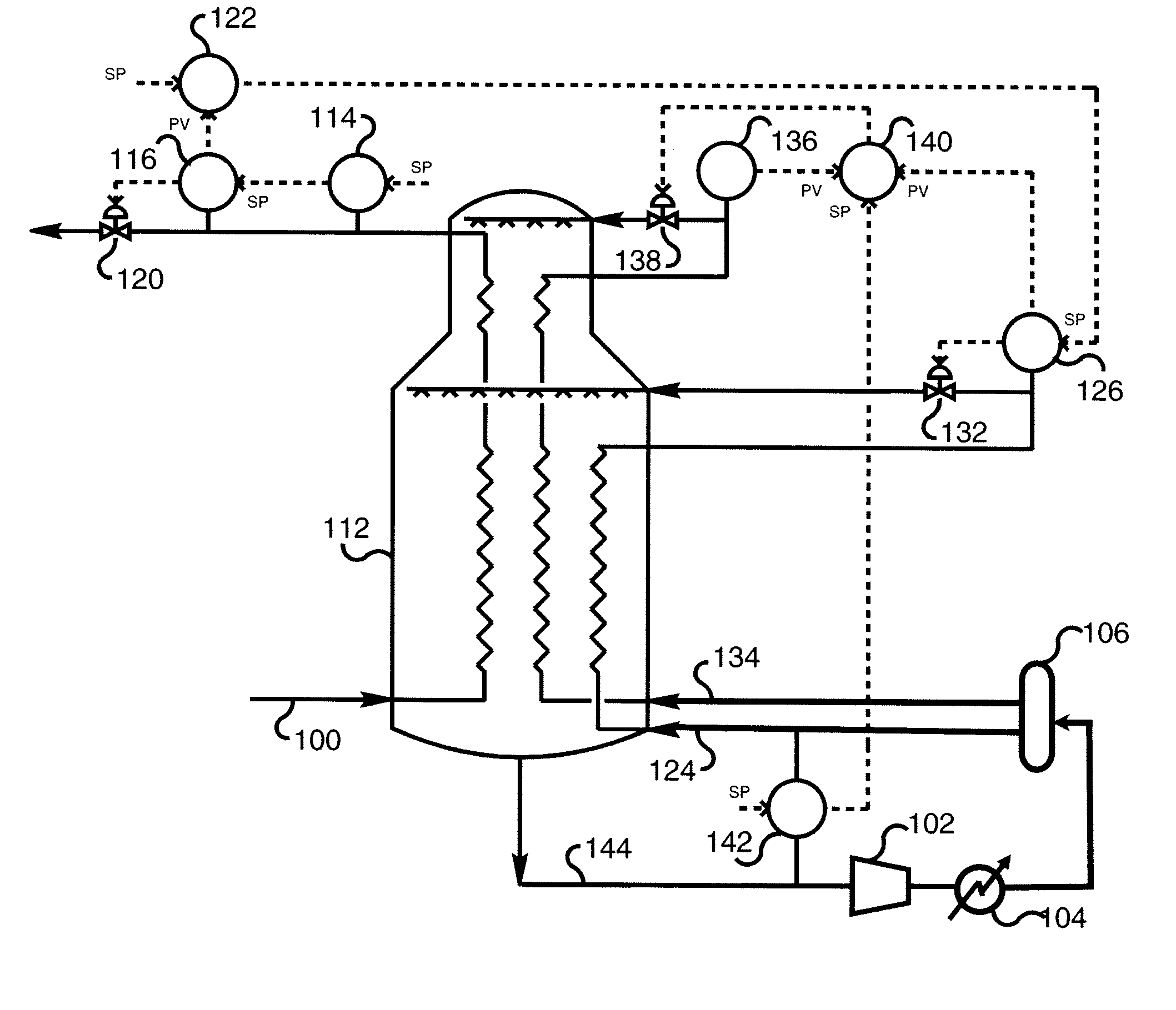

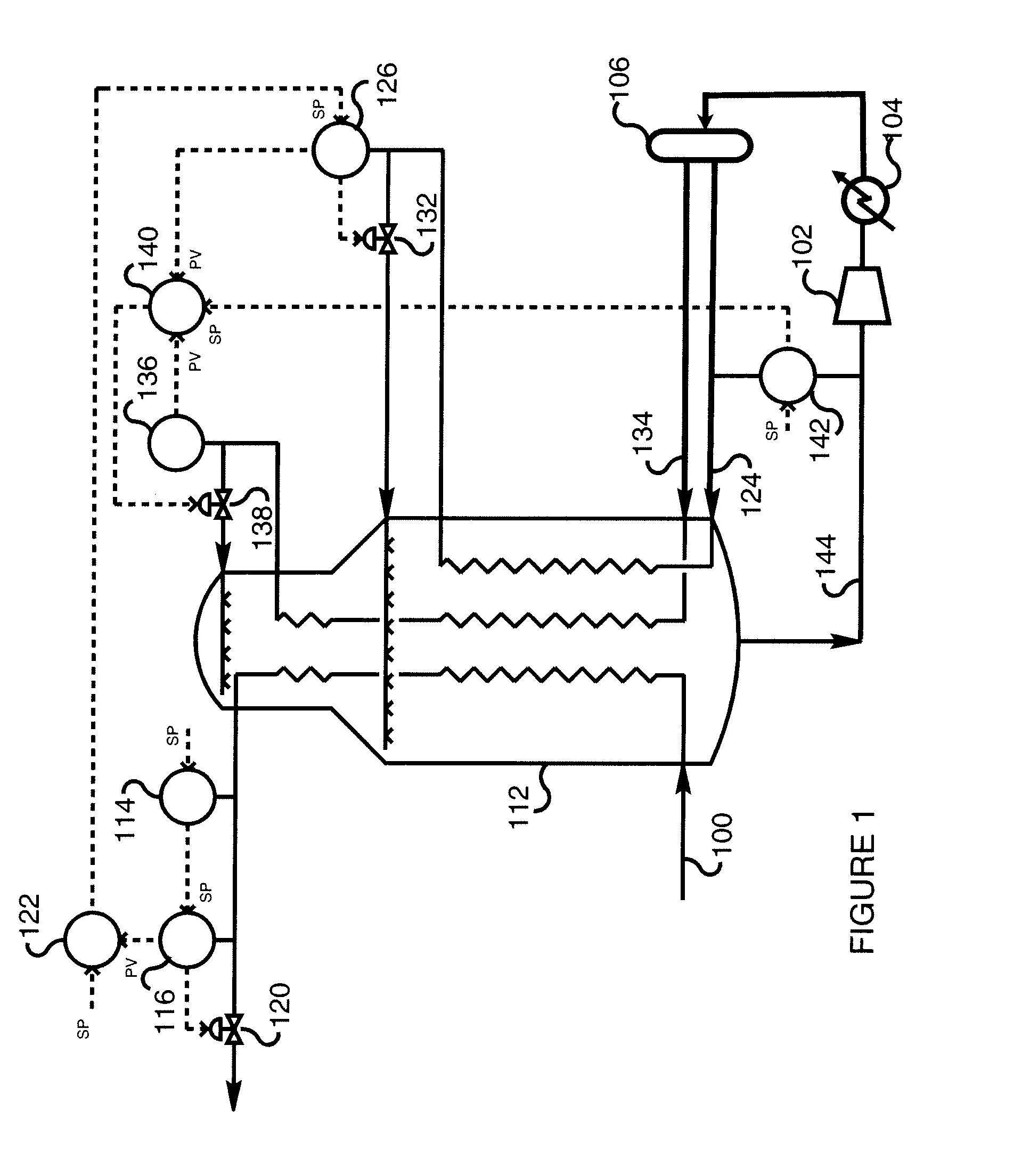

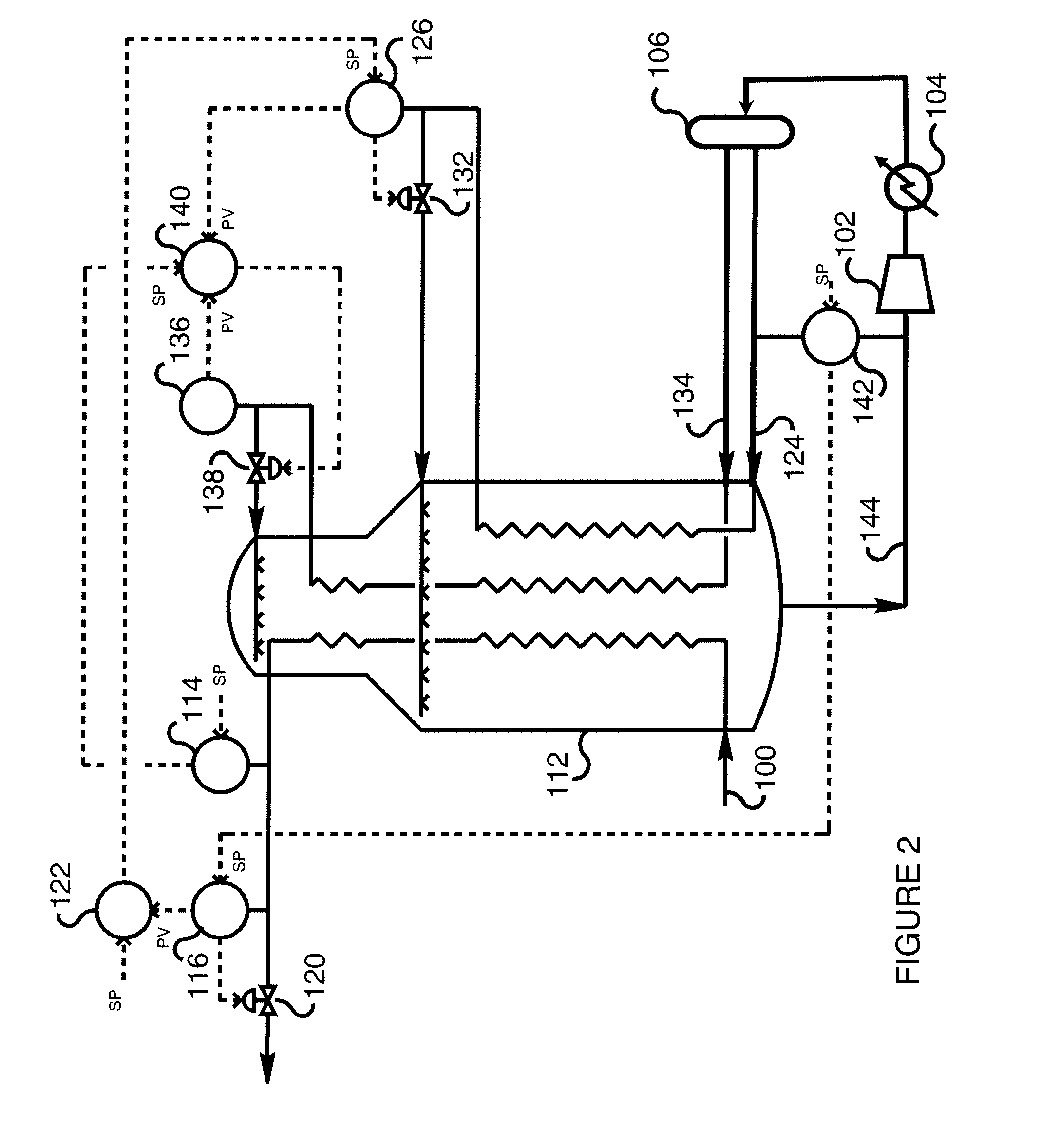

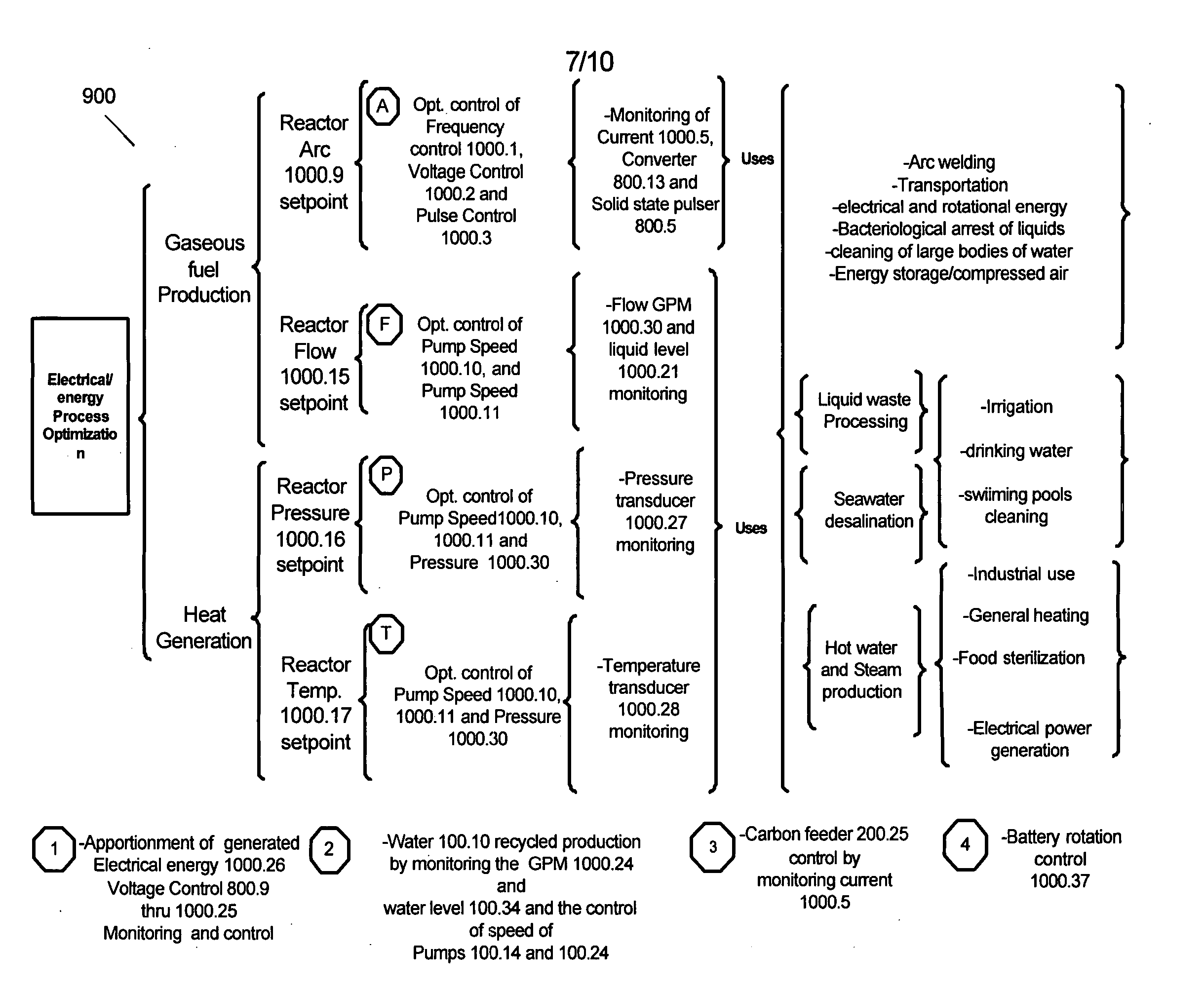

Arc-hydrolysis fuel generator with supplemental energy recovery

InactiveUS20060042955A1HarvestProvide energyHydrogenPhotography auxillary processesNuclear engineeringWater vapor

An arc-hydrolysis fuel generator and method of use thereof, the generator comprising an inductor placed around an arc-hydrolysis unit, wherein the inductor recovers. magnetic energy generated by the electric arc discharge to supplement the energy recoverable from the hydrogen and / or carbon monoxide / dioxide fuel generated from water and / or biomass by the arc-hydrolysis unit. The arc-hydrolysis fuel generator may further comprise a water vapor recovery system, a steam generation system and / or a gas liquefying system, utilizing fuel generated by the arc-hydrolysis fuel generator during use.

Owner:VILLALOBOS VICTOR M

Gas liquefaction device with compression heat recovery function and liquefaction method thereof

ActiveCN106091574AReduce energy consumptionEasy to operateSolidificationLiquefactionSocial benefitsElectricity price

The invention discloses a gas liquefaction device with a compression heat recovery function. The gas liquefaction device comprises a feed gas treatment system, a refrigerant treatment system and a compression heat recovery system. The invention further discloses a liquefaction method of the gas liquefaction device with the compression heat recovery function. The liquefaction method includes the process steps of feed gas compression cooling, feed gas liquefaction, refrigerant compression, refrigerant liquefaction, refrigerant reheating, heat transport fluid cooling, and supply of normal temperature water and low temperature water. The gas liquefaction device with the compression heat recovery function and the liquefaction method thereof have the beneficial effects that the low temperature water is obtained by recovering compression heat, and thus the energy consumption of the liquefaction device is substantially reduced; a low temperature water tank can also be used for cold accumulation, the low temperature water or ice can be obtained extra according to an electricity price difference, the low temperature water can be fed only at the pinnacle or peak time of electricity price, and the energy consumption of the liquefaction device is further reduced; and operation is easy, the energy consumption is low, the general trends of saving energy and reducing consumption are met, and social benefits and economical benefits are good.

Owner:四川蜀道装备科技股份有限公司

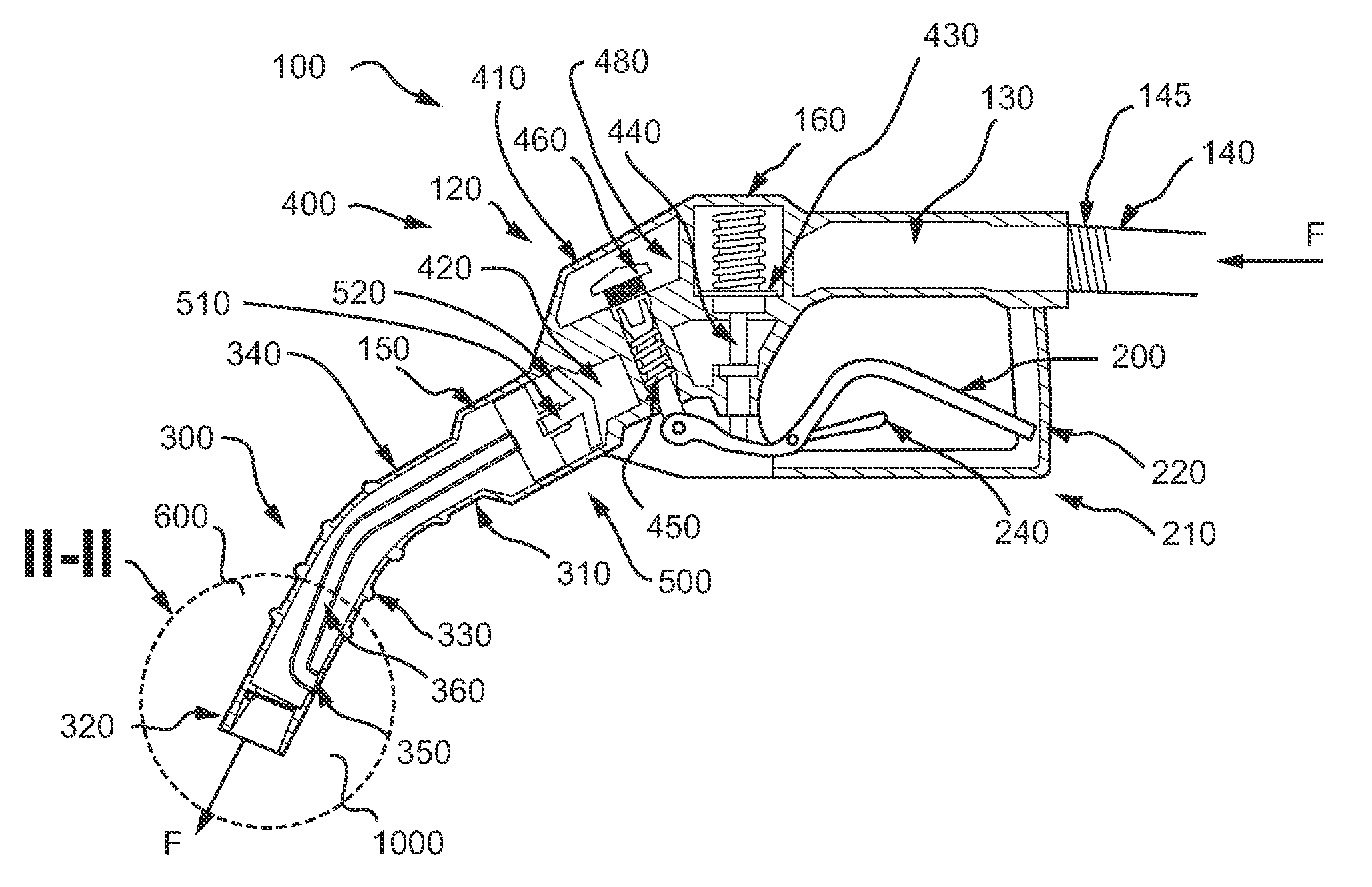

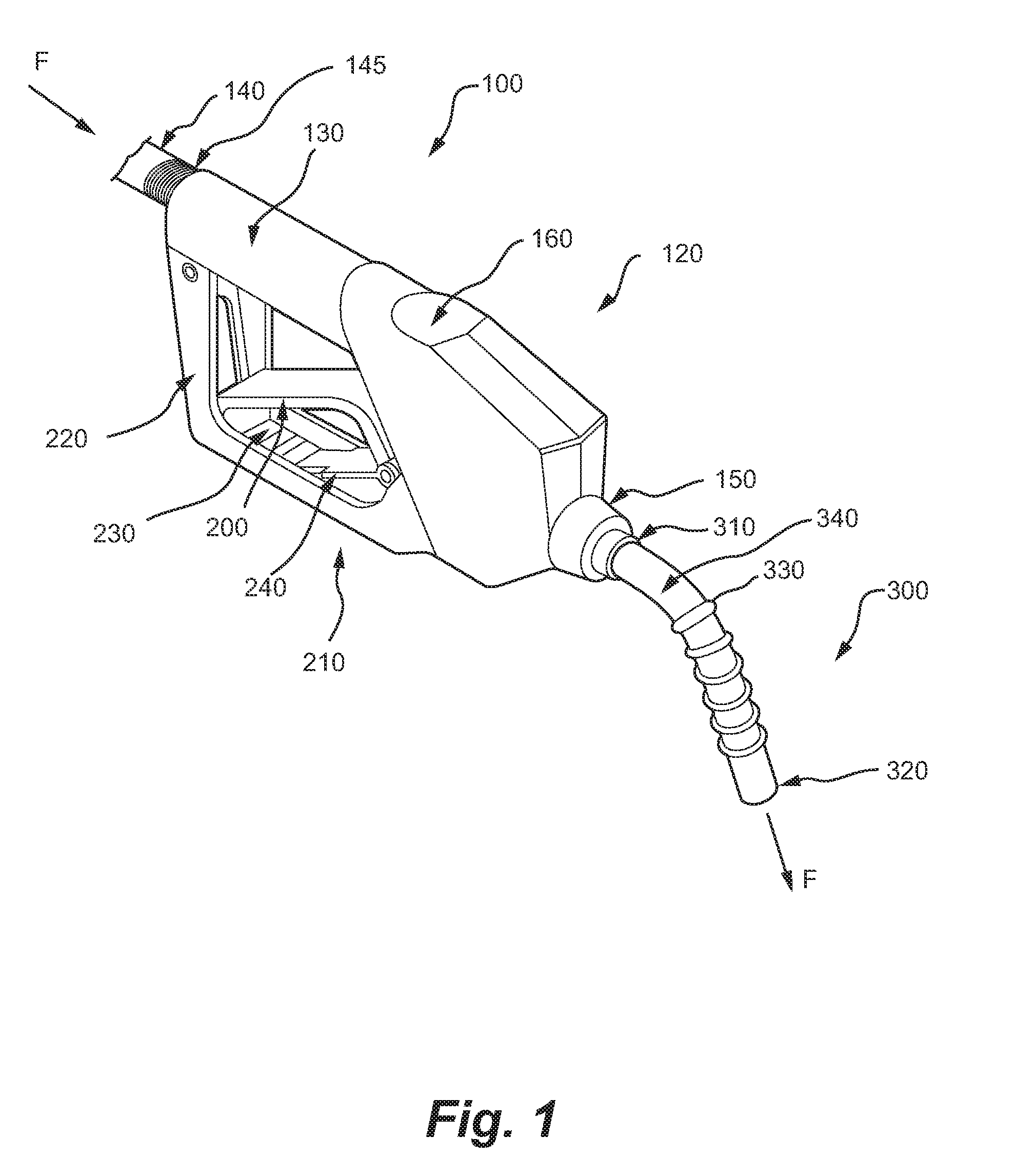

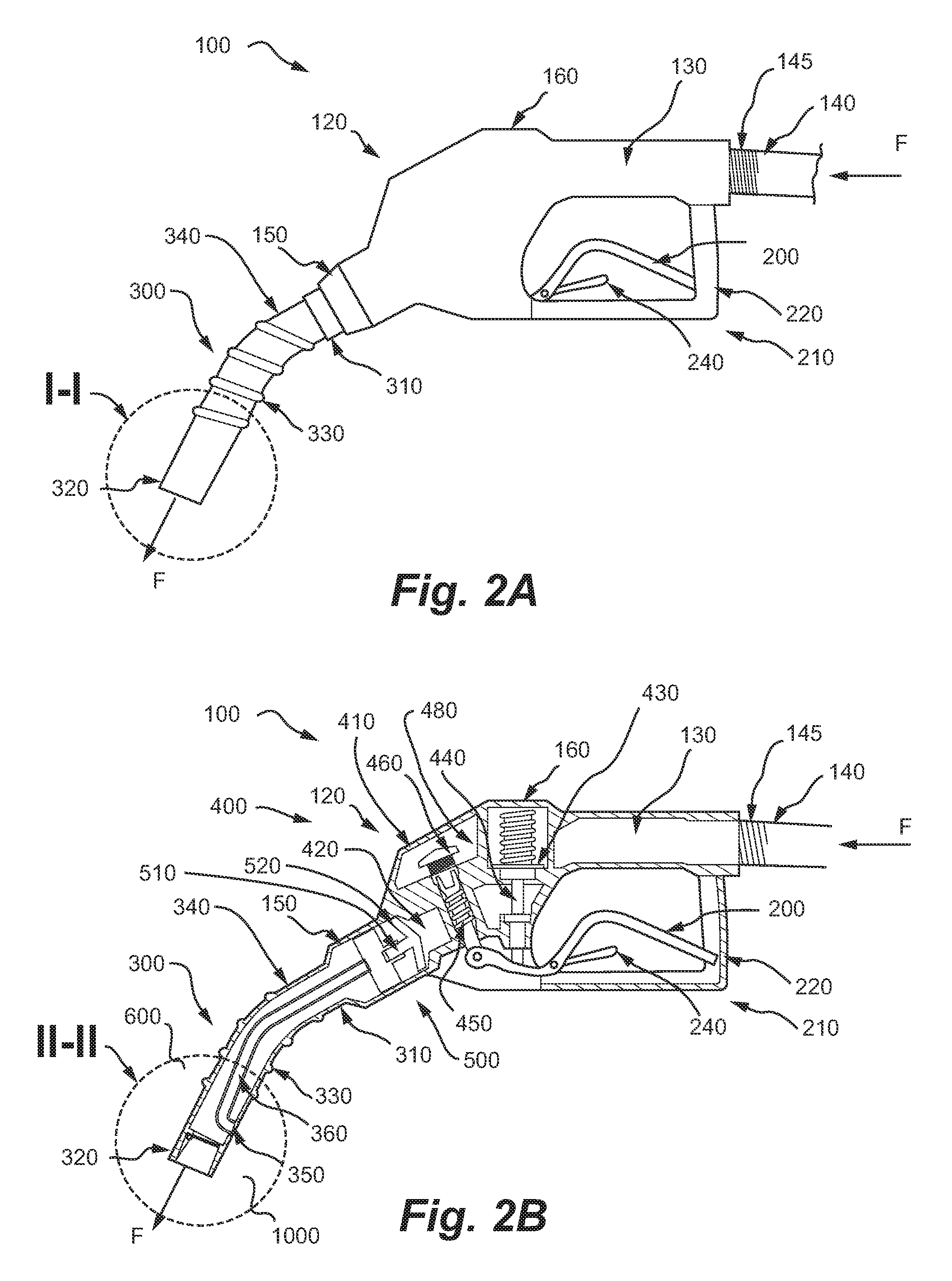

Fuel Leak Prevention System

InactiveUS20100224280A1Avoid flowPrevent leakageCheck valvesLiquid transferring devicesKeroseneControl valves

A fuel leak prevention system and method for providing same includes a check valve for insertion into the discharge end of a spout assembly of a fuel dispensing nozzle, the check valve being located downstream of the nozzle's fuel control valve so as to prevent any leaking or dripping of fuel from the spout when the nozzle is deactivated. The check valve includes a pivoting flap that is preferably spring-loaded and predisposed to remain closed to seal the spout when there is no fuel flowing through the nozzle, but which is allowed to rotate within the spout to open the nozzle and allow the flow of fuel when the nozzle is activated. In one embodiment, the check valve can be inserted into the spout during fabrication of the nozzle. An alternate embodiment allows the retrofit of an existing nozzle by adding an extension that contains the check valve to the spout on the nozzle. The system and method disclosed has application to any liquids that are to be dispensed, including petrol, diesel, kerosene, gas oil, gas, liquid petroleum gas, av-gas, chemicals, and water.

Owner:STRICTLY GREEN

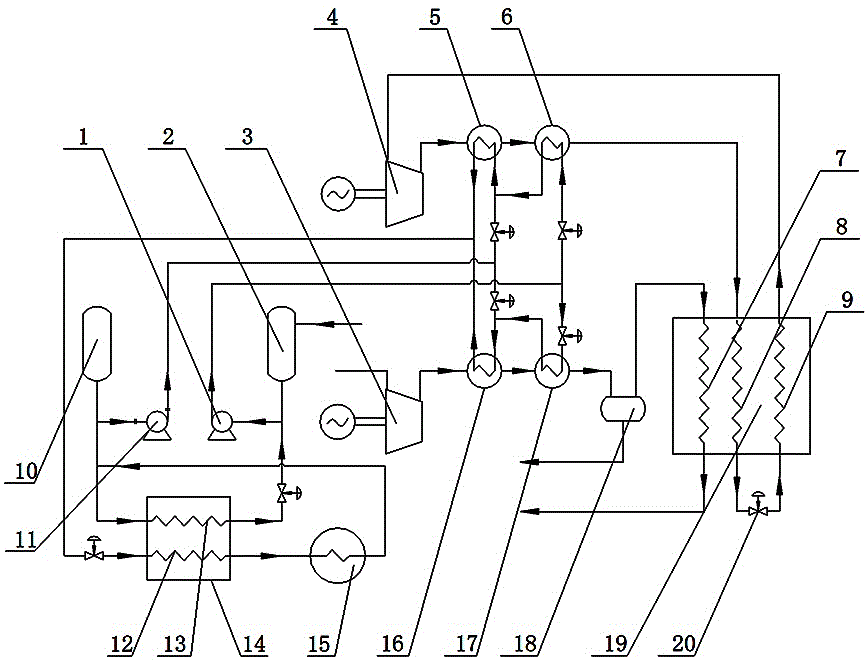

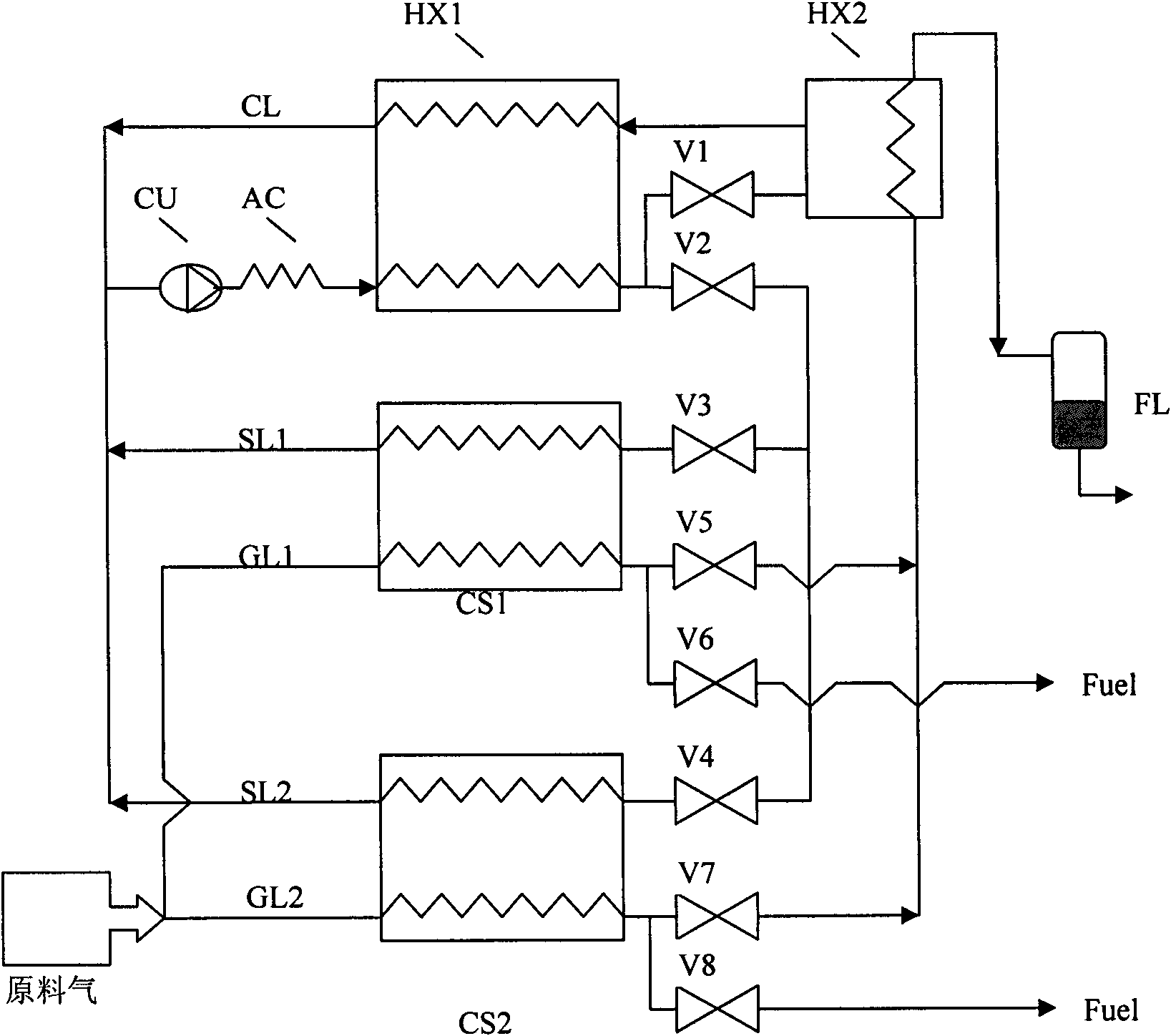

Rectification-type self-overlaying gas liquefying system

ActiveCN102141317ASimple structureGuaranteed uptimeCompression machines with non-reversible cycleFluid circulation arrangementEngineeringProcess engineering

The invention discloses a rectification-type self-overlaying gas liquefying system, which comprises a compressor, a condenser, a rectifying device and a raw material gas liquefying loop. A discharging port of the compressor is connected with a feeding port of the condenser; a discharging port of the condenser is connected with a feeding port in a kettle of the rectifying device; the rectifying device comprises a rectifying tower and a tower top heat exchanger, wherein the tower top heat exchanger is communicated with the top of a rectifying section of the rectifying tower; a discharging port at the top of the tower top heat exchanger is connected with the raw material gas liquefying loop; and the raw material gas passes through the raw material gas liquefying loop and a final liquefying product is obtained. In the invention, a multi-stage separation process of the traditional mixed working medium liquefying system is replaced by the rectifying device, the high-pressure liquids with different components led out from the bottom and the top of the rectifying device are respectively subject to pressure reduction to enter the raw material gas liquefying loop, the change of the water equivalent weight in the temperature-reduction liquefying process is matched in an optimized way so that the raw material gas is cooled section by section. The rectification-type self-overlaying gas liquefying system has the advantages of simple structure, reliability in operation, high system liquefying efficiency and the like, and is particularly suitable for various mini-type and micro-type gas liquefying systems.

Owner:ZHEJIANG UNIV

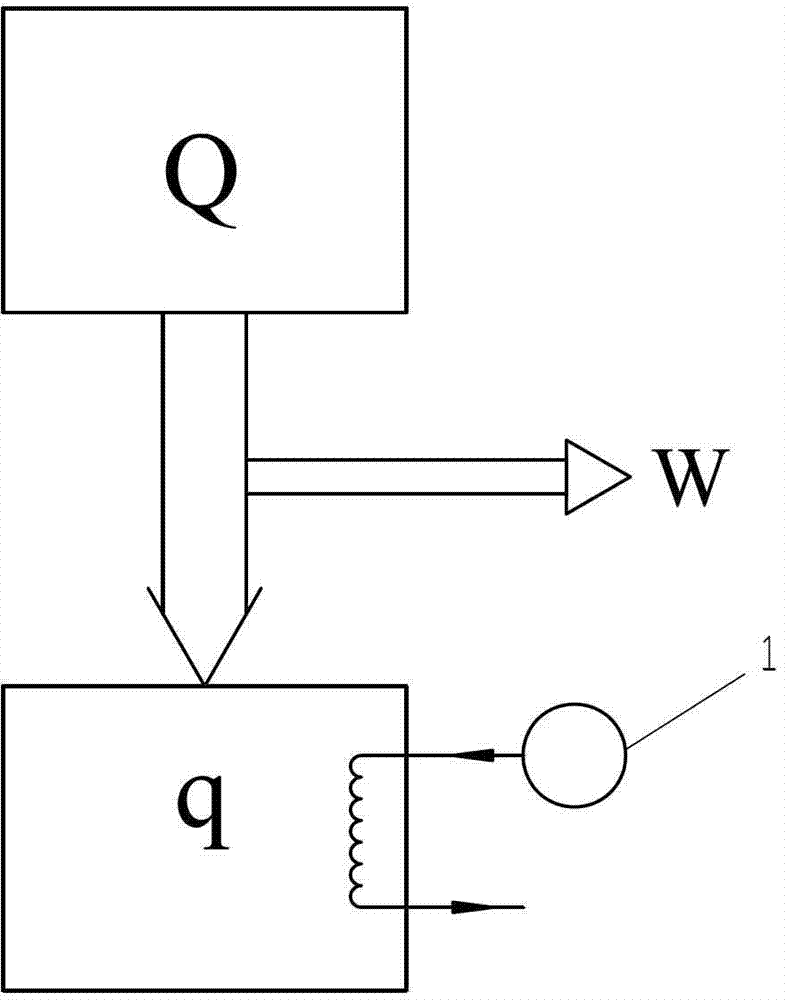

Low temperature cold source heat engine

InactiveCN103047044AImprove efficiencyInternal combustion piston enginesGas turbine plantsThermal energyProduct gas

The invention relates to the field of heat energy and power, in particular to a heat engine. The heat engine comprises a heat engine body and a gas liquefaction resultant source. The gas liquefaction resultant source is provided with gas liquefaction resultant which serves as the cold source of the heat engine body. The low temperature cold source heat engine uses the gas liquefaction resultant as the low temperature heat source, so that the efficiency of the heat engine is greatly improved.

Owner:ZEROQ SCI & TECH

Method for providing cooling for gas liquefaction

A method for generating refrigeration for cooling a product gas wherein a first or working gas undergoes a staged expansion to a first temperature and a subsequent turboexpansion to a second higher temperature and both the expanded gas and the turboexpanded gas provide cooling to the product gas.

Owner:PRAXAIR TECH INC

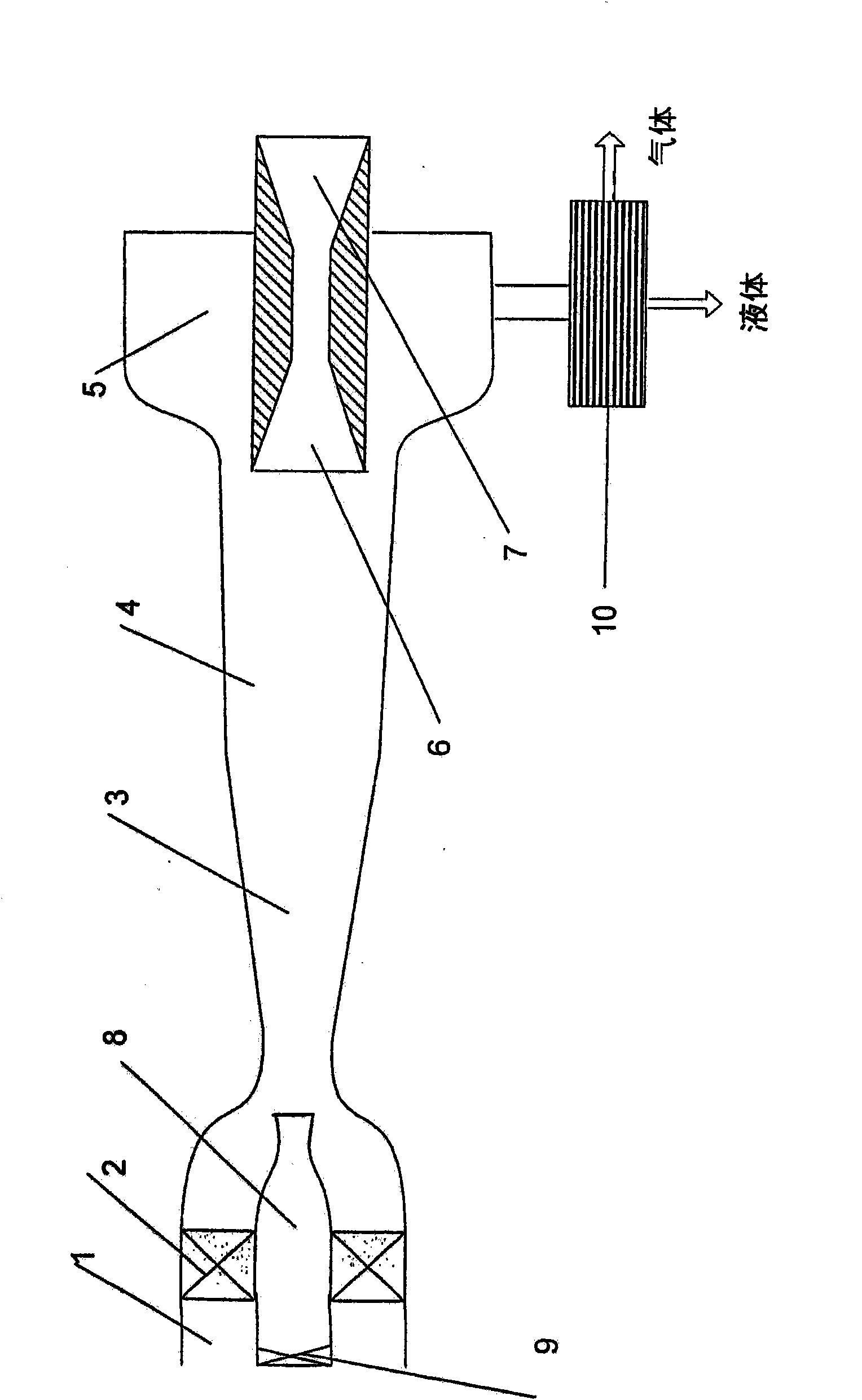

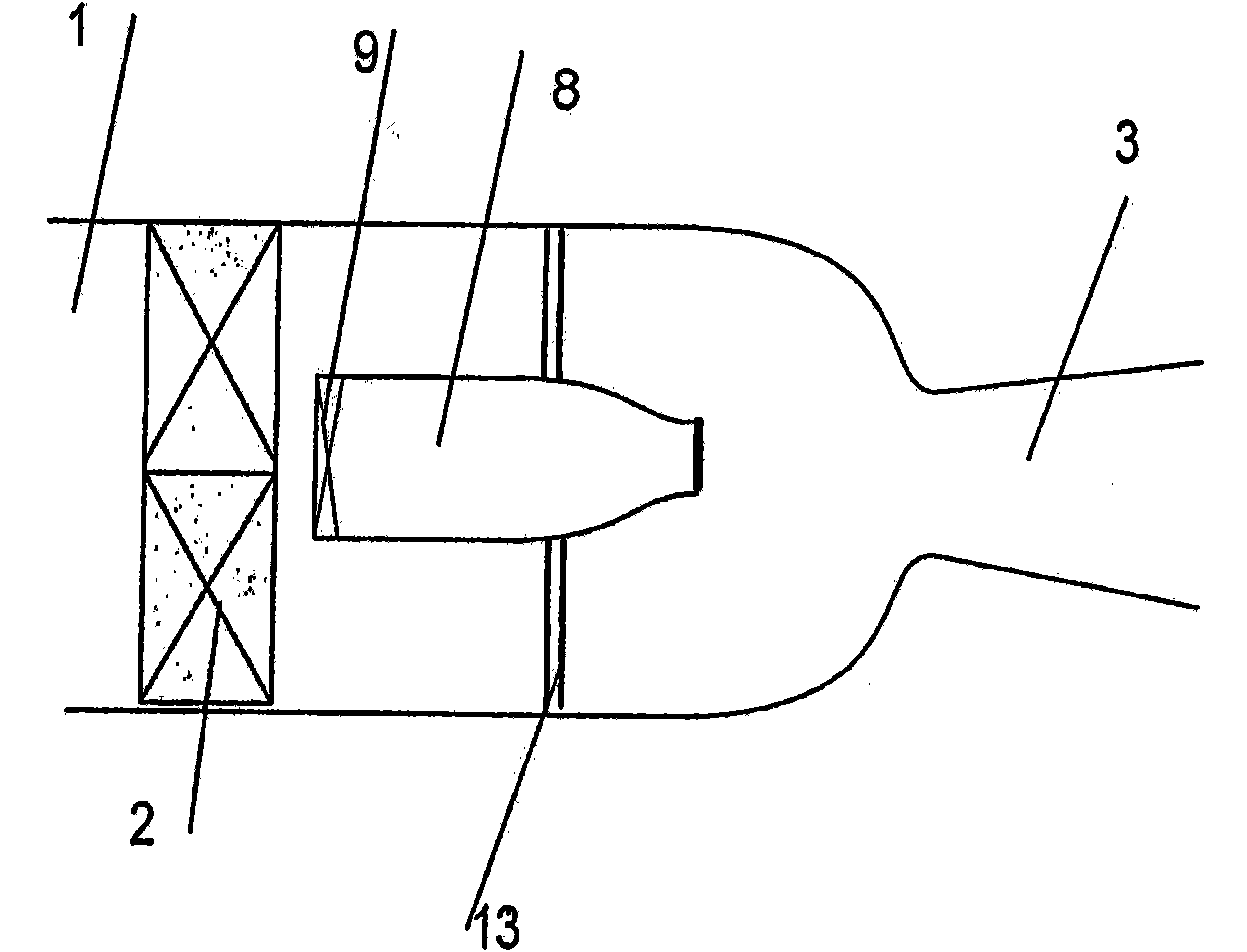

Gas liquefaction and separation device

ActiveCN101828088AReduce pressure differenceImprove equipment efficiencySolidificationVacuum condensationProduct gasEngineering

The invention relates to cryogenic engineering. The inventive device for liquefying and separating gas and for releasing one or more gases from a mixture thereof, comprises, in series axially positioned, a prechamber (1) with gas flow whirling means (2) arranged therein, a subsonic or supersonic nozzle (3) with a working segment (4), which is abutted thereto and to which liquid phase extracting means (5) is connected, and a subsonic diffuser (7) or the combination of a supersonic (6) and the subsonic diffuser (7). The nozzle (3) is designed in such a way that it makes it possible to achieve the ratios, between the inlet and outlet cross-sectional areas and the minimum cross-section thereof, which provides, at the output of the nozzle, a statical pressure and a statical temperature corresponding to the conditions of condensation of gas or target gas mixture components. The length of the working segment (4) is selected according to a condition of forming condensate drops with a size greater than 0.5 mkm and of drifting them, by centrifugal forces, from the axial area of the working segment to the walls of the drop extracting means, and the aperture angle of the working segment (4) is selected such as to maintain the conditions of condensation of the gas or the target components thereof. The device is provided with an additional nozzle (8) arranged in the prechamber. The invention makes it possible to increase the separation efficiency.

Owner:3S GAS TECH LTD

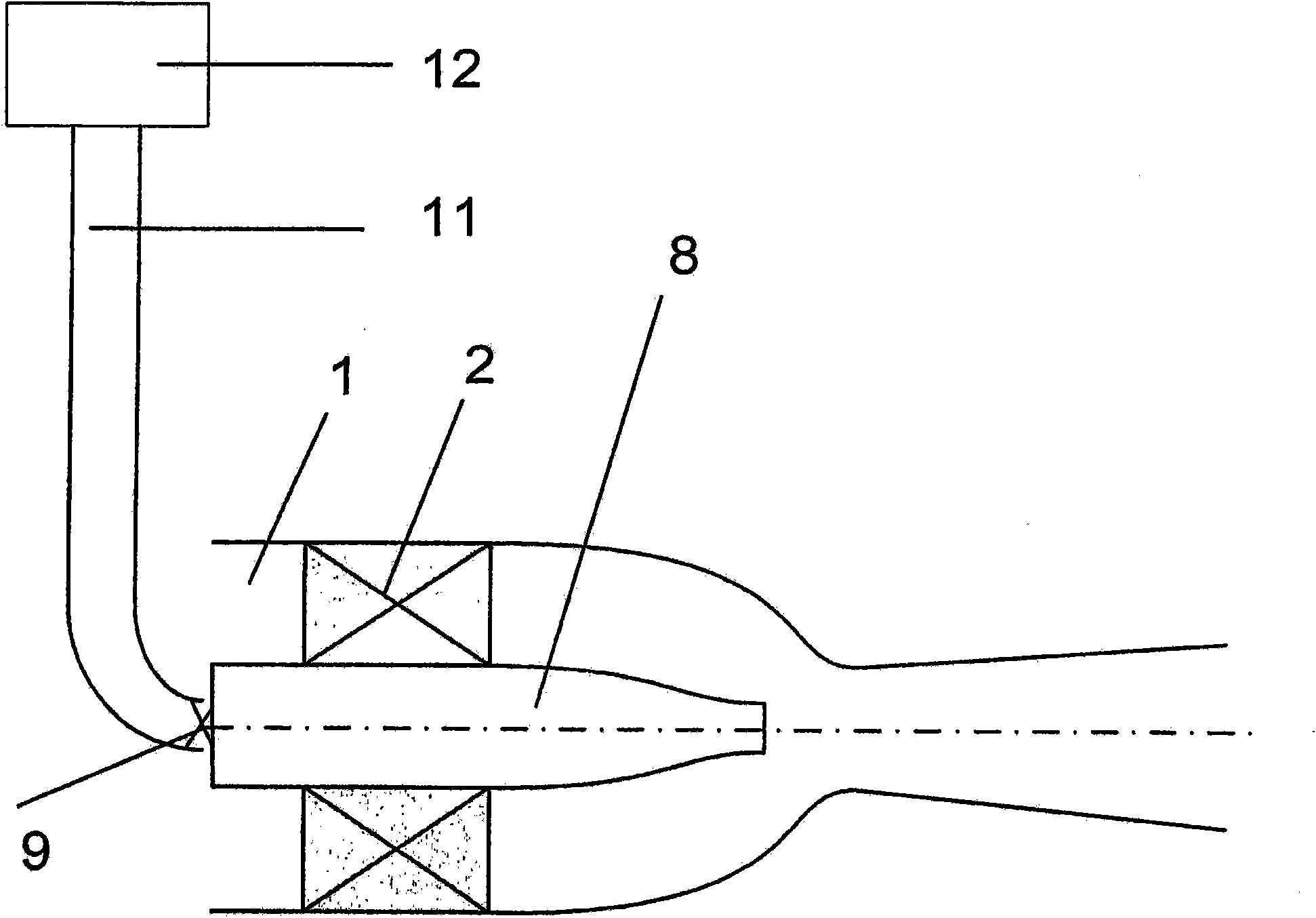

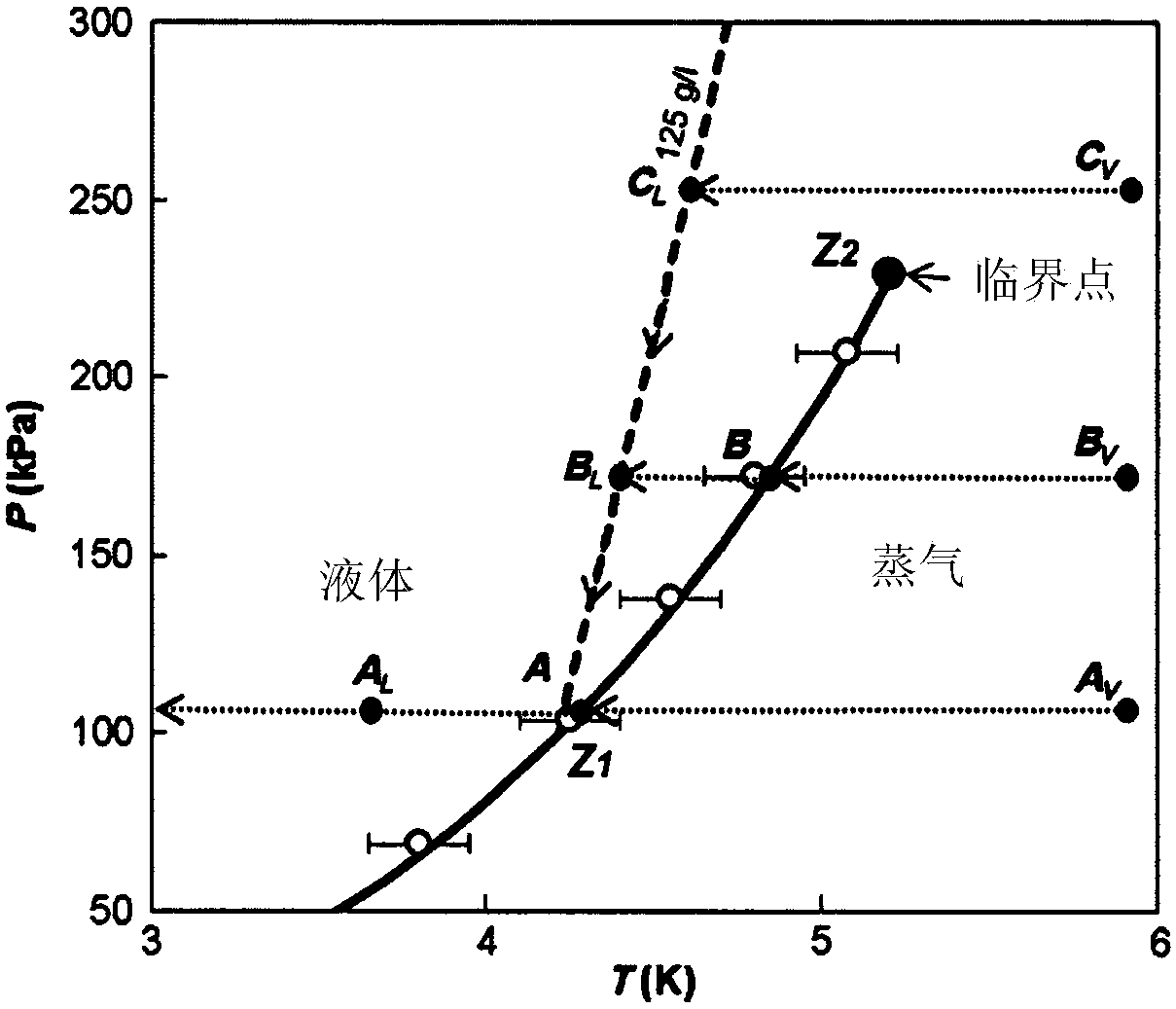

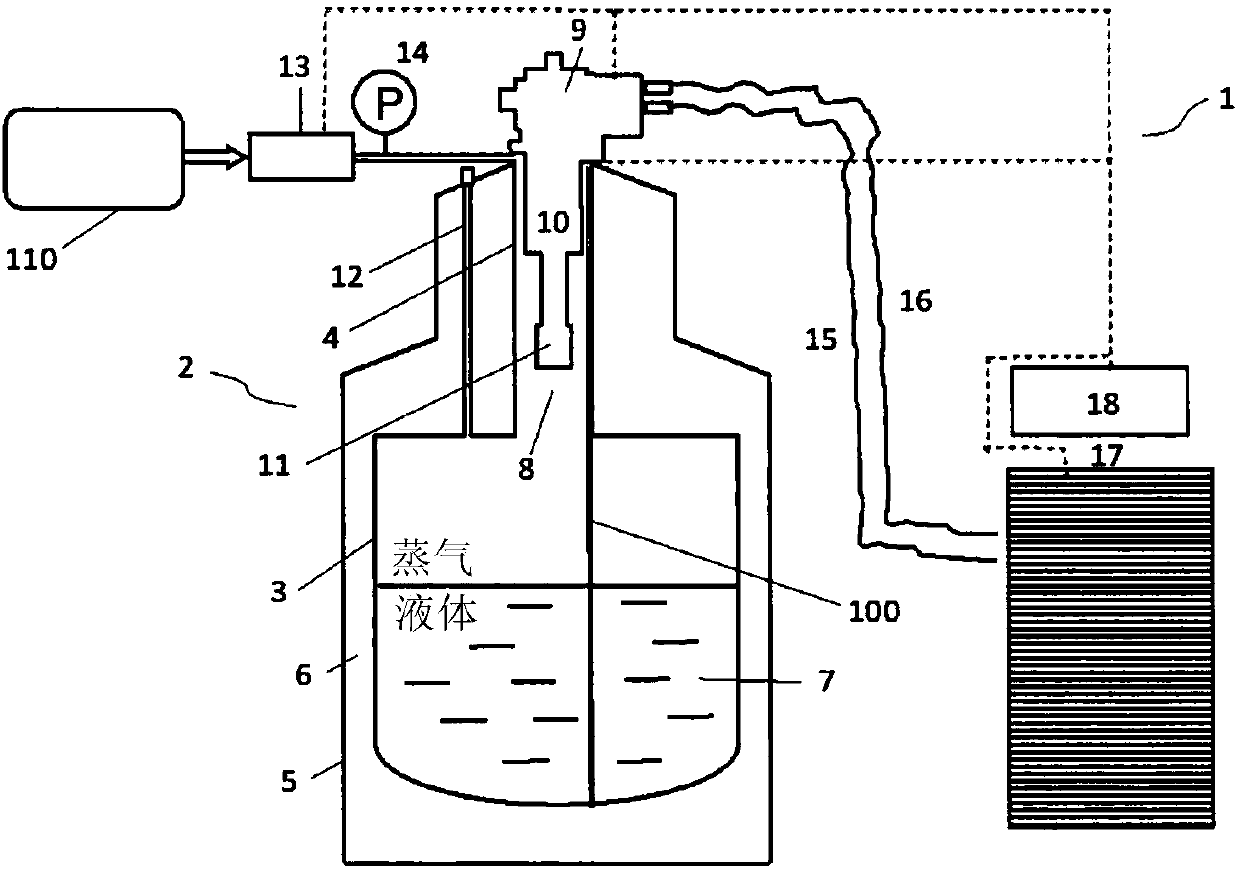

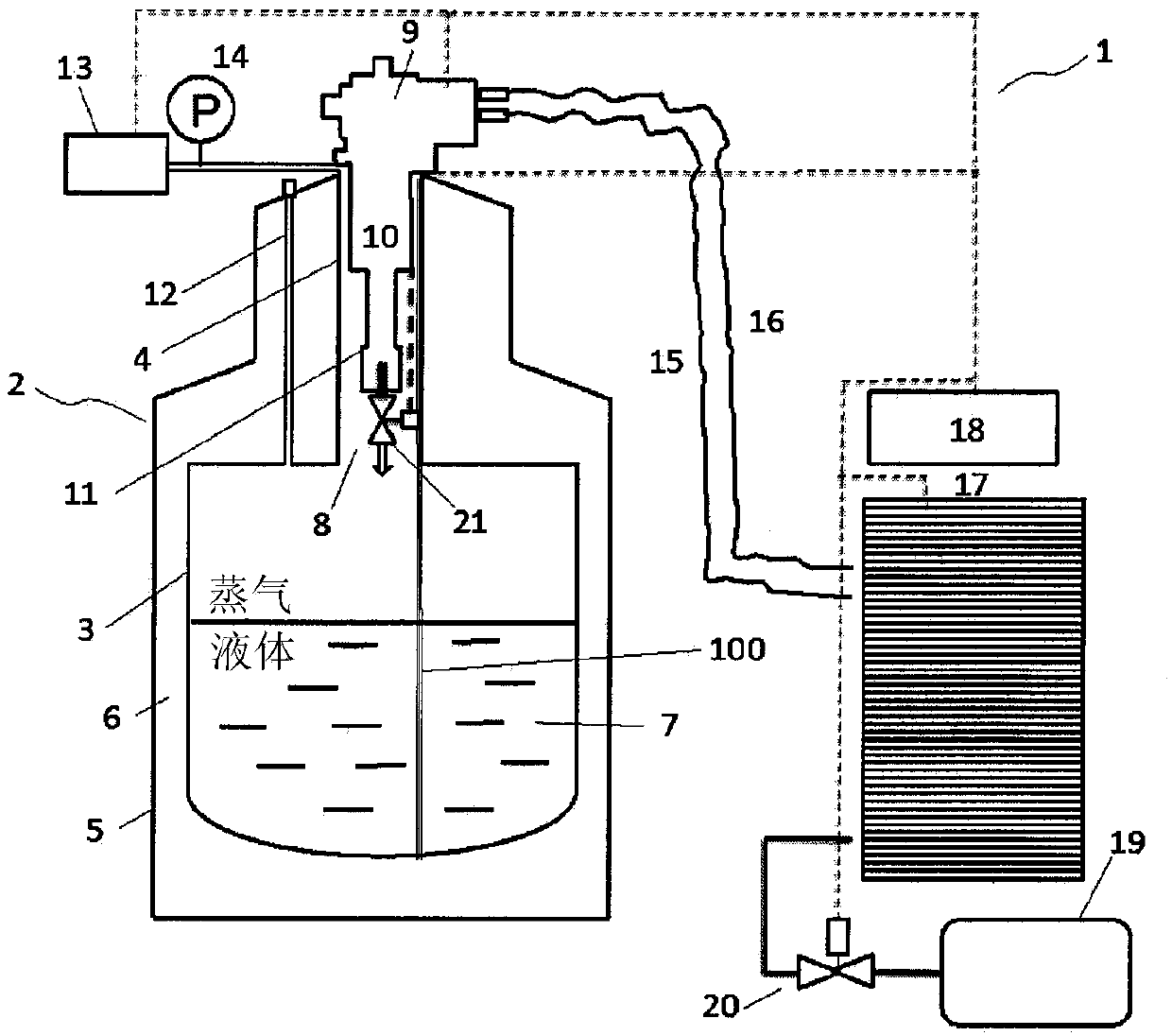

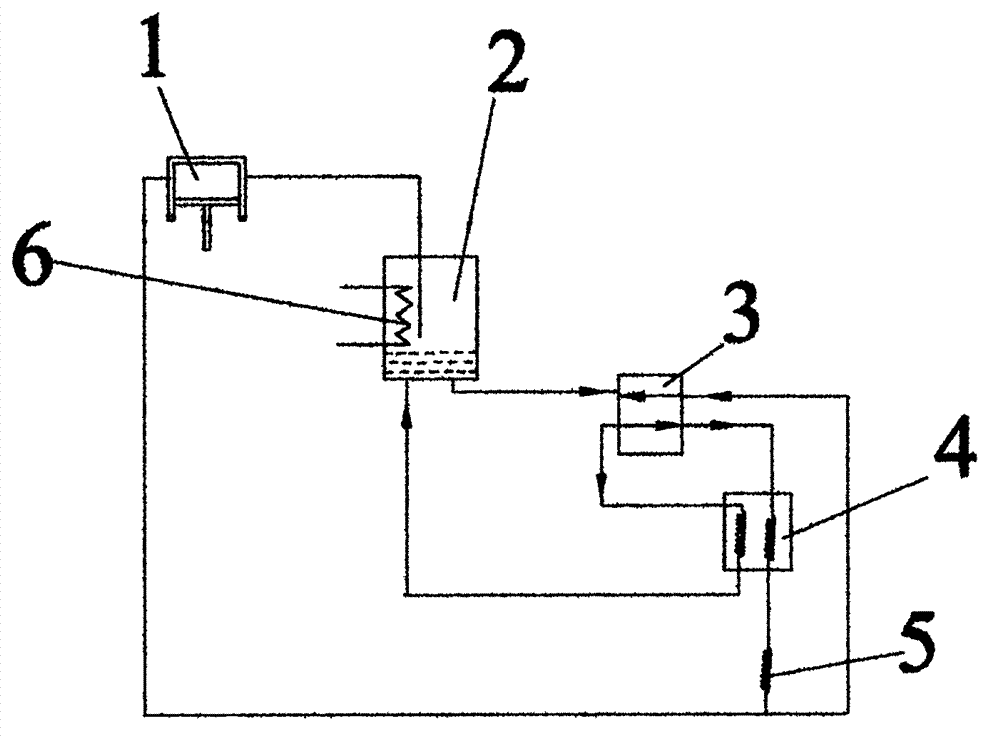

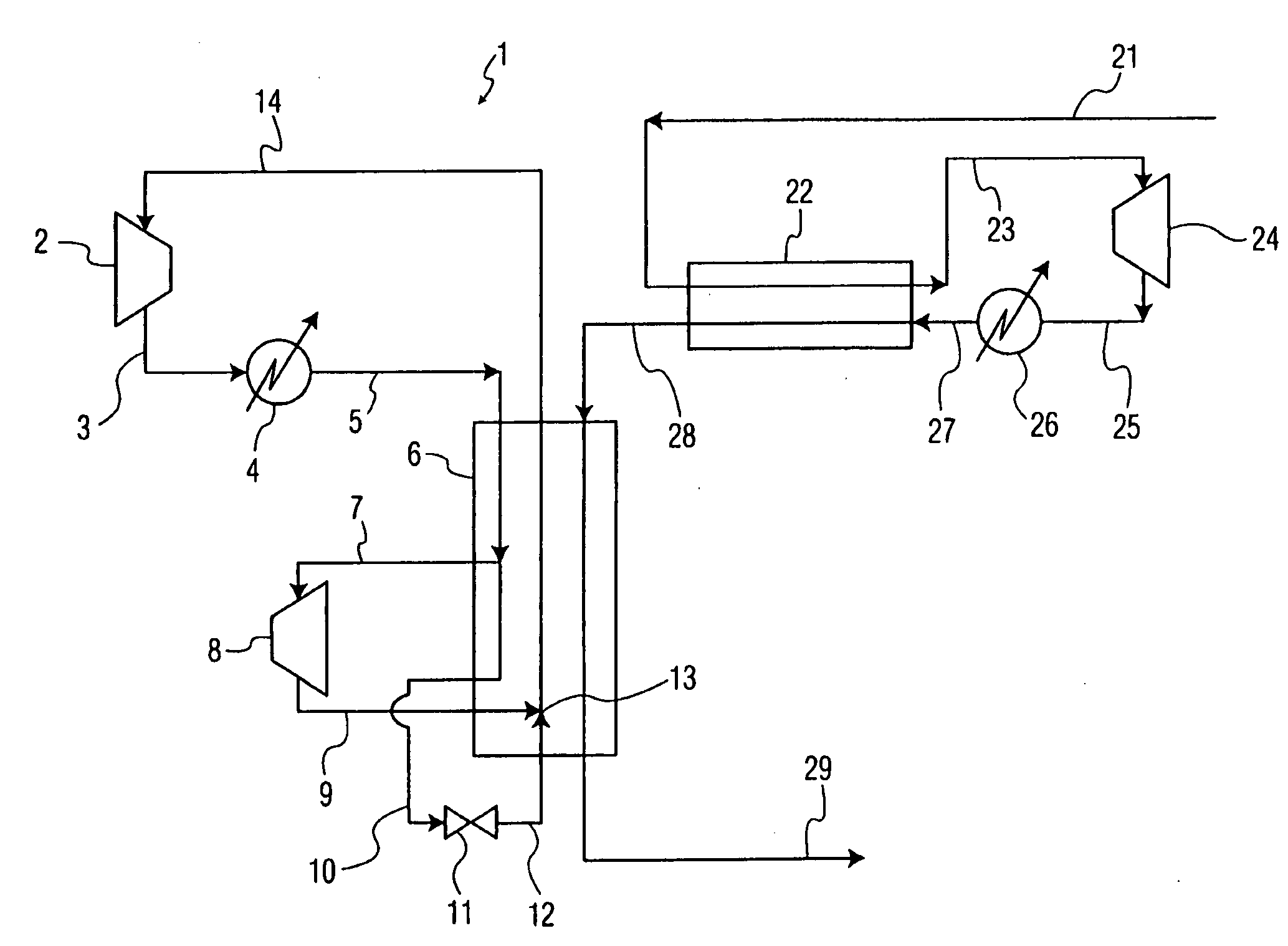

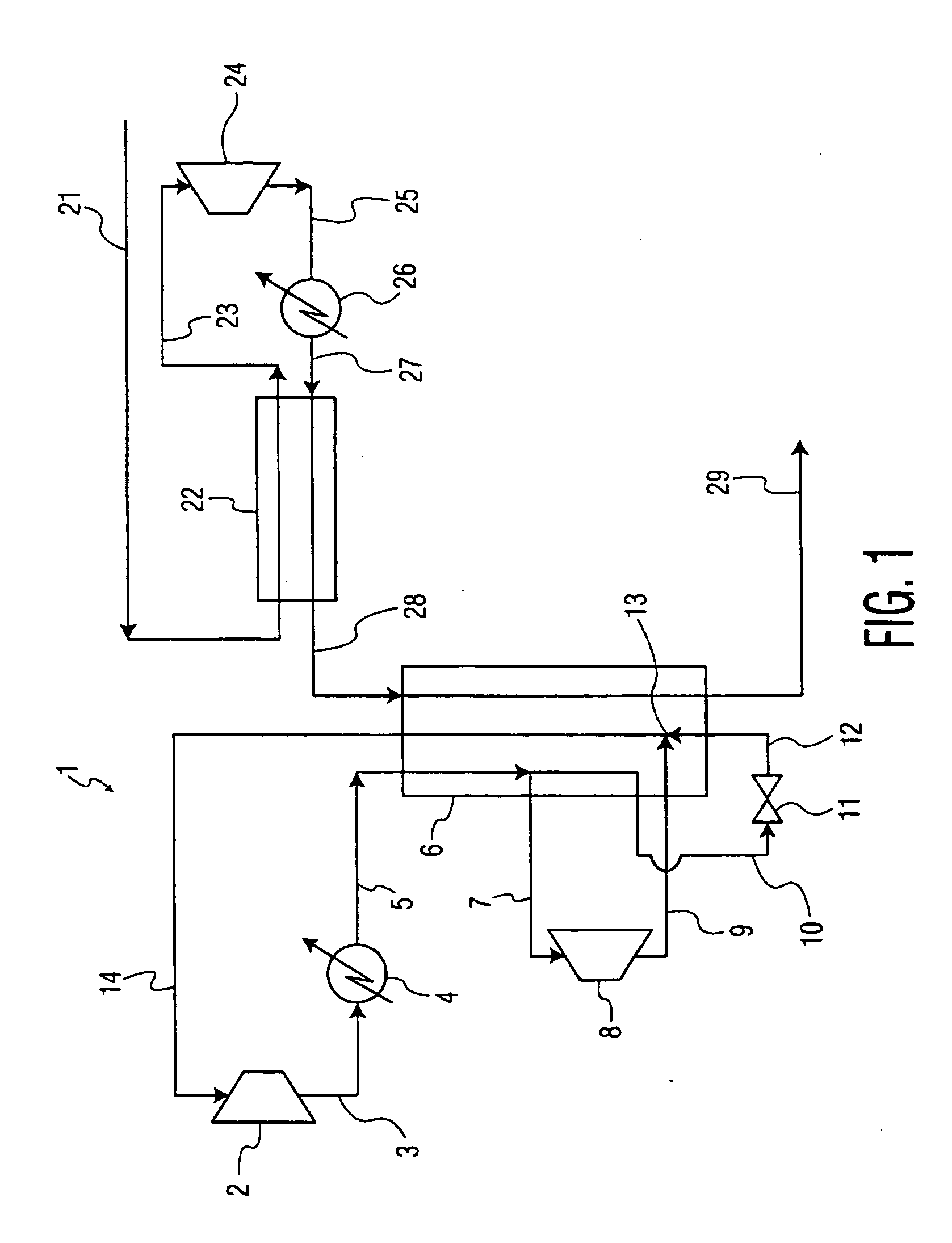

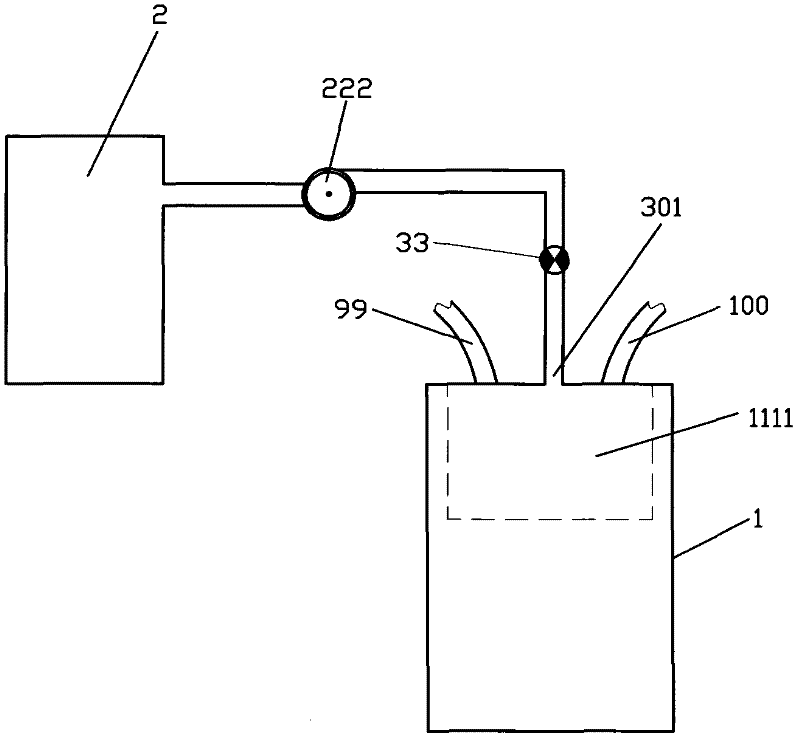

System and method for improving the liquefaction rate in cryocooler-based cryogen gas liquefiers

InactiveCN107906844APrecise pressure controlImprove efficiencySolidificationLiquefactionGas phaseProcess engineering

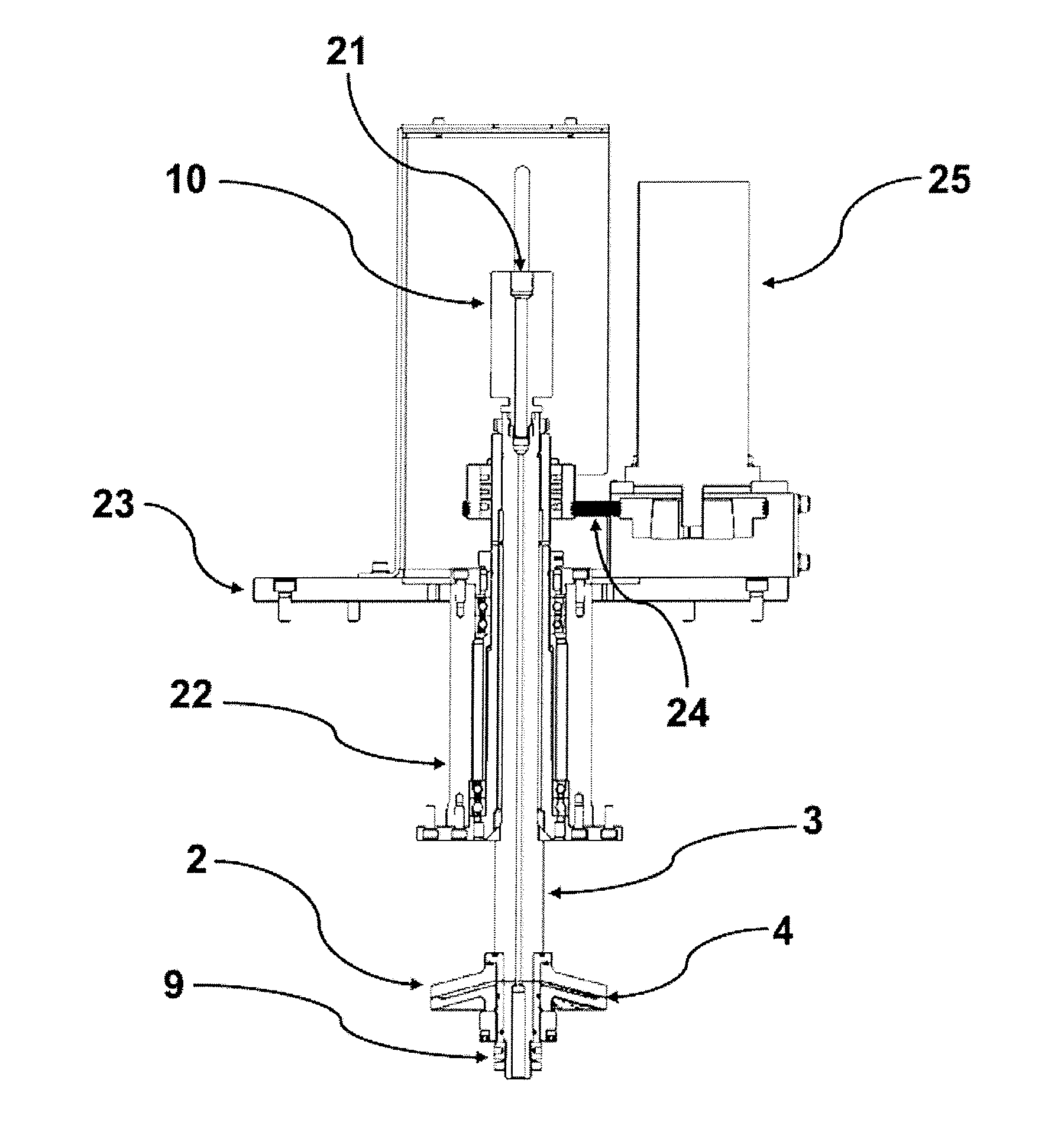

The present invention relates to a system and method for improving the liquefaction rate in cryocooler-based cryogen gas liquefiers. The present invention relates to a cryogen-gas liquefaction system(1) and method comprising: a storage container (2) comprising a liquid storage portion (3) and a neck portion (4) with a liquefaction region (8) above said bath (7); a coldhead (9) arranged at the neck portion (4) comprising one or more refrigeration stages (10, 11); a gas intake module (12) containing an amount of gas-phase cryogen for its introduction into the storage container (2); and a pressure control mechanism (13) for controlling the cryogen gas pressure within the liquefaction region (8) of the storage container (2).

Owner:UNIV DE ZARAGOZA +1

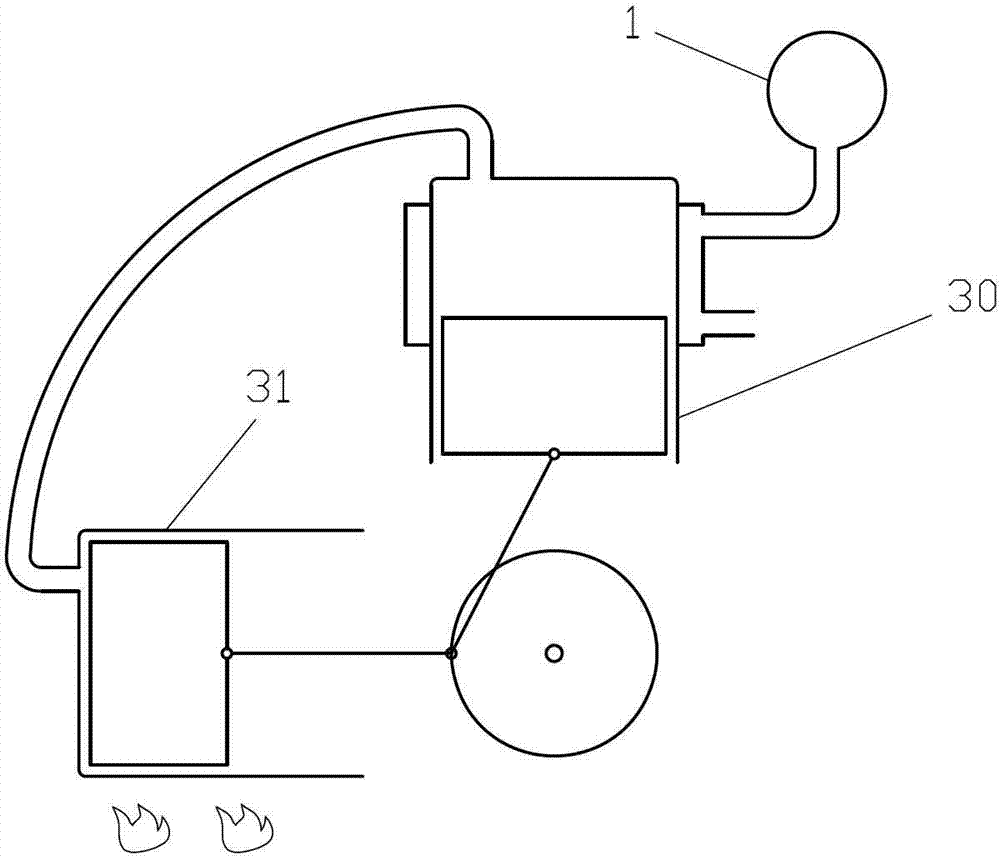

Low-temperature heat engine device

The invention belongs to the technical field of heat engines and particularly relates to a low-temperature heat engine device which comprises a control system, a phase change working system, a heat absorber, a compression cooling and depressurization system and a pressurization system, wherein the heat absorber, the phase change working system, the compression cooling and depressurization system and the pressurization system are controlled by the control system and are sequentially connected to form a loop capable of absorbing heat in the environment temperature smaller than 100 DEG C and capable of performing phase change working, and the loop contains mixed dielectric gases. Compared with the prior art, gas phase change working is performed so that output power of the systems is remarkably increased. In the working process of the systems, the gases are liquefied after phase change working so that in the circulating process of the systems, not massive external work is needed to be consumed to liquefy the gases through a compressor. Most consumed matters in the balance exchange process of the pressurization system are cold capacity generated by the dielectric gases in the process. Therefore, output power of the systems is remarkably increased, consumed external work is remarkably reduced, and the low-temperature heat engine device can be achieved completely.

Owner:谢瑞友

Controlling Liquefaction of Natrual Gas

ActiveUS20120079850A1Reduce the differenceSolidificationLiquefactionProcess engineeringRefrigeration

A gas liquefaction process, especially for producing LNG, maintains product flow rate and temperature by controlling the refrigeration so that variation to reduce any difference between actual and required product temperatures is initiated before variation of the product flow rate to reduce any difference between actual and required flow rates.

Owner:AIR PROD & CHEM INC

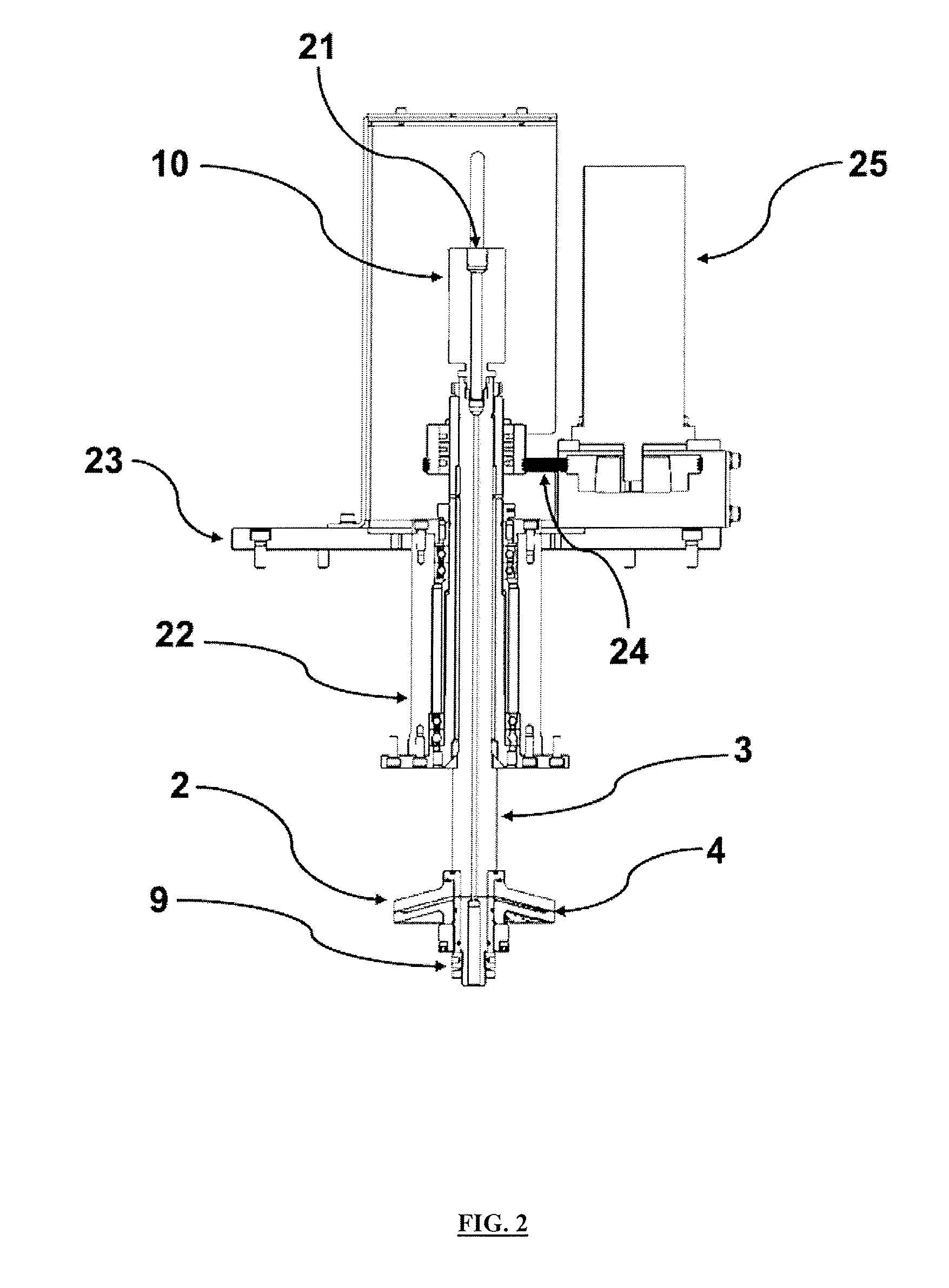

A method for producing nanostructured or microstructured materials and a device for their production

InactiveUS20160367950A1Increase flow rateRetain activityBacteriaDrying solid materials with heatEngineeringNanostructure

A device for producing nanostructured or microstructured with materials comprises a chamber in which a hollow shaft is assembled, at least one disc provided with an expansion gap. The hollow shaft has openings which connect the inner space of the hollow shaft with the expansion gap.A solution, emulsion or liquid suspension of substances or microorganisms optionally saturated with a gas, liquefied gas or supercritical liquid, is fed into an inner space of a disc through a hollow shaft. By means of the combination of a centrifugal force and fluid pressure occurs the outlet of the liquid through an expansion gap, to form microscopic droplets. The microscopic droplets are subsequently disintegrated by expansion of the gas to form an aerosol. The aerosol is subsequently dried by a drying gas stream to form solids.

Owner:CZECH TECH UNIV IN PRAGUE

Hydrate absorption supercharging device and method

ActiveCN102182666AReduce noiseSimple structurePositive displacement pump componentsPositive-displacement liquid enginesLow noiseEngineering

The invention discloses a hydrate absorption supercharging device. The hydrate absorption supercharging device comprises a hydrate generator, a hydrate decomposer, a low-temperature and constant-temperature system, a solution pump, a transfusion pipeline, a pressure reduction valve and a reflux liquid pipeline, wherein the hydrate generator is a low-pressure sealed container in which water is filled; a low-pressure gas inlet is formed on the wall of the container; the low-temperature and constant-temperature system is arranged outside the hydrate generator so as to keep the water temperature in the hydrate generator; the hydrate decomposer is a high-pressure sealed container; a high-pressure gas outlet is formed in the top of the hydrate decomposer; the transfusion pipeline and the refluxliquid pipeline are connected with the hydrate generator and the hydrate decomposer; the solution pump is arranged on the transfusion pipeline; and the pressure reduction valve is arranged on the reflux liquid pipeline. The invention also discloses a method for supercharging gas by using the device. The device has a simple structure and low cost; as a mechanical moving component is absent in the device, the device runs quietly and has advantages of small vibration, low noise and high reliability; and the invention can be applied to various systems such as chemical engineering, gas liquefaction separation, refrigeration, power and the like for realizing supercharging of the gas.

Owner:南京更佳安全设备有限公司

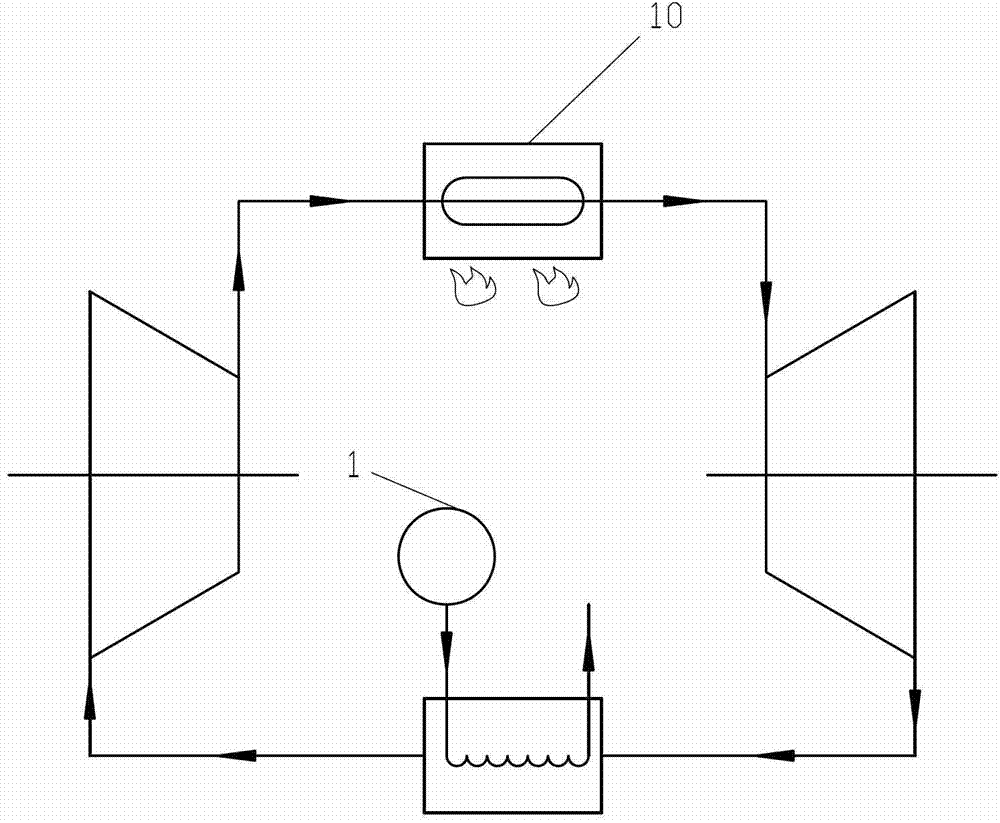

Gas liquefying and circulating structure

The invention relates to a gas liquefying and circulating structure which comprises a main refrigerating circuit, a first refrigerating circuit and a raw gas pipeline, wherein the main refrigerating circuit is a circuit formed by the connection of a compressor unit, a cooler, a main heat exchanger, a latent heat exchanger, a main throttling and refrigerating element and a pipeline; the first refrigerating circuit is a circuit formed by the connection of a compressor unit, a cooler, a main heat exchanger, an auxiliary throttling and refrigerating element, a first sensible heat exchanger and a pipeline; and the first raw gas pipeline is a circuit formed by the connection of the first sensible heat exchanger, the latent heat exchanger, an LNG storage tank and a pipeline. The gas liquefying and circulating structure is simple, has no absorption tower, regeneration tower or other complicated devices, enables the overall system to be more compact and greatly lowers the cost.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI +1

Equipment and process for liquefaction of LNG boiloff gas

Owner:AIR WATER GAS SOLUTIONS INC

Low-entropy mixed combustion gas-liquified substance engine

InactiveCN102410110AImprove efficiencyInternal combustion piston enginesFuel supply apparatusCombustionCombustion chamber

The invention discloses a low-entropy mixed combustion gas-liquified substance engine, which comprises an internal combustion engine and a gas-liquified substance storage tank, a combustion chamber of the internal combustion engine is provided with an admission passage and an exhaust passage, the gas-liquified substance storage tank is communicated with the combustion chamber sequentially via a high-pressure liquid pump and a gas-liquified substance control valve, the gas-liquified substance in the gas-liquified substance storage tank enters the combustion chamber in the form of liquid or a critical state or ultrahigh-pressure gas, and after the gas-liquified substance in the gas-liquified substance storage tank and existing gaseous working medium are mixed, the next process is carried out. The low-entropy mixed combustion gas-liquified substance engine disclosed by the invention not only is highly efficient, but also can utilize the gas-liquified substance produced by a valley current or unstable generating system to increase the efficiency of utilizing wind energy, solar energy and water resources.

Owner:靳北彪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com