Controlling Liquefaction of Natural Gas

a technology of natural gas and control system, which is applied in the direction of refrigeration and liquifaction, lighting and heating apparatus, solidification, etc., can solve the problems of adverse effects on the standard day to day operation, and achieve the effect of avoiding the need to manipulate the mr compressor and stress on the heat exchange means

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

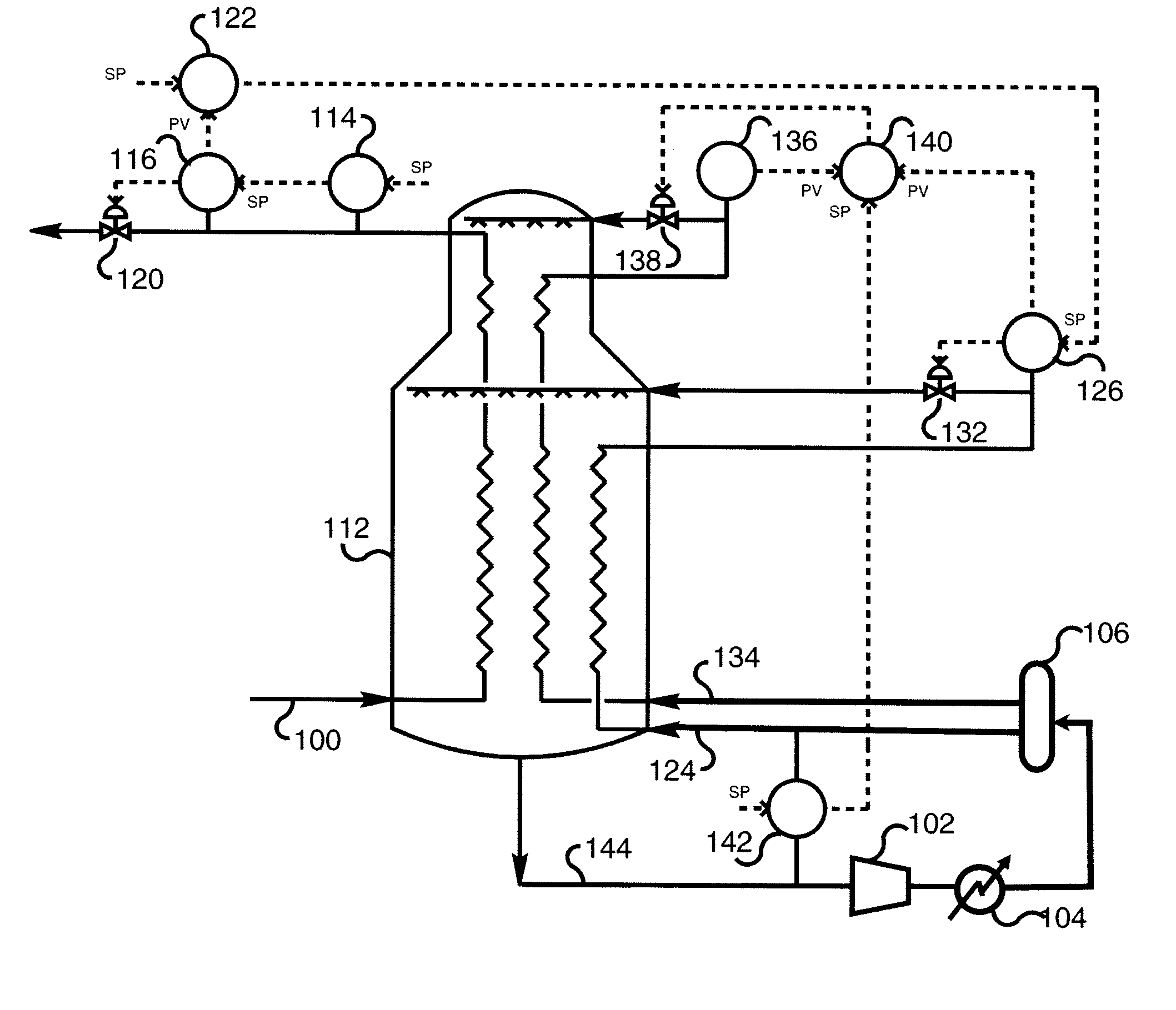

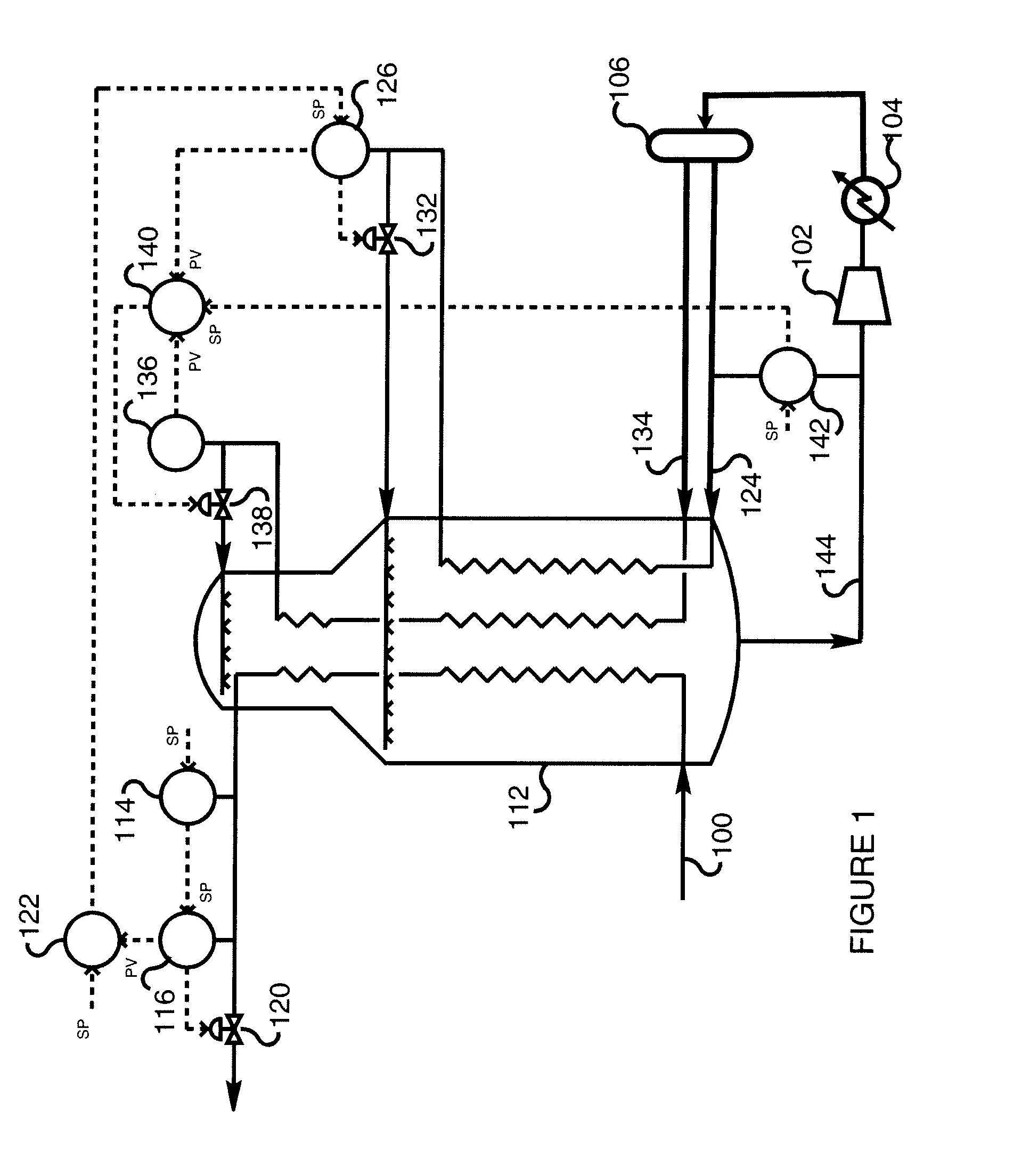

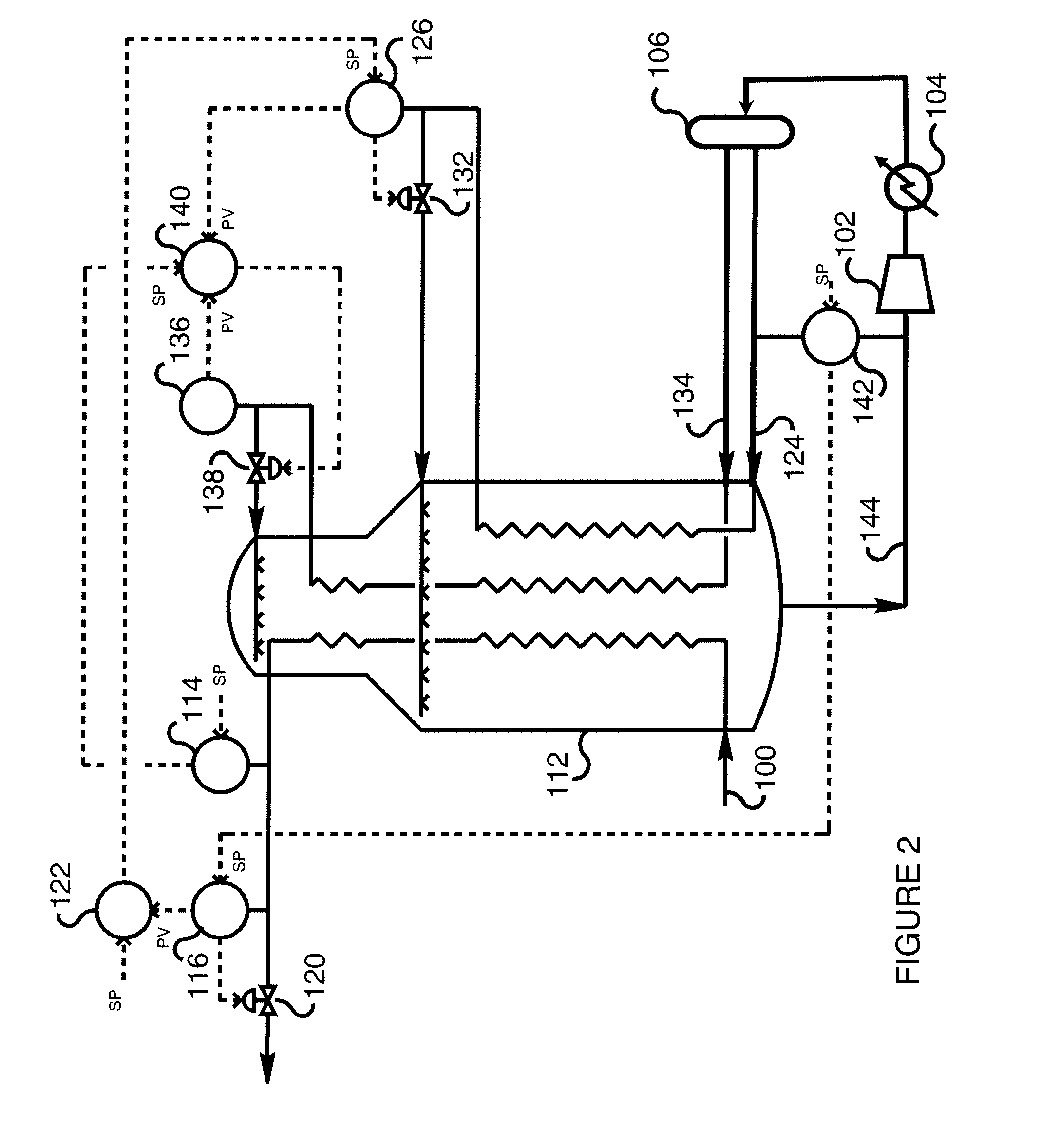

[0245]Each of the embodiments of FIGS. 2 to 5 and the comparative process of FIG. 7 was subject to the following disturbances:[0246]Increase LNG rundown temperature from −247° F. (−155° C.) to −245° F. (−153.9° C.) in 24 minutes;[0247]Decrease production by 5% while simultaneously decreasing turbine speed by 1% in 24 minutes; and[0248]Increase production by 2.8% in 24 minutes.

[0249]The process of FIG. 7 differs from that of FIG. 1 in that the LNG product flow rate is directly adjusted to the required value and FIC 126 is controlled by the difference between actual and desired LNG product temperature difference

Response to Increase LNG Rundown Temperature

[0250]The process of FIG. 1 had some oscillations in its response to the increased rundown temperature with both the LNG flow rate and the LNG temperature oscillating somewhat as they reached the new steady state. It is believed that this was more a result of conflict between the two controllers rather than a tuning issue. The process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com