Hydrate absorption supercharging device and method

A gas pressurization and absorption technology, which is applied in variable capacity pump components, liquid variable capacity machines, machines/engines, etc., can solve the problems of complex machine structure and low efficiency of gas compressors, and achieve low noise and good structure Simple, low-vibration effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described in detail below with reference to specific embodiments and accompanying drawings.

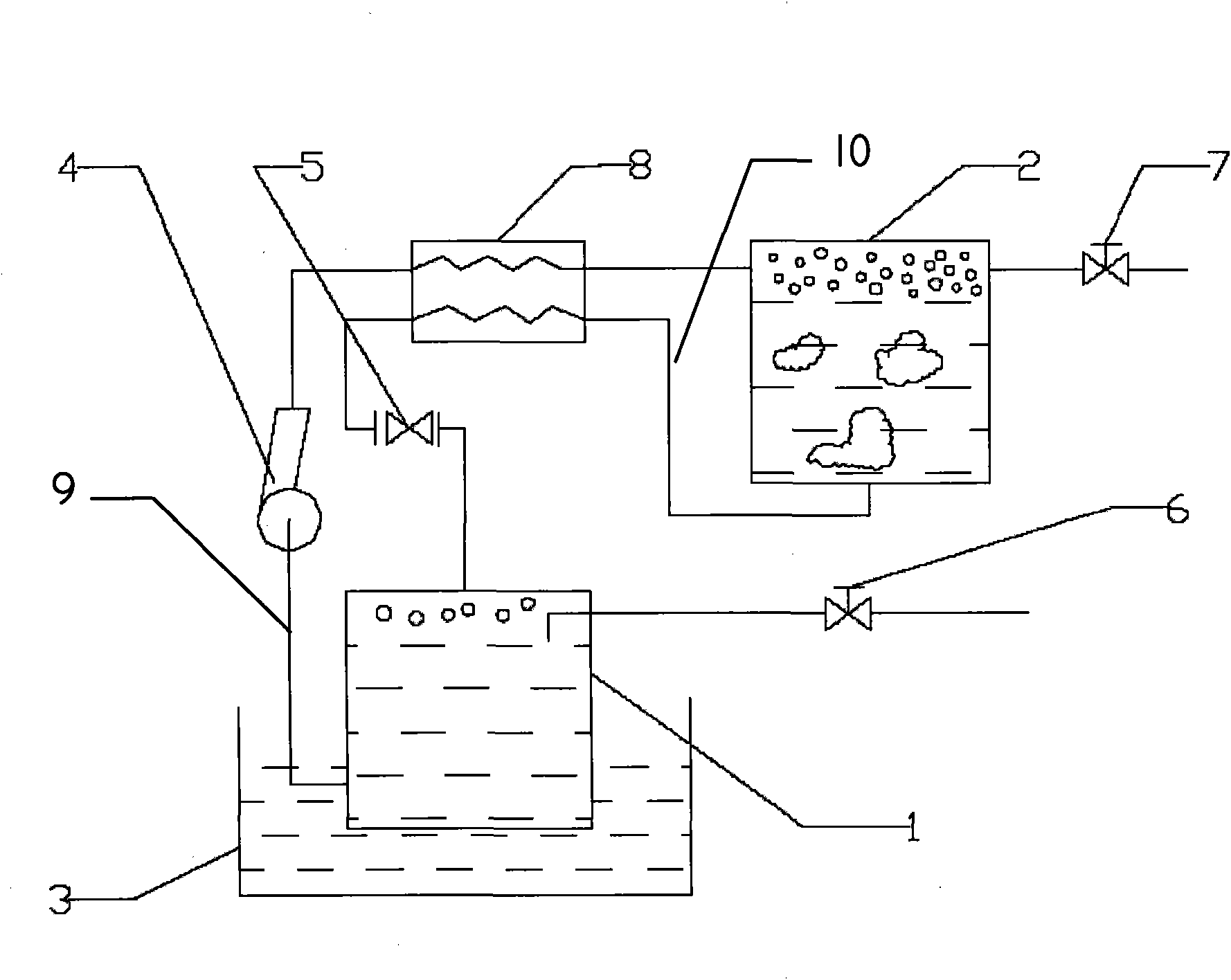

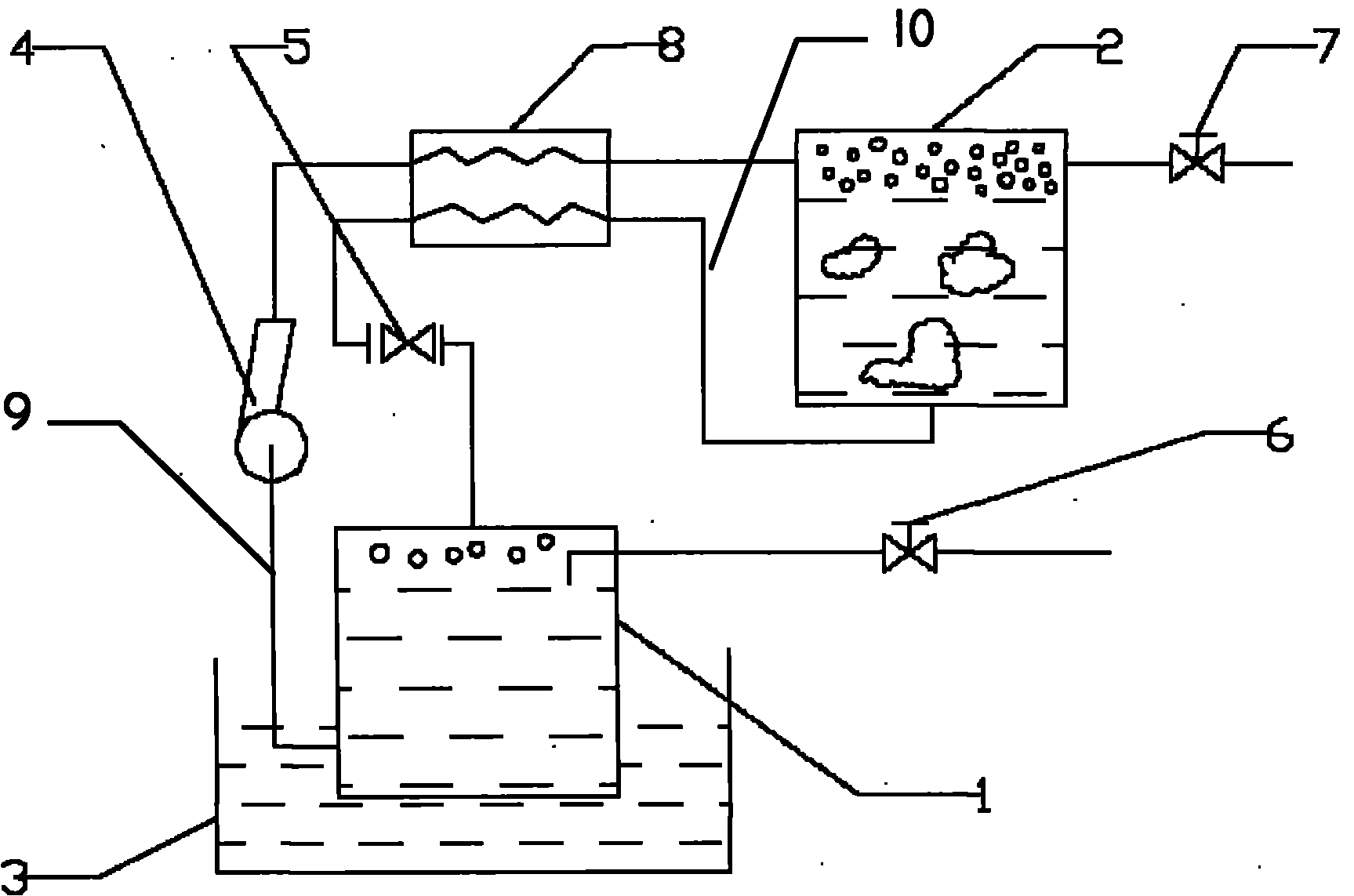

[0019] see figure 1 Schematic diagram of the structure of the present invention, which shows that the hydrate absorption type gas booster device includes a hydrate generator 1, a hydrate decomposer 2, a low temperature constant temperature system 3, a solution pump 4, a liquid infusion pipeline 9, a pressure reducing valve 5, and a heat exchange. 8 and reflux liquid pipeline 10. The hydrate generator 1 is a low-pressure sealed container for generating hydrate slurry therein. The hydrate generator 1 is filled with water, which can be an aqueous solution containing additives or pure water; the hydrate generator 1 is filled with water. A low-pressure gas inlet and a hydrate slurry outlet are arranged on the container wall of the generator 1, the low-pressure gas inlet is connected to a low-pressure gas inlet pipe provided with a valve 6, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com