Low temperature cold source heat engine

A low-temperature cold source, heat engine technology, applied in the field of thermal energy and power, can solve problems such as greater impact, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

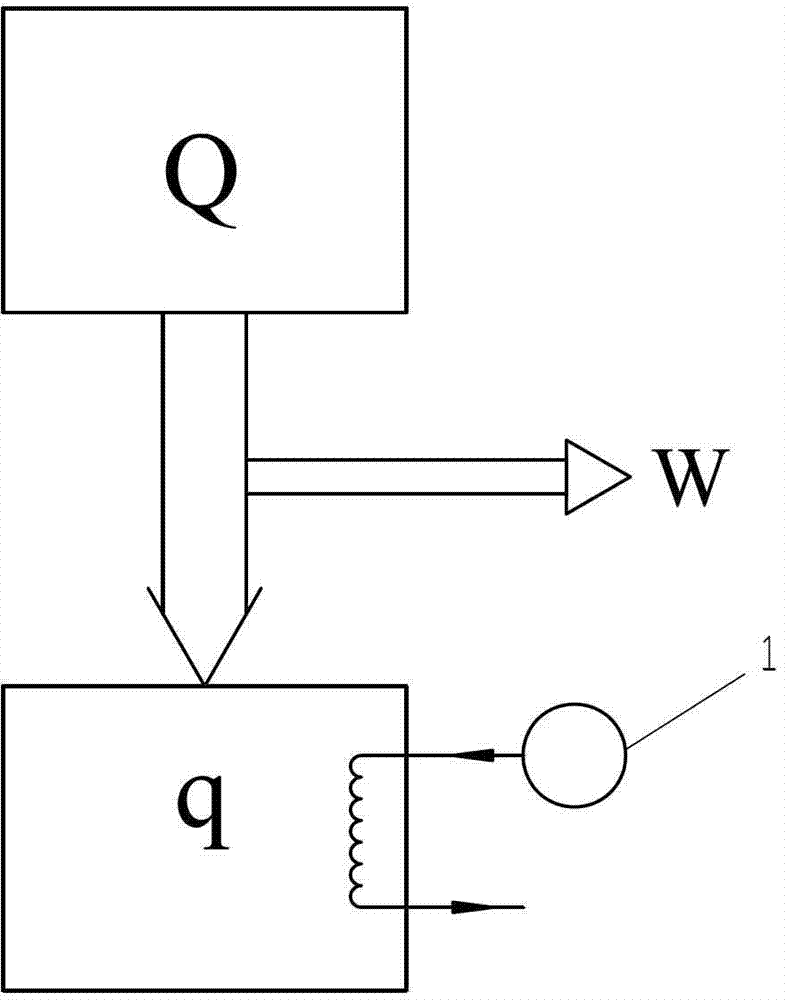

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

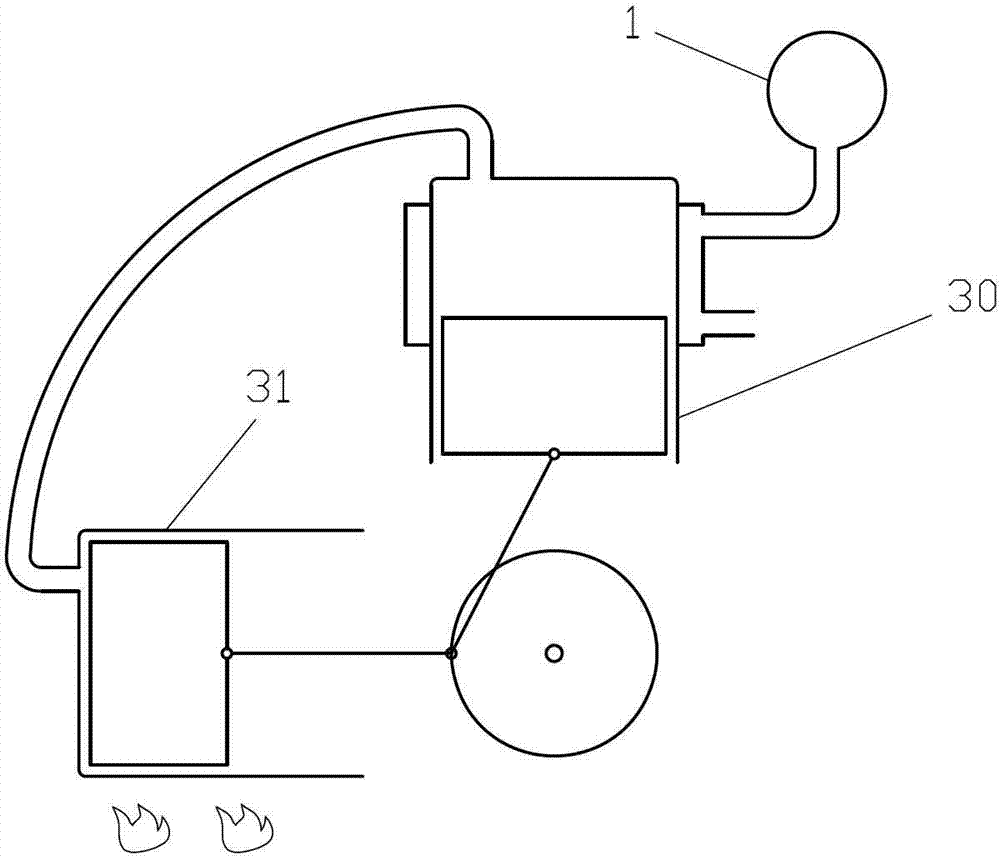

[0030] Such as figure 2 The shown low-temperature cold source heat engine includes an external combustion engine and a gas liquefied substance source 1, the external combustion engine is set as a Stirling engine, and the gas liquefied substance source 1 is set as a storage tank containing gas liquefied substance, and the The gas liquefied product is liquefied air. The storage tank communicates with the cold source of the external combustion engine, that is, it communicates with the cooling fluid channel on the cold cylinder 30 of the Stirling engine, that is, the gas liquefied product is used as the cold source of the external combustion engine. Heat absorbing carrier.

[0031] Optionally, the liquefied gas is liquefied carbon dioxide, liquid oxygen, liquid nitrogen or liquid helium.

Embodiment 2

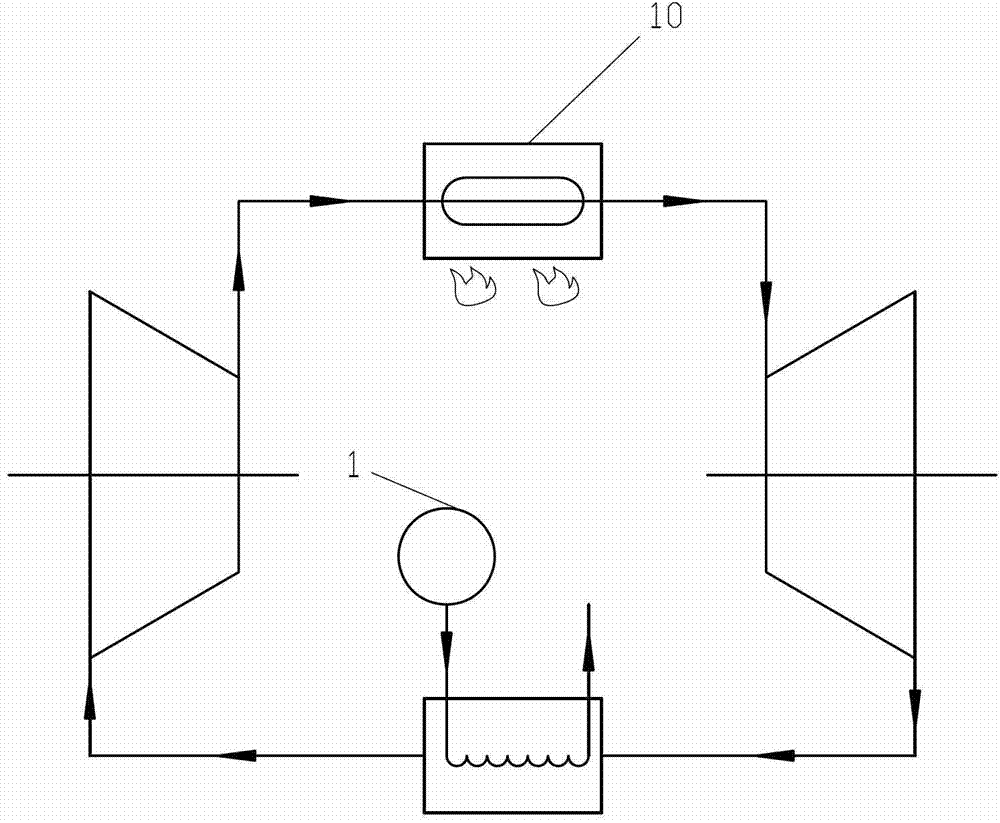

[0033] Such as image 3 The difference between the low-temperature cold source heat engine shown in Embodiment 1 is that the external combustion engine is set as a Brayden cycle thermodynamic system.

Embodiment 3

[0035] Such as Figure 4 The low-temperature cold source heat engine shown is based on Embodiment 2: the cooling fluid outlet of the cold source communicates with the working fluid inlet of the power turbine in the Brayden cycle thermodynamic system, and the gas-liquid extraction The liquefied substance absorbs heat and vaporizes into a high-temperature gas, which can enter the circulation pipeline in the Brayden cycle thermodynamic system and participate in the thermodynamic cycle as a working medium. The gas liquefied product is set as liquid helium.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com