Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

110 results about "Isaria fumosorosea" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

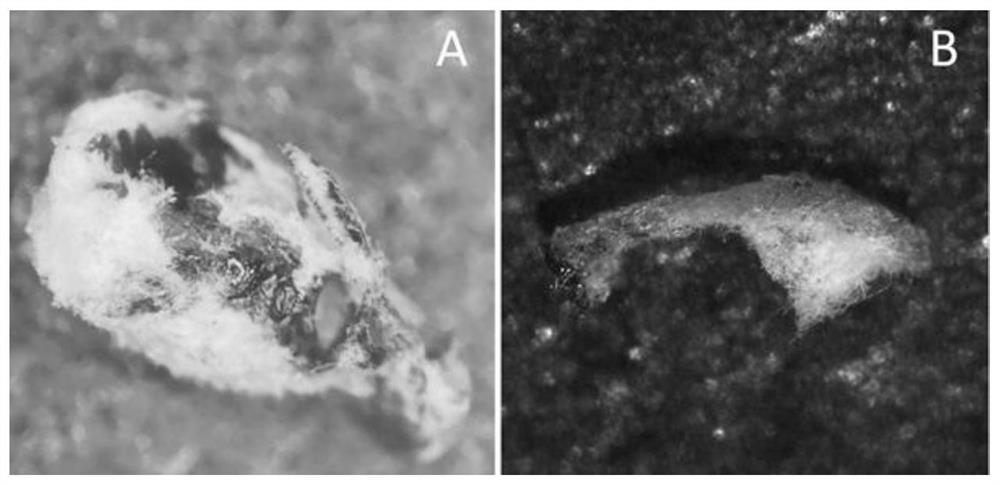

Isaria fumosorosea is an entomopathogenic fungus, formerly known as Paecilomyces fumosoroseus. It shows promise as a biological pesticide with an extensive host range.

Isaria fumosorosea oil suspending agent and preparation method as well as application thereof

InactiveCN102246750ALower resistanceEffective controlBiocideAnimal repellantsSpore germinationCabbage moth

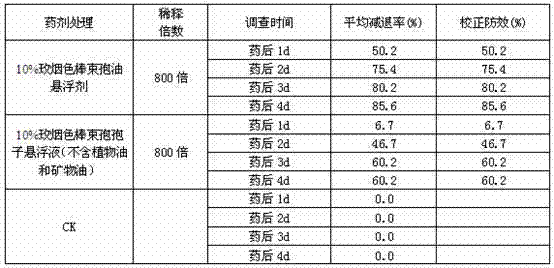

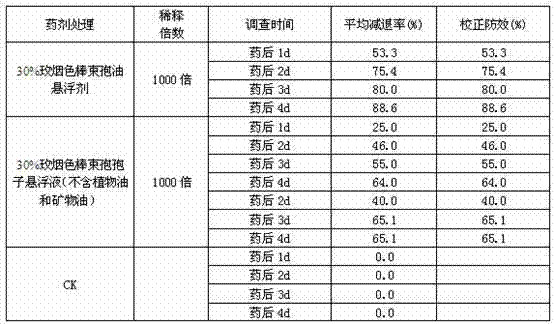

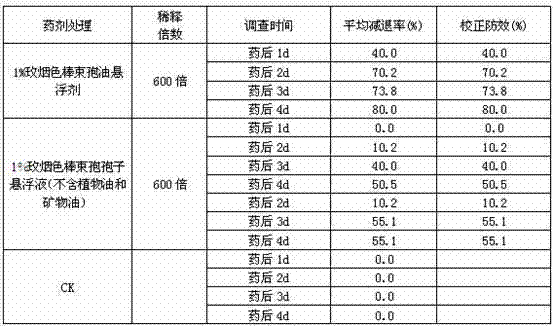

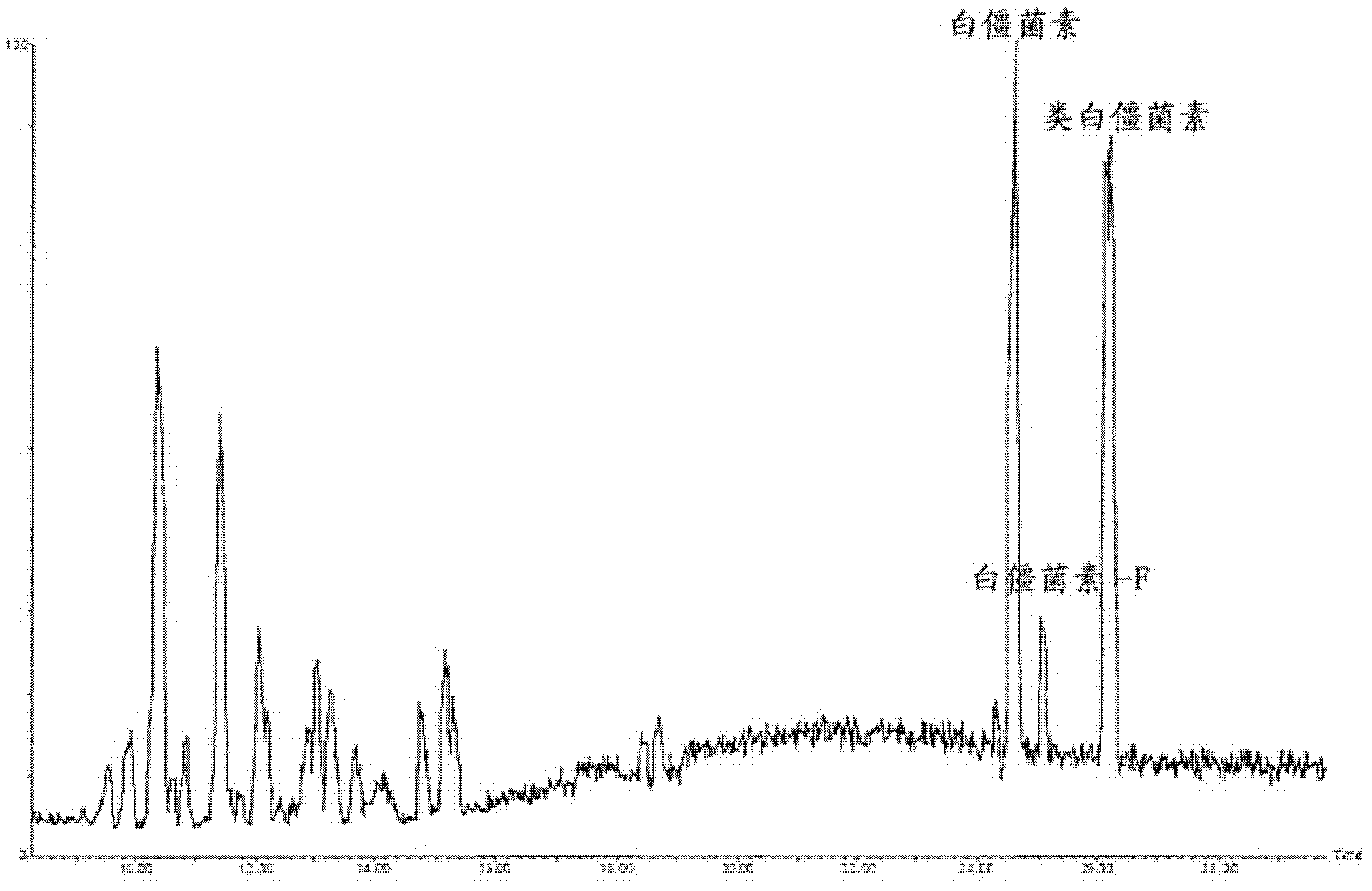

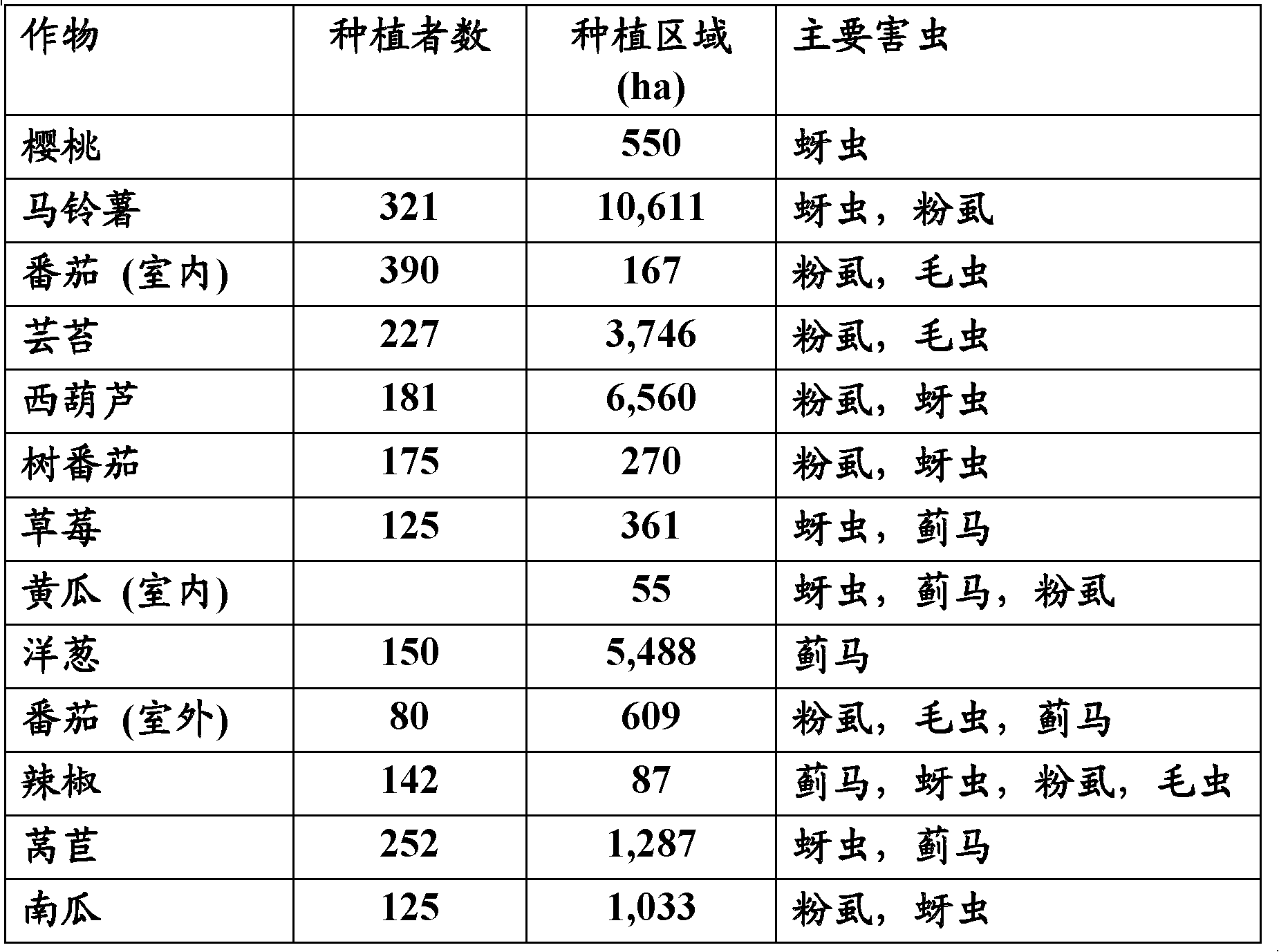

The invention discloses an isaria fumosorosea oil suspending agent and a preparation method as well as application thereof. The oil suspending agent is prepared from the following components in mass percent: 1-40% of isaria fumosorosea spore suspension, 1-20% of vegetable oil, 3-8% of emulsifying agent, 0.1-5% of dispersing agent, 1-5% of stabilizing agent, 1-5% of anti-freezing agent and the balance of inert mineral oil or aromatic hydrocarbon solvent. The spore of the isaria fumosorosea oil suspending agent disclosed by the invention has long survival time, and the germination rate of the spore which is stored for 2 years is 80%; the isaria fumosorosea oil suspending agent has good ageing stability and is safe to crops and environments; and the isaria fumosorosea oil suspending agent is mainly used for pest control of crops including fruit trees, vegetables, wheat, rice, flowers and the like, and especially has an obvious effect on controlling myzus persicae, whiteflies, cabbage caterpillars, cabbage moths and the like.

Owner:SOUTH CHINA AGRI UNIV

Paecilomyces Fumosoroseus strain and uses thereof

InactiveCN101182466AAdapt to production requirementsNo pollution in the processBiocideFungiBiotechnologyIsaria fumosorosea

Owner:SOUTH CHINA AGRI UNIV

Entomopathogenic Fungi and Uses Thereof

Owner:GREENTIDE

Entomopathogenic Fungi and Uses Thereof ?

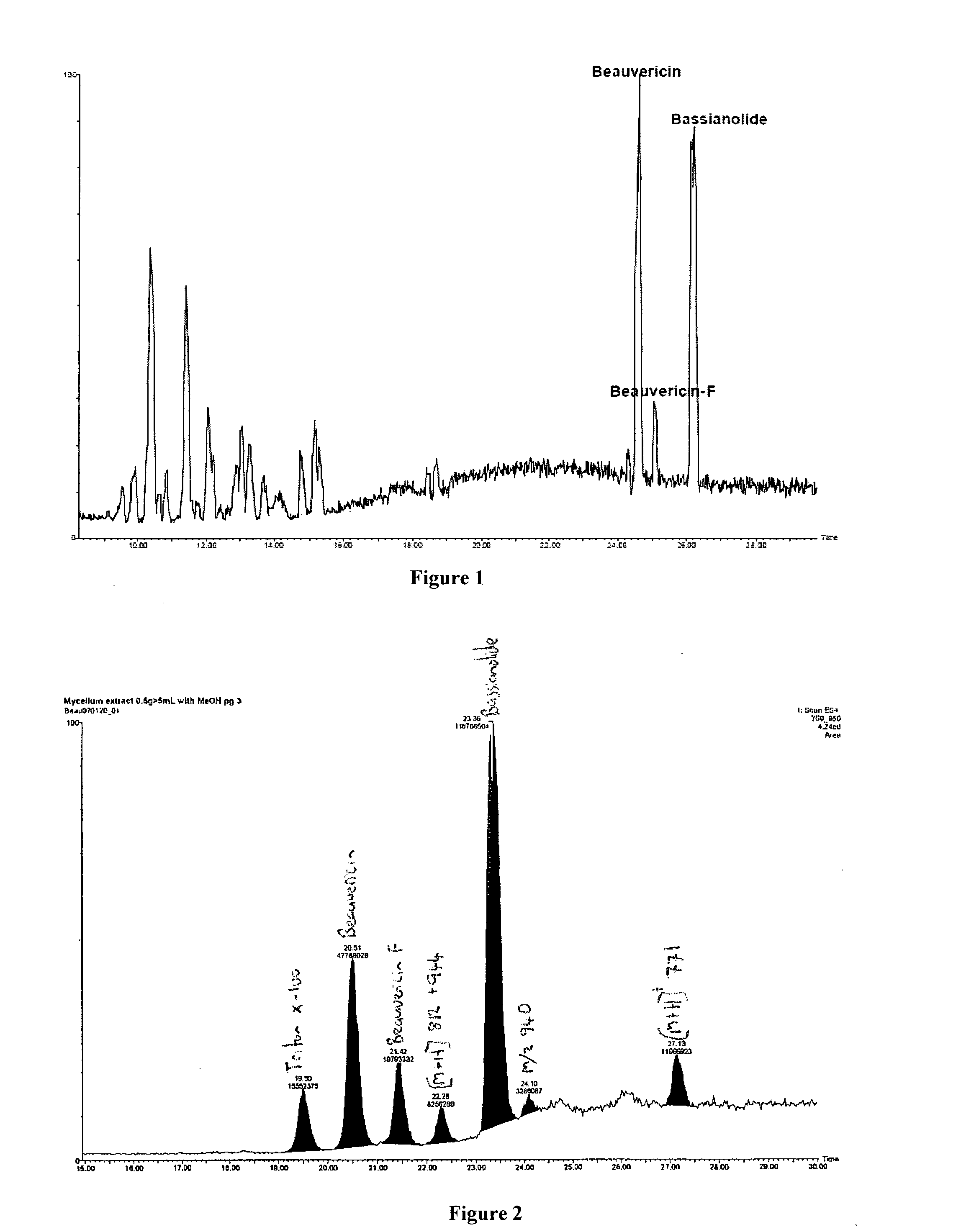

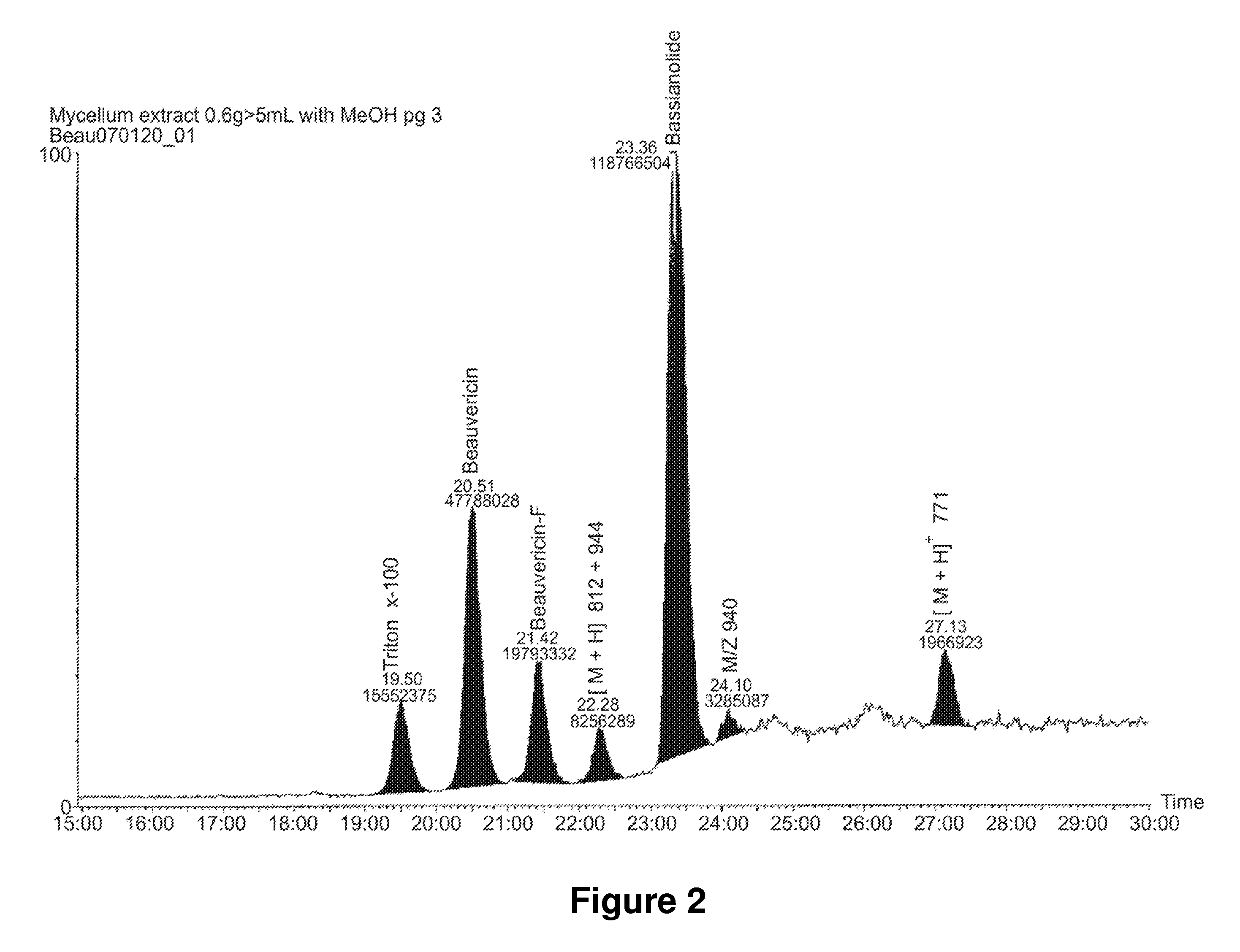

The present invention provides a strain of entomopathogenic Beauveria bassiana, compositions comprising the entomopathogenic fungi strain or metabolites of the strain, and the use of the entomopathogenic fungi strain and compositions as biological control agents. Methods for the biological control of phytopathogenic insects using an entomopathogenic Beauveria bassiana fungi strain or one or more metabolites thereof, optionally together with other entomopathogenic fungi including fungi selected from strains of Lecanicillium spp., Paecilomyces fumosoroseus, and compositions comprising said fungi or metabolites thereof are also provided.

Owner:BIOTELLIGA HLDG

Isaria fumosorosea wettable powder as well as preparation method and application thereof

InactiveCN103749441AExcellent performance indexGood biocompatibilityBiocideAnimal repellantsIsaria fumosoroseaPlutella

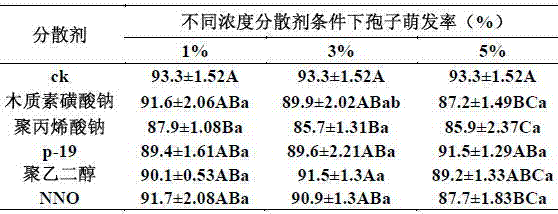

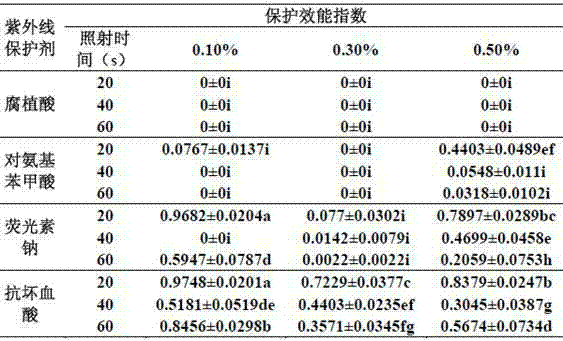

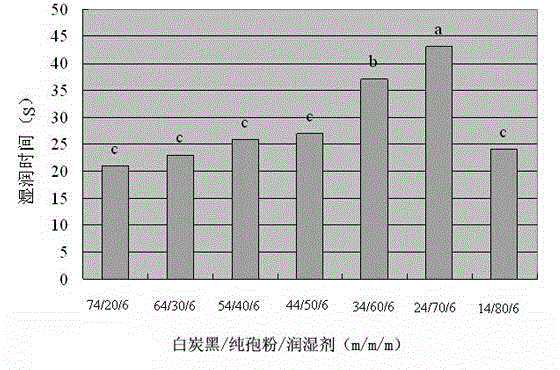

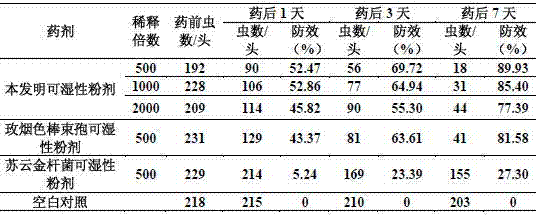

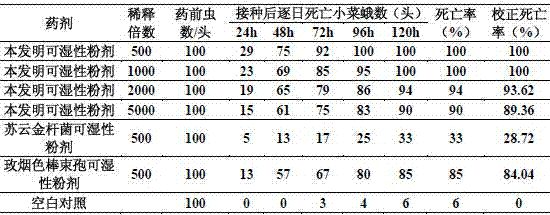

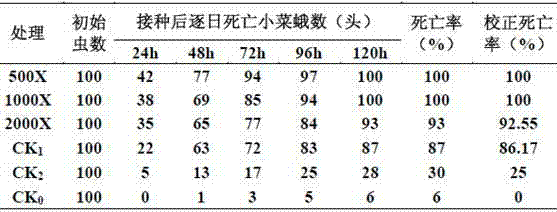

The invention discloses isaria fumosorosea wettable powder as well as a preparation method and an application thereof. The isaria fumosorosea wettable powder comprises the following components by mass percent: 5%-20% of isaria fumosorosea conidiophore powder, 3%-5% of wetting agent, 3%-5% of dispersing agent, 0.1%-0.5% of ultraviolet protective agent, and the balance of carrier. The isaria fumosorosea is an isaria fumosorosea strain SCAU-IFCF02 which is preserved in China Center for Type Culture Collection on November 1, 2013 with the preservation number CCTCCNO: M2013526. The isaria fumosorosea wettable powder is mainly used for preventing and treating brassicaceous vegetable pests, has good effect in preventing and treating pests such as plutella xylostella and the like, and has the advantages of high insecticidal activity, stable effect, lasting effect, small impact on environment, and convenience in use.

Owner:SOUTH CHINA AGRI UNIV

Aschersonia aleyrodis strain and uses thereof

InactiveCN101182467AAdapt to production requirementsNo pollution in the processBiocideFungiArthropod mouthpartsSpore

The invention discloses an aschersonia aleyrodis strain and the application of the strain. The aschersonia aleyrodis strain is a wild strain separated from bemisia tabaci body in Guangzhou area, which is naturally infected by worm living fungus. The wild strain is multi-planted on the bemisia tabaci body for the rejuvenation, so that the aschersonia aleyrodis strain is obtained; the purified strain is obtained through single spore isolation. The paecilomyces fumosoroseus strain is AA01-N8; the preservation number of the strain is CCTCC No: M207087; the strain is stored in China Center for Type Culture Collection on 27 June, 2007. Through a long term of infectious biology research and the indoor biology testing, the aschersonia aleyrodis has strong infectious and killing effects for a plurality of sucking mouth parts insects, such as the white fly and the cotton worm etc.

Owner:SOUTH CHINA AGRI UNIV

Separation and cultivation method for isaria fumosorosea

InactiveCN103451113APrevent ejectionLarge diameter areaFungiMicroorganism based processesSporeIsaria fumosorosea

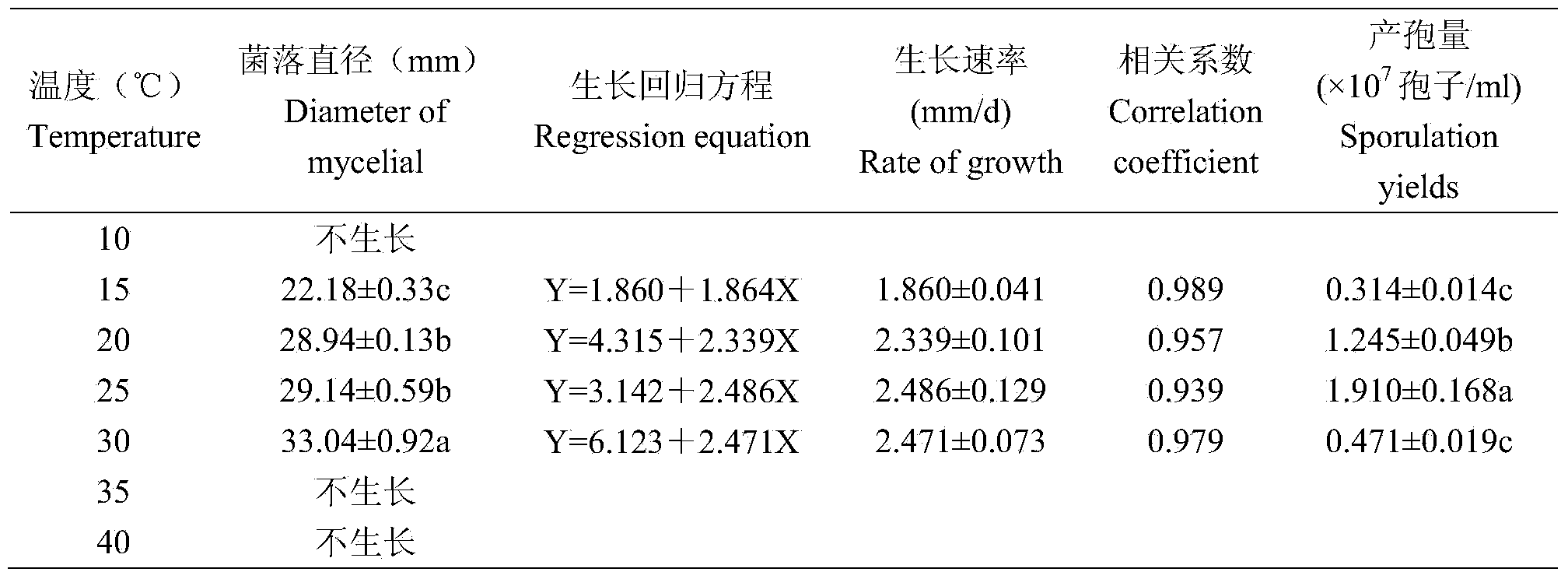

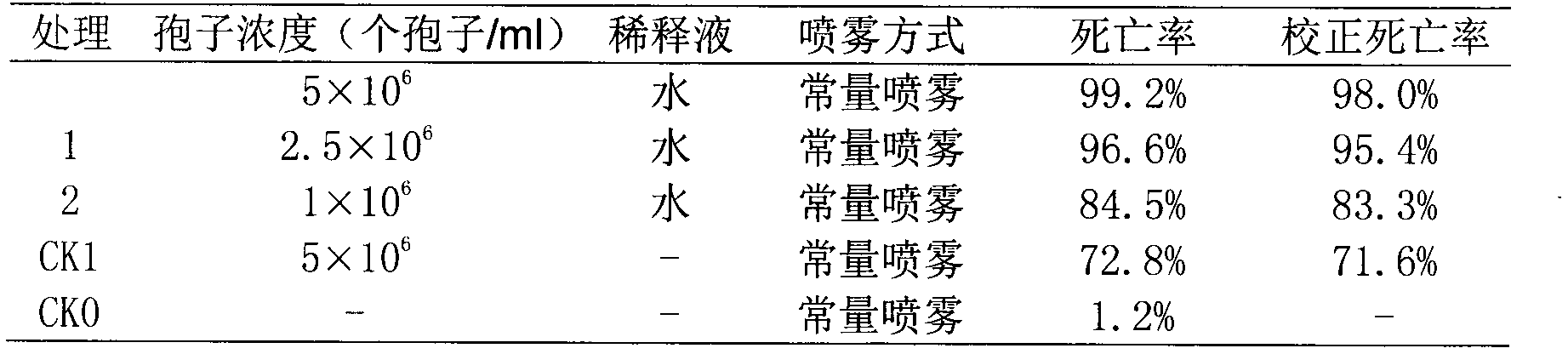

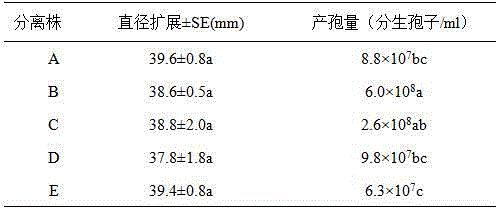

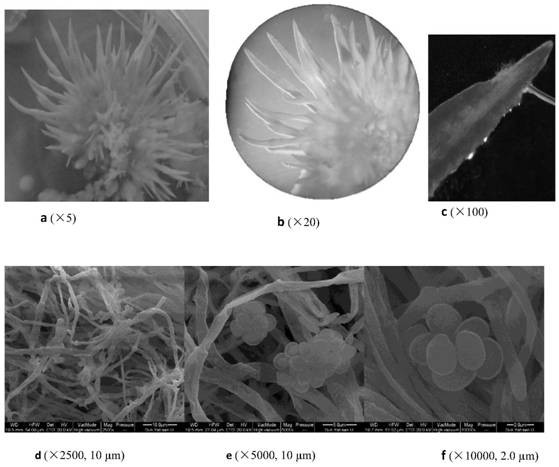

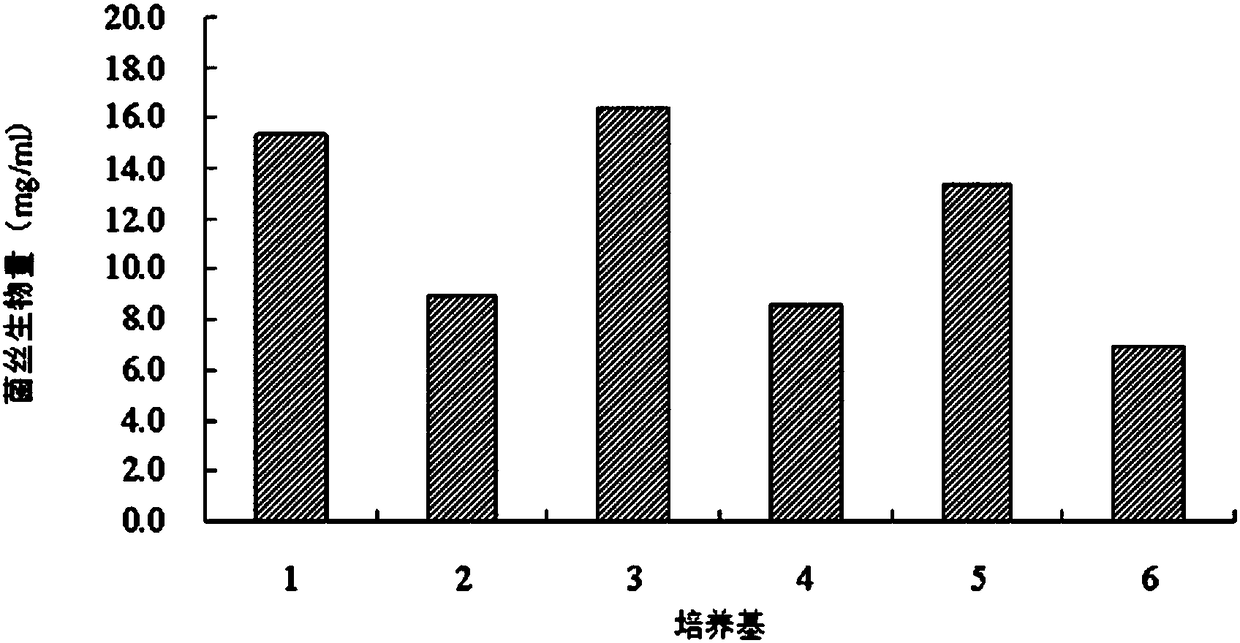

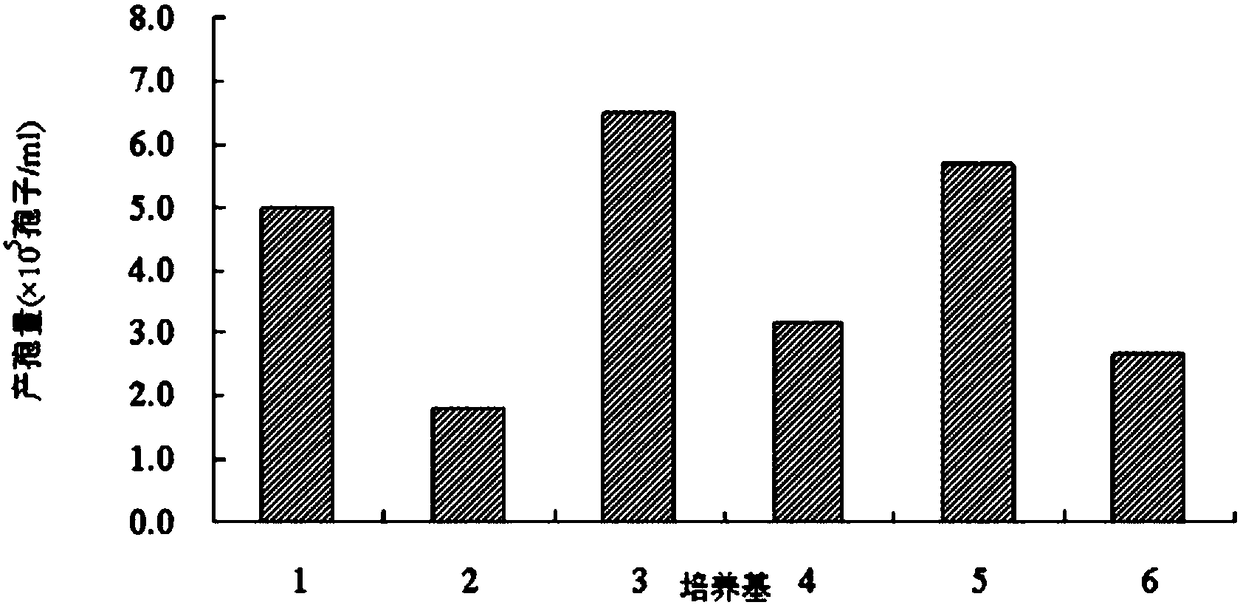

The invention discloses a separation and cultivation method for isaria fumosorosea. The method comprises the following steps of collecting bemisia tabaci bodies infected with entomogenous fungus from vegetable leaves, separating the entomogenous fungus from the bodies, putting the entomogenous fungus on a PDA (potato dextrose agar) culture medium for cultivating to obtain spore suspension which is sprayed on two-year-old nymphs of bemisia tabaci, then separating the entomogenous fungus from the bodies again after cultivation, storing the entomogenous fungus on a slope of a test tube and storing the test tube in a refrigerator; taking the entomogenous fungus out of the refrigerator, preparing the spore suspension, dipping the spore suspension through filtration paper, inoculating the spore suspension onto the culture medium, cultivating in a mildew incubator, picking up hypha, inoculating the hypha into germfree water, then stirring and filtering; putting the spore suspension at the center of a culture dish, perforating a hole in the center of a bacterial colony, dispersing tween-80, stirring and filtering again, and calculating the sporulation quantity and the diameter of the bacterial colony. The method is used for screening an optimal culture medium formula, the optimal temperature, an optimal pH, a lighting condition and a ventilating condition. The method has the advantages that the diameter area of the bacterial colony is large and the sporulation yield is large.

Owner:SHANXI AGRI UNIV

Isaria fumosorosea oil suspension

InactiveCN104255809AImprove efficiencyReduce exposureBiocideAnimal repellantsVegetable oilIsaria fumosorosea

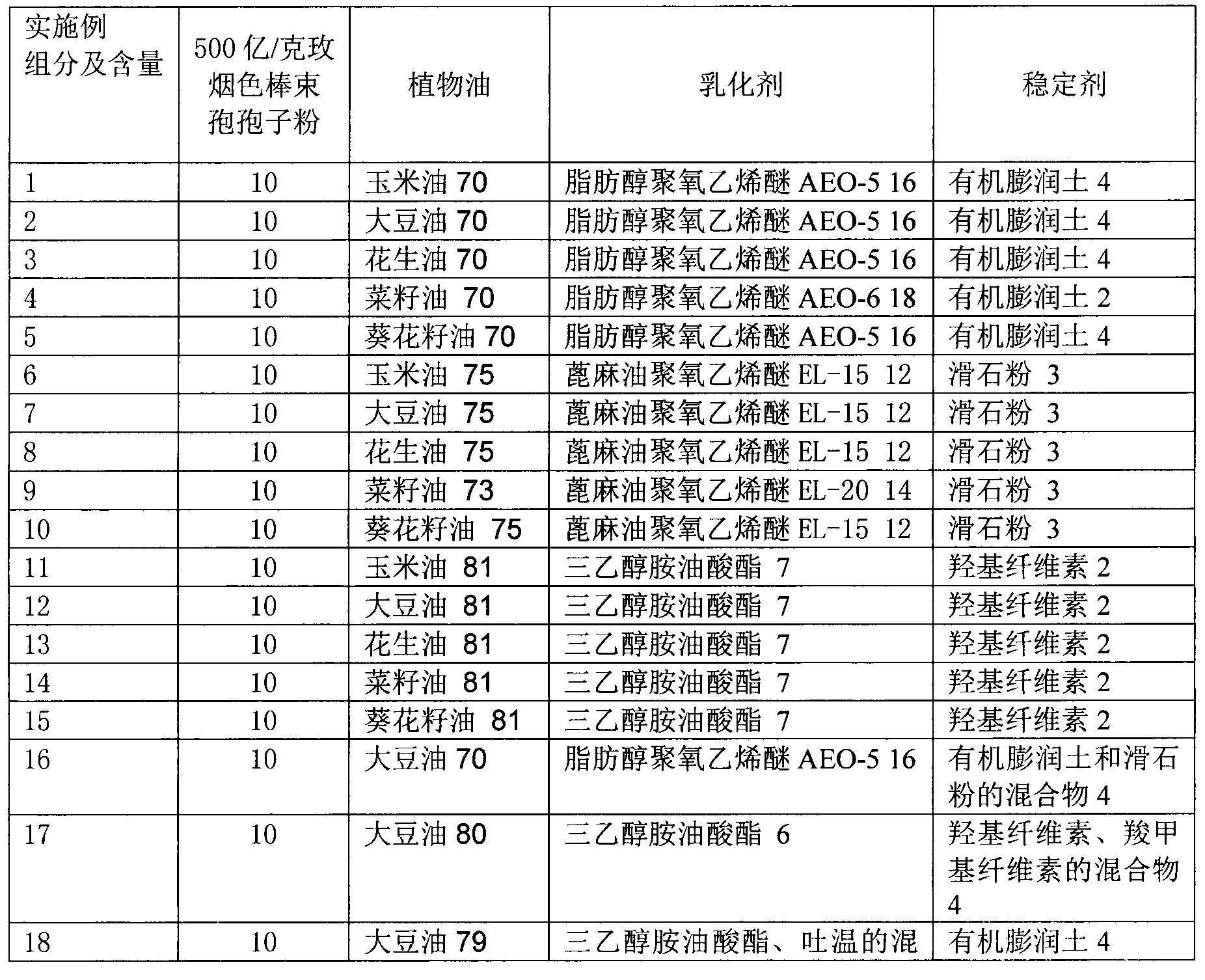

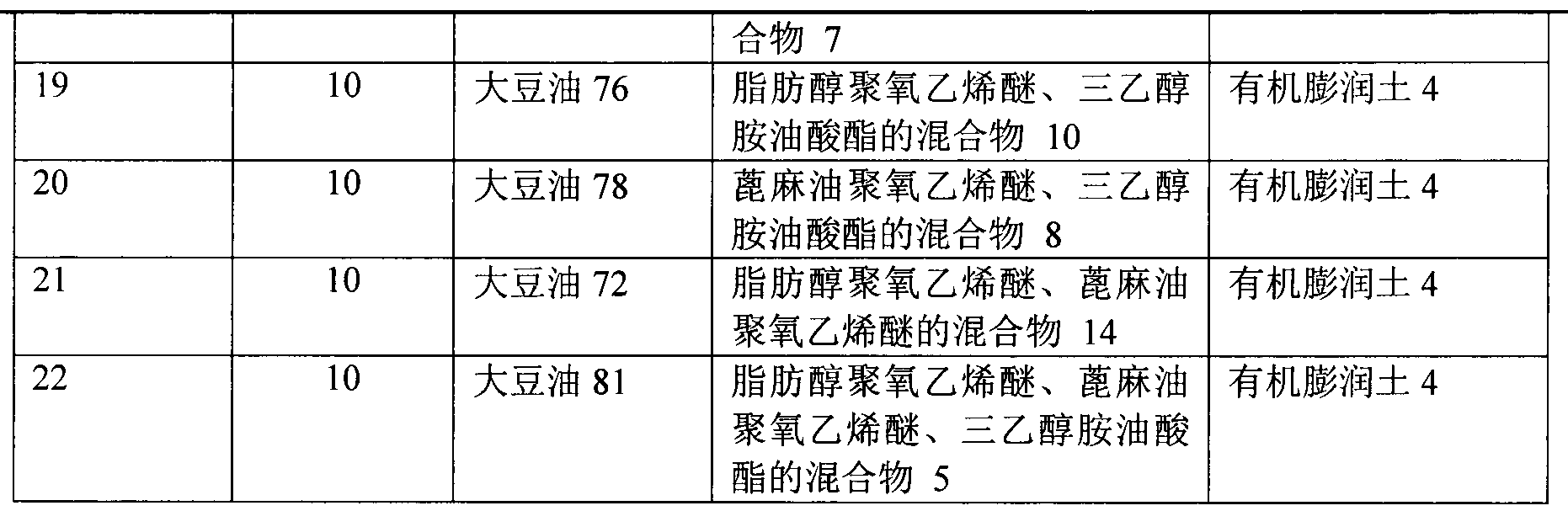

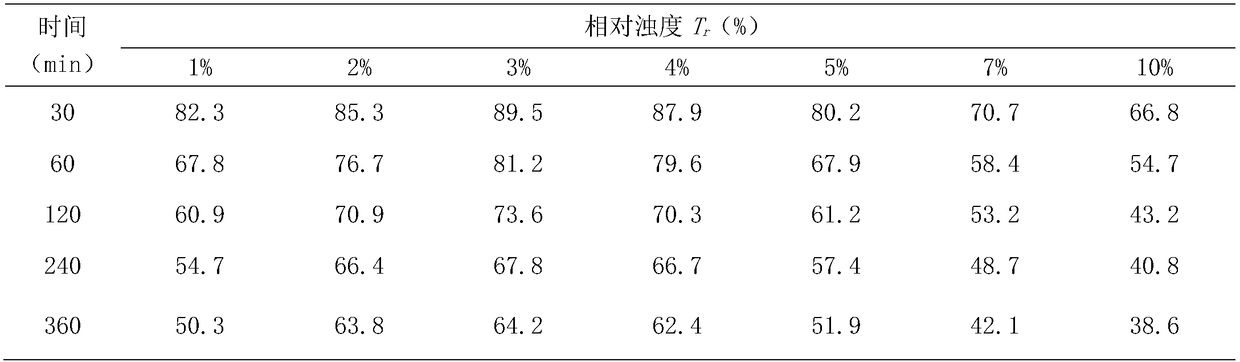

The invention discloses isaria fumosorosea oil suspension which mainly comprises 1%-10% of isaria fumosorosea conidial powder, 50%-80% of vegetable oil or inert mineral oil, 5%-30% of an emulsifying agent and 1%-10% of a stabilizer. The isaria fumosorosea oil suspension has the advantages as follows: the storage period of isaria fumosorosea is long, and the survival rate of the isaria fumosorosea is higher than 85% after two years of storage; after the oil suspension is diluted by water, the mixture is slightly stirred to form transparent or semitransparent emulsion, the emulsification is thorough, and the stability is good; the oil suspension can be sprayed after mixed with water, and the use is convenient in the farming area; after drug application, the vegetable oil can effectively absorb ultraviolet rays, damage of the ultraviolet rays to the isaria fumosorosea is reduced, and the protection effect of the isaria fumosorosea is improved; the processing technology is simple, and the preparation method is simple and convenient; and long-term infection biological study and indoor biological assay prove that the isaria fumosorosea oil suspension has higher infection and insecticidal efficacy on pests such as bemisia tabaci, aphids and the like.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Diaphorina citri Kuwayama high pathogenic Isaria fumosorosea strain and application thereof

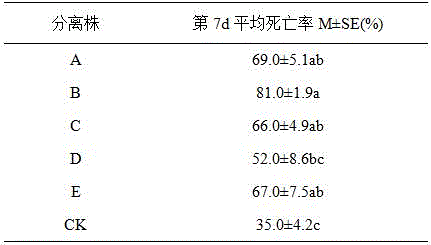

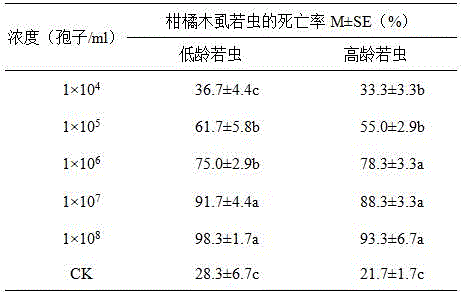

ActiveCN106065392AStrong infestation and insecticidal effectStrong application potentialBiocideFungiIsaria fumosoroseaIn vivo

The invention discloses a Diaphorina citri Kuwayama high pathogenic Isaria fumosorosea strain IF-BDC01 and application thereof. The Isaria fumosorosea strain IF-BDC01 is preserved in Guangdong Microbiology Culture Center on March 1, 2016 with a preservation number of GDMCC No:60011, and the preservation address is building 59, 100th yard on middle martyr road, Guangzhou. Long-term infection biology and indoor biological determination proves that the Isaria fumosorosea strain IF-BDC01 has very high pathogenicity on Diaphorina citri Kuwayama and very strong infecting insecticidal effect. The strain is an entomopathogenic fungus, and has very strong application potential as an in vivo biopesticide in biological control of Diaphorina citri Kuwayama.

Owner:SOUTH CHINA AGRI UNIV

Isaria fumosorosea conidia wettable powder and application thereof

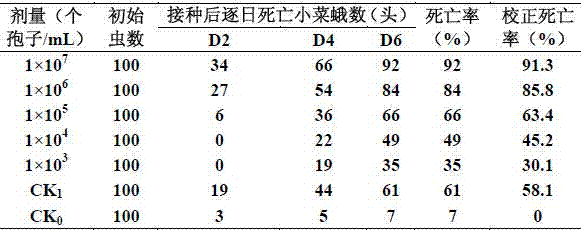

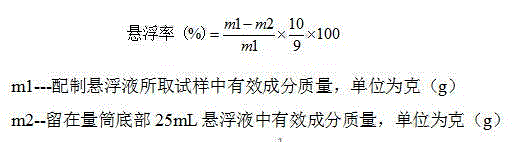

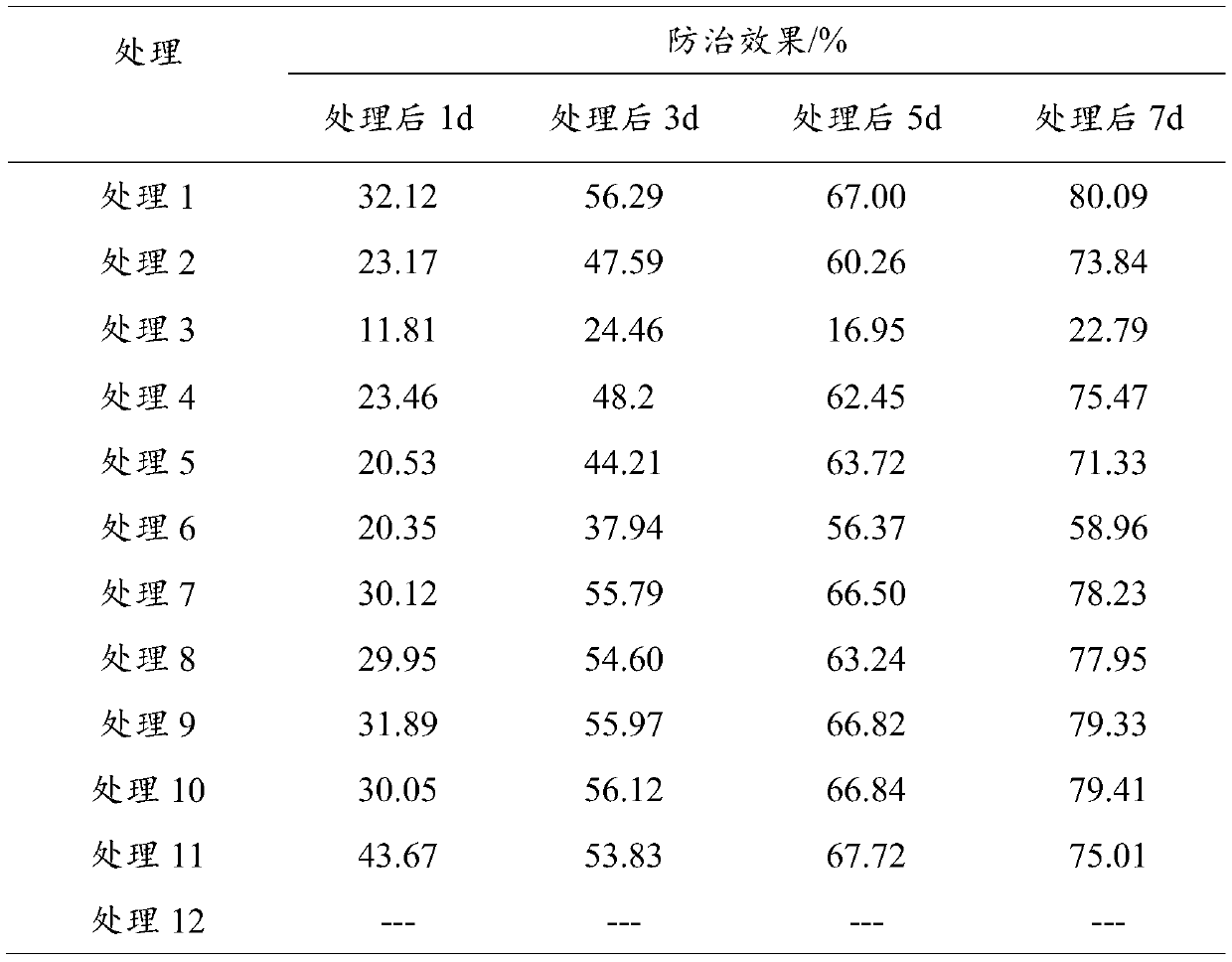

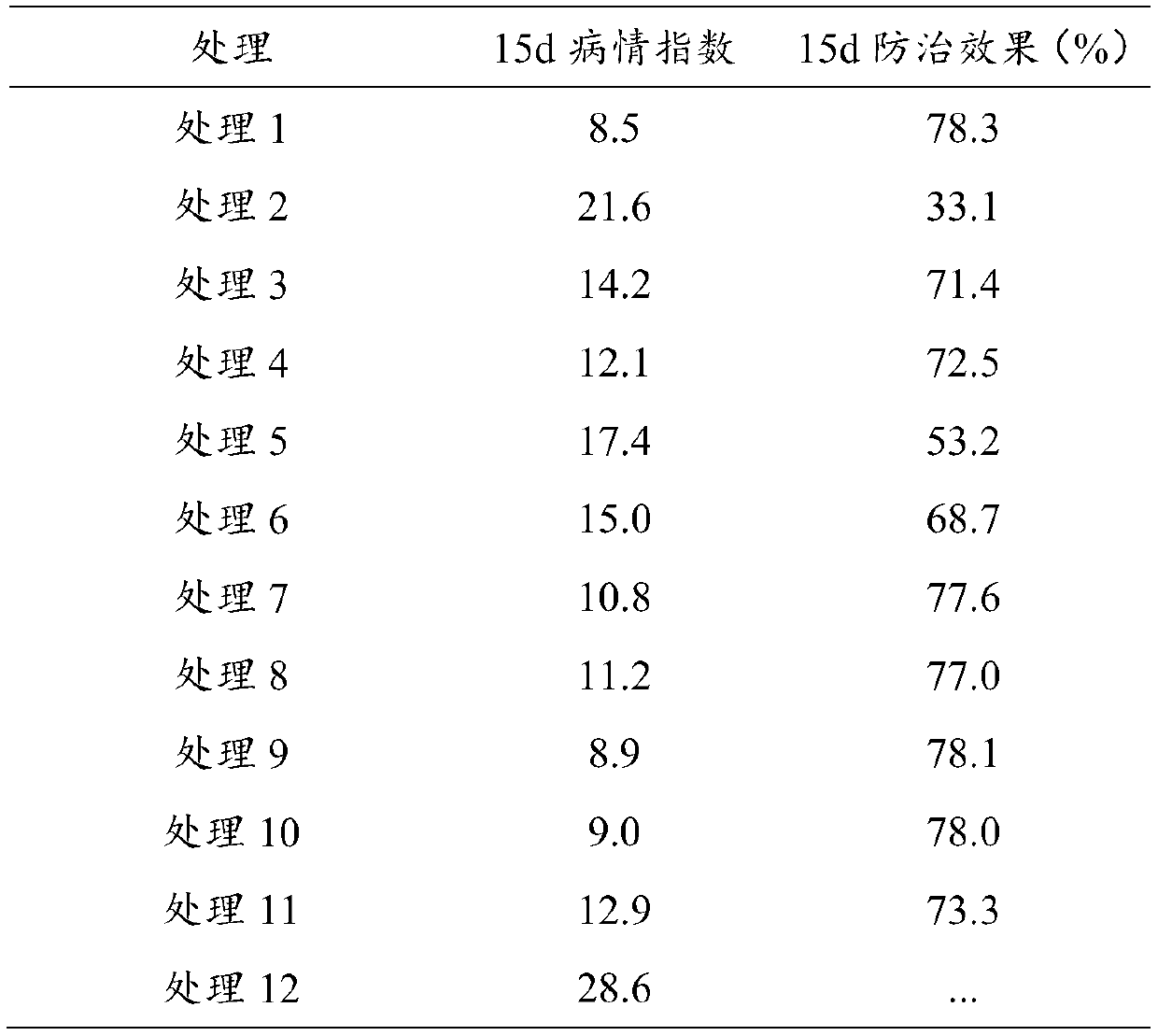

The invention relates to the technical field of biological control of insect pests and particularly discloses isaria fumosorosea conidia wettable powder. The isaria fumosorosea conidia wettable powder is prepared from the following components in percentage by weight: 15-25% of conidia pure spore powder of isaria fumosorosea conidia IfB01, 1-5% of a wetting agent, 5-10% of a dispersant, 0.5-1.5% of an ultraviolet protective agent, 1-3% of a stabilizer and 60-74% of a carrier, wherein the carrier is white carbon black. The wettable powder can be used for preventing and treating bemisia tabaci and according to the indoor toxicity, the medial lethal concentration LC50 on the 13th day of treatment is 0.04*10<6> spores / mL while that of the pure spore powder is 0.07*10<6> spores / mL; the half lethal time LT50 when the concentration is 1*10<6> spore / mL is 8.76 days while that of the pure spore powder is 9.25 days. Treated by 2*10<7> spore / mL, for bemisia tabaci on tomatoes and cabbage mustards treated on the 14th days, the field control efficiencies are respectively 82.73% and 66.58% which are remarkably higher than those of other treatment.

Owner:SOUTH CHINA AGRI UNIV

Isaria fumosorosea and bacillus thuringiensis wettable powder

InactiveCN103749545AObvious pollution-free prevention and controlSignificant and sustained effect of comprehensive prevention and controlBiocideAnimal repellantsBrassicaceaeBacillus thuringiensis

The invention discloses isaria fumosorosea and bacillus thuringiensis wettable powder. The wettable powder comprises the following ingredients in percentage by mass: 8%-20% of isaria fumosorosea and bacillus thuringiensis, 1-8% of wetting agent, 1-12% of dispersing agent, 0.1-0.5% of ultraviolet protective agent, and the balance of carriers. The weight part ratio of the isaria fumosorosea to bacillus thuringiensis is (10:0.4) to (10:1). The isaria fumosorosea is isaria fumosorosea strain SCAU-IFCF02 which is preserved in CCTCC (China Center for Type Culture Collection) at November 1rst, 2013, with the preservation number of CCTCC NO:M2013526. The bacillus thuringiensis is subsp. Kurstaki. The wettable powder is fast and efficient, has no pesticide residues, postpones the occurrence of pest resistance to insecticide, is environment-friendly, and especially has a good prevention effect on pests on brassicaceous vegetables of plutella xylostella and the like.

Owner:SOUTH CHINA AGRI UNIV

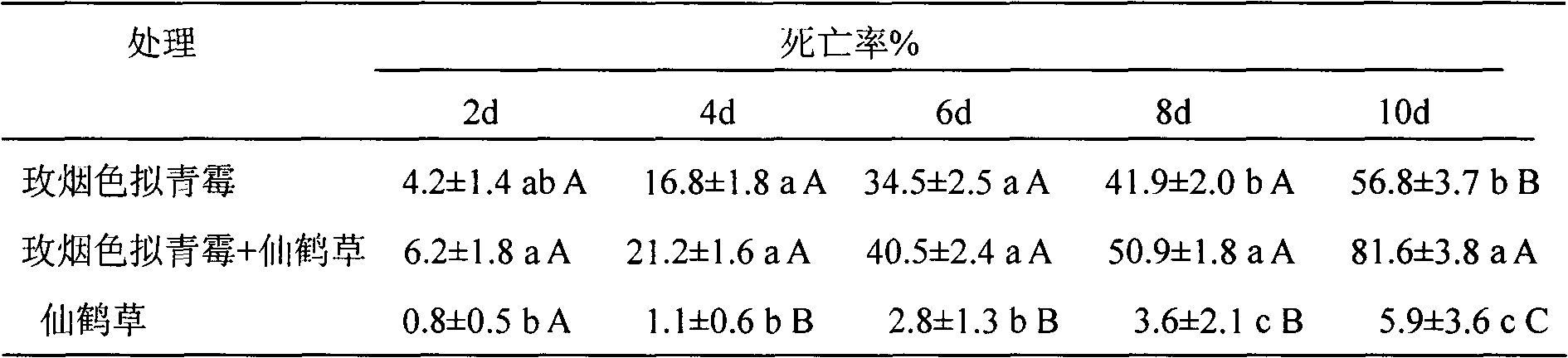

Method for increasing infectivity of Paecilomyces fumosoroseus on Bemisia tabaci by utilizing plant source extract

InactiveCN102630710AImprove damage control effectImprove the level of prevention and controlBiocideAnimal repellantsInfection rateIsaria fumosorosea

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES

Strain of entomopathogenic fungus Isaria fumosorosea CCM 8367 (CCEFO.011.PFR) and the method for controlling insect and mite pests

Owner:BIOLOGICKE CENT AV CR V V I

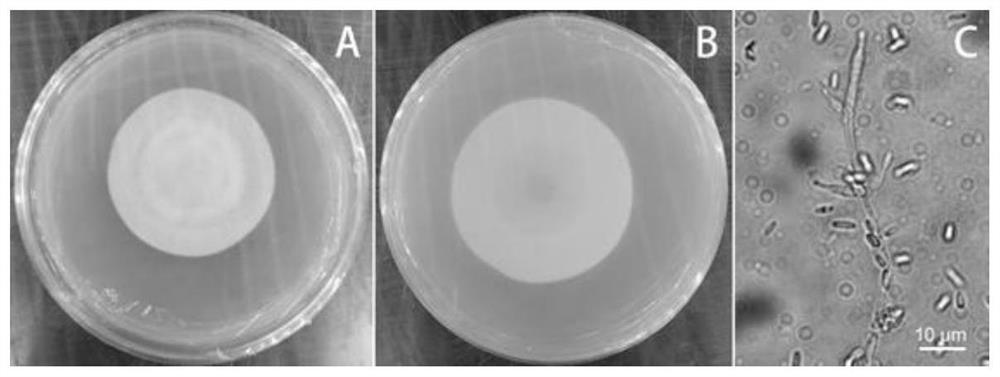

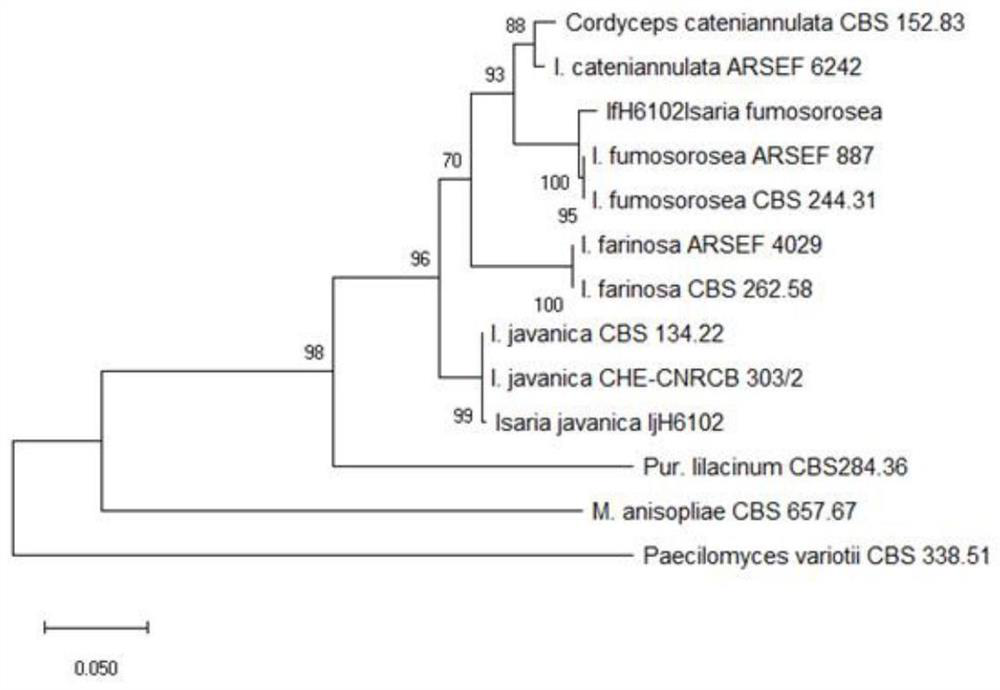

Isaria javanica strain and application thereof in prevention and treatment of phyllotreta striolata

The invention relates to an isaria javanica IjH6102 strain and also relates to application of the isaria javanica strain in prevention and treatment of phyllotreta striolata, and belongs to the technical field of biological pesticides. The isaria javanica IjH6102 strain belongs to fungi, Ascomycota, Sordariomycetes, Hypocreales, Cordycipitaceae and Isaria according to the taxonomic status, the strain is collected in Guangdong Microbial Culture Collection Center on December 18, 2019, with the collection number of GDMCC No: 60936. The strain is an entomopathogenic fungus and a biological livingpesticide, is highly effective in preventing and treating the phyllotreta striolata, is safe to the environment and the human body, and has the potential as an environment-friendly fungal insecticide.

Owner:SOUTH CHINA AGRI UNIV

New strain of isaria tenuipes, culturing method and application thereof

ActiveCN107475130ARealize artificial cultivationIncrease the lengthFungiFungi productsMicrobiologyCulture mediums

The invention relates to a new strain, a culturing method and an application thereof and specifically relates to the new strain of isaria tenuipes, the culturing method and the application thereof. The new strain of isaria tenuipes is Isaria tenuipes HMGIM-W150712, and the collection number is CCTCC No: M2017430. The method comprises the following steps: separating the stock culture, purifying the stock culture and then preparing a liquid stock; inoculating the liquid stock into a culture medium for culturing; and managing the culturing. Through repeated test and research, the inventor finds the culture medium and the culturing method suitable for the strain of isaria tenuipes provided by the invention; the artificial cultivation for the isaria tenuipes is realized; and after the artificial cultivation, the length of the sporocarp thereof is greatly longer than the length of wild strain, the biological conversion rate is about 33.36% and the fruiting period is short.

Owner:GUANGDONG INST OF MICROBIOLOGY GUANGDONG DETECTION CENT OF MICROBIOLOGY +1

Pesticides combined with Paecilomyces fumosoroseus and Acetamiprid

InactiveCN101273727AResidue reductionImprove quicknessBiocideArthropodicidesAdjuvantIsaria fumosorosea

The invention discloses a combination pesticide of paecilomyces fumosoroseus and acetamiprid, comprising 22 to 61 percent of host crystal and 39 to 78 percent of adjuvant according to mass percent, the host crystal is the mixture of paecilomyces fumosoroseus and acetamiprid, the mass ratio of the paecilomyces fumosoroseus and the acetamiprid is 100: 1.5 to 10; the adjuvant is stabilizer, addition agent and filler. The invention discloses wettable powder of fungal spore, suspending agent of fungal spore and medicinal oil made by using the bacterial strain. By adopting the blending of agricultural chemical and biopesticide with sub-dose, the combination pesticide of the invention can improve the quick-acting property of microbial pesticide and reduce the residual amount of agricultural chemical, meets the production demands of organic foods, has no pollution and residue to environment and is beneficial to deferring the generation of drug fastness of pests, especially has good control effects on pests such as whitefly and aphis and diamondback moth, etc.

Owner:SOUTH CHINA AGRI UNIV

Insecticide composition as well as preparation method and application of insecticide composition

ActiveCN104222161AImprove stabilityImprove survival rateBiocideAnimal repellantsSporeActive component

The invention discloses an insecticide composition as well as a preparation method and application of the insecticide composition. The insecticide composition comprises active components, namely isaria fumosorosea and rotenone, wherein the mass percentage of isaria fumosorosea to rotenone in the insecticide composition is 2%-80%; and the mass ratio of isaria fumosorosea to rotenone is (0.1-70) to 1. The active components of the insecticide composition are compounded by adopting isaria fumosorosea and rotenone, so that the stability and validity period of the isaria fumosorosea are effectively increased, the spore survival rate is increased, the validity period is long, the insecticidal efficiency is high, the control efficiency reaches over 80%, and meanwhile, the insecticide composition is safe to environment, people and livestock, does not pollute the environment, and is beneficial to ecological balance.

Owner:PLANT PROTECTION RES INST OF GUANGDONG ACADEMY OF AGRI SCI +1

Isaria fumosorosea water dispersible granule and preparation method thereof

ActiveCN108770870AExcellent formulation performanceImprove germination abilityBiocideAnimal repellantsWater dispersibleBiocompatibility Testing

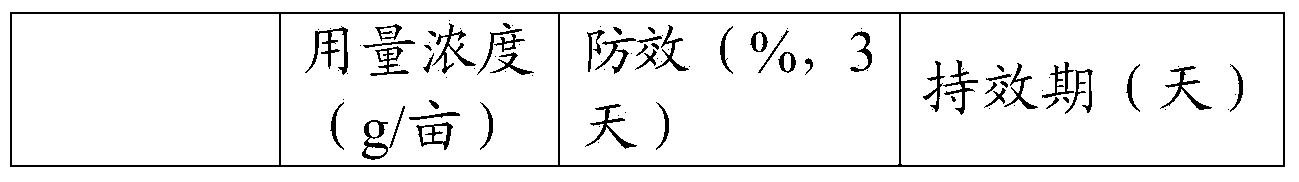

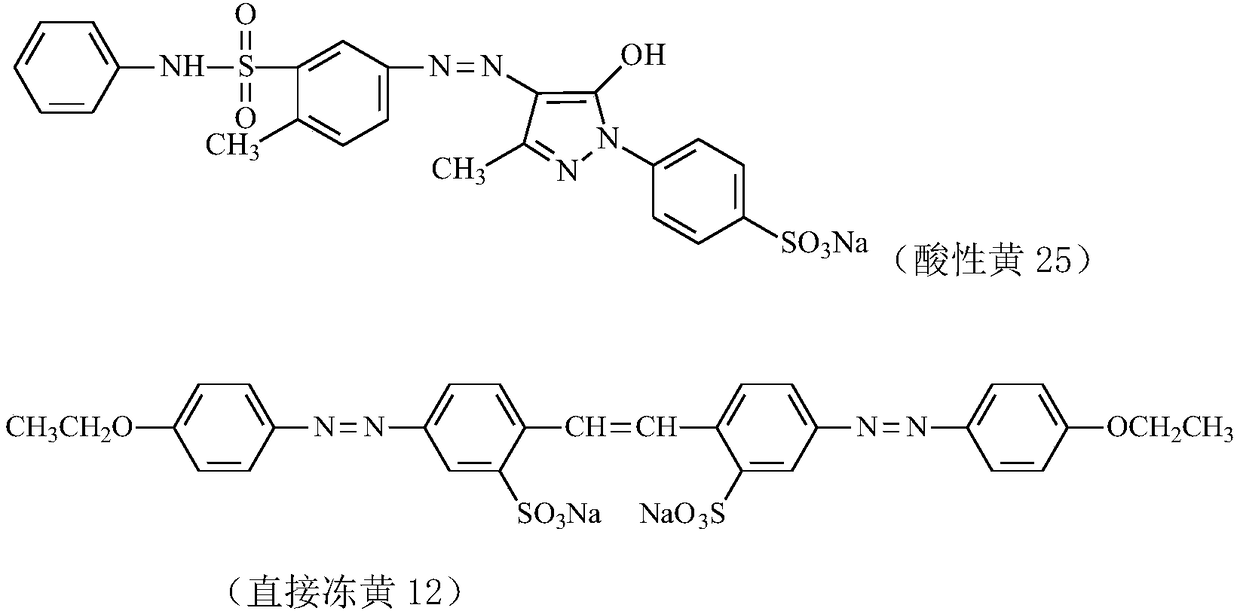

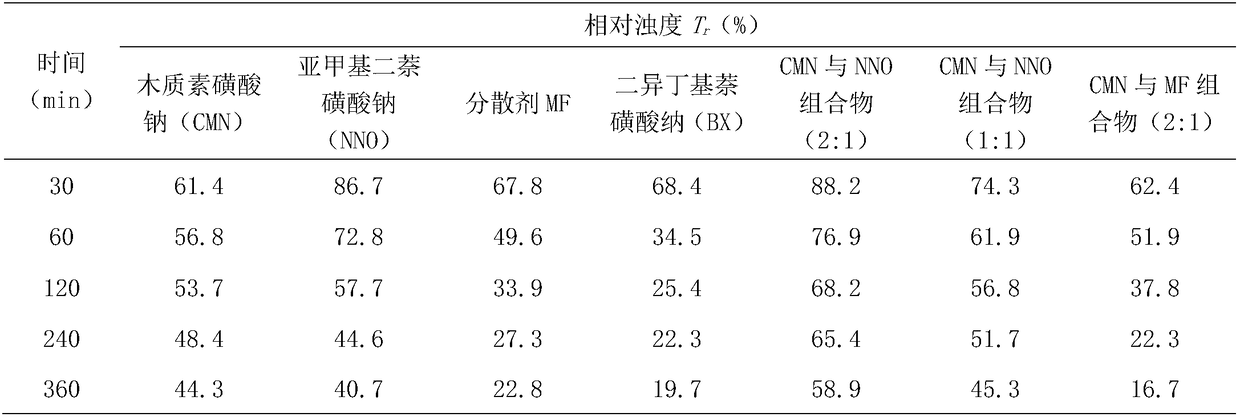

The invention discloses an Isaria fumosorosea water dispersible granule. The water dispersible granule is prepared from Isaria fumosorosea spore powder, sodium lignosulfonate (CMN), sodium dinaphthylmethanedisulfonate (NNO), isooctyl alcohol polyoxyethylene ether polyoxypropylene ether (CA-60), sodium alpha-olefin sulfonate, corn starch, fumed silica, ammonium sulfate, polyvinylpyrrolidone K30, pre-gelatinized starch, a combination of fumed silica and acid yellow 25 or chrysophenine 12, skim milk powder or chitosan oligosaccharide, water-absorbent resin SAP and diatomaceous earth. Low-cost andhigh-stress resistance fermentation, drying and coarse spore powder preparation processes are adopted; a surfactant with best biocompatibility, wettability, dispersibility, disintegration property and adhesion property is screened; and the invasion and germination ability of the above preparation in low-humidity fields is improved. The production cost is reduced, the performances of the preparation are effectively improved, the shelf life is especially prolonged, and the field drug effect is especially improved.

Owner:SHANXI AGRI UNIV

Isaria fumosorosea and beta-cypermethrin oil suspension and applications thereof

InactiveCN103749546AThe proportion of dosage is smallImprove insecticidal efficiencyBiocideAnimal repellantsCypermethrinVegetable oil

The invention discloses an isaria fumosorosea and beta-cypermethrin oil suspension and applications thereof. The isaria fumosorosea and beta-cypermethrin oil suspension comprises the following ingredients in percentage by mass: 8-30% of isaria fumosorosea and beta-cypermethrin, 1-20% of plant oil, 10-20% of emulsifier, 4-10% of dispersing agent, 2-7% of stabilizer, 2-7% of suspending agent, and the balance of mineral oil or methyl oleate. The oil suspension is prepared by taking isaria fumosorosea and beta-cypermethrin as active ingredients, and is mainly used for preventing pests of coptotermes formosanus, plutella xylostella and the like, the complex insecticide has excellent compatibility, the insecticide toxicity of single agents can be obviously enhanced, the complex insecticide can kill various pests, and has the advantages of being synergistic, good in permeability, strong in adhesion, evaporation-resistant, environment-friendly, long in lasting effect period and the like.

Owner:SOUTH CHINA AGRI UNIV

Styela plicata-derived fungus and application thereof

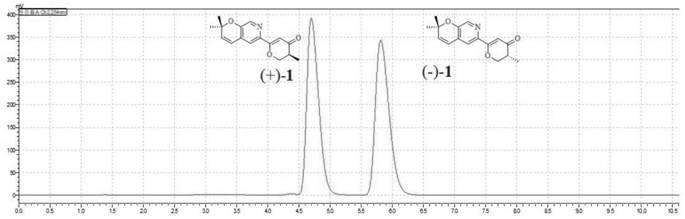

ActiveCN112646729ASignificant anti-acetylcholinesterase activityNo worriesFungiNervous disorderBiotechnologyDisease

The invention belongs to the technical field of fungus biological medicine application, and particularly relates to a styela plicata-derived fungus and application thereof. The styela plicata-derived fungus, Beauveria felina fungus strain SYSU-MS7908, can be metabolized to synthesize a pyridine-containing novel skeleton meroterpenoid compound--amphichoterpenoid. Experimental verification shows that the compound has remarkable acetylcholinesterase activity resistance, and has a good development prospect in the preparation of medicines for preventing and / or treating acetylcholinesterase-mediated diseases; and modern microbial fermentation engineering technology is used for reproduction, and worries about raw materials are avoided. Meanwhile, the invention has the advantages that ecological balance is not destroyed, industrialization is easy to achieve, etc. The styela plicata-derived fungus is a renewable drug resource with development prospects, and abundant raw materials are provided for research and development of marine microbial products and marine microbial drugs.

Owner:SUN YAT SEN UNIV

Entomopathogenic Fungi and Uses Thereof

Owner:GREENTIDE

Mixed insecticide of paecilomyces fumosa-roseus brown et smith and avermectin

InactiveCN101317581ANo pollution in the processDelay drug resistanceBiocideArthropodicidesIsaria fumosoroseaAbamectin

The invention discloses an insecticide compounded by paecilomyces fumosoroseus and avermectin, which consists of a main agent and an auxiliary agent. According to the mass percentage, the main agent occupies 20-60% and the auxiliary agent occupies 40-80%; the main agent is the mixture of the paecilomyces fumosoroseus and the avermectin with the mass proportion of 100:0.1-0.5; the auxiliary agent is stabilizer, assisting agent and filling material. The compounded insecticide of the invention can be processed into wettable powder, suspension agent or oil agent; according to long-term infection biological study and indoor biological testing, the paecilomyces fumosoroseus has extremely strong infection insecticidal effects on a plurality of pests, especially for the pests of piercing-sucking mouthpart. The compounded insecticide of the invention has excellent control effects on the pests such as diamondback moth, aphid, whitefly, and the like, and has a certain control effect on mites.

Owner:SOUTH CHINA AGRI UNIV

Application of biocontrol strain FZ01-GFP capable of expressing GFP to targeted pest epidemiology

InactiveCN105132297AStrong specificityHigh sensitivityFungiMicrobiological testing/measurementBiotechnologyIsaria fumosorosea

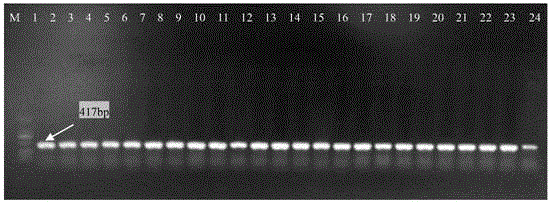

The invention discloses application of a biocontrol bacterium paecilomyces fumosoroseus strain capable of expressing green fluorescent protein (GFP) to the targeted pest epidemiology. According to the biocontrol bacterium, through protoplast transformation technology, an expression plasmid vector pCT74-GFP with green fluorescent protein marks is converted into a genome of the paecilomyces fumosoroseus strain FZ01, and the biocontrol strain FZ01-GFP capable of expressing the GFP is obtained. The bacterial strain is used for researches on the targeted pest epidemiology, the biocontrol strain FZ01-GFP is released, collection is conducted at a fixed time and location, the number of targeted pests is recorded, sick pest samples are collected, PCR molecular detection identification is conducted on the sick pest samples through a pair of specific primers of the plasmid vector pCT74-GFP, data are analyzed, and the plasmid vector pCT74-GFP and tendency of targeted pest infection of the biocontrol strain FZ01-GFP are determined; the problem that it is difficult to identify the pathogenesis of the targeted pests in the researches on the biocontrol bacterium epidemiology in the prior art is solved; the application has the advantages of being simple in step, convenient to operate and capable of effectively monitoring and objectively reflecting the targeted pest occurrence and development rules of the biocontrol bacterium paecilomyces fumosoroseus strain and the like.

Owner:INST OF PLANT PROTECTION FAAS

Isaria fumosorosea

InactiveCN103756913AGood control effectLow lethal concentrationFungiMicroorganism based processesBiotechnologySporeling

The invention discloses an isaria fumosorosea. The isaria fumosorosea is a wild strain obtained from a coptotermes body naturally soaked in entomogenous fungi in a separating manner from the national nature conservation area of Jiulianshan in Jiangxi province. The wild strain is grafted back to the coptotermes body so as to be rejuvenated, thereby obtaining the isaria fumosorosea. A purification strain is obtained by performing monospore separation on the isaria fumosorosea. The purification strain is an isaria fumosorosea SCAU-IFCF02 which is collected in CCTCC (China Center for Type Culture Collection) on November 1st, 2013 and has the collection number of CCTCCNO:M2013526. According to a long-term infection biology study and indoor bioassay, the isaria fumosorosea has very strong application potential for the biological prevention and control of diamond black moths and coptotermes.

Owner:SOUTH CHINA AGRI UNIV

Compound continuous-cropping-resistant biological fungicide special for ginsengs/Chinese yams/peanuts and preparation method thereof

ActiveCN106431609AIncrease profitEnhance resilienceExcrement fertilisersFertilizer mixturesContinuous croppingDioscorea polystachya

The invention provides a compound continuous-cropping-resistant biological fungicide special for ginsengs / Chinese yams / peanuts and a preparation method thereof. The compound continuous-cropping-resistant biological fungicide is prepared from sheep manure, short and small bacillus pumilus, bacillus amyloliquefaciens liquid, bacillus sphaericus liquid, bacillus licheniformis liquid, paecilomyces fumosoroseus liquid, penicillium oxalicum liquid, streptomyces hygroscopicus liquid, streptomyces griseochromogenes liquid and an auxiliary matrix. The preparation method comprises the steps that 1, the bacterial liquids are prepared respectively and are mixed evenly; 2, main and auxiliary matrixes are evenly mixed, and then drying is performed under the pressure of 30-50 DEG C. The biological fungicide is resistant to continuous cropping, fixes nitrogen, dissolves phosphorus, releases potassium, absorbs moisture, keeps soil humidity, promotes decomposition of soil organic matter, is bacteriostatic and insect-resistant, improves micropopulation in soil, improves the functions of a soil structure, does not pollute the environment and is free of toxicity and residues and safe to human.

Owner:ANSHAN HERUI BIOTECH

Diamondback moth peptidoglycan recognition protein, preparation method and application thereof

The present invention discloses diamondback moth peptidoglycan recognition protein, a preparation method and an application thereof, wherein the nucleotide sequence of the diamondback moth peptidoglycan recognition protein gene is represented by SEQIDNO:1-2, and semi-quantitative RT-PCR is adopted to detect temporal and spatial expression of diamondback moth PGRP-S1 in the body. According to the present invention, isaria fumosorosea is adopted to treat diamondback moth larva, quantitative RT-PCR is adopted to detect an immune recognition effect of the diamondback moth PGRP-SA gene on fungi paecilomyces fumosoroseus isaria, and the PGRP-S1 is the innate immune recognition receptor of diamondback moth, activates innate immunity, regulates antibacterial peptide expression, and provides a new target for prevention and control of diamondback moth from immunology.

Owner:SOUTH CHINA AGRI UNIV

Composite bacterial powder, composite microbial agent thereof, and preparation method and application of composite microbial agent

InactiveCN111518707AExcellent performance indexMeet production requirementsBiocideFungiBiotechnologyMicrobial agent

The invention provides a composite bacterial powder, a composite microbial agent thereof and a preparation method and application of the composite microbial agent. The composite bacterial powder is formed by compounding spore powder of trichoderma harzianum and spore powder of isaria fumosorosea. Isaria fumosorosea and trichoderma harzianum are combined for use, diseases and insect pests such as aphids, cabbage caterpillars, whiteflies, tomato leaf mold, pepper phytophthora blight and cucumber fusarium wilt can be effectively prevented and controlled, and the method has the advantages of beingstable in effect, safe, efficient and the like. The agricultural composite microbial agent can effectively reduce the use amount of pesticides, reduce pesticide residues and delay the pesticide resistance of pests, and has the potential of replacing part of chemical pesticides.

Owner:SHANDONG BEE LAN BIOTECHNOLOGY CO LTD

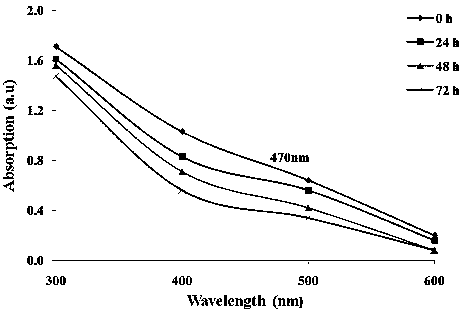

Zero-valent iron-isaria fumosorosea nanoparticles, preparation method and application thereof

InactiveCN109548795ANo pollution in the processProlong survival timeBiocideMaterial nanotechnologySporeNanoparticle

The invention discloses zero-valent iron-isaria fumosorosea nanoparticles, a preparation method and an application thereof. The method comprises the following steps: inoculating a fermentation culturebroth with a spore suspension of isaria fumosorosea, and performing culturing for 48-72 hours; collecting the mycelia and putting the mycelia into sterilized distilled water and performing culturingfor 48-72 hours; collecting the conidium filtrate, adding zero-valent iron into the conidium filtrate, performing incubating for 24-96 hours to obtain the zero-valent iron-isaria fumosorosea nanoparticles. The preparation method creatively adopts the combination of zero-valent iron and isaria fumosorosea to prepare high-efficient green environmental-friendly nano-particle biological pesticide withhigh purity, strong activity, simplicity and rapidness, produced significant synergistic effects, more efficiency, longer survival time of spores in the environment, more stability, more environmental friendliness and other characteristics, has a good control effect on whitefly pests, has a very strong application potential in the biological control of whitefly pests.

Owner:SOUTH CHINA AGRI UNIV

Paecilomyces fumosoroseus oil, preparation method of paecilomyces fumosoroseus oil and insecticide

The invention provides paecilomyces fumosoroseus oil which comprises the following components in percentage by mass: 30-50% of paecilomyces fumosoroseus, 15-40% of a solvent, 2-20% of an emulsifier, 2-40% of an adsorbent, 1-10% of an ultraviolet absorbent, 1-10% of an antioxidant and 2-20% of a dispersing agent. The paecilomyces fumosoroseus oil prepared by the invention is respectively stored in environments at the temperature of 4 DEG C and 25 DEG C, the germination rate is determined every six months, and the germination rate within 24 months is respectively 90.4% and 82.9%. The paecilomyces fumosoroseus oil prepared by the invention has an insect dropping rate of 69.1-86.0%.

Owner:INST OF MICROBIOLOGY JIANGXI ACADEMY OF SCI +1

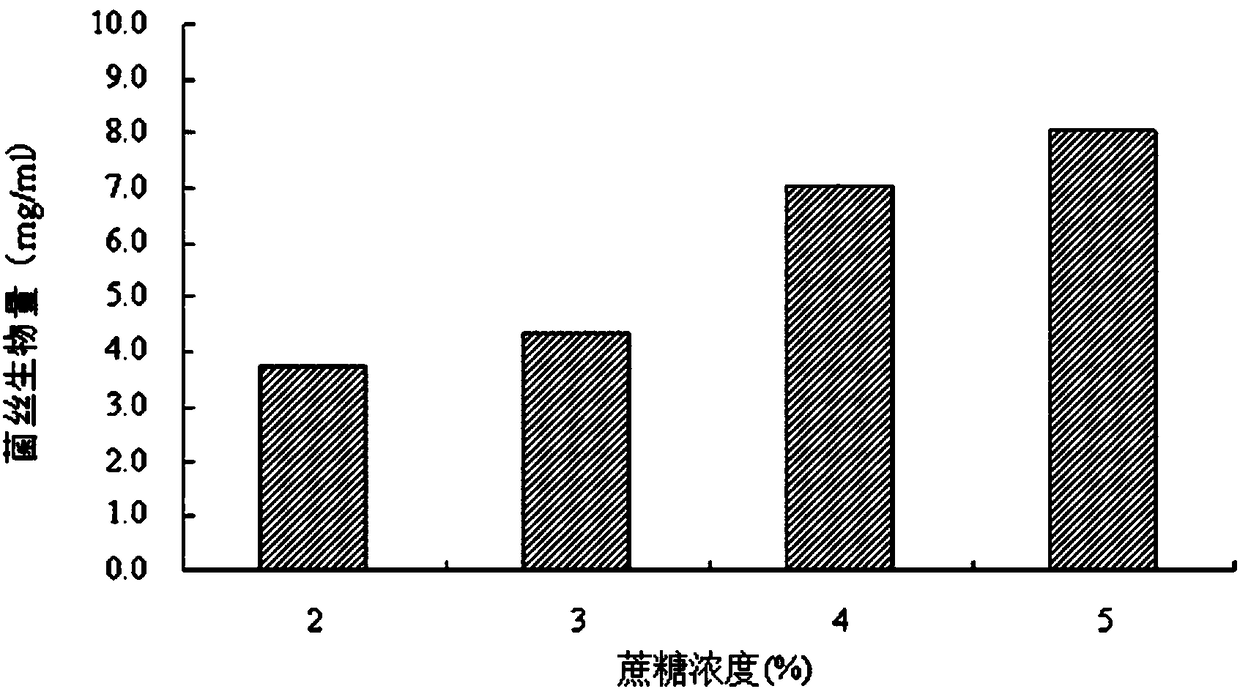

Isaria fumosorosea IF-1106 bacterial strain liquid fermentation optimizing process

The invention relates to an isaria fumosorosea IF-1106 bacterial strain liquid fermentation optimizing process. The fermentation steps are as follows: 1, taking out an isaria fumosorosea IF-1106 bacterial strain and activating the isaria fumosorosea IF-1106 bacterial strain; inoculating a PDA culture medium with the isaria fumosorosea IF-1106 bacterial strain and performing culturing in a 25-DEG Cmould incubator; 2, ensuring that each 50ml of liquid culture medium contains 0.5g of MgSO4.7H2O, 0.5g of KCl, 1.0g of KH2PO4, 0.1g of FeSO4.7H2O, crane sugar and peptone, wherein the concentration of the crane sugar is 4.3 percent, and the concentration of the peptone is 0.7 percent; 3, culturing the bacterial strain for 10 days, and adding sterile water containing 0.1 percent of tween 80 to prepare spore suspension solutions, wherein the concentration is adjusted to be 1*10<7> spores / ml; 4, adding a liquid culture medium into a culture dish and carrying out sterilization, inoculating the spore suspension solutions under a sterile condition according to the inoculation quantity of 15 percent by volume ratio, and carrying out fermentation and culturing for 6 to 7 days under whole dark conditions that a temperature is 20 to 30 DEG C and the rotation speed of a shaking table is 150r / min. According to the isaria fumosorosea IF-1106 bacterial strain liquid fermentation optimizing processdisclosed by the invention, a foundation is laid for large-scale production and industrialized application of the isaria fumosorosea IF-1106 bacterial strain, and the isaria fumosorosea IF-1106 bacterial strain liquid fermentation optimizing process has good application prospects.

Owner:LULIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com