Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

63 results about "Creeping wave" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

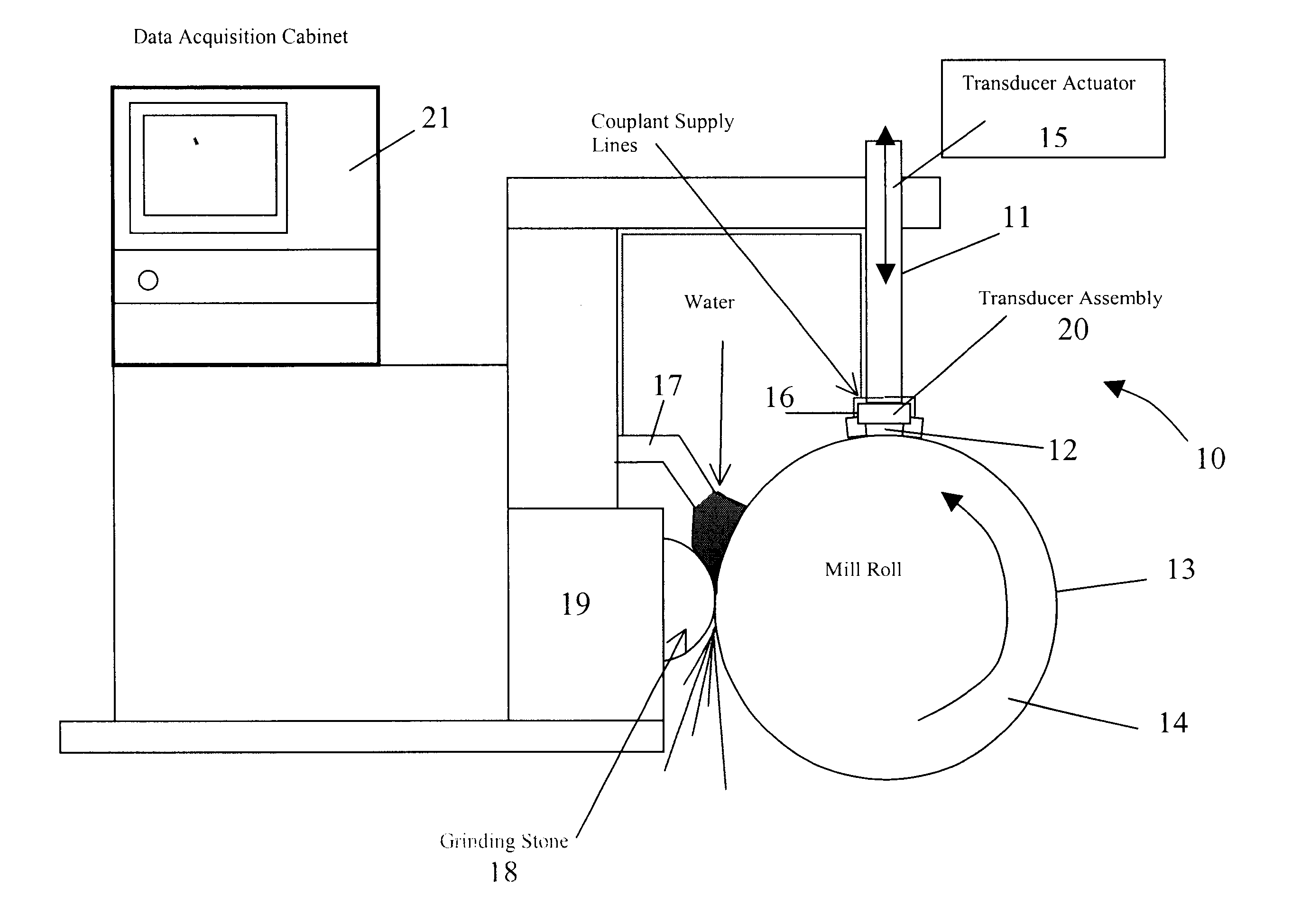

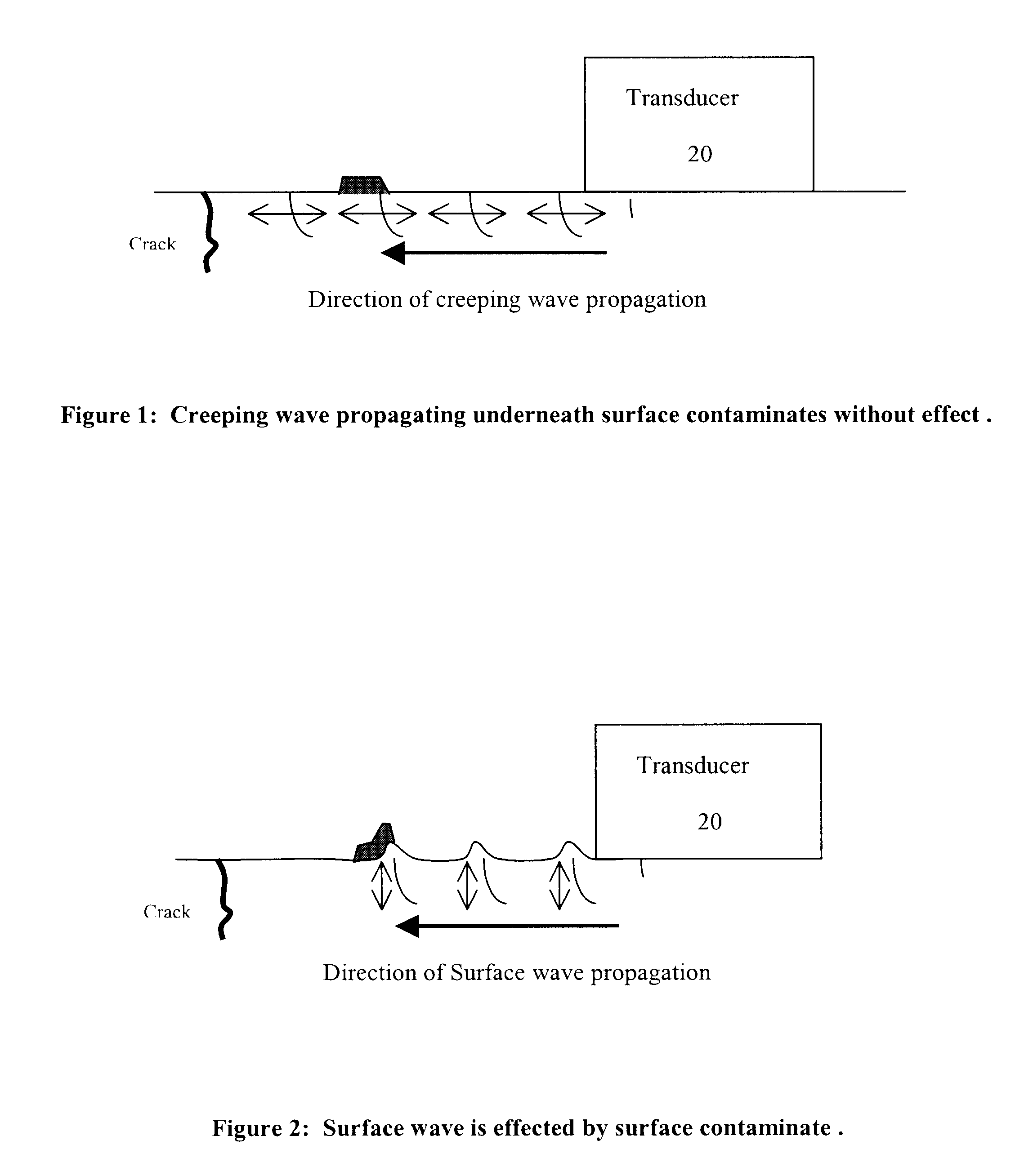

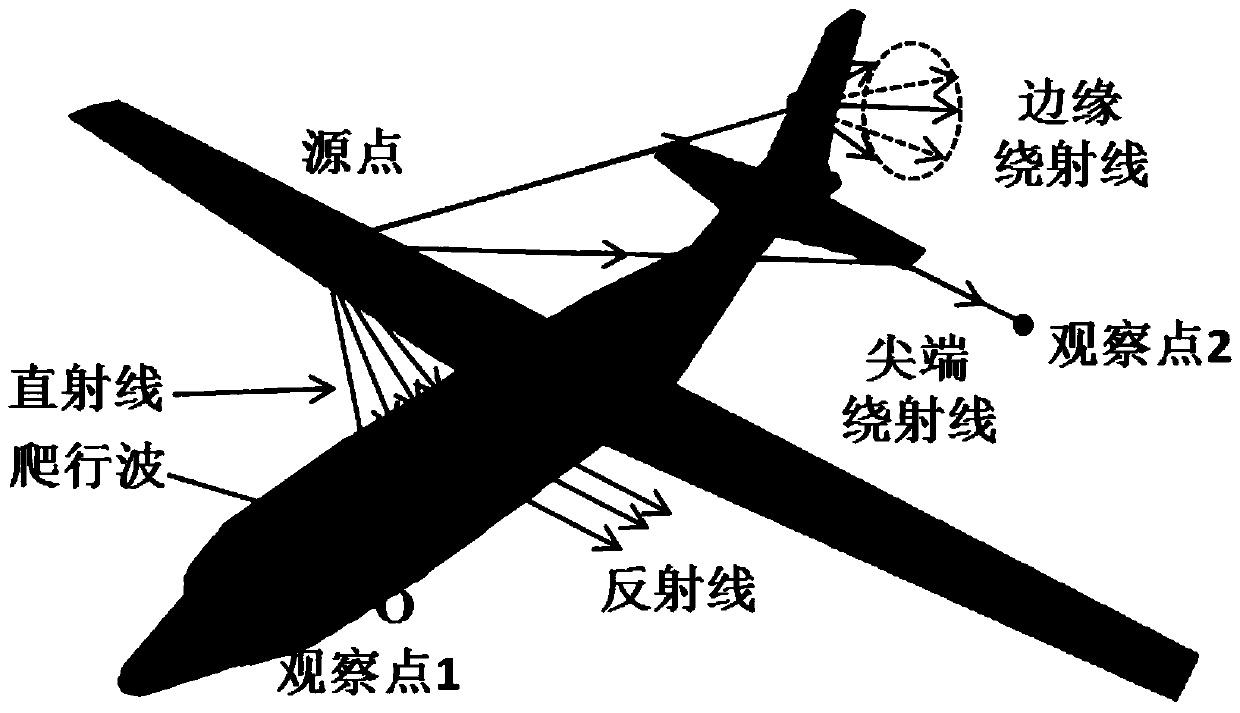

According to the principle of diffraction, when a wave front passes an obstruction, it spreads out into the shadowed space. A creeping wave in electromagnetism or acoustics is the wave that is diffracted around the shadowed surface of a smooth body such as a sphere.

Method for determining the sound velocity in a basic material, particularly for measuring the thickness of a wall

InactiveUS7415880B2Accurate informationAvoid mistakesAnalysing fluids using sonic/ultrasonic/infrasonic wavesAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping waveCoupling

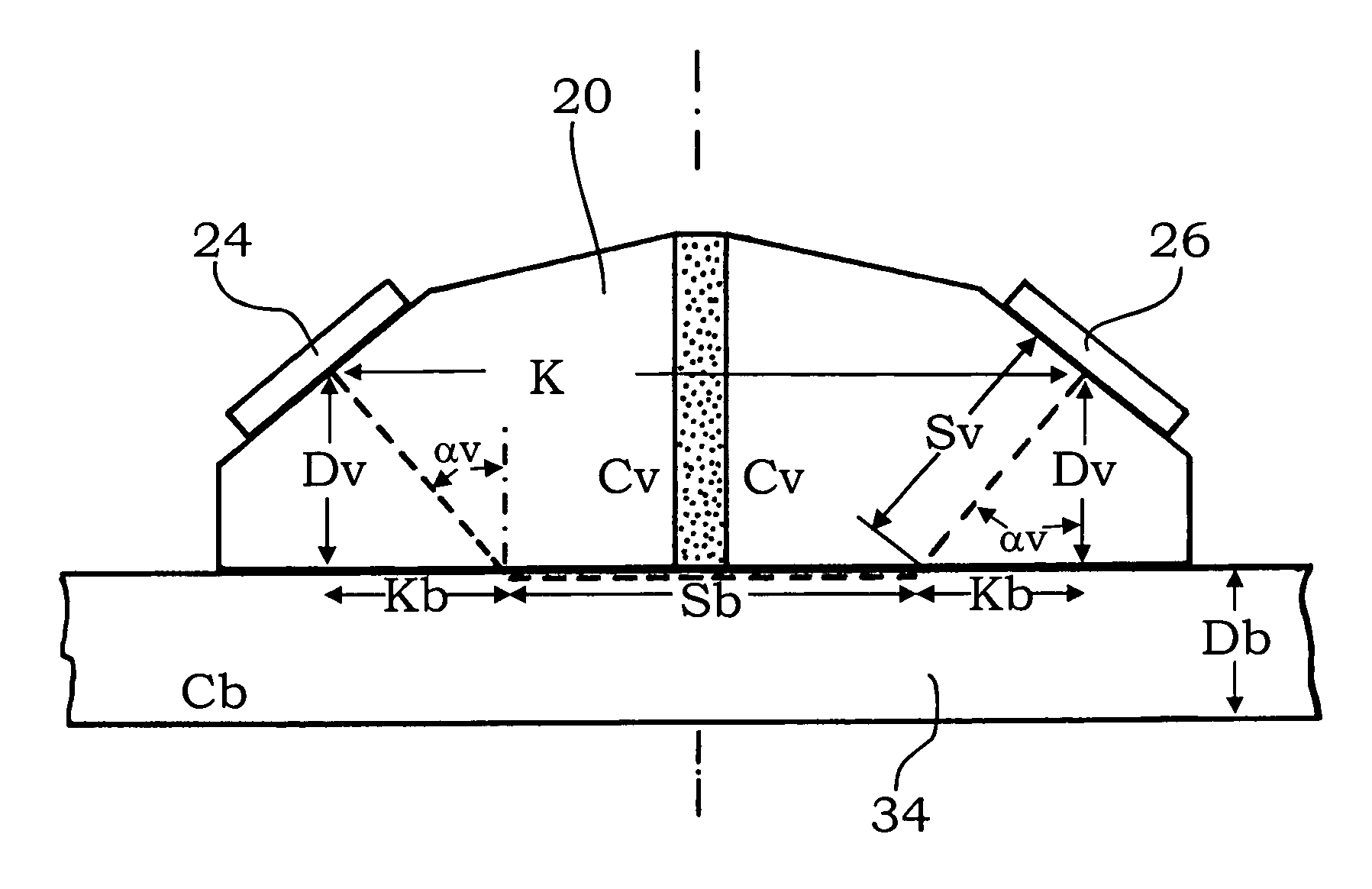

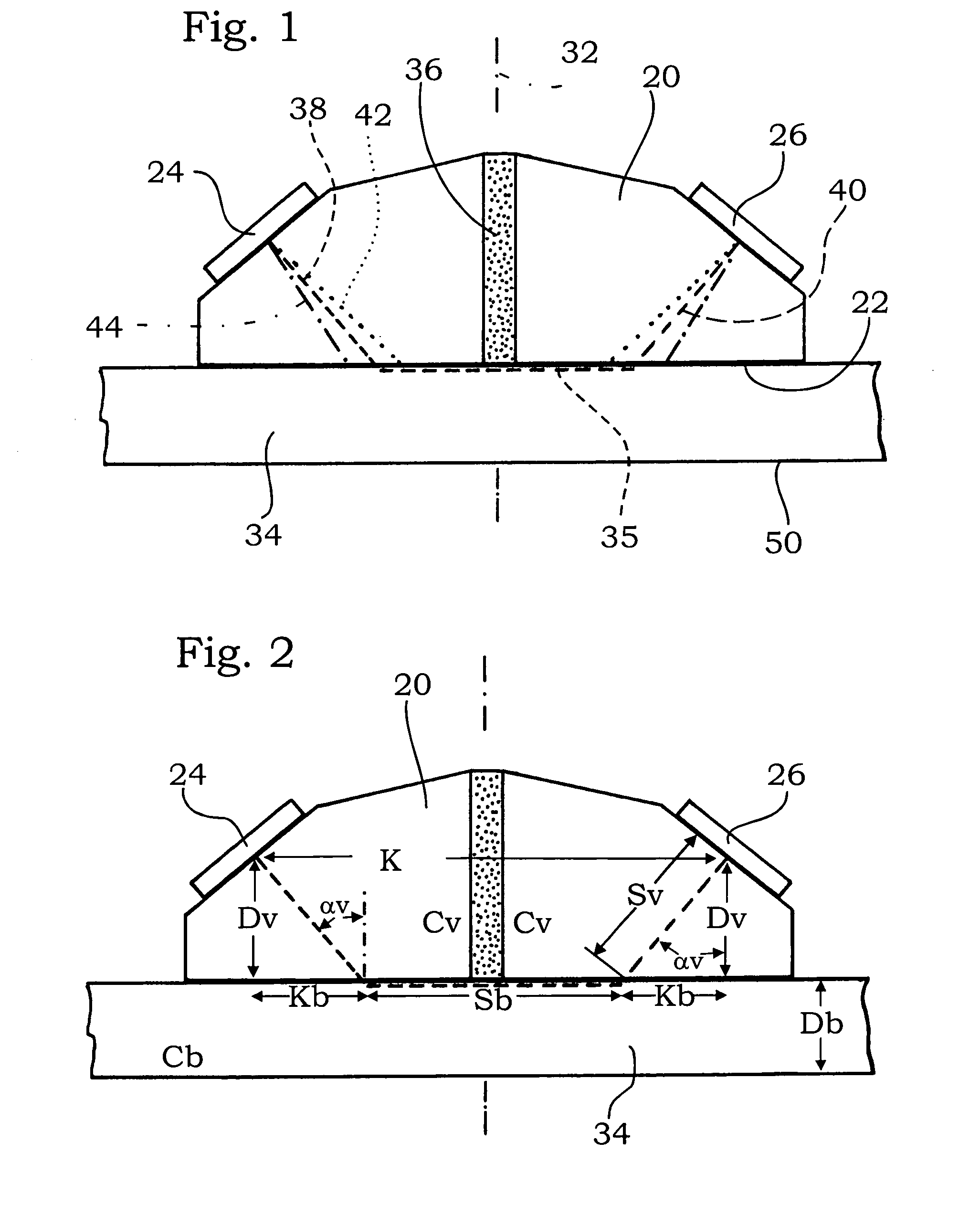

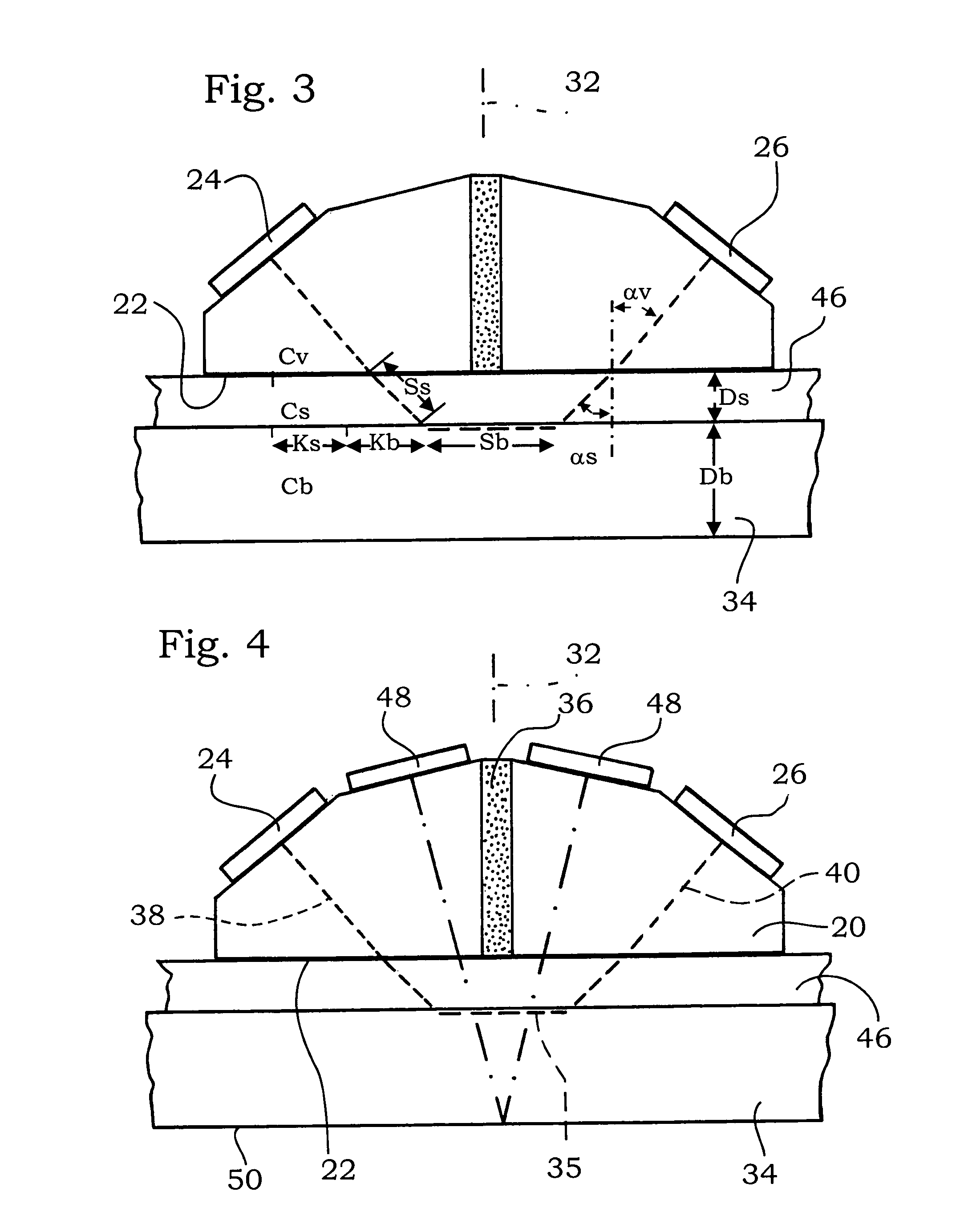

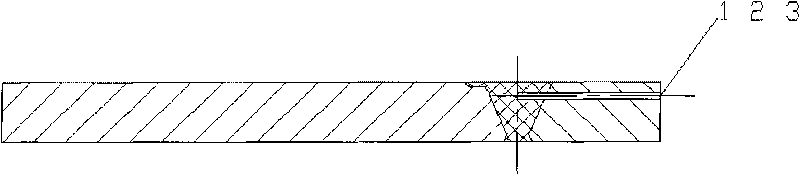

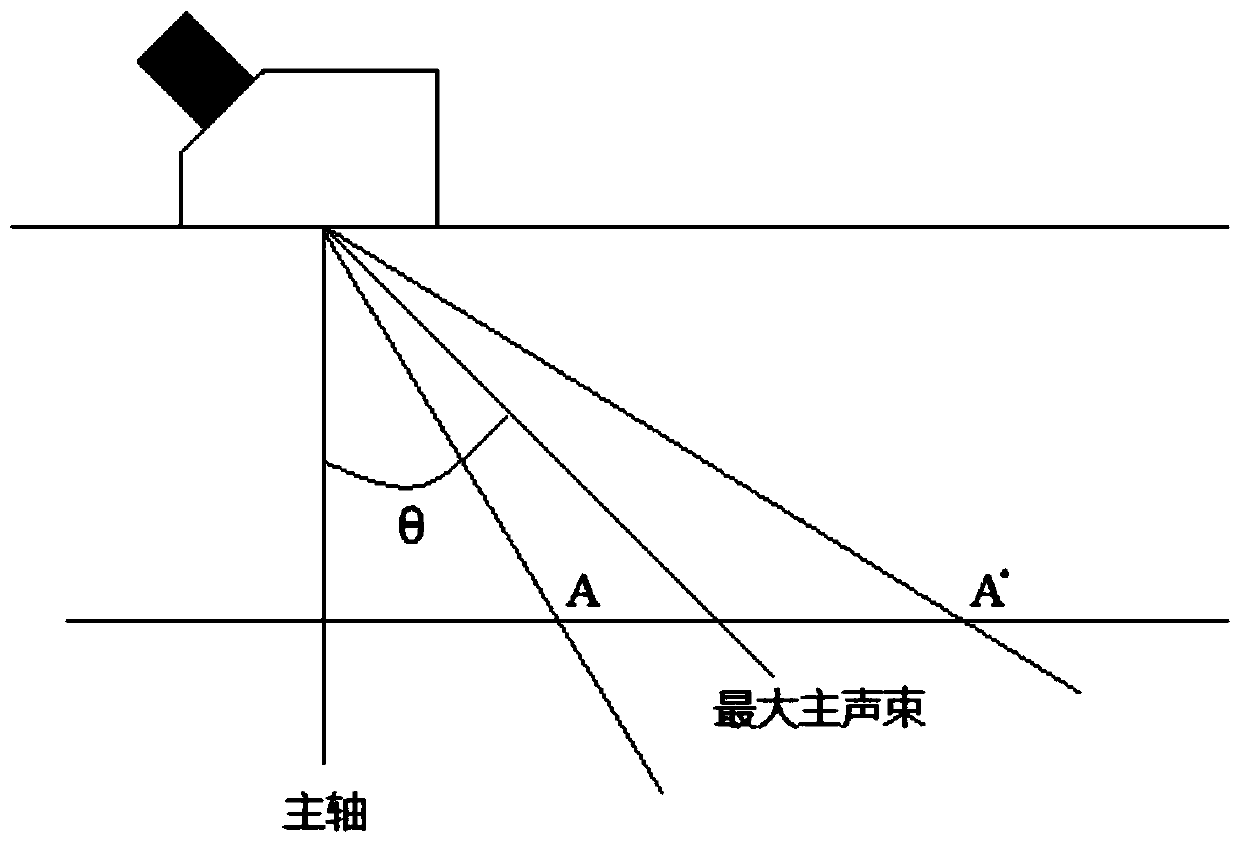

Disclosed is a method for determining the sound velocity (Cb) in a basic material, in which an ultrasonic probe having a transmitting probe, a receiver transducer, and a forward member is used. The forward member is provided with a coupling surface that couples the probe to the basic material, and has a sound velocity (Cv). The transmitting probe and the receiver transducer are aligned in an oblique manner from each other and from the coupling surface such that a main transmission direction of the transmitting probe and a main receiving direction of the receiver transducer intersect below the coupling surface. The centers of the transmitting probe and the receiver transducer are located at a distance K from each other and are located at a distance Dv from the coupling surface. According to the inventive method, the transmitting probe generates an ultrasonic pulse which runs through the forward member into the basic material, where the ultrasonic pulse creates a creeping wave, a portion of which arrives at the receiver transducer. The shortest sound traveling time (Ttot) is measured and the sound velocity (Cb) within the basic material is determined via the path between the transmitting probe and the receiver transducer, which supplies the shortest total traveling time (Ttot).

Owner:AGFA NDT

Ultrasonic inspection method, ultrasonic inspection device and integrated longitudinal wave, transverse wave and creeping wave ultrasonic angle beam probe

ActiveCN103954687ARealize all-round scanningSolve the problems of flaw detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping waveUltrasonic beam

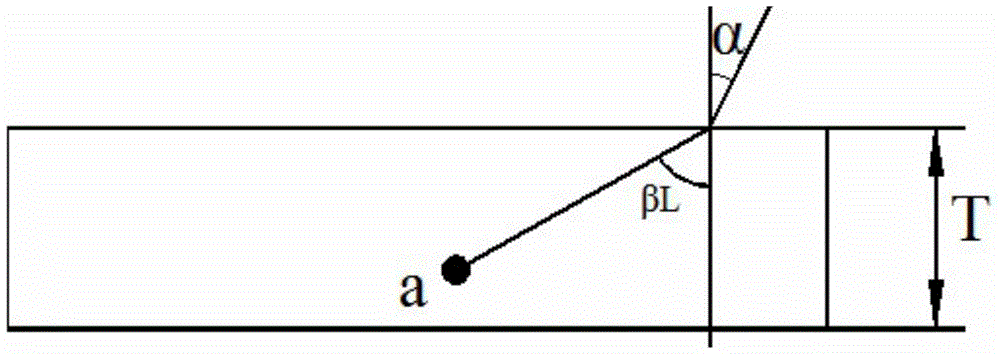

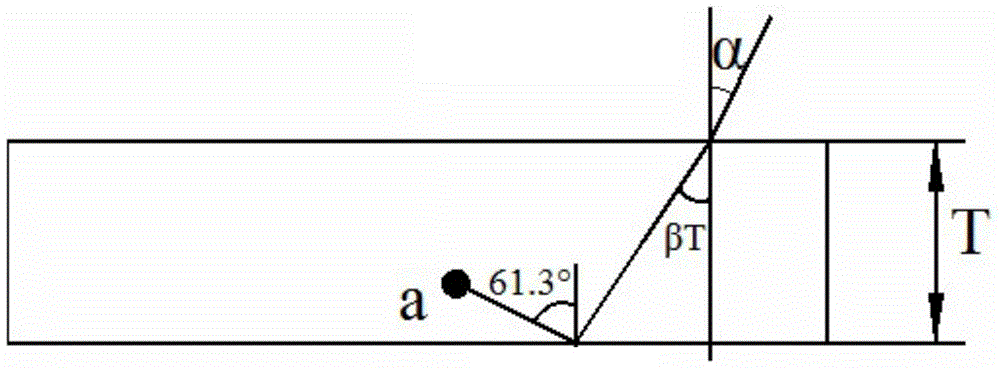

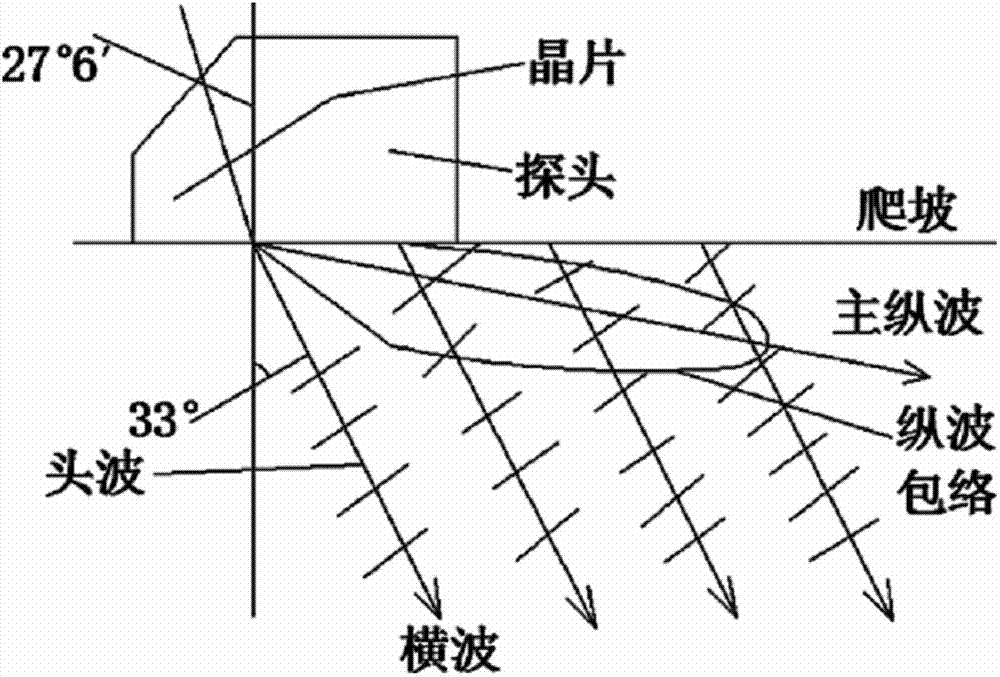

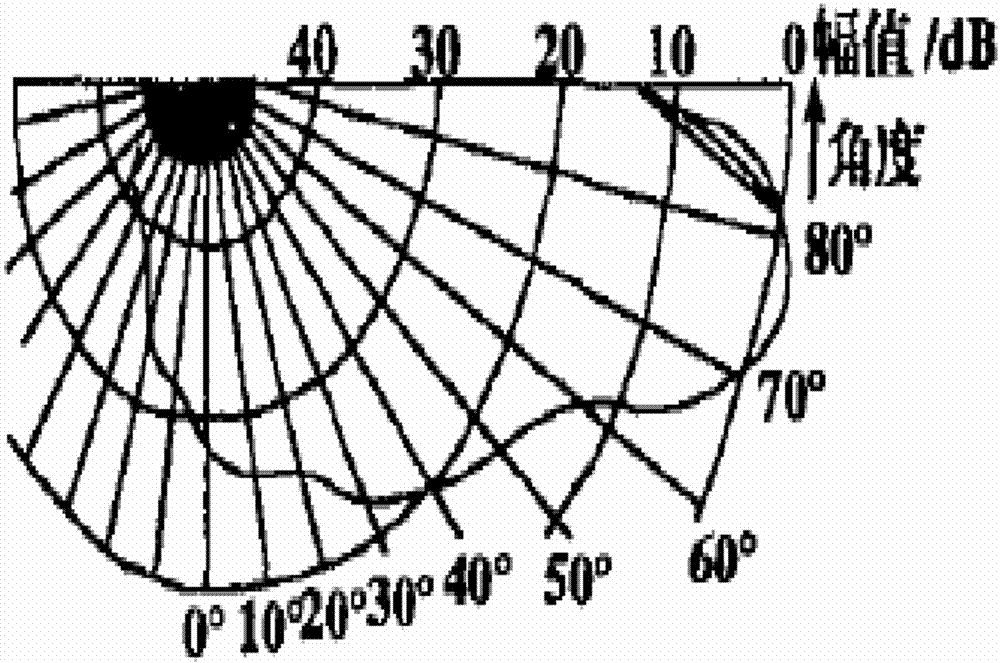

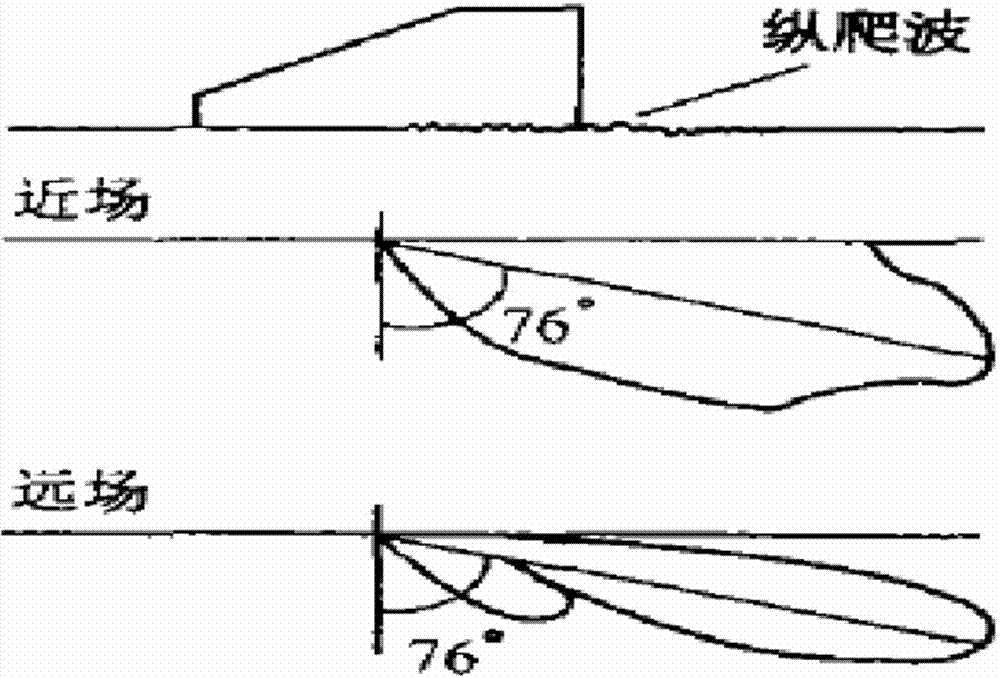

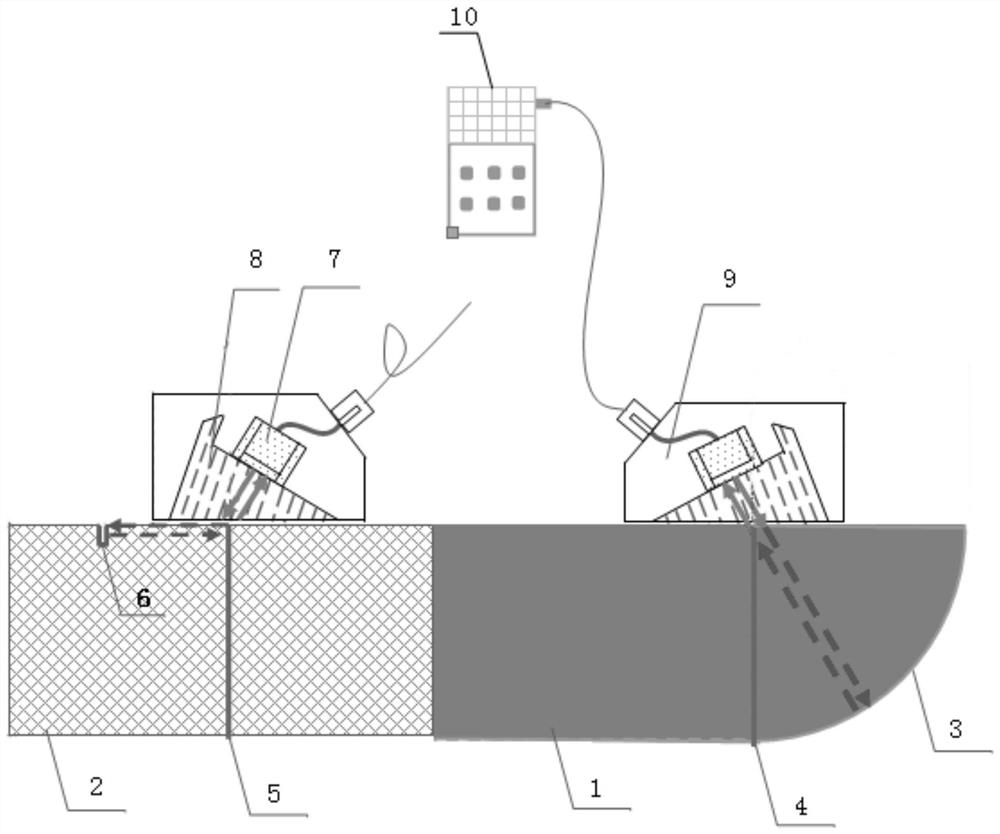

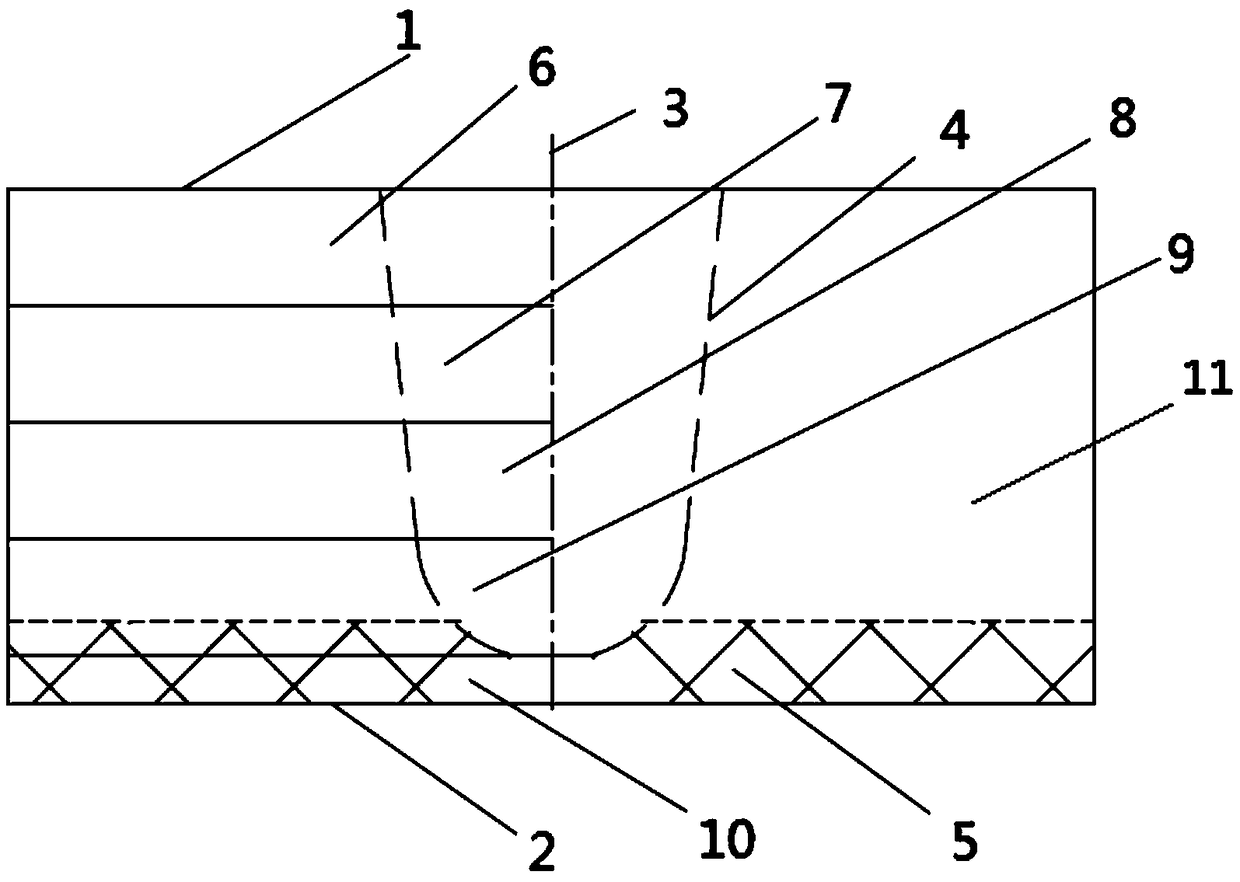

The invention discloses an ultrasonic inspection method, an ultrasonic inspection device and an integrated longitudinal wave, transverse wave and creeping wave ultrasonic angle beam probe. The ultrasonic inspection method comprises the following steps: preparing an ultrasonic angle beam probe with an incident angle of alpha, a longitudinal wave refraction angle of betaL and a transverse wave refraction angle of betaT; adjusting the ultrasonic angle beam probe; arranging the ultrasonic angle beam probe on the outer surface of a workpiece to be detected; inspecting the workpiece to be detected by ultrasonic beams emitted from the ultrasonic angle beam probe; and judging whether the workpiece to be detected has defects and corresponding defect positions according to reflection echo received by the ultrasonic angle beam probe. Omni-directional scanning of a steel weld to be detected is realized, a detection leakage rate is reduced, the inspection efficiency is improved, the inspection cost is lowered, the probe traveling distance is reduced by 40 percent compared with that of a transverse wave angle beam probe, and the inspection accuracy can be improved to be over 90 percent.

Owner:TEWARE

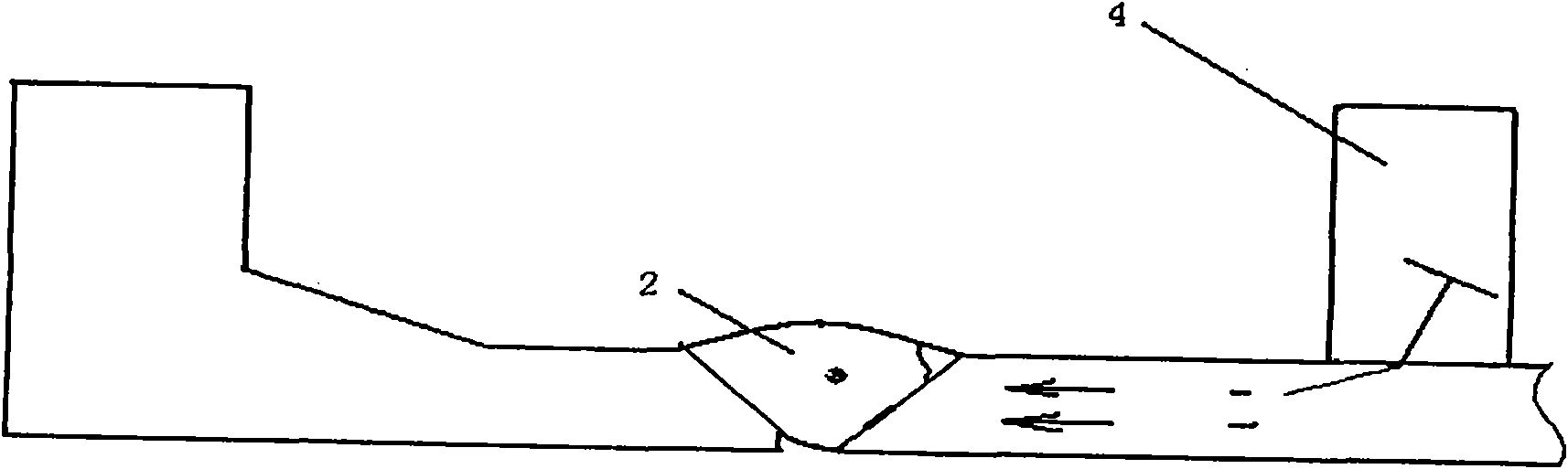

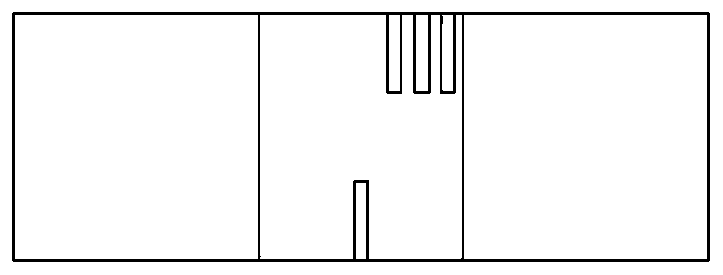

Ultrasonic TOFD technology detection method for butt seam of different thickness plates

ActiveCN102435675AAchieving identifiabilityAchieve positioningAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping waveThick plate

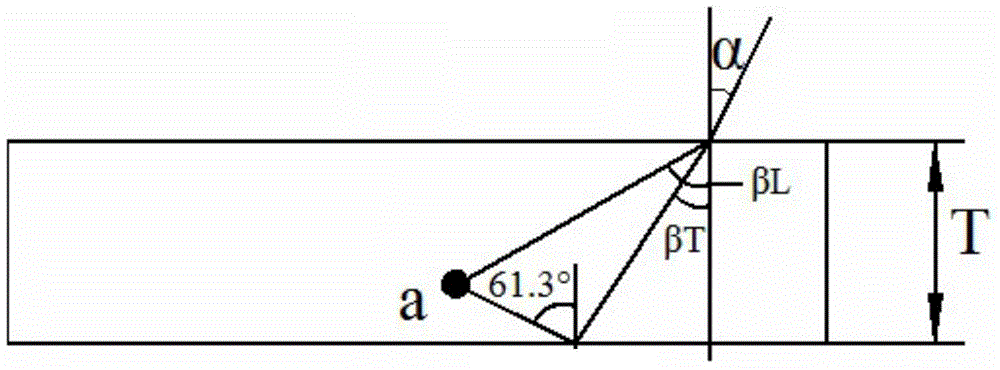

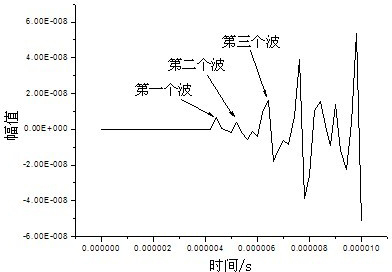

An ultrasonic TOFD technology detection method for butt seam of different thickness plates comprises the following steps of: Step 1, placing an emission probe on the upper plane of a thick plate of a butt seam of different thickness plates and placing a reception probe on the upper plane of a thin plate of the butt seam of different thickness plates; Step 2, determining the probe angle and the probe spacing by means of a method same with that described in the traditional TOFD method; Step 3, allowing the emission probe to firstly generate an incident longitudinal wave with a certain angle in the thick plate; Step 4, ending with bottom echo; and Step 5, calculating the defect depth. The technical effects of the invention are as follows: the novel TOFD technology is adopted to inspect the butt seam part of different thickness plates with a new near surface creeping wave replacing the traditional creeping wave disappeared in the plane so as to realize identification and positioning of defects and widen the range of TOFD inspection objects.

Owner:NANCHANG HANGKONG UNIVERSITY

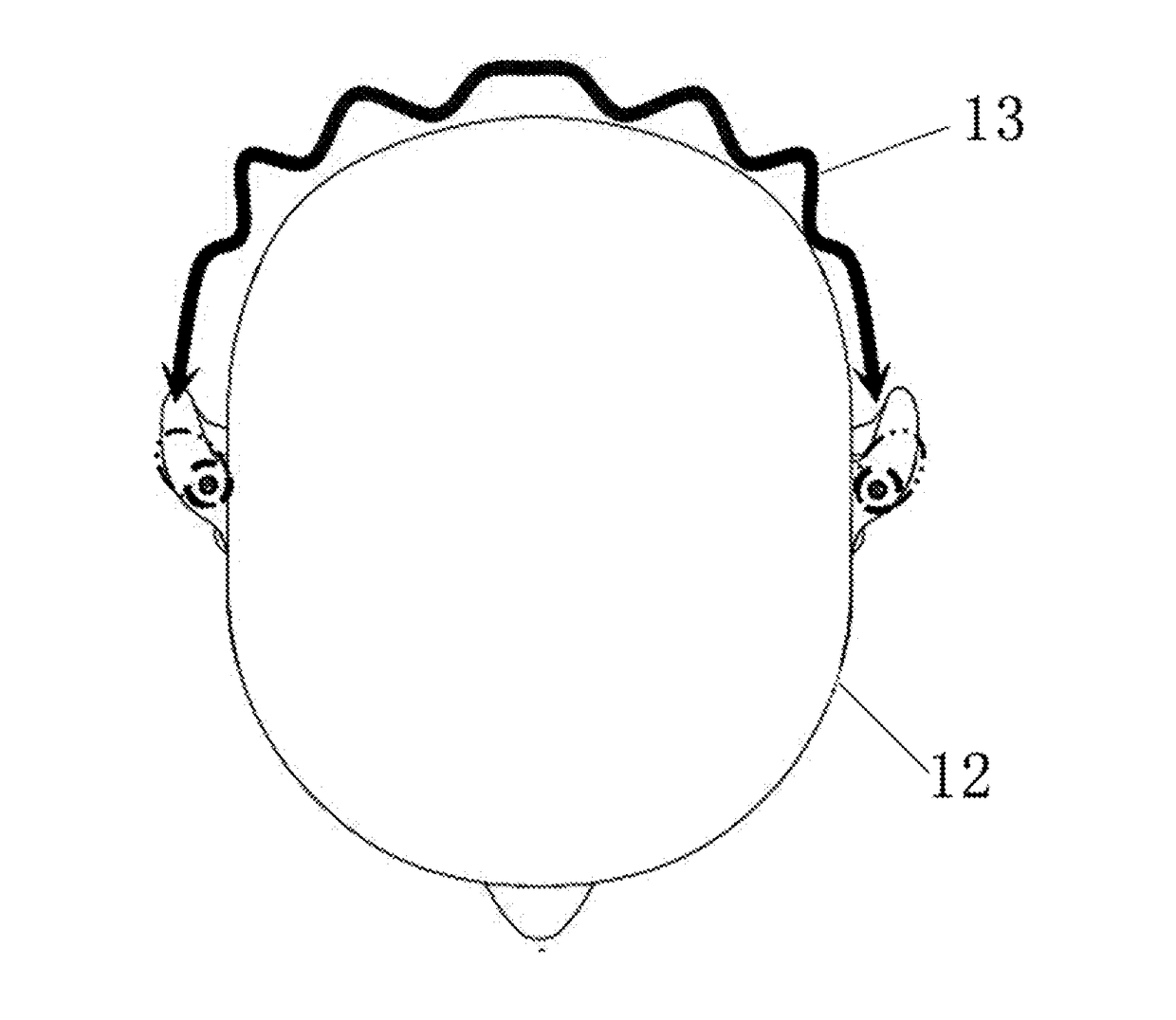

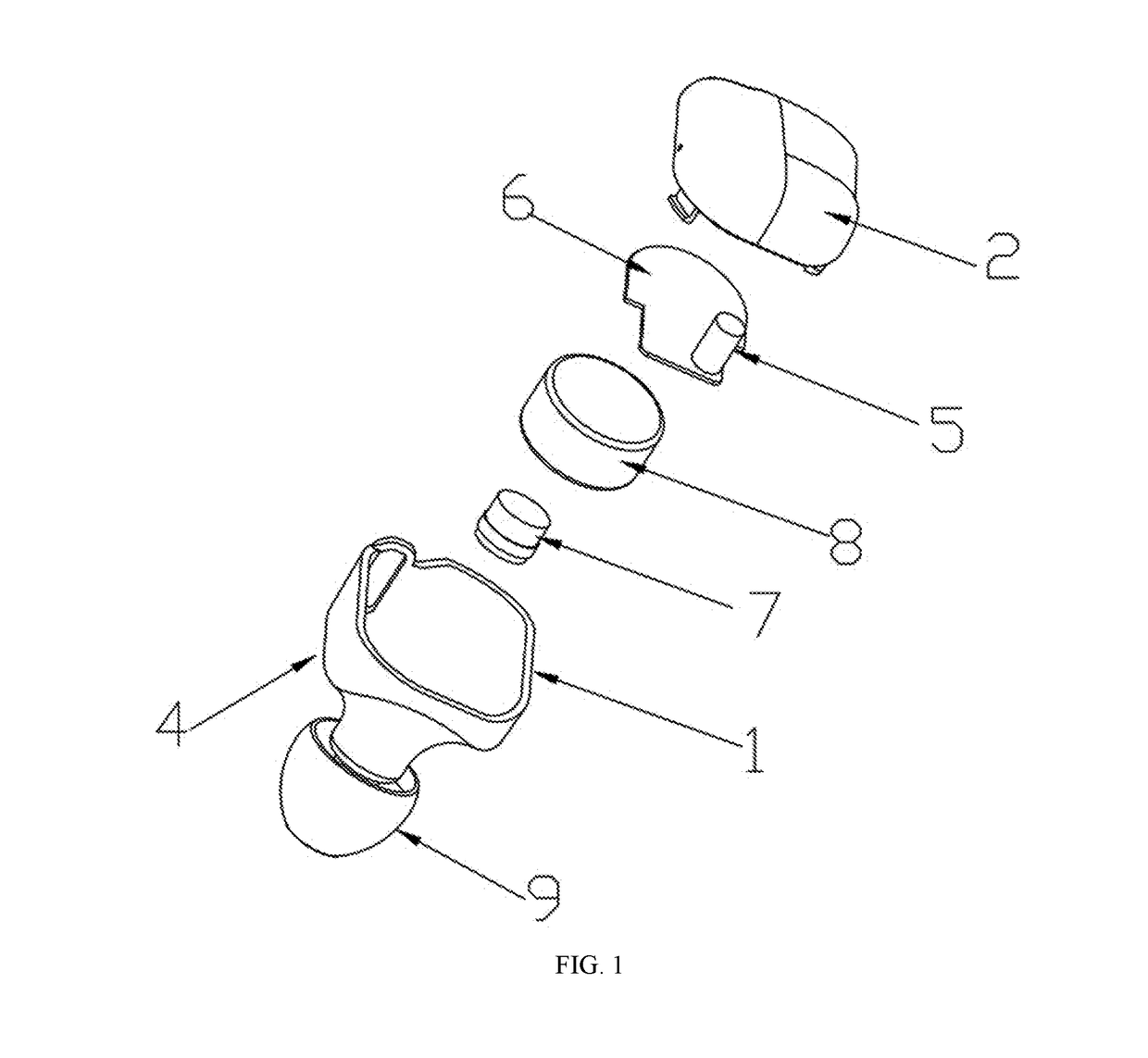

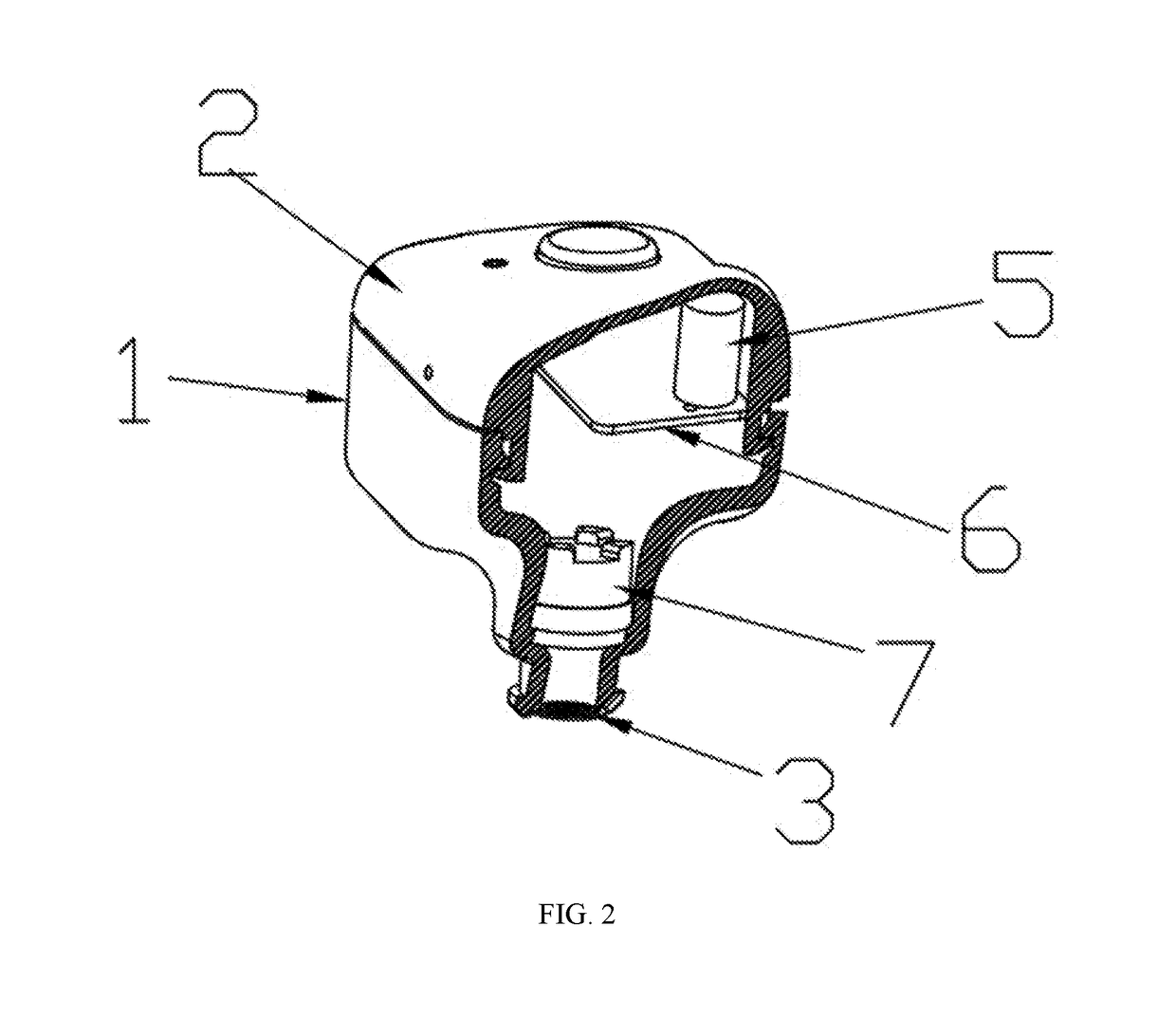

Pure wireless earphones using optimal monopole antennae

InactiveUS20170295420A1Facilitate communicationHeadphones for stereophonic communicationAntenna adaptation in movable bodiesCreeping waveUltrasound attenuation

The present invention relates to a pair of pure wireless earphones using optimal monopole antennae in the technical field of communications, comprising in-ear type earphone housings and RF signal generation devices disposed in the in-ear type earphone housings, wherein positioning stages matched with the shape of auricular concha cavities are at the tops of bottom housings; each RF signal generation device consists of an antenna, a main PCB and a battery; each antenna is used for establishing an RF communication link with an audio source and a secondary earpiece; and a ball is drawn with each antenna as a center point and the outer wall of the corresponding in-ear type earphone housing closest to the antenna as a radius to form a space as an antenna holding area in which the antenna is located, and the radius of the ball is greater than 4 mm. When a distance between each antenna and the skin or tissues of a human body is greater than 4 mm, an optimal coupling can be formed therebetween to possibly create an optimal RF creeping wave communication link, the antenna gain and efficiency attenuation of an in-ear type Bluetooth device is within an acceptable range, and the antenna can also maintain a proper RF communication link between a primary earpiece and a mobile phone.

Owner:FUJIKON INDAL

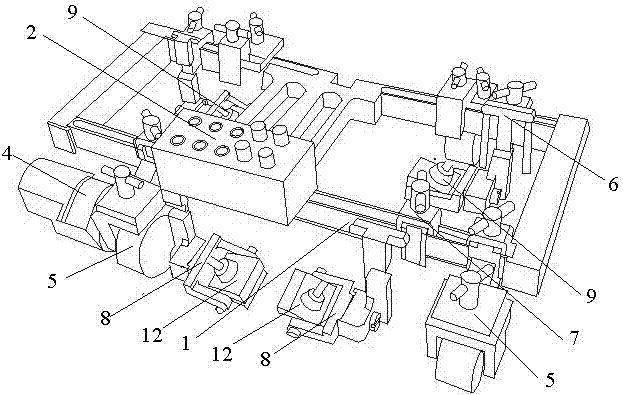

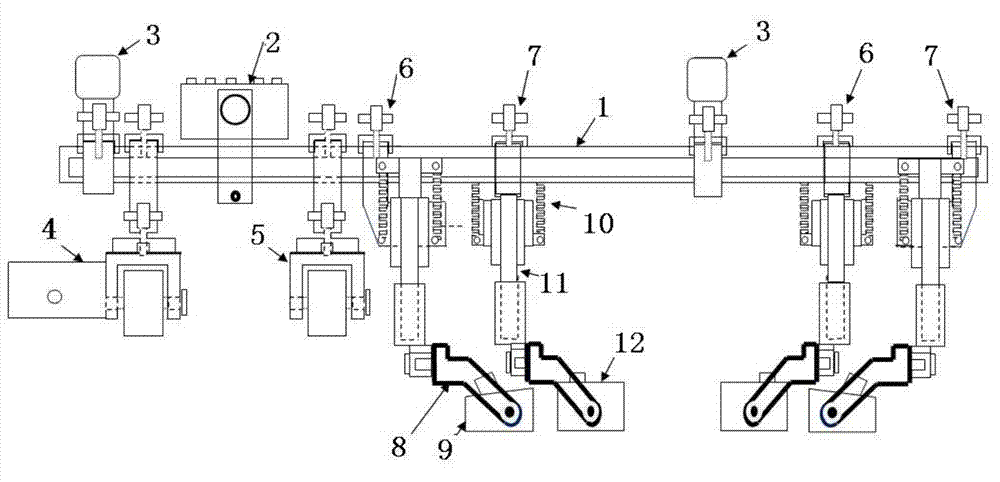

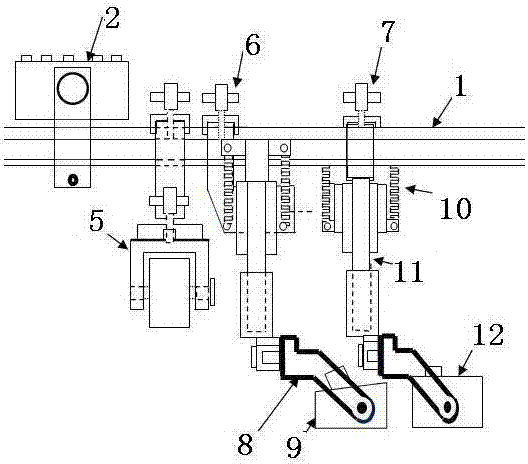

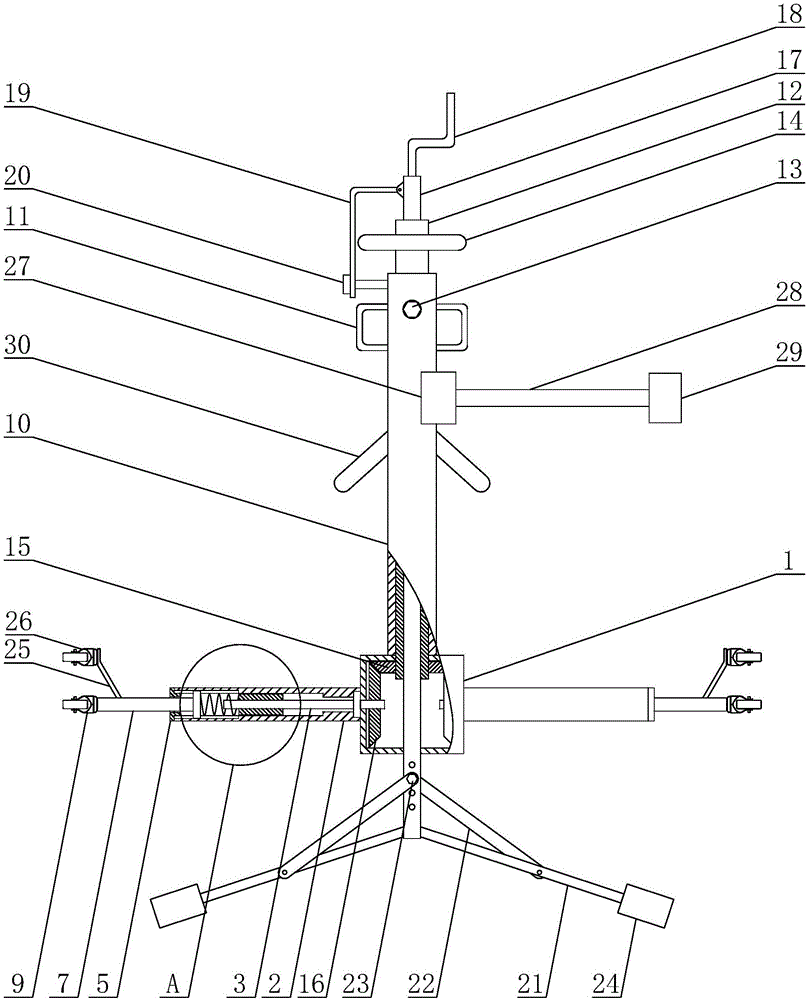

Ultrasonic detection scanner for welding joint of double-channel bent tube

ActiveCN104777223AReduce spacingSuitable for testingAnalysing solids using sonic/ultrasonic/infrasonic wavesButt weldingEngineering

The invention provides a multifunctional double-channel welding line ultrasonic testing scanner. The multifunctional double-channel welding line ultrasonic testing scanner comprises a whole sliding main supporting rod, a filter, a junction box, a handle, a digital encoder, a magnetic wheel set, two corresponding TOFD (Time Of Flight Diffraction) probe systems and two corresponding creeping wave probe supporting systems. The scanner has the advantages that firstly, the distance between transverse magnetic wheels is small to be applicable to adjusting a large-range curvature so that the scanner can be used for detecting an elbow welding line with a small diameter; secondly, after the upper-lower displacement of a probe bracket is increased, the scanner can be applicable to scanning butt welding lines of an elbow and large and small heads; thirdly, a probe wedge block is reduced so as to be more applicable to detecting an elbow welding opening; fourthly, a slope climbing probe is mounted so as to carry out once scanning on the dead zone of a scanning surface and improve the working efficiency.

Owner:中国石油天然气第一建设有限公司

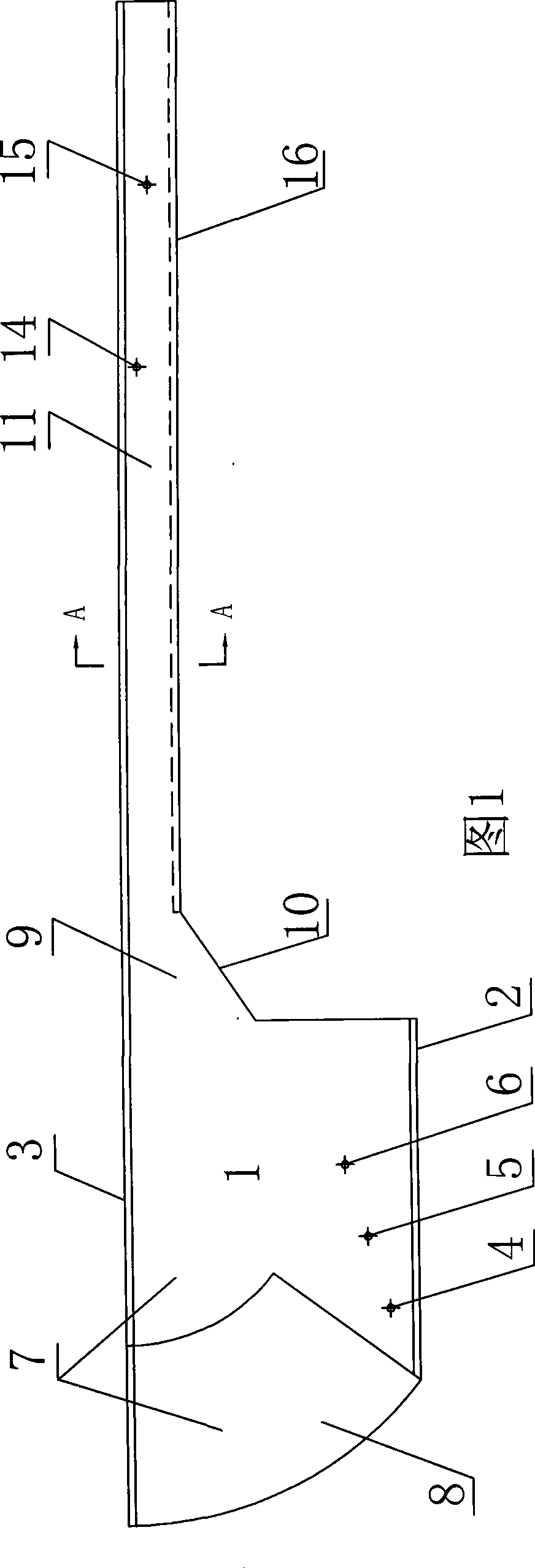

Test block special for butt-jointed seam ultrasonic wave climbing flaw detection of heterogeneity steel minor diameter tube

ActiveCN101435800AThe test parameters are accurateTotal Quality Inspection SolutionMaterial analysis using sonic/ultrasonic/infrasonic wavesCreeping waveTool bit

The invention discloses a special test block for ultrasonic creeping wave flaw detection of butt-jointed welding seams of a special steel small-diameter tube, which comprises a tool body and a tool shank, wherein the tool body comprises a tool bit, a tool back and a tool edge, the tool shank is connected to the tool back side of the tool body through a connecting body, the tool back and the tool edge of the tool body are convex arc surfaces of which the curvatures are the same as that of an outer circle of the small-diameter tube, and the side surface of the tool body is provided with three transverse through holes; the tool bit is formed by concentrically and co-directionally overlapping two concentric sectors of which the diameters have one-time difference, and one radial edge of each of the sectors is coincidently arranged with the tool back; and the thickness of the tool shank is the same as the wall thickness of the small-diameter tube, the upper and lower surfaces of the tool shank are convex and concave arc surfaces of which the curvatures are the same as those of the outer circle and an inner circle of the small-diameter tube respectively, the convex and concave arc surfaces of the tool shank are provided with straight grooves with equal-depth openings respectively, and the side surface of the tool shank is provided with two transverse through holes. The special test block has a simple and practical structure, and can accurately test parameters of a creeping wave probe, check monitoring process parameters, and be matched with a creeping wave flaw detection process to realize the ultrasonic creeping wave flaw detection of the butt-jointed welding seams of the special steel small-diameter tube.

Owner:STATE GRID HENAN ELECTRIC POWER ELECTRIC POWER SCI RES INST +2

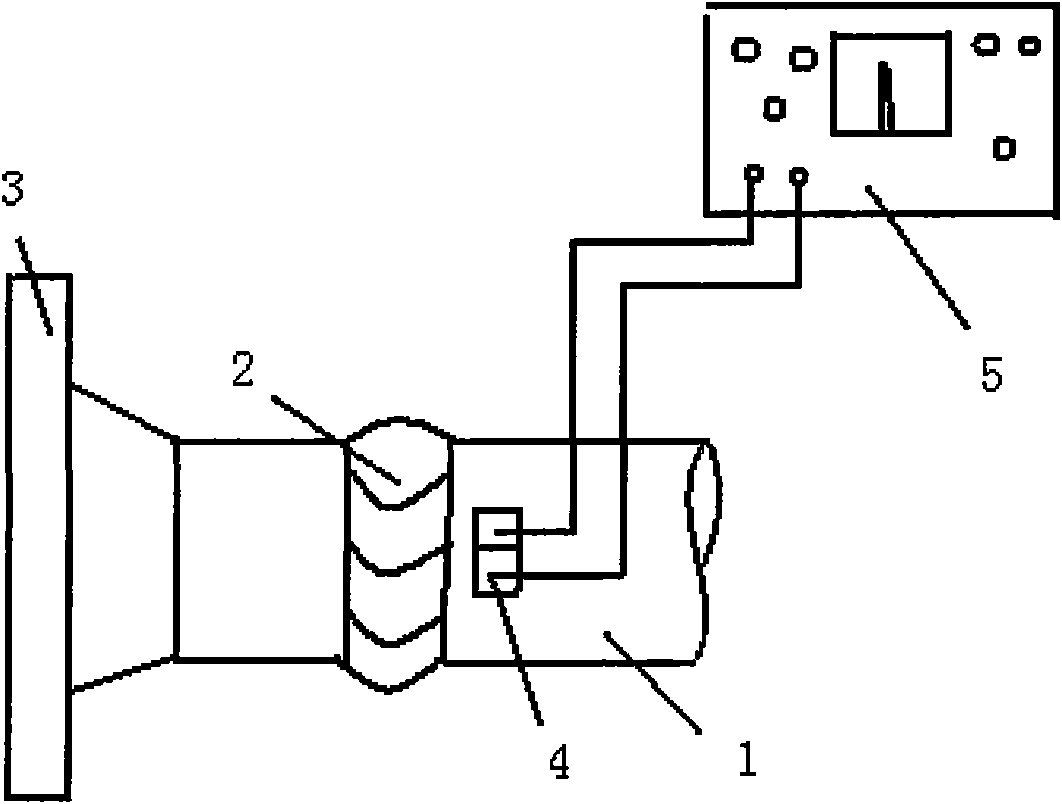

Method for collecting surface wave and creeping wave of ultrasonic flaw detector

InactiveCN101813671AExtended service lifeReduce manufacturing costMaterial analysis using sonic/ultrasonic/infrasonic wavesCreeping waveFront edge

The invention discloses a method for collecting a surface wave and a creeping wave of an ultrasonic flaw detector, relating to an apparatus collecting method. The apparatus comprises an ultrasonic flaw detector which detects the flaw of a work piece by transmitting the ultrasonic wave through a probe head, wherein the detected distance of the flaw of the work piece is the sum of practical distance and corrected distance. The method sequentially comprises the following steps of: preparing a standard test block for correcting the probe head, and the surface wave or the creeping wave probe head for the ultrasonic flaw detector; leading the probe head to move on the test block back and forth till that the ultrasonic flaw detector displays that the surface wave and the creeping wave generate highest reflected wave at the flaw of the standard test block so as to obtain the distance S from an ultrasonic wave-transmitting end in the probe head to the flaw; detecting the distance L from the headmost end of the probe head to the flaw; and subtracting L from S to obtain the correcting distance for correcting ultrasonic flaw detector. The method fills in gap that the existing ultrasonic flaw detector is difficult to correct the front edge of the transverse wave (the surface wave and the creeping wave) probe head and the route of the ultrasonic wave in the probe head.

Owner:符丰

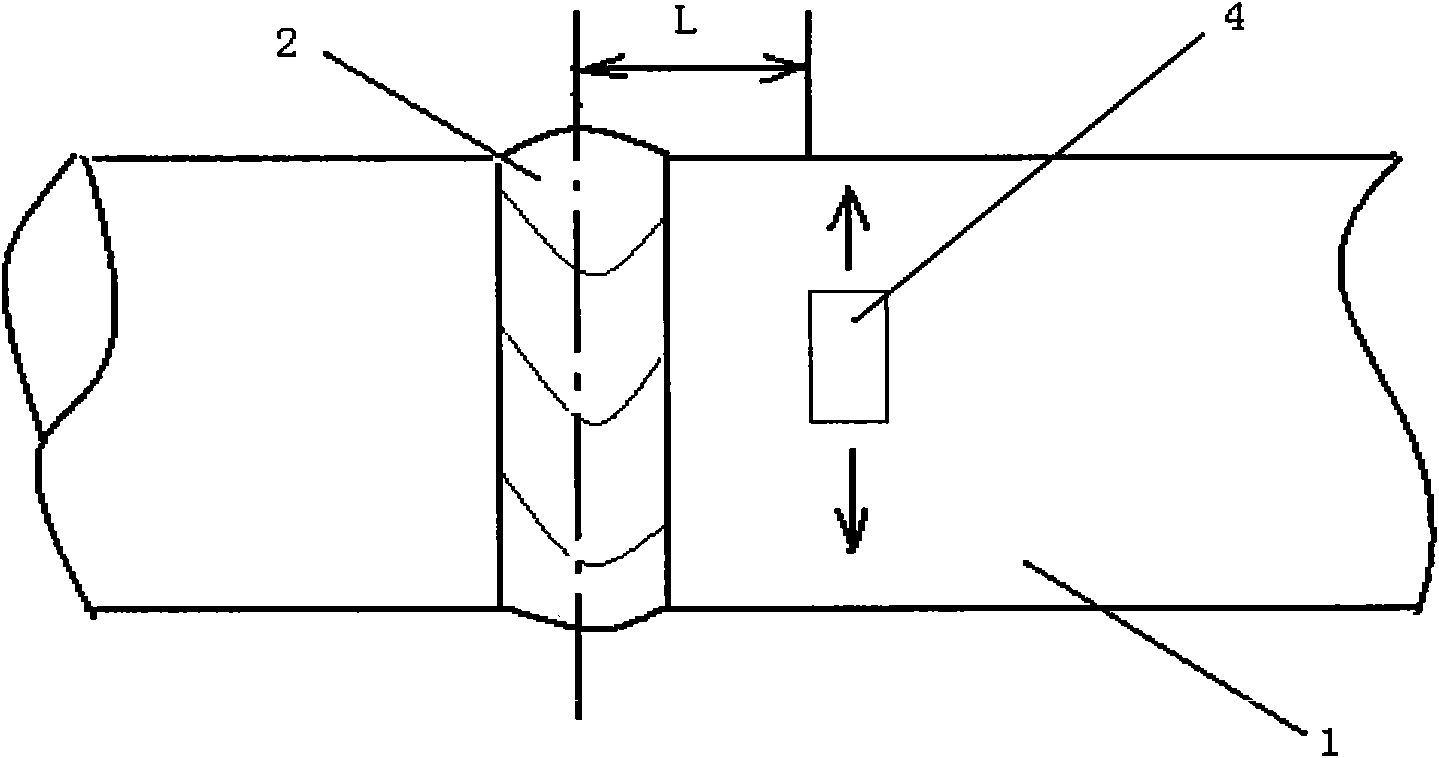

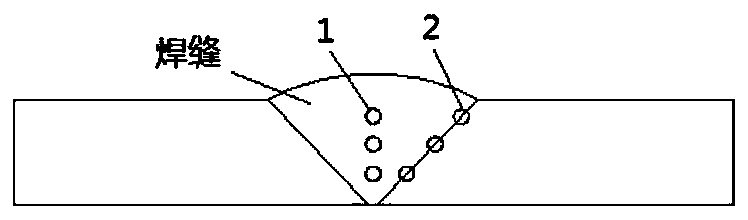

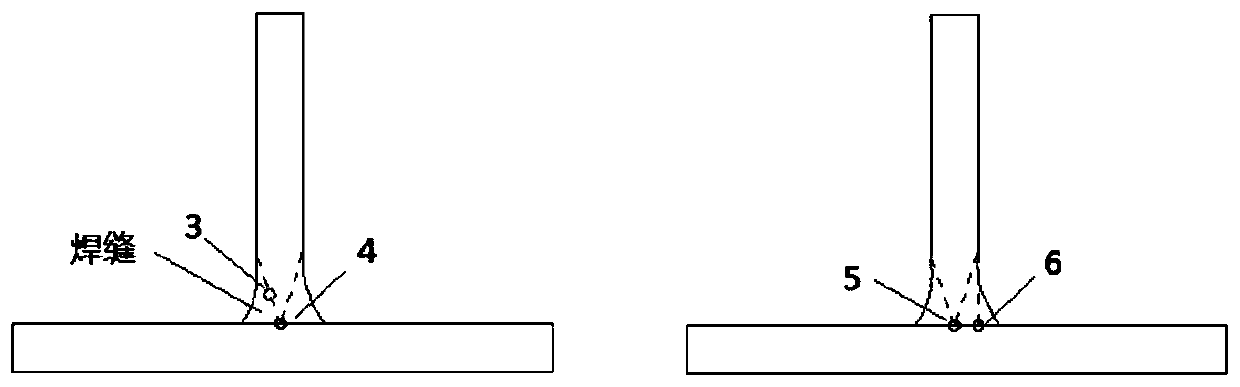

Method for detecting welding seam of resistance weld pipe through creeping wave and creeping wave probe for method

InactiveCN103115963ARealize detectionHigh detection sensitivityAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping waveElectrical resistance and conductance

The invention discloses a method for detecting a welding seam of a resistance weld pipe through a creeping wave and a creeping wave probe for the method. The method comprises the following steps of: S100, selecting the specification of the creeping wave probe according to the curvature of the resistance weld pipe; S200, regulating the ratio of the sound path and depth of a reflected wave to 2:1; S300, selecting a reference point as the first point of a DAC curve, sequentially determining points at an interval of 5mm to the first point, measuring the amplitude of the reflected wave, drawing a distance-wave amplitude curve according to a measurement result, and attenuating the DAC curve by 10 dB as an evaluation line; S400, placing the sound beam center line of the creeping wave probe on a detection surface in such a way that the sound beam center line of the creeping wave probe is perpendicular to the center of the welding seam, and scanning the part, which is 20-25 mm far away from the center of the welding seam, of one side of the welding seam, wherein the scanning speed of the creeping wave probe is not more than 50mm / s; and S500, comparing a detection result obtained from the step S400 with the evaluation line. The creeping wave probe is a twin-lamella parallel creeping wave probe. The method disclosed by the invention can be used for accurately detecting the defects of the welding seam.

Owner:上海中油天宝巴圣钢管有限公司

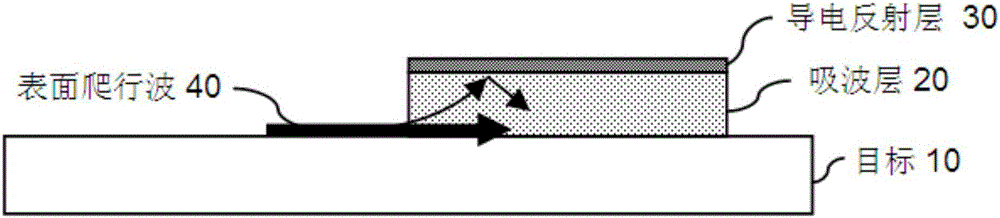

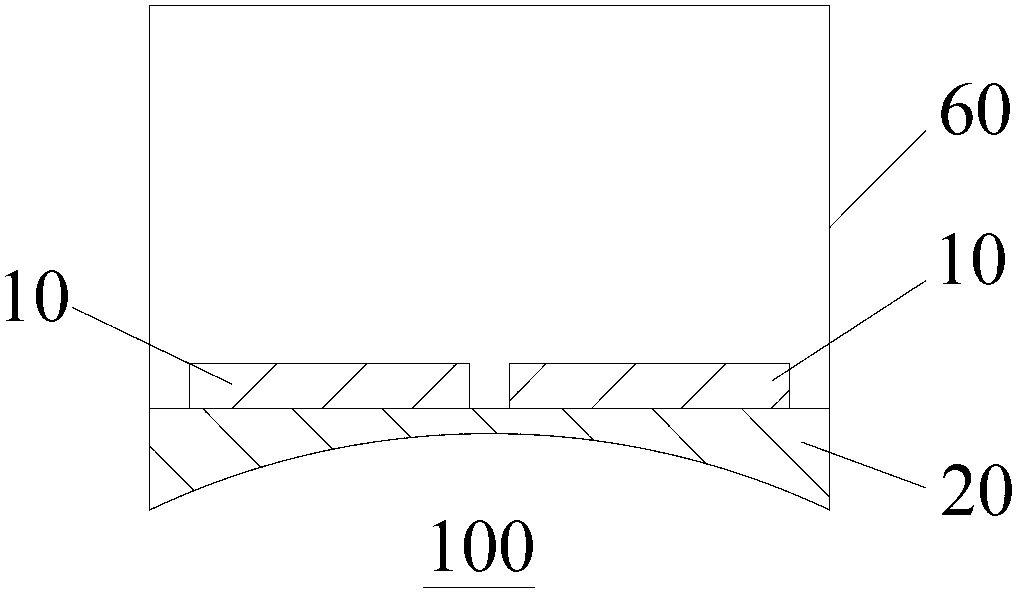

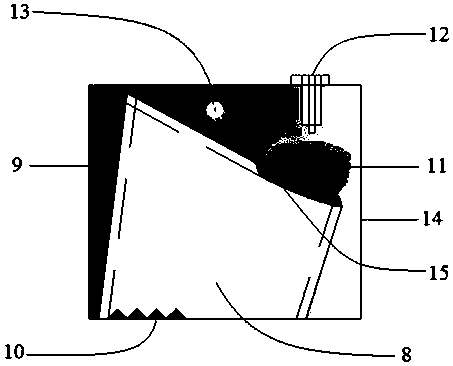

Surface creeping wave absorption coating structure

The invention discloses a surface creeping wave absorption coating structure, which is coated on a target surface. The coating structure comprises a wave-absorbing layer and an electric conduction reflection layer, wherein the wave-absorbing layer and the electric conduction reflection layer are bonded from inside to outside on the target surface; the wave-absorbing layer can adsorb target surface creeping electromagnetic wave and convert the target surface creeping electromagnetic wave into thermal energy; the electric conduction reflection layer has a reflection function, can inhibit the creeping electromagnetic wave which enters the wave-absorbing layer from outwards radiating; and the material of the wave-absorbing layer has impedance characteristics to cause the creeping electromagnetic wave to enter the wave-absorbing layer as many as possible. By use of the surface creeping wave absorption coating structure provided by the invention, the surface creeping electromagnetic wave can be thoroughly eliminated so as to greatly lower the influence of the creeping wave on antenna, and high efficiency of the antenna is guaranteed. In addition, the thickness and the width of the coating are greatly reduced than those of a conventional coating, and the structure is suitable for a wide surface creeping wave adsorption situation.

Owner:SHANGHAI RADIO EQUIP RES INST

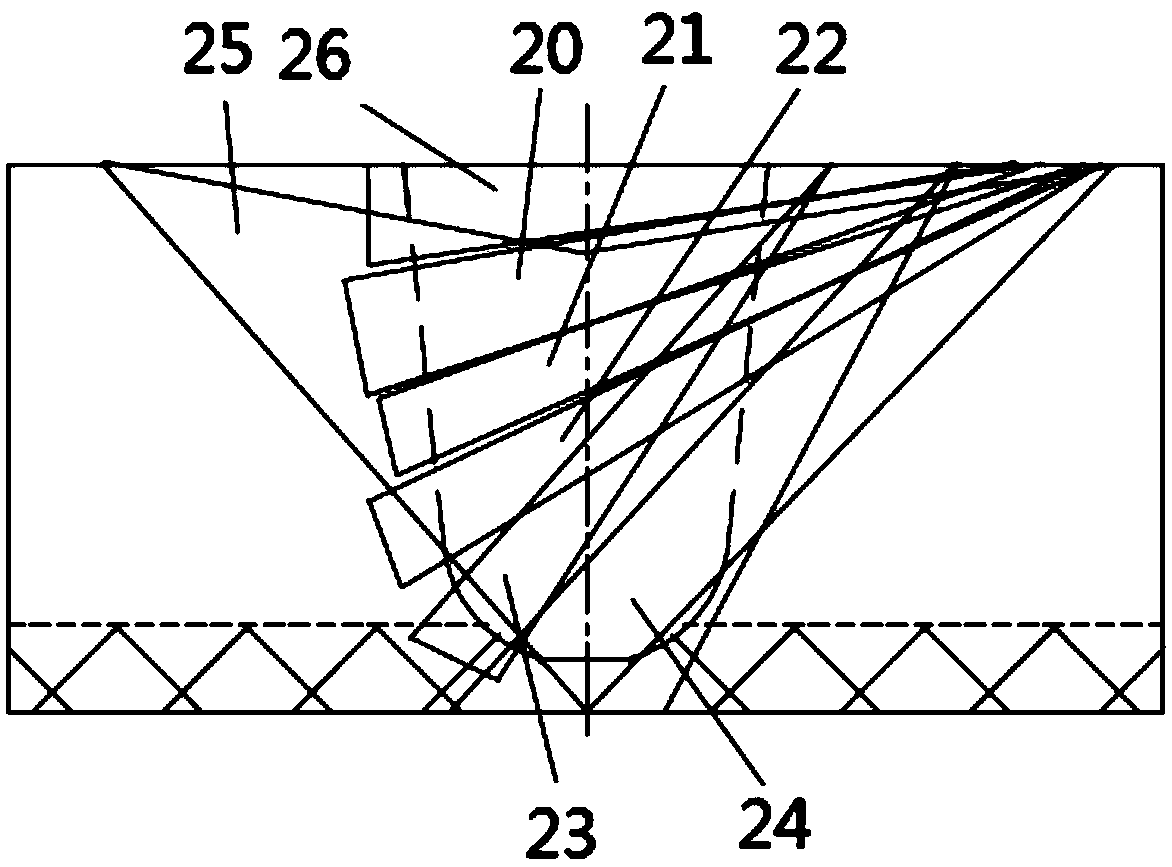

Method for setting calibration block for phased-array ultrasonic testing of bimetal composite material

ActiveCN106525985AMeet the testing requirementsSolve the problem of detecting different types of defects at various positionsMaterial analysis using sonic/ultrasonic/infrasonic wavesCreeping waveUltrasonic testing

A method for setting a calibration block for phased-array ultrasonic testing of a bimetal composite material includes the specific steps of firstly, partitioning a filling region groove type of the calibration block; secondly, setting testing reflectors at different positions on the filling region groove surfaces; thirdly, determining central coordinates on weld joint central lines of first, second, third and fourth upstream filling region reflectors; fourthly, determining central coordinates on a weld joint central line of an upstream hot weld region reflector; fifthly, setting two kinds of root groove region reflectors; sixthly, setting multiple kinds of creeping wave channel reflectors; seventhly, setting time-difference diffraction calibration reflectors; eighthly, setting a channel gate positioning reflector; ninthly, setting two kinds of volume channel reflectors; tenthly, symmetrically setting downstream reflectors. The method has the advantages that the requirements on testing of submarine pipelines made of the bimetal composite material are met, the problem that different types of defects at different positions are tested by a calibrated phased-array system, and reliability and onsite testing efficiency of the whole phased-array system are improved.

Owner:CHINA NAT OFFSHORE OIL CORP +1

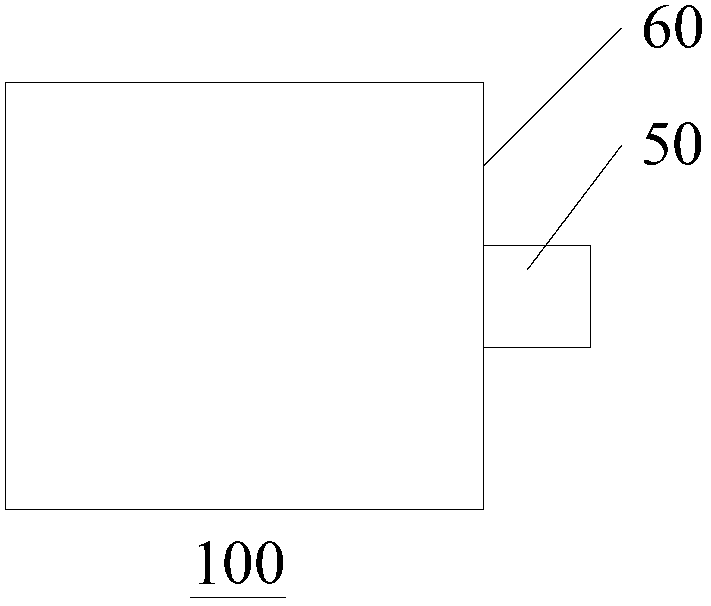

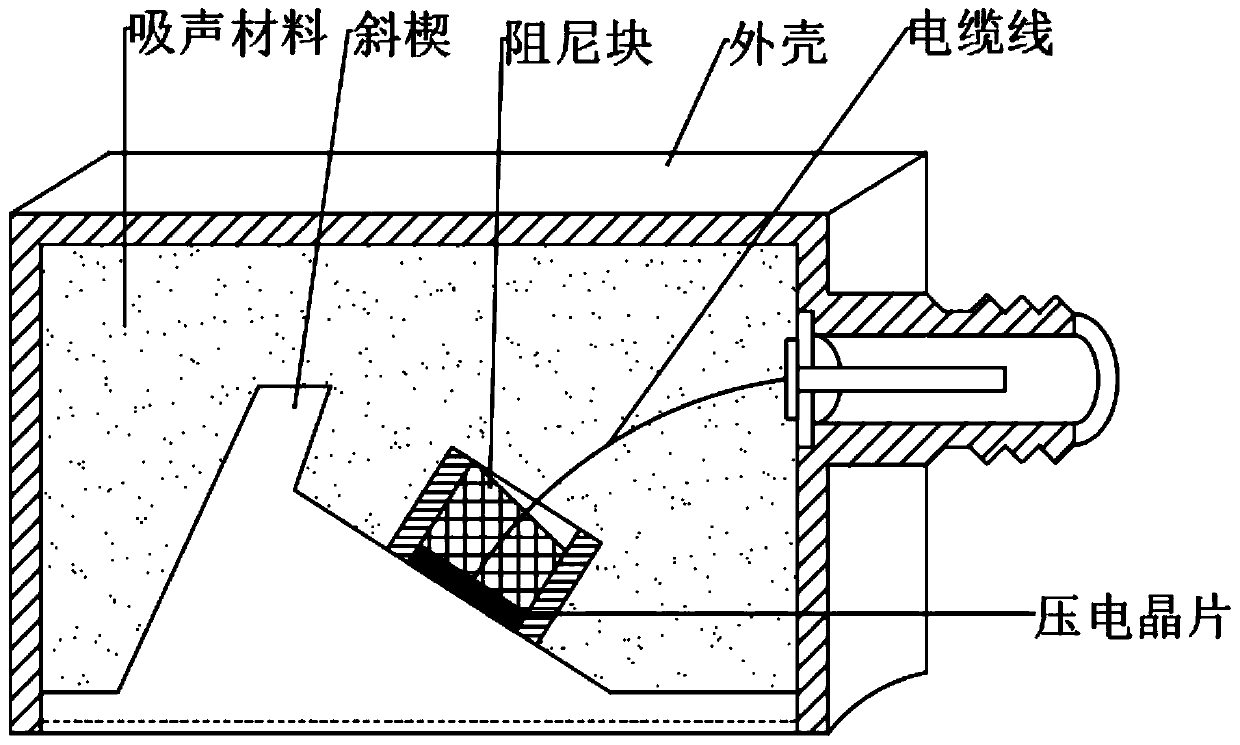

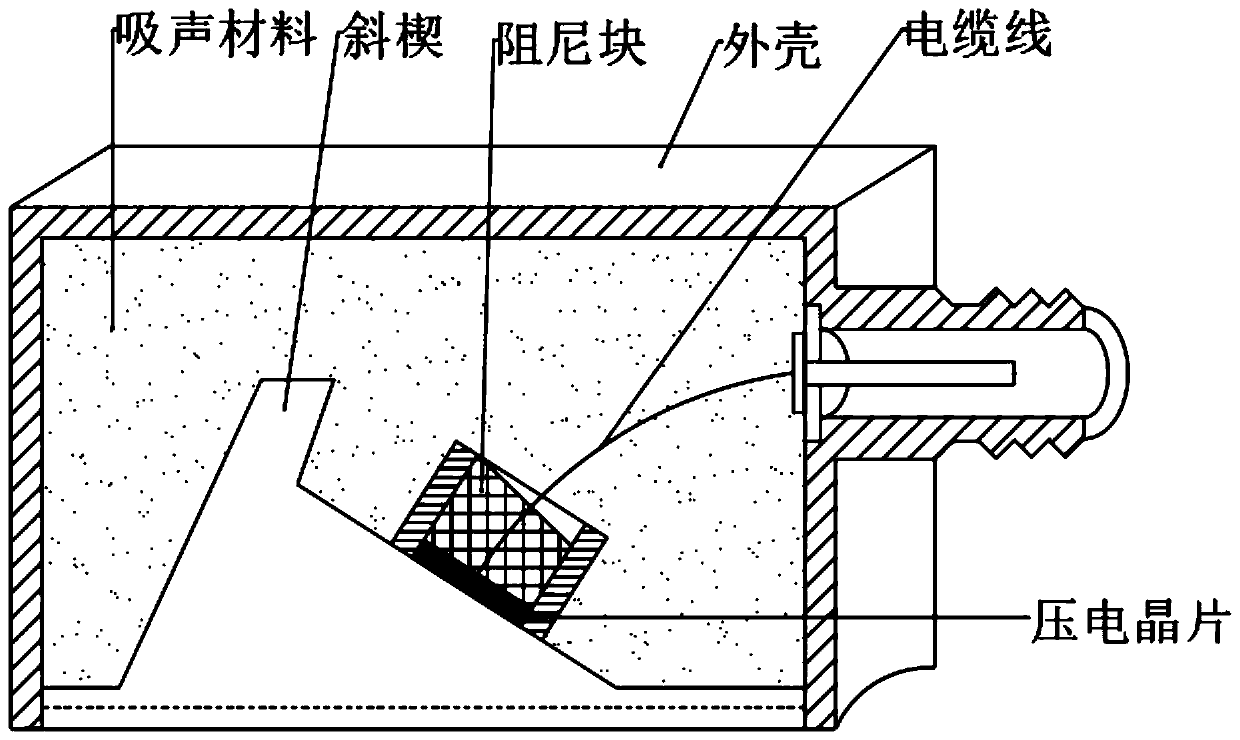

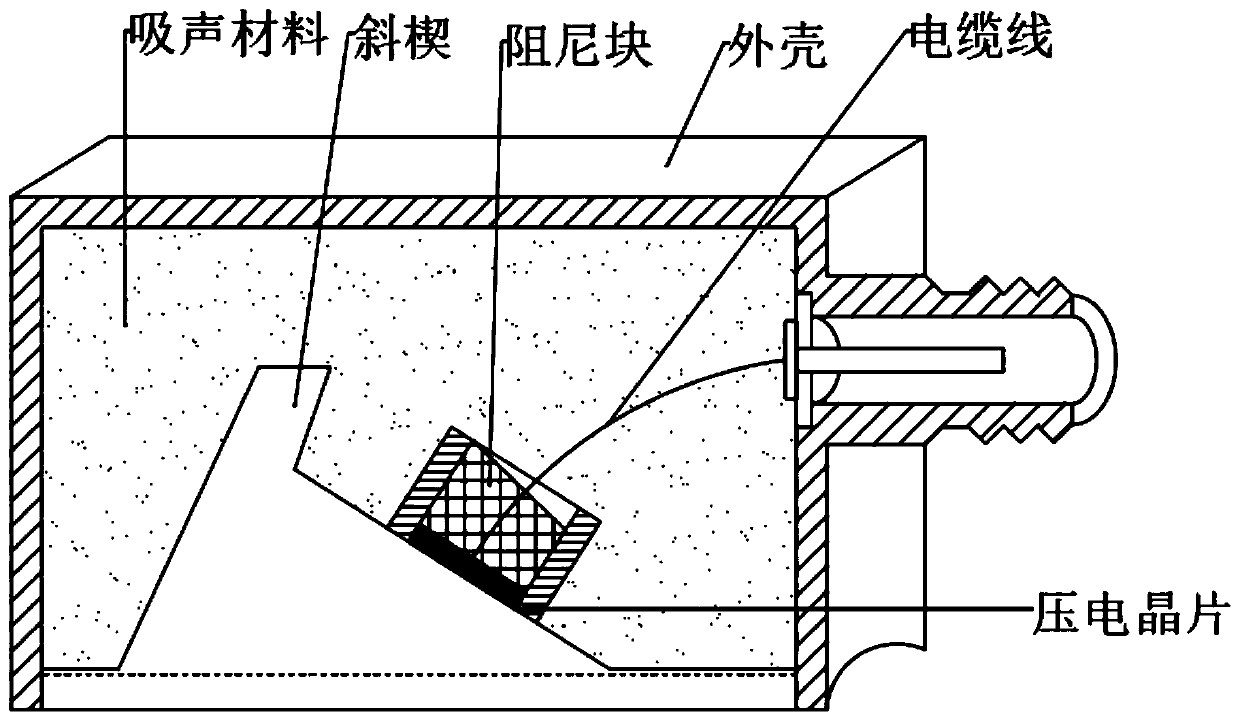

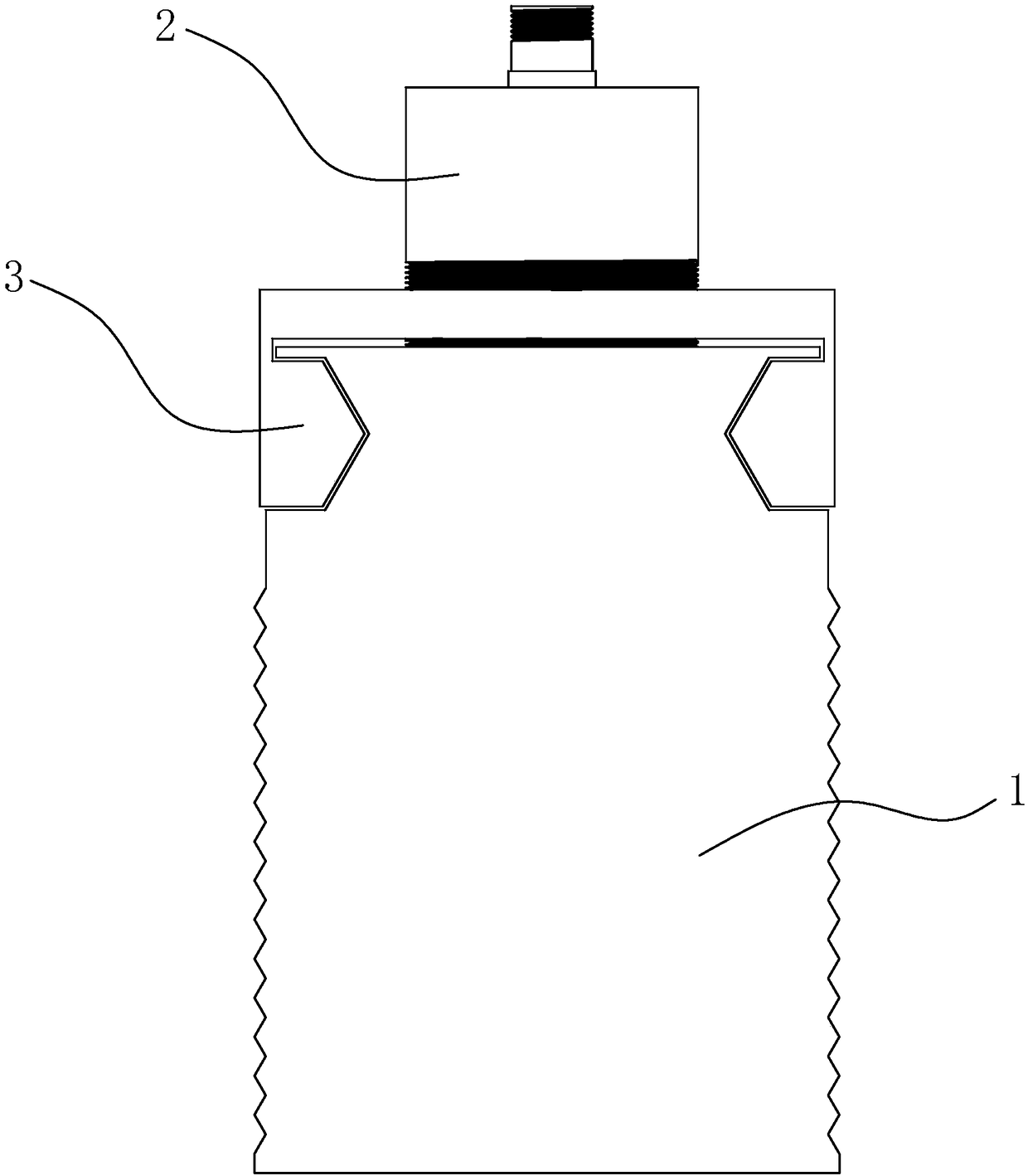

Creeping-wave fault detecting probe and creeping wave fault detecting method

InactiveCN102841145AAbility to improve defectsAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping waveEngineering

The invention discloses a creeping-wave fault detecting probe. The probe comprises a shell body (60) provided with an opening, crystal plates (10) and a protection layer (20). The crystal plates are arranged inside the shell body. The protection layer is arranged at the opening of the shell body and seals the shell body up. One end face of the protection layer is attached to the crystal plates and the protection layer is fixedly connected with the crystal plates. The other end face of the protection layer is used for being attached to an object to be detected. The shape of the other end face of the protection layer is matched with the shape of the surface of the object to be detected. The invention further discloses a creeping-wave fault detecting method. When the creeping-wave fault detecting probe is used for creeping-wave fault detecting, the surface of the protection layer of the probe can be attached to the object to be detected so that the majority of ultrasonic waves generated by the crystal plates can penetrate through the protection layer and enter the inside of the object to be detected. Consequently, capacity of detecting faults of the probe in the process of creeping-wave fault detecting is improved.

Owner:CHINA SHENHUA ENERGY CO LTD +2

Welding surface and near-surface crack depth detection device

ActiveCN106093203APrevent popupFixed tightlyAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping waveArchitectural engineering

The invention discloses a welding surface and near-surface crack depth detection device and mainly relates to the technical field of welding quality detection. The welding surface and near-surface crack depth detection device comprises a supporting seat which is provided with a supporting barrel, a screw is arranged in the supporting barrel and sleeved with a transmission pipe, one end of the transmission pipe is provided with a spring, a supporting rod is arranged at one end of the spring, and one end of the supporting rod is provided with a first universal wheel. The top of the supporting seat is provided with an outer barrel, an inner barrel is arranged in the outer barrel, one end of the inner barrel is provided with a first bevel gear, the screw is provided with a second bevel gear, a center rod is arranged in the inner barrel, the bottom of the center rod is provided with a supporting arm, and one end of the supporting arm is provided with a creeping wave probe. The welding surface and near-surface crack depth detection device has the advantages that the device can be quickly fixed into a large chemical engineering container and a pipe, welding surface and near-surface crack depths can be quickly detected, a missing detection phenomenon can be avoided, detection efficiency can be improved, and detectors' working strength is reduced.

Owner:杨振峰

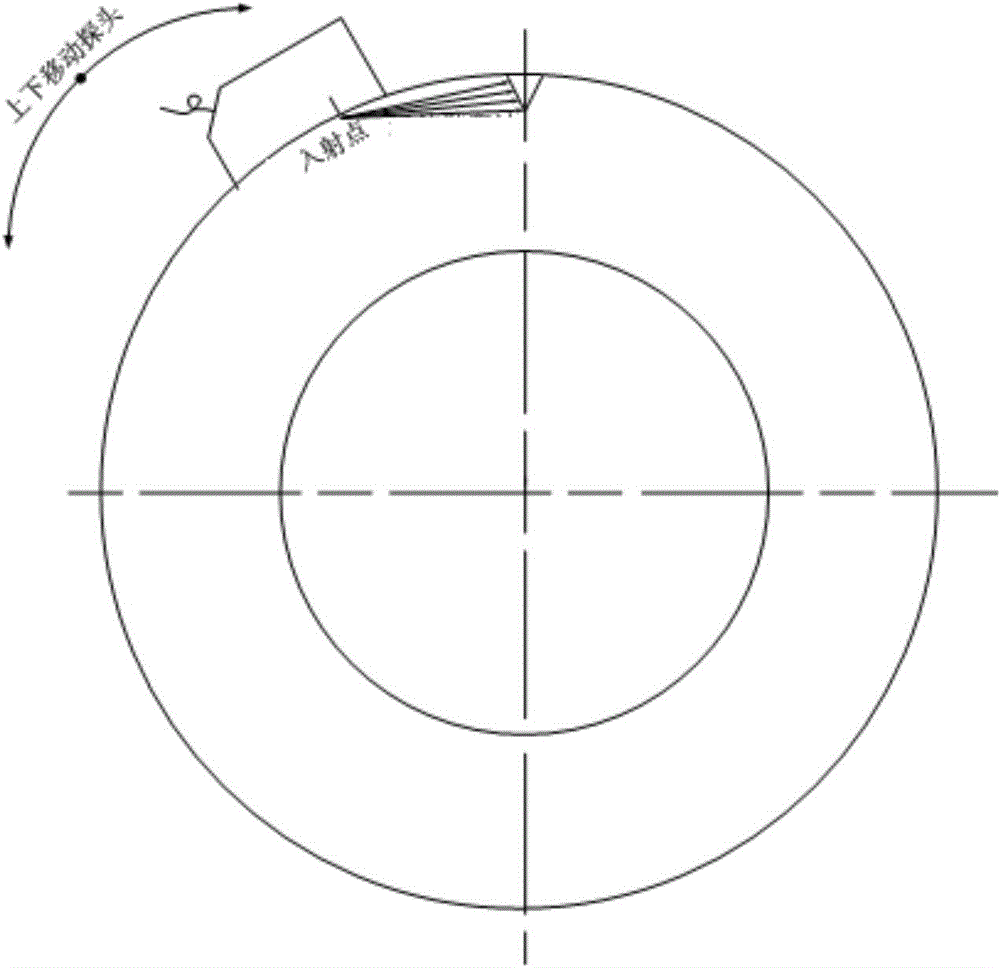

Ultrasonic testing method for butt-jointed seam of steel tube tower in electric transmission line

InactiveCN101793871AImprove featuresGood effectAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping waveButt joint

The invention provides an ultrasonic testing method for a butt-jointed seam of a steel tube tower in an electric transmission line, which belongs to the technical field of nondestructive testing of butt-jointed seams. The method comprises the following steps: the probe connected with an ultrasonic tester is put at the side end of the steel tube with the butt-jointed seam, wherein the probe tallies with the outside diameter of the steel tube; and when the ultrasonic tester sends out a signal, the probe emits ultrasonic waves to cover the entire butt-jointed seam to carry out ultrasonic creeping wave testing, thereby analyzing the defects of the butt-jointed seam. The testing method of the invention can realize three-dimensional scanning, and has the advantages of convenient operation, easy mastering, high work efficiency and high testing sensitivity.

Owner:CHINA ELECTRIC POWER RES INST +1

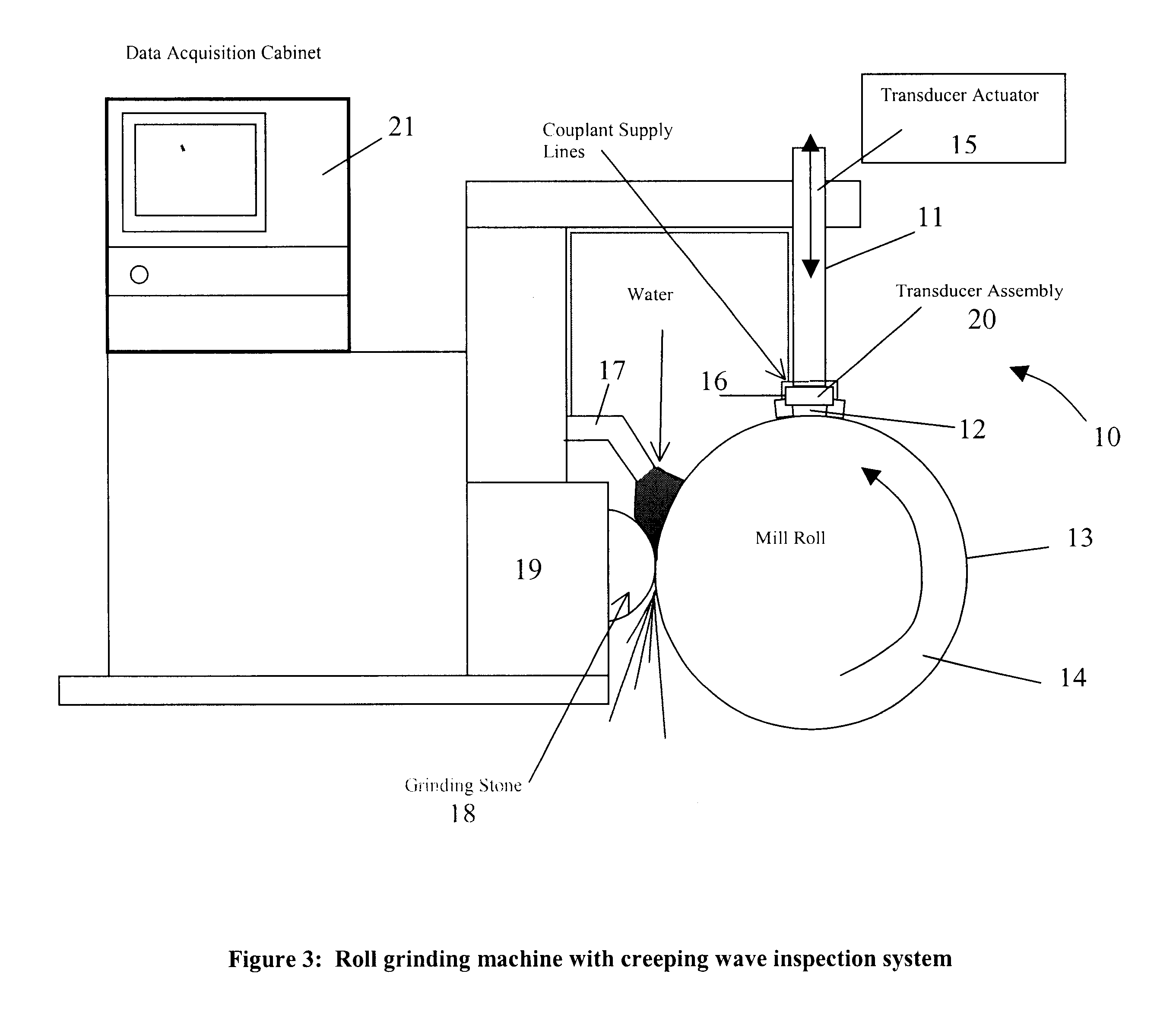

Creeping wave technique for mill roll inspection

InactiveUS6769957B2Surface of becomes very sensitiveAnalysing solids using sonic/ultrasonic/infrasonic wavesRevolution surface grinding machinesCreeping waveTransducer

A method and apparatus for simultaneously inspecting and grinding roll mills which utilizes a transducer assembly which produces a creeping wave propagation in conjunction with a couplant fluid provider and data acquisition circuit which allows the operator to see the crack and imperfections in on the surface of the mill rolls as they are rotated and to grind them off.

Owner:INNERSPEC TECH

Dissimilar metal welding line ultrasonic creeping wave testing method

The invention belongs to an ultrasonic creeping wave testing method, particularly relates to a dissimilar metal welding line ultrasonic creeping wave testing method, which comprises the following steps: (1) calibrating instrument depth measurement, (2) demarcating sensitivity, and (3) testing. The invention has the effects that: (1) the effect of creeping wave for defect depth measurement is that the creeping wave can test the depth of 0.5 to 9mm, and the depth measurement error is plus and minus 0.5mm, (2) the effect of creeping wave for defect height measurement is that the creeping wave can perform the height measurement for the planar defect with the self height of larger than or equal to 2mm, with the measurement error is plus and minus 1mm.

Owner:THIRD QINSHAN NUCLEAR POWER

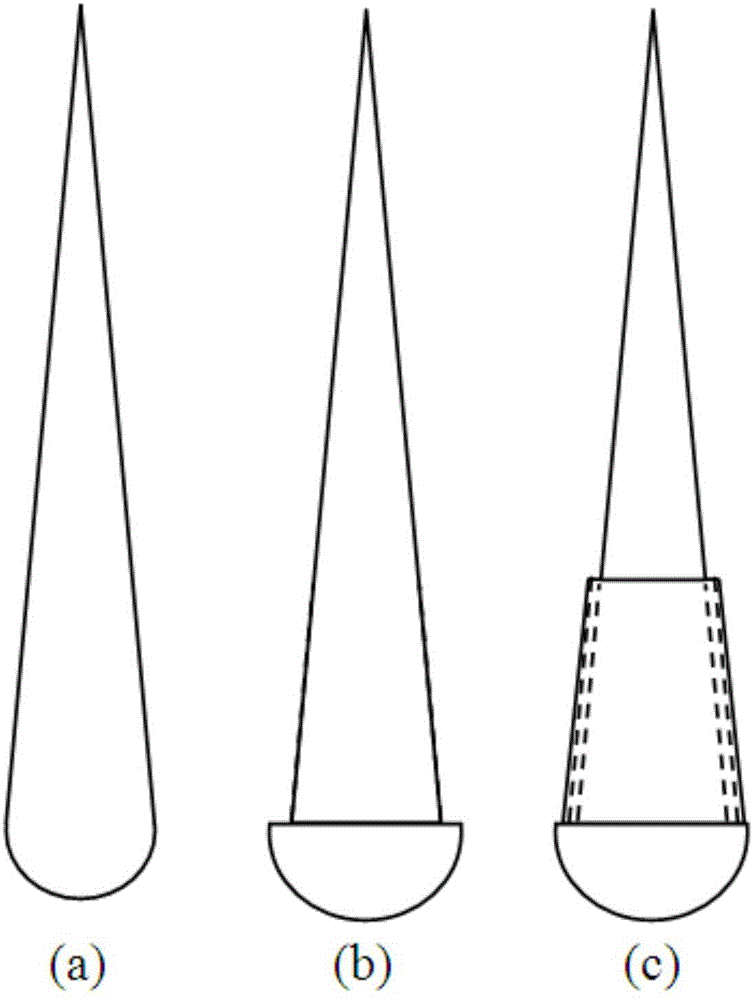

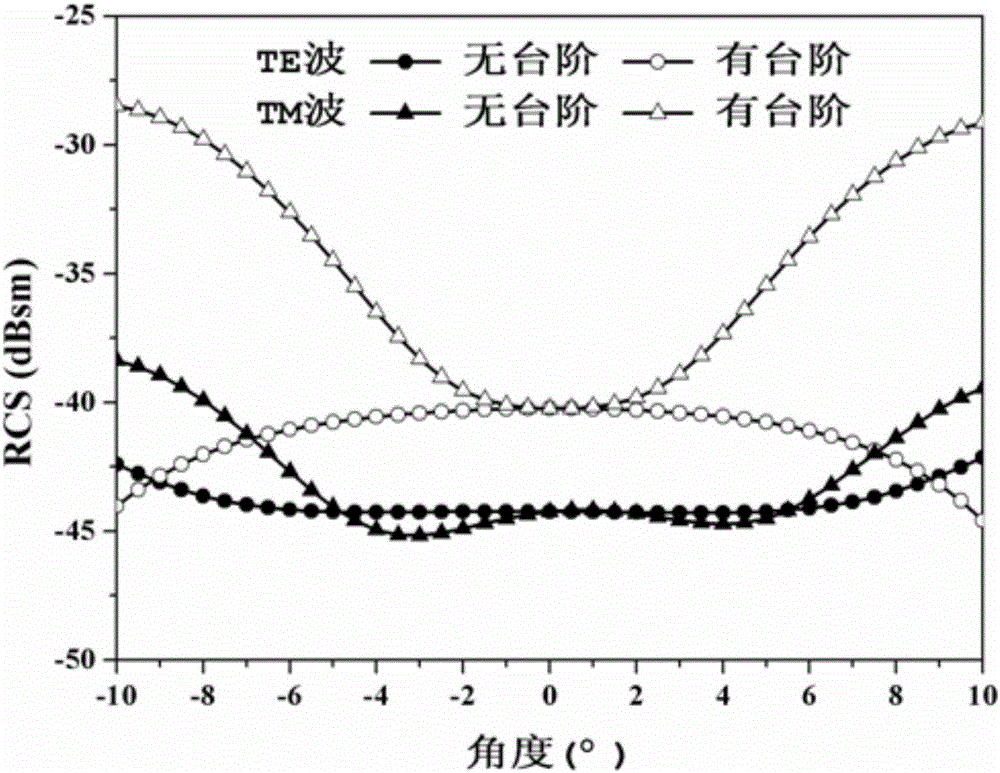

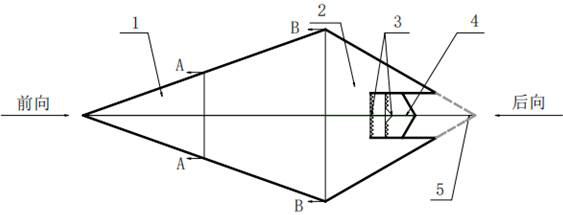

Low-scattering shell for binary vector engine and application of low-scattering shell

The invention provides a low-scattering shell for a binary vector engine and application of the low-scattering shell, the low-scattering shell comprises a flat mouse-shaped structure defined by a plane bottom, a conical side wall and an arc-surface top, the low-scattering shell comprises a front section and a rear section, a notch part is formed in the tail part of the rear section, and the size of the notch part is matched with the size of a to-be-tested binary vector engine jet pipe test mounting part. According to the method, the radar scattering cross section of the inner region of the backward cavity of an aero-engine can be independently obtained, and meanwhile, the influence of creeping waves and diffracted waves of an outer adjusting sheet of the aero-engine on forward radar scattering of an aircraft can be obtained.

Owner:AECC SICHUAN GAS TURBINE RES INST

Supersonic flaw detection method of weld joint

InactiveCN103926314AGuaranteed detection accuracyAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping waveEngineering

Owner:SEPCOIII ELECTRIC POWER CONSTR CO LTD

Ultrasonic detection method for defects of welding position of through-wall pipe of peak shaving unit

ActiveCN111239251AImprove fitGuaranteed incomingAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationCreeping waveButt welding

The invention relates to an ultrasonic detection method for defects of a welding position of through-wall pipe of a peak shaving unit, and belongs to the field of nondestructive detection. The methodcomprises the steps: manufacturing a test block by utilizing the same batch of original pipes of a to-be-detected through-wall pipe; designing a detection probe with radian, adjusting the sensitivityby using the test block, and determining an AVG curve and a DAC curve; selecting a K1 probe and detecting the K1 probe by using a secondary wave; selecting a K2 probe and detecting by using a primarywave; selecting a creeping wave probe to detect the butt weld of the through-wall pipe, and detecting the weld at the joint of the defective through-wall pipe and the sleeve to judge whether the defect is expanded to the wall of the through-wall pipe or not; and performing analysis to obtain a detection result. The method has the advantages of being capable of effectively detecting the defects ofthe welding positions of the through-wall pipes such as the peak shaving unit heating surface pipe, accurate in detection result, not prone to missing detection, capable of solving the problem of defect detection of the welding seams of the through-wall pipes of a peak shaving unit reheater and capable of guaranteeing safe operation of a power generation boiler of a thermal power plant.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +4

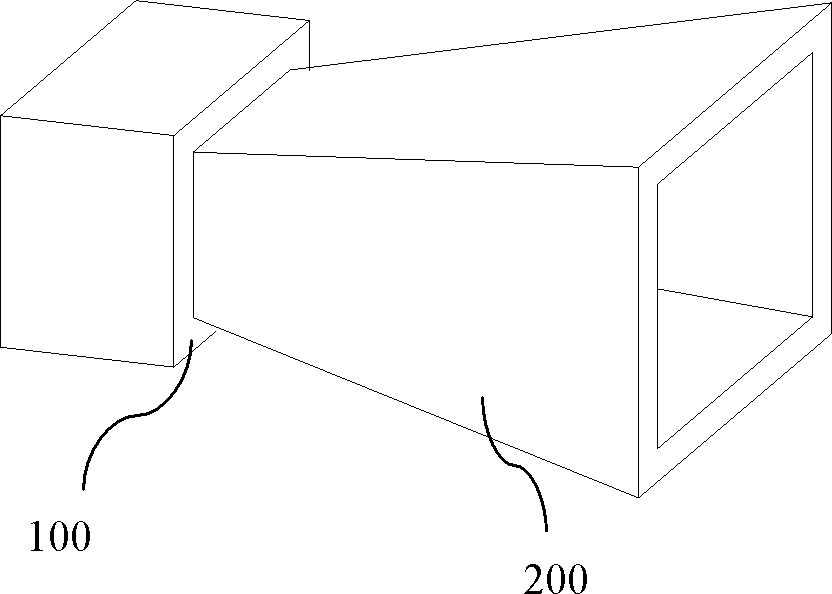

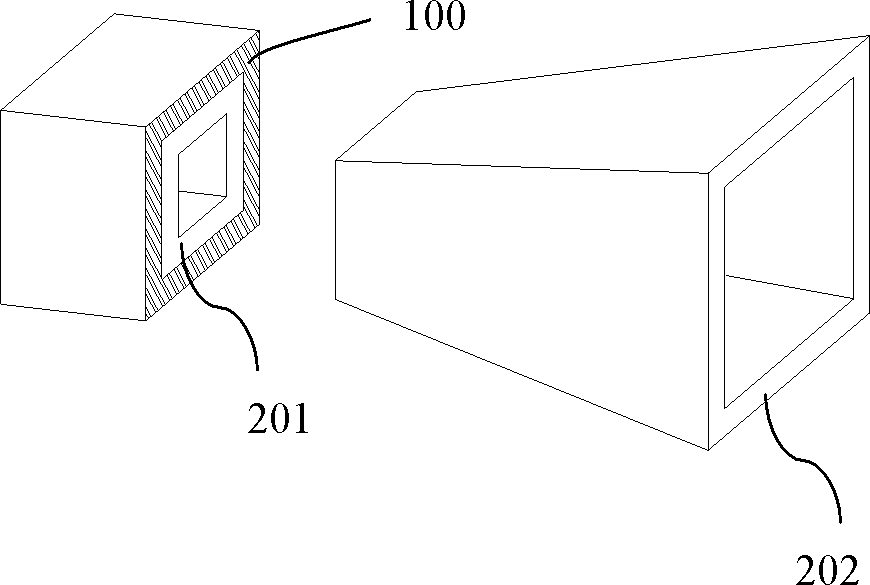

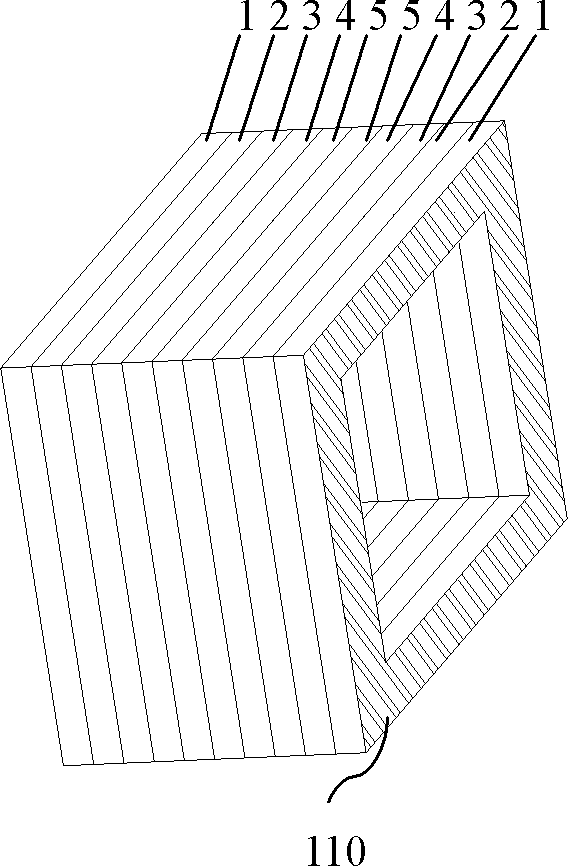

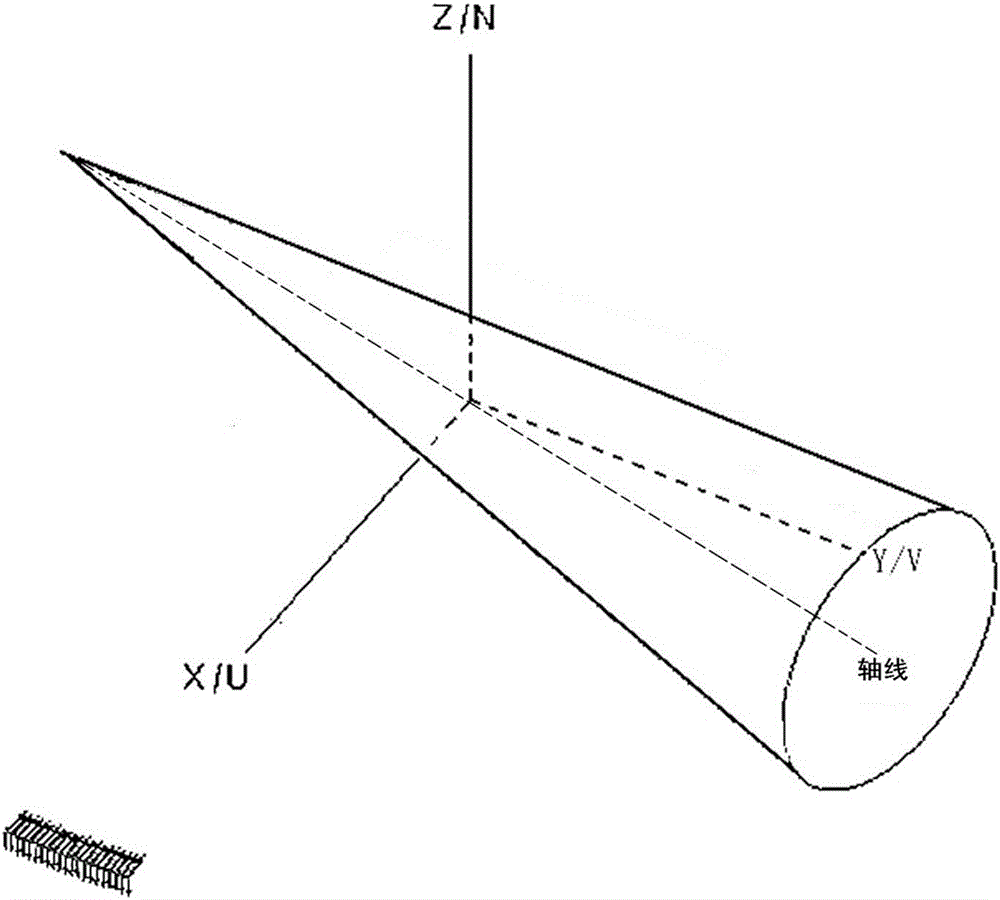

Device for attenuating creeping wave on antenna surface

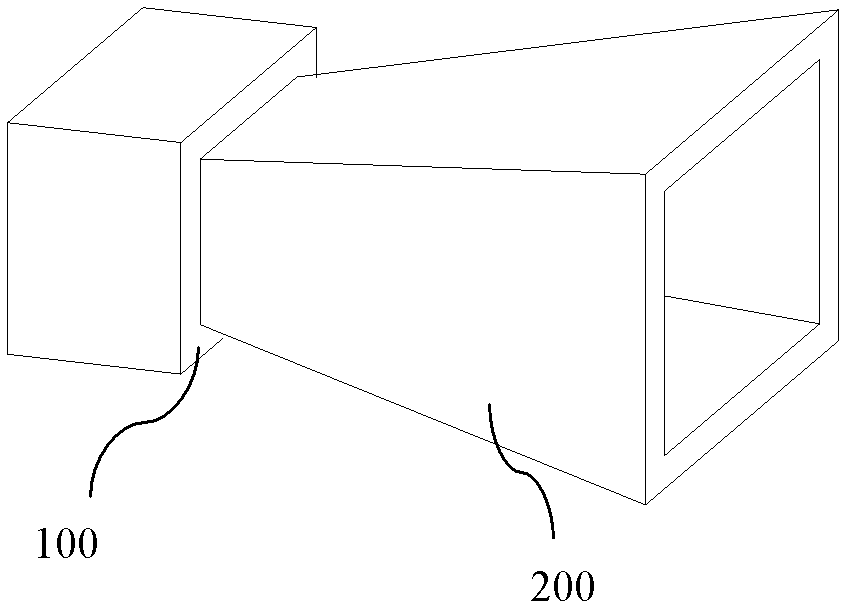

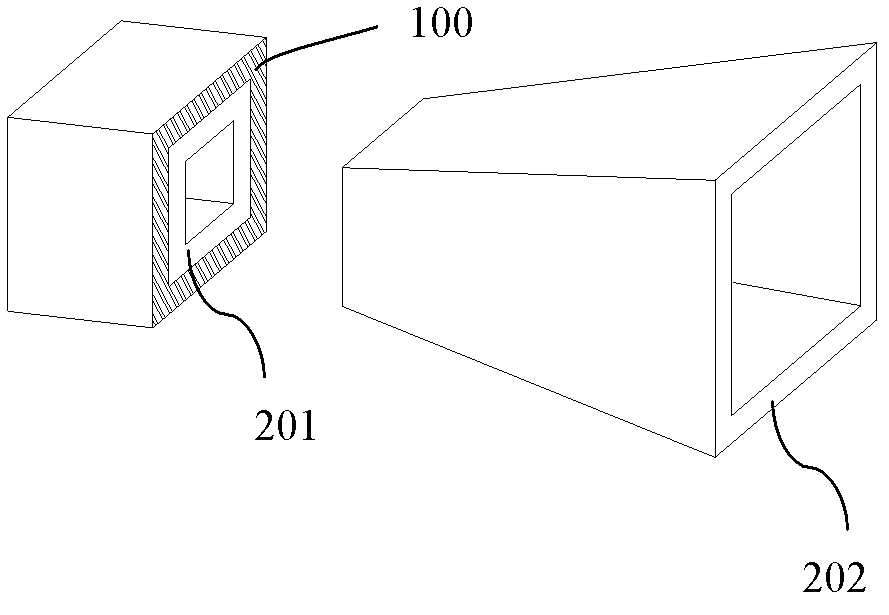

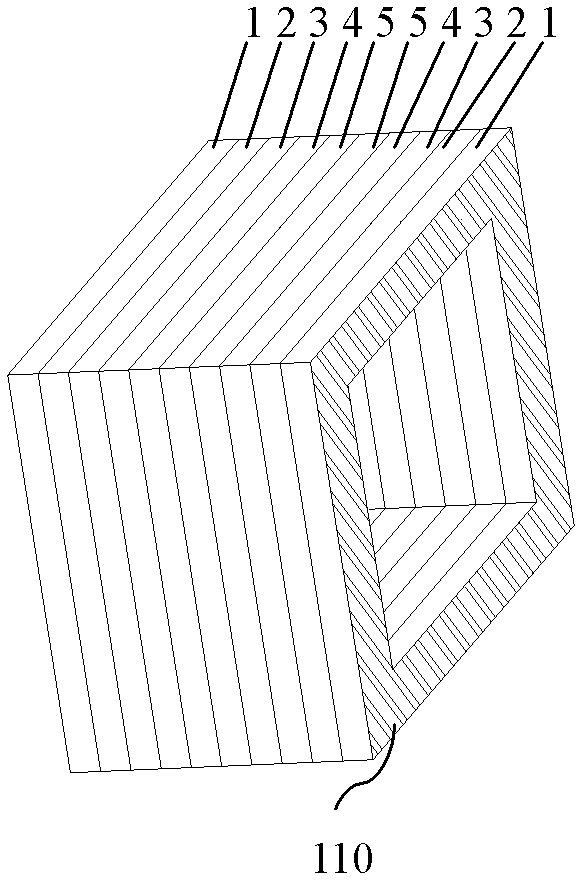

ActiveCN102810743AReduce the impactImprove front-to-back ratioWaveguide hornsCreeping waveRefractive index

The invention relates to a device for attenuating creeping wave on antenna surface. The device comprises an antenna and a metamaterial film layer, wherein the antenna comprises a waveguide tube and a bell mouth; the metamaterial film layer consists of a plurality of metamaterial gradient layers, and is distributed on the surface of the waveguide tube of the antenna; and each metamaterial gradient layer comprises a platy substrate and a plurality of artificial microstructures arranged on the substrate. By the device, the metamaterial film layer is arranged on the surface of the antenna, and the creeping wave which occurs on the surface of the antenna is attenuated by changing refractive index of the metamaterial film layer, so that the influence of the creeping wave on the antenna can be greatly reduced to ensure that front-to-rear ratio of the antenna is obviously improved; and therefore, the high efficiency of the antenna is guaranteed.

Owner:KUANG CHI INST OF ADVANCED TECH +1

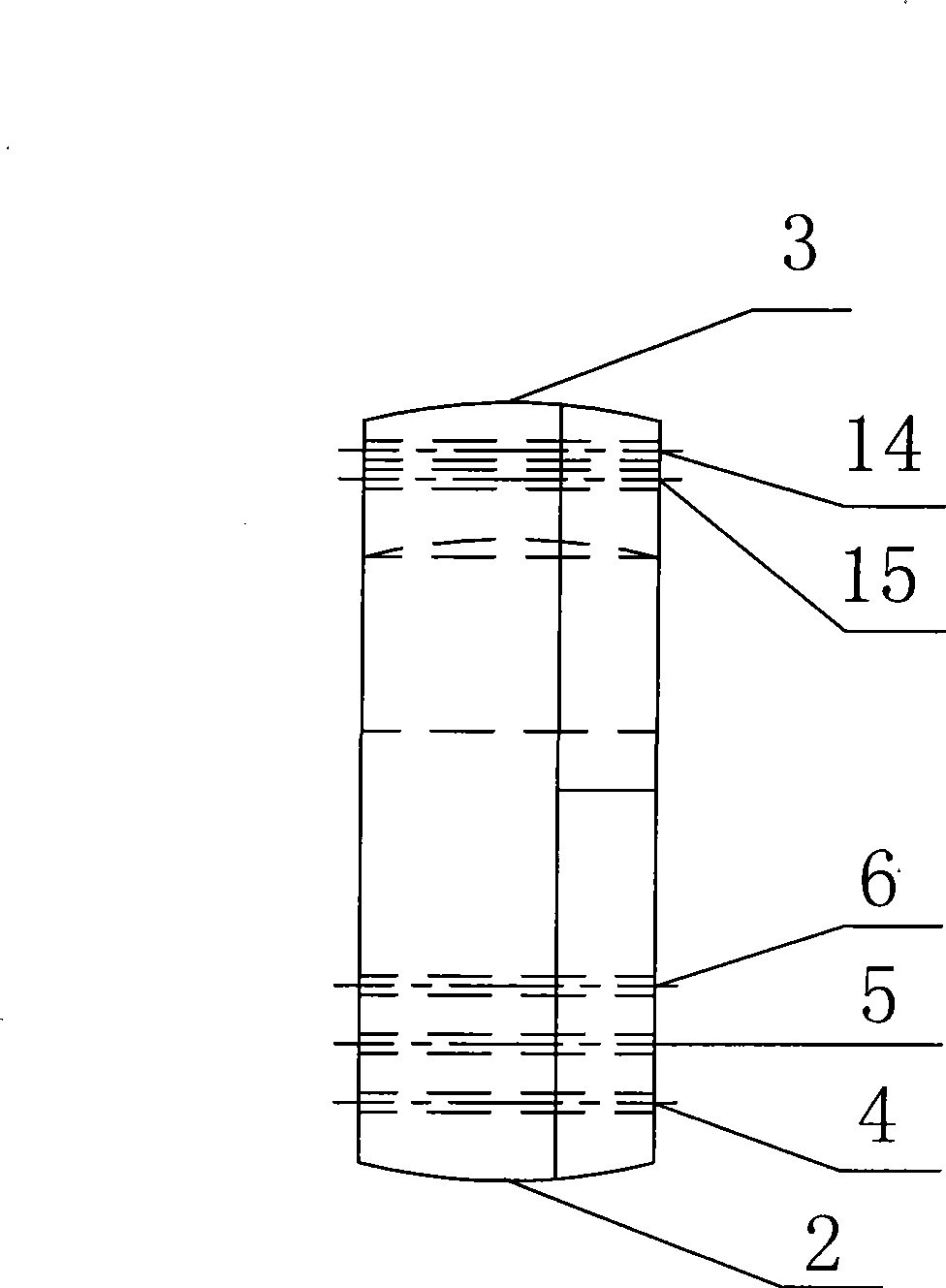

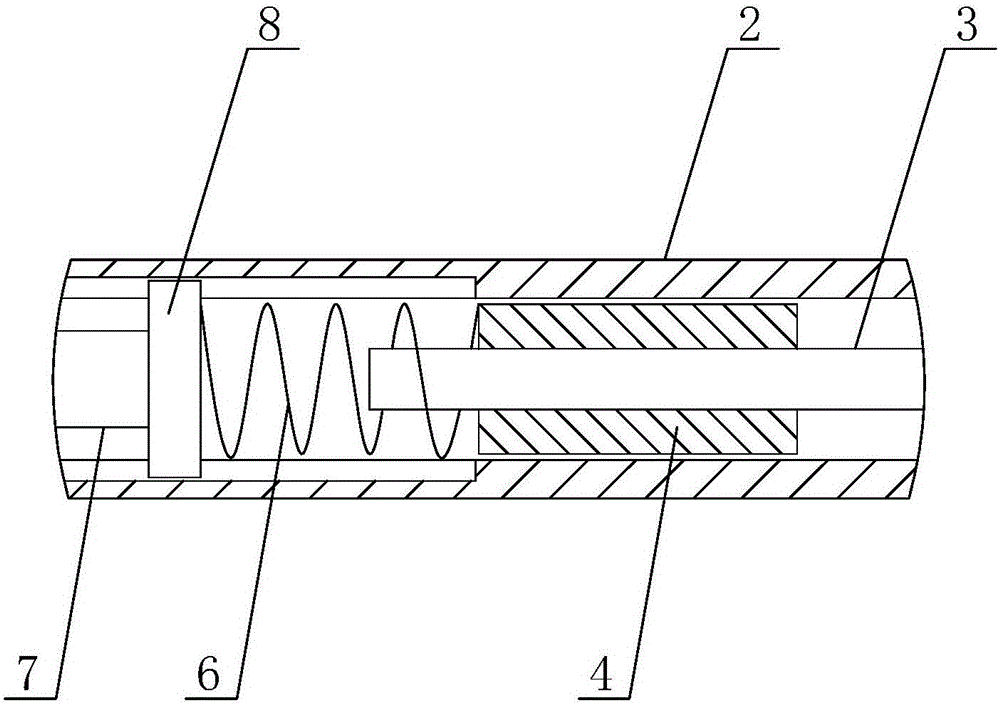

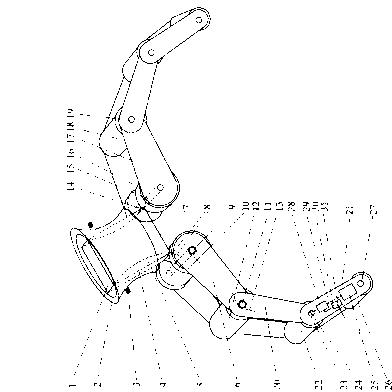

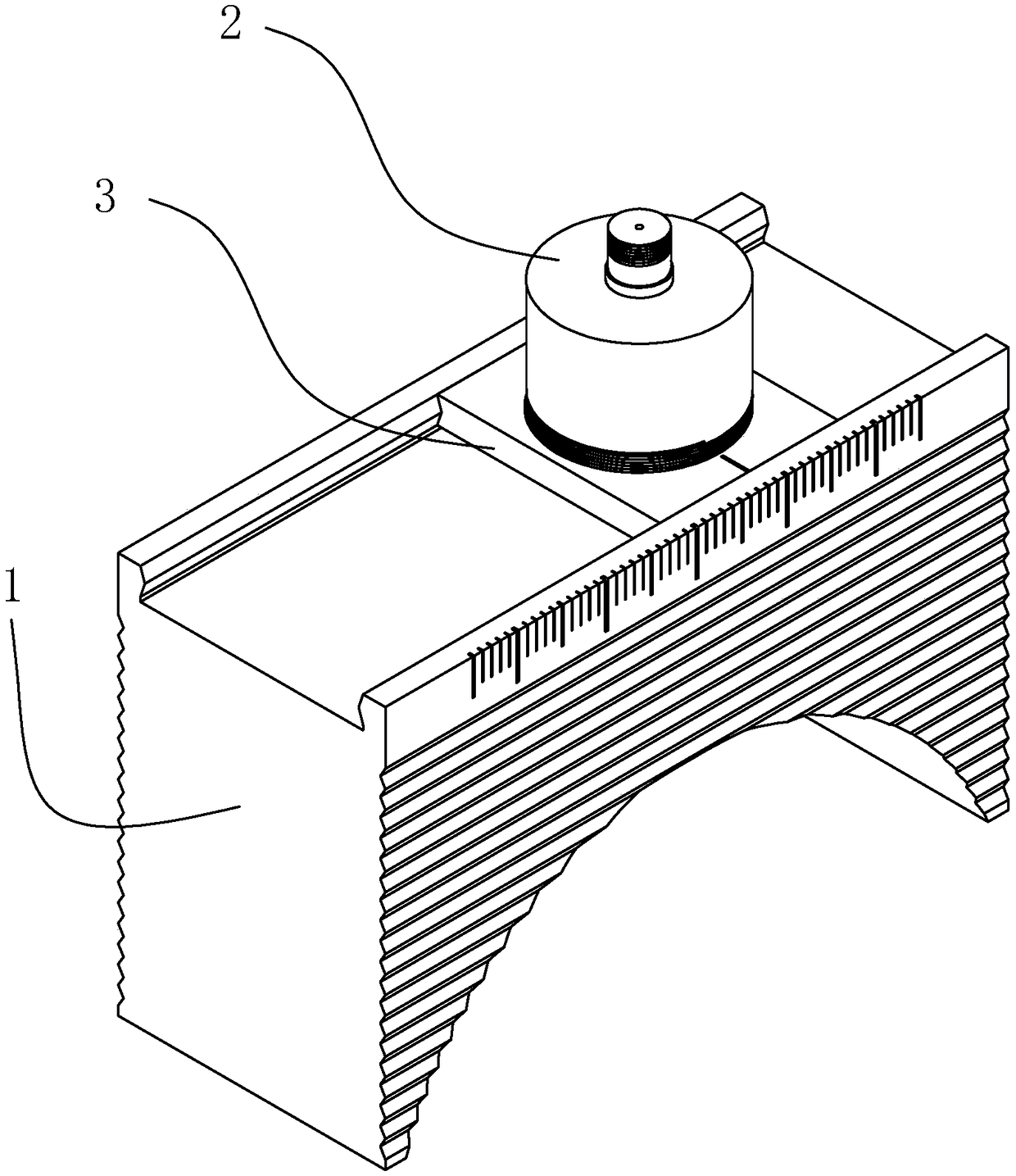

Remote-controlled rotatable pillar insulator creeping wave probe support

ActiveCN103235043AImprove fitEasy to keep detectableMaterial analysis using sonic/ultrasonic/infrasonic wavesCreeping waveRemote control

The invention discloses a remote-controlled rotatable pillar insulator creeping wave probe support to solve a problem that the contact of the coupling surface of a creeping wave probe and a pillar insulator is bad in the prior art. The remote-controlled rotatable pillar insulator creeping wave probe support comprises a probe clamp seat cover (2), a probe clamp seat (1) is jointed in the probe clamp seat cover (2), a pair of spring clamp sheets (5) is arranged in the probe clamp seat (1), connection rods are arranged at two sides of the bottom end surface (7) of the probe clamp seat (1), the top of each of the connection rods is fixedly connected with a roller shaft, each of roller shafts is provided with a roller, joint chain sheets and rollers form two outstretched chain-shaped pawls, and two ends of each of the roller shaft are respectively provided with a peg spring to make the two outstretched chain-shaped pawls in a cling state. Spring sheets (5) in the clamp seat and small roller shafts (4) above the clamp seat clamp the creeping wave probe and are beneficial for installing and pulling out the creeping wave probe. The insulator rounding scanning can be realized only by jointing the support on the pillar insulator through remote control in the invention.

Owner:STATE GRID CORP OF CHINA +1

Device for attenuating creeping wave on antenna surface

ActiveCN102810743BImprove front-to-back ratioImprove efficiencyWaveguide hornsCreeping waveRefractive index

The invention relates to a device for attenuating creeping wave on antenna surface. The device comprises an antenna and a metamaterial film layer, wherein the antenna comprises a waveguide tube and a bell mouth; the metamaterial film layer consists of a plurality of metamaterial gradient layers, and is distributed on the surface of the waveguide tube of the antenna; and each metamaterial gradient layer comprises a platy substrate and a plurality of artificial microstructures arranged on the substrate. By the device, the metamaterial film layer is arranged on the surface of the antenna, and the creeping wave which occurs on the surface of the antenna is attenuated by changing refractive index of the metamaterial film layer, so that the influence of the creeping wave on the antenna can be greatly reduced to ensure that front-to-rear ratio of the antenna is obviously improved; and therefore, the high efficiency of the antenna is guaranteed.

Owner:KUANG CHI INST OF ADVANCED TECH +1

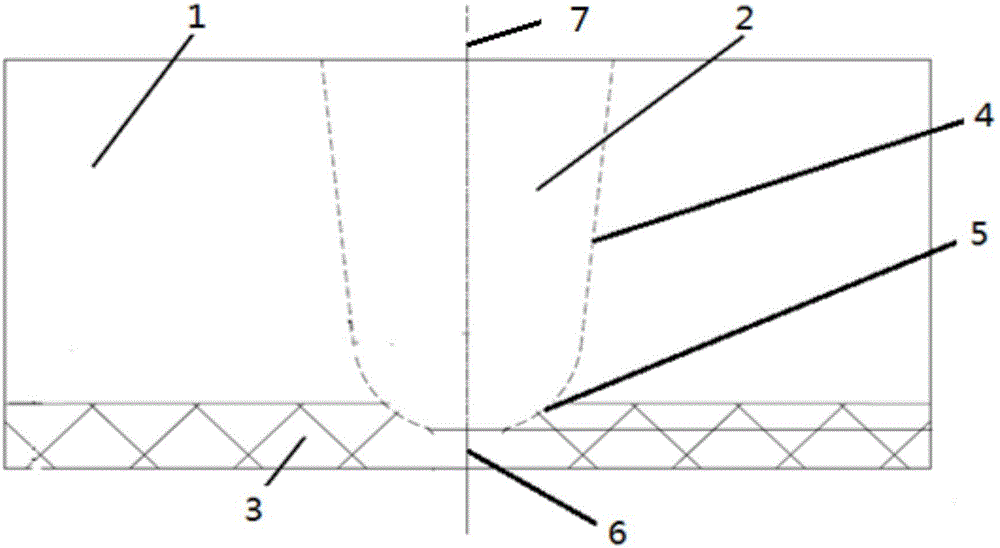

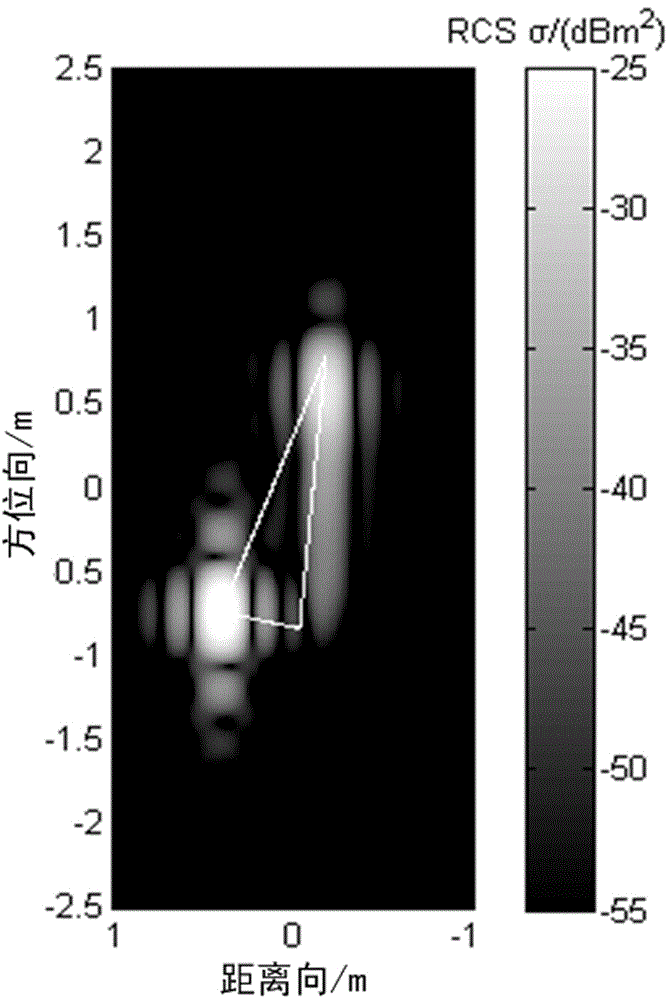

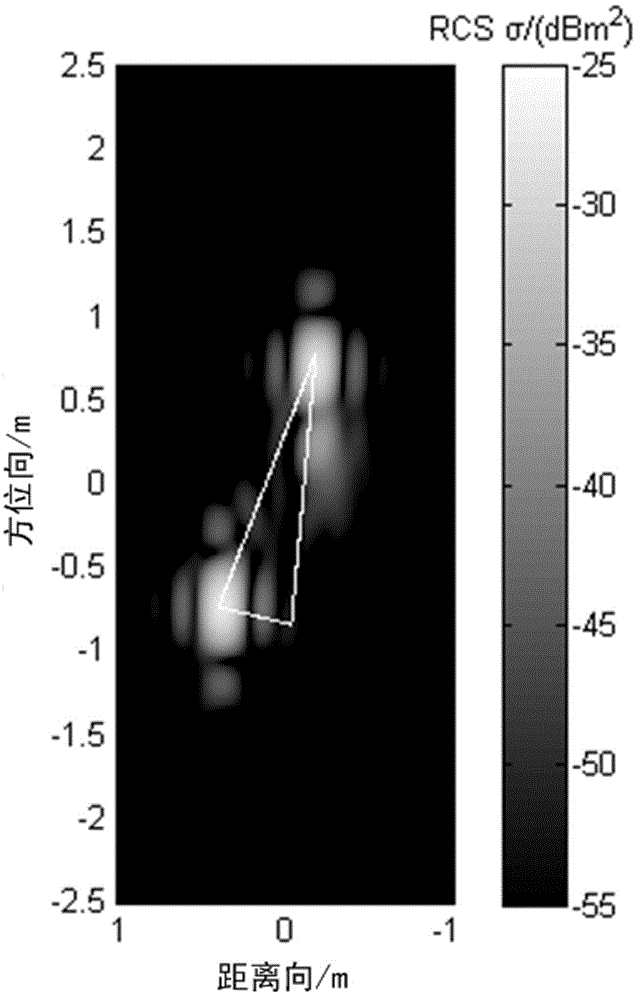

Imaging-based analysis method for absorbing material coated target creeping wave

ActiveCN106599421ASolve complexitySolve the problem of the influence of absorbing material coating on creeping wavesDesign optimisation/simulationSpecial data processing applicationsHigh resolution imagingHigh resolution image

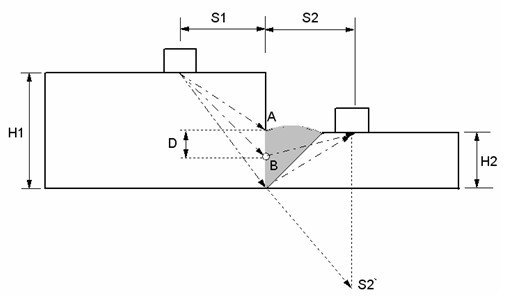

The invention discloses an imaging-based analysis method for absorbing material coated target creeping wave. The method comprises the following steps of step 1.constructing a three-dimensional geometrical model and setting material properties of the model; step 2.setting a scanning frequency range and a frequency interval of radar according to range resolution, determining a scanning position range and an interval according to azimuth resolution and carrying out imaging and computing a scattered field of a far zone or a near zone in needed bandwidth and angle range; step 3.adopting an FBP algorithm to carry out data processing on the scattered field in the step 2 to realize high-resolution imaging in order to obtain a two-dimensional ISAR image; and step 4.analyzing a specific location of the creeping wave according to the two-dimensional ISAR image and further extracting a creeping wave component, wherein the properties of a selected material are optimal when the creeping wave component is smallest. The method of the invention is universally applicable to creeping wave analysis, the imaging analysis is simple and a method for restraining the creeping wave is provided.

Owner:SHANGHAI RADIO EQUIP RES INST

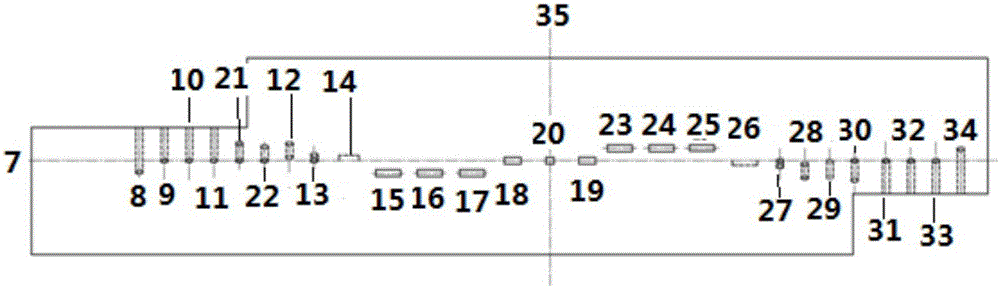

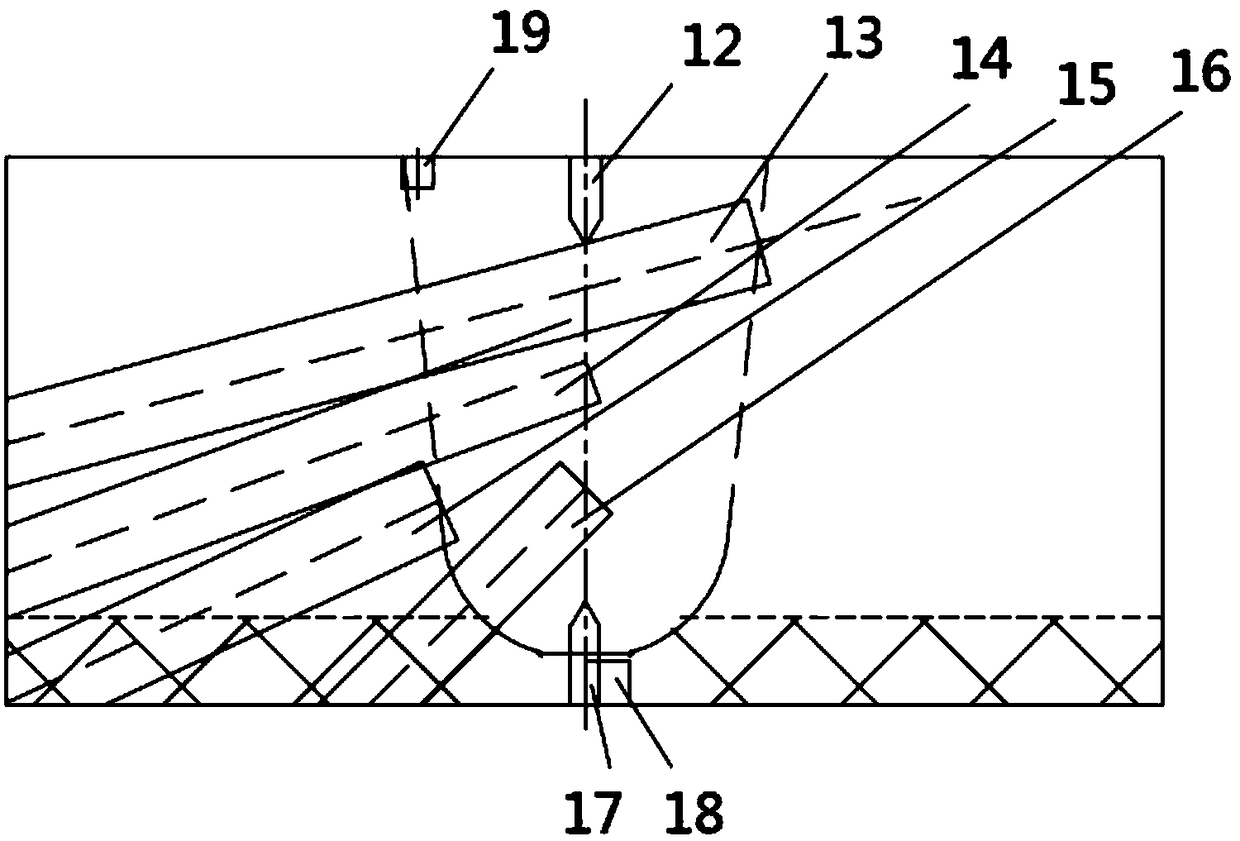

Combined detection method of ultrasonic longitudinal wave reflection method and diffraction time difference method, and TOFD probe applied therein

InactiveCN110687205AIncrease the angleHigh energyAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping waveLongitudinal wave

The invention discloses a combined detection method of an ultrasonic longitudinal wave reflection method and a diffraction time difference method. The combined detection method comprises the followingsteps that 1, a TOFD probe and a creeping wave probe are installed on a scanning frame; 2, TOFD probe parameters and creeping wave probe parameters are set; 3, a workpiece is scanned; and 4, an imageis analyzed after the scanning is finished. According to the method, the defects that defects near a near surface and a bottom surface are missed and a plurality of pairs of probes need to be adoptedfor thick welding seams in an existing TOFD detection method are overcome, and ultrasonic automatic and semi-automatic detection is more perfect.

Owner:HARBIN ELECTRIC CORP QINHUANGDAO HEAVY EQUIP

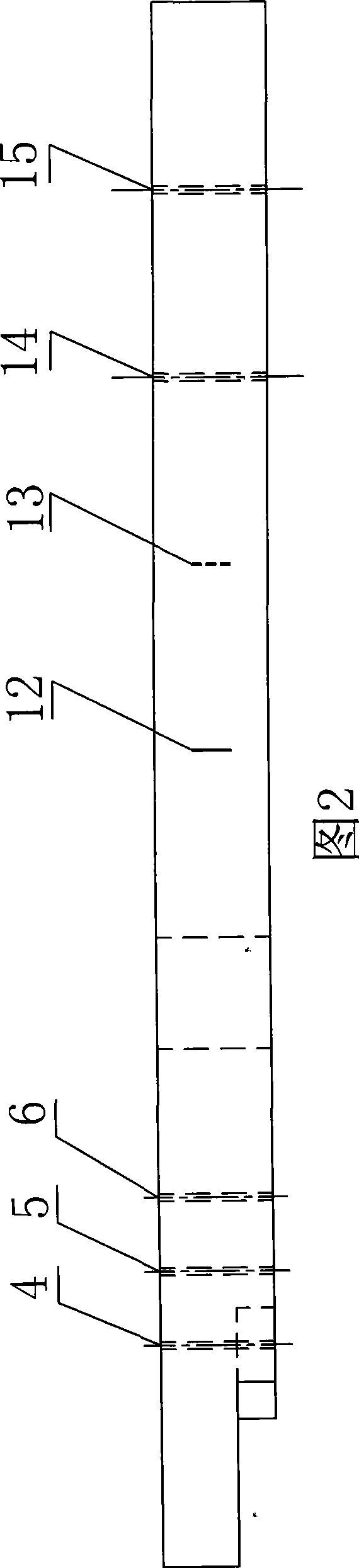

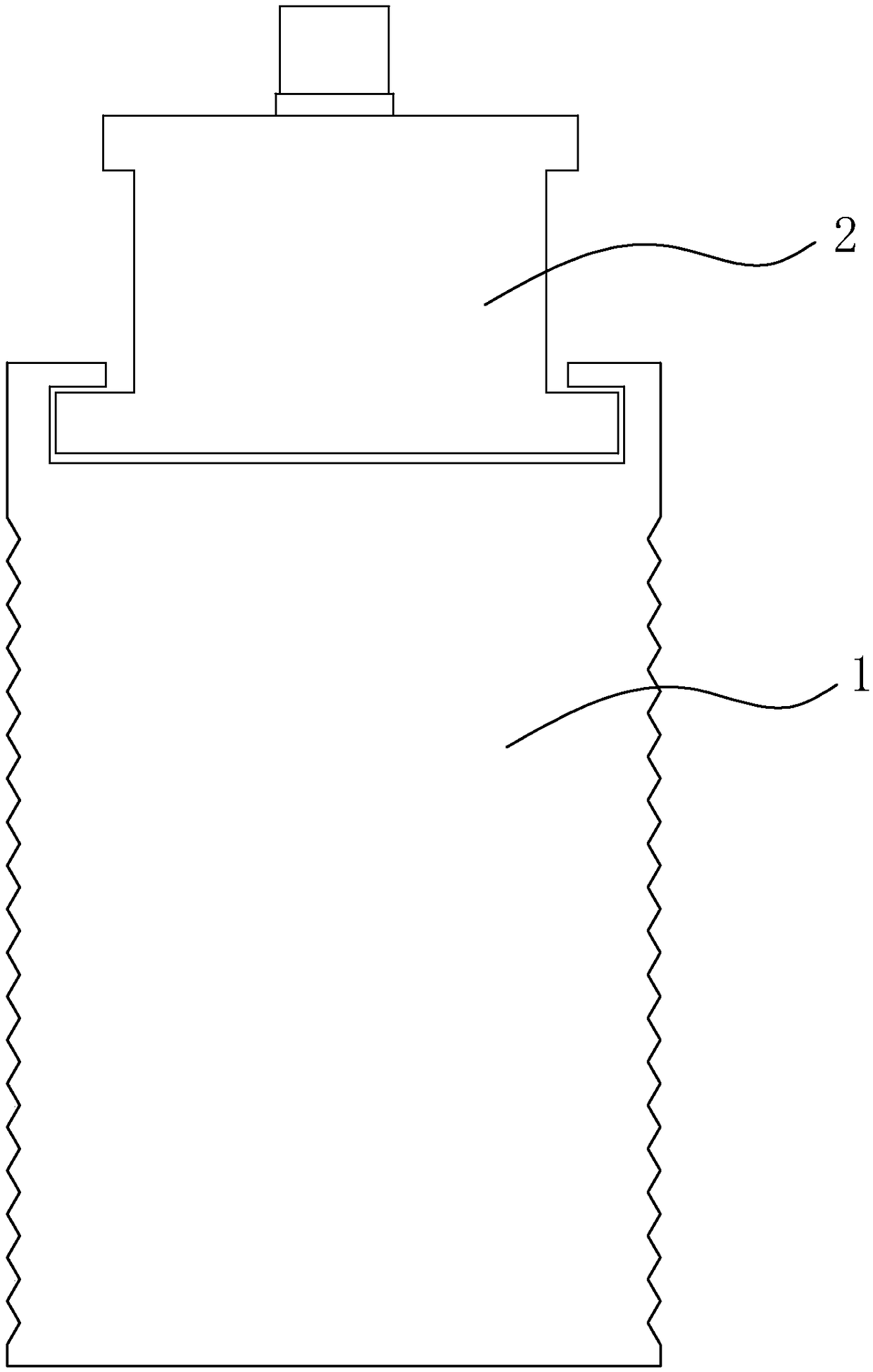

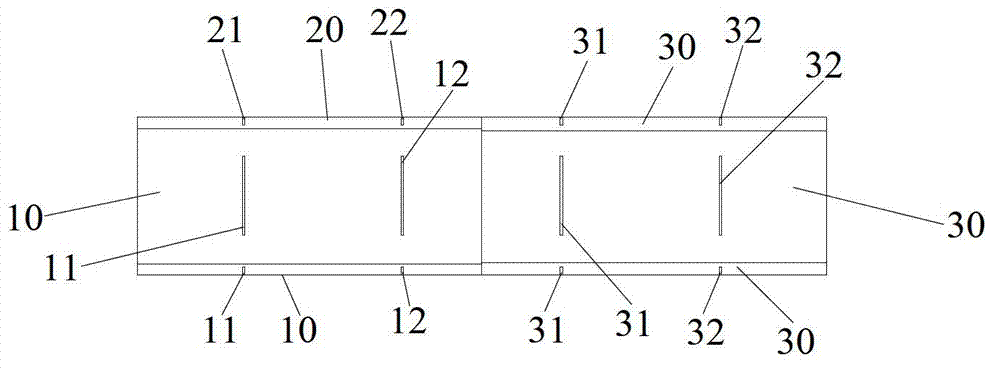

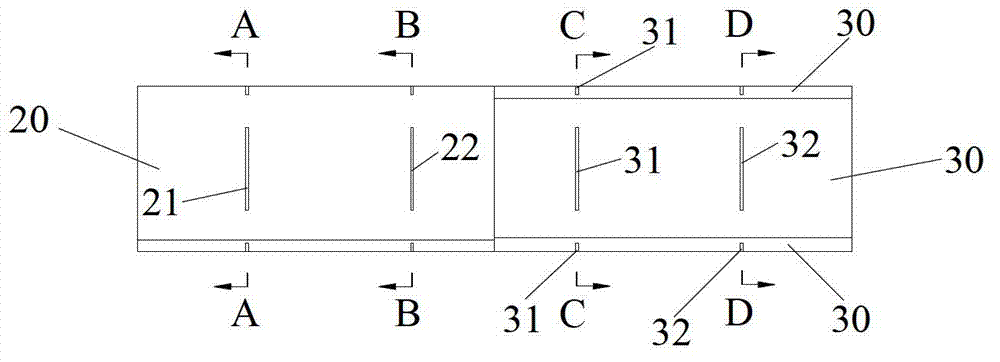

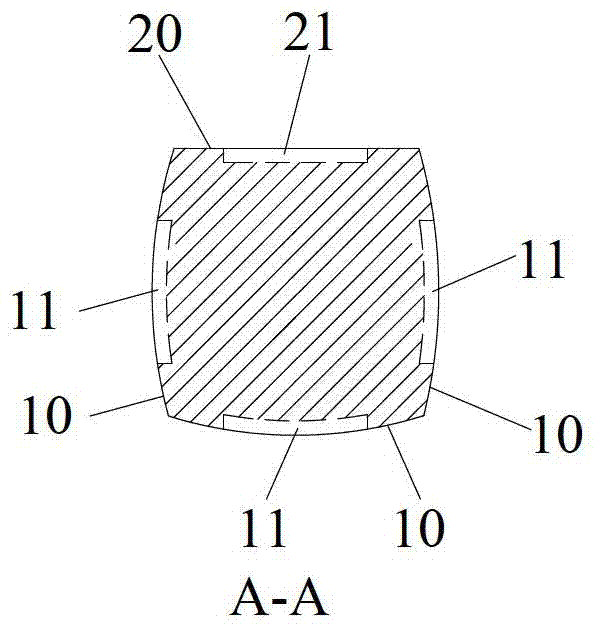

Ultrasonic creeping wave probe defect echo positioning device and method

PendingCN111610253ASolve the problem that the delay cannot be measured on ordinary test blocksSolve the problem of entry pointAnalysing solids using sonic/ultrasonic/infrasonic wavesNuclear energy generationCreeping waveWafering

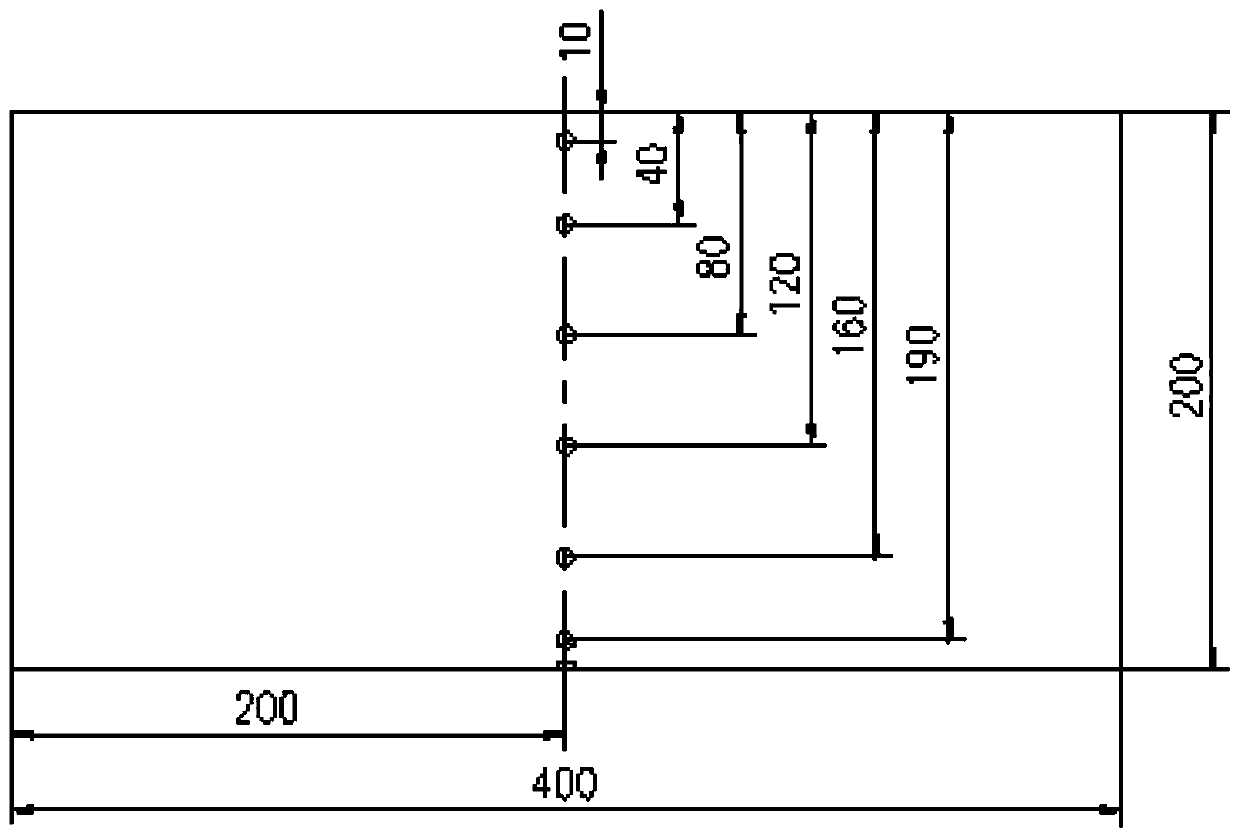

The invention discloses an ultrasonic creeping wave probe defect echo positioning device and method. The device comprises a block A, and the block A comprises a block C at the right end; scale marks Aare arranged on the front side surface of the block A; the block C is positioned on the right side of the scale line A; a block B is welded on the left side of the block A; a manual notch groove is formed in the upper side surface of the block B; scale marks B are arranged on the front side face of the block B, the scale marks B are located on the right side of the artificial notch groove, ultrasonic creeping wave probes are arranged above the block A and the block B, wedge blocks are arranged in the ultrasonic creeping wave probes, piezoelectric wafers are arranged on the wedge blocks, and the ultrasonic creeping wave probes are connected with an ultrasonic flaw detector through signal lines. According to the method, the incident point and the time delay of the ultrasonic creeping wave probe can be conveniently, rapidly and accurately measured, the problem that the time delay and the incident point of the ultrasonic creeping wave probe cannot be measured on a common test block is solved, and then accurate positioning of the horizontal position of a defect can be found.

Owner:国能锅炉压力容器检验有限公司

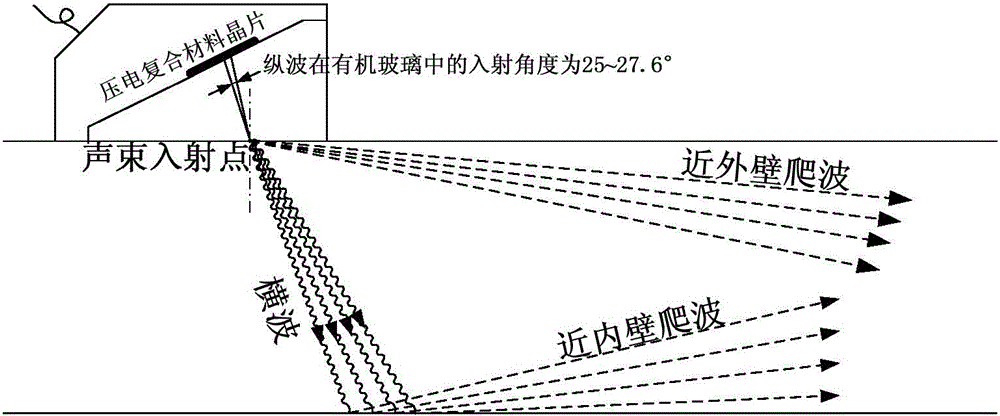

Creeping wave detection method for crack defects of austenitic stainless steel pipe for power station boiler

InactiveCN104634875AEasy to operatePracticalAnalysing solids using sonic/ultrasonic/infrasonic wavesCreeping wavePower station

The invention discloses a creeping wave detection method for crack defects of an austenitic stainless steel pipe for a power station boiler. The method comprises the following steps: (1) selecting frequencies of a creeping wave probe, a wedge block and a probe, polishing the bottom of the wedge block into an arc surface which is matched with a to-be-detected position of the austenitic stainless steel pipe for the power station boiler; (2) emitting a creeping wave by the creeping wave probe, bonding the creeping wave probe on the wedge block, and adjusting the incident angle of a transmitted longitudinal wave in a wafer wedge block of the creeping wave probe to be 25-27.6 degrees; and (3) attaching the arc surface of the bottom of the wedge block of the creeping wave probe to the to-be-detected position of the austenitic stainless steel pipe for the power station boiler, emitting the creeping wave through the creeping wave probe, emitting the creeping wave to the inner surface and the outer surface of the austenitic stainless steel pipe for the power station boiler, and then judging whether the crack defects exist or not according to the collected reflected waves on the inner surface and the outer surface of the austenitic stainless steel pipe for the power station boiler. According to the creeping wave detection method, detection of the crack defects on the austenitic stainless steel pipe for the power station boiler can be effectively finished.

Owner:XIAN THERMAL POWER RES INST CO LTD

Detection method of double-metal composite material seabed pipeline circumferential welding seam phased array partitioning method

InactiveCN108982663AImprove laying efficiencySolving the problem of shear wave detectionAnalysing solids using sonic/ultrasonic/infrasonic wavesArray data structureWeld seam

The invention provides a detection method of a double-metal composite material seabed pipeline circumferential welding seam phased array partitioning method. The detection method comprises the following detection steps: 1: placing a probe on a weld welding seam; 2: setting a plurality of reflection bodies on a groove and setting upper and lower time difference diffraction reflection bodies on inner and outer surfaces in the center of the welding seam respectively; 3: setting a plurality of groups of phased array probe covering region probes and a plurality of groups of creeping wave probe covering regions; carrying out monitoring detection on opening defects of upper and lower surfaces; 4: setting two display strip shapes; calibrating on a calibration test block and mounting a scanning device on the calibration test block; carrying out sensitivity calibration on each partitioned zone; 5: carrying out dynamic calibration on the calibration test block and detecting the welding seam; and6: carrying out comprehensive evaluation on the quality of the welding seam. According to the detection method provided by the invention, the difficulty of transverse wave detection of a composite material is overcome and defects with different types of each position are effectively detected; and the field detection efficiency and the detection quantitative precision of welding the seabed pipelinewelding seam are greatly improved and the quality of the welding seam is controlled.

Owner:OFFSHORE OIL ENG

Austenitic stainless steel fillet weld ultrasonic detection method

ActiveCN111458406ASolving Ultrasonic Testing NeedsGuarantee welding qualityAnalysing solids using sonic/ultrasonic/infrasonic wavesFillet weldCreeping wave

The invention discloses an austenitic stainless steel fillet weld ultrasonic detection method. The method comprises the steps that: an A-type pulse reflection type ultrasonic flaw detector is adopted;different types of probes are adopted according to different detection positions and objects; reference blocks are selected and manufactured; detection sensitivity is adjusted; a workpiece is prepared; scanning is performed through probes; defect quantification and evaluation are performed. A longitudinal wave bicrystal angle probe, a longitudinal wave bicrystal straight probe and a bicrystal creeping wave probe are comprehensively used; an angle butt joint comparison sample is developed; a set of special detection method is formed; the ultrasonic detection requirement of an austenitic stainless steel fillet weld is met; and the quality of the weld is guaranteed.

Owner:NANJING CHENGUANG GRP

Creeping wave detection device for inner wall defects of thick-walled tube

PendingCN109085253AAvoid the problem of not being able to reach the inner wallSolve the problem of large limitations of deformed shear wavesUltrasonic/sonic/infrasonic wave generationCreeping waveLongitudinal wave

Owner:GUANGDONG INSPECTION & RES INST OF SPECIAL EQUIP ZHUHAI INSPECTION INST

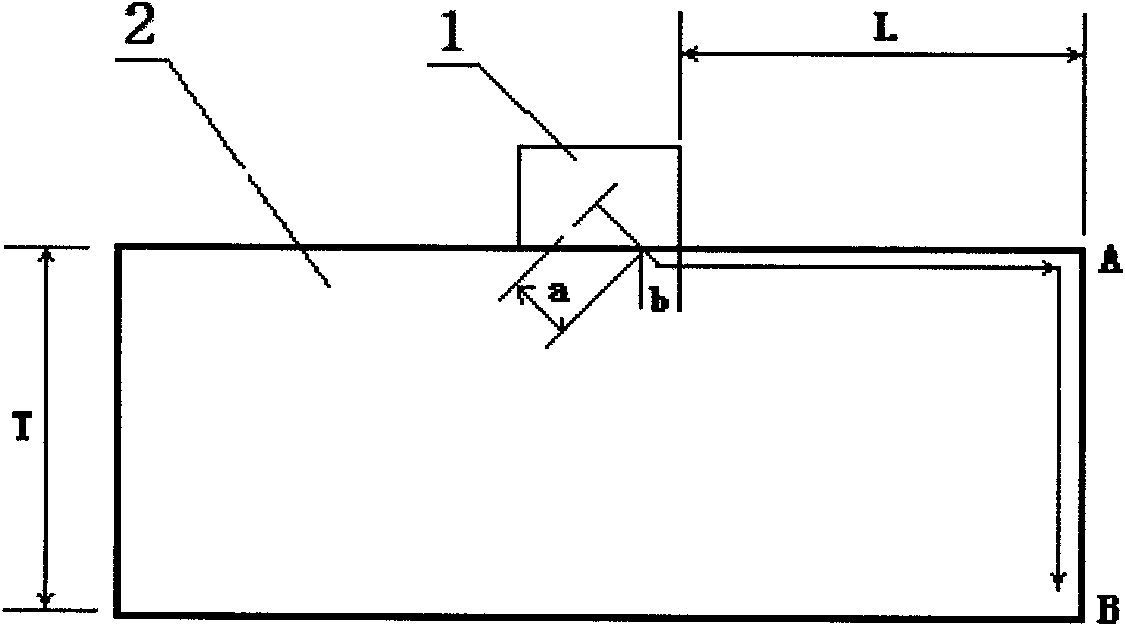

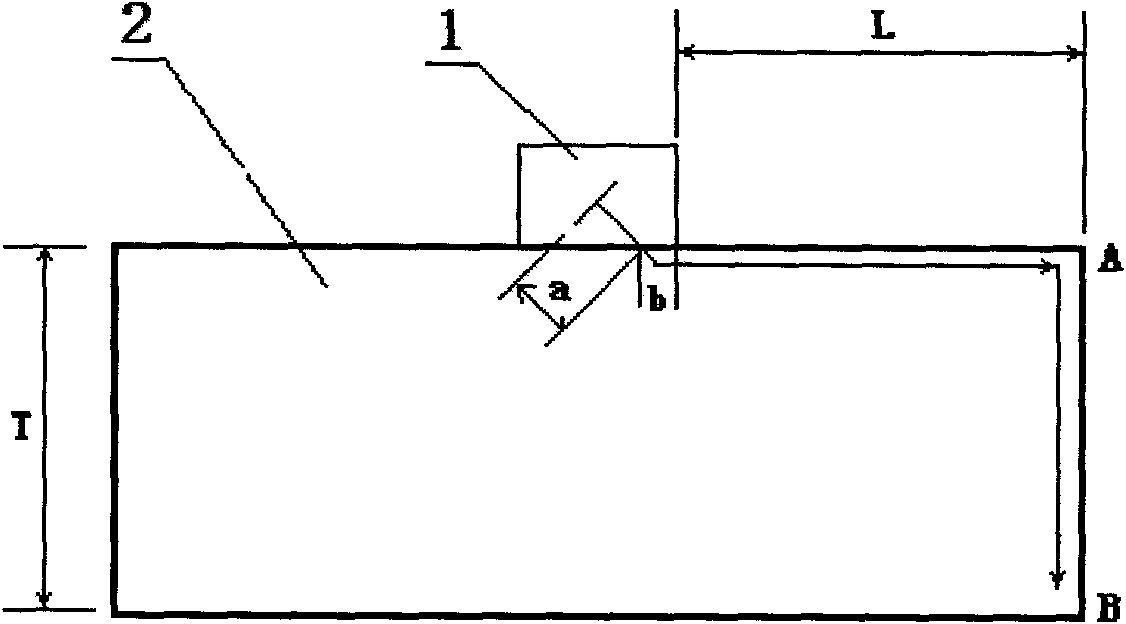

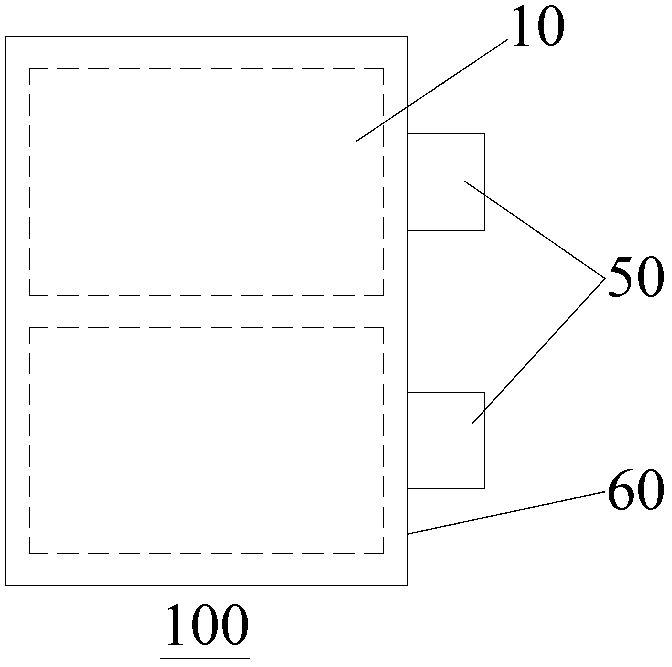

Comparison test block for creeping wave fault detection

InactiveCN102818858ADetermine sensitivityDetermine the standard amount of crackMaterial analysis using sonic/ultrasonic/infrasonic wavesCreeping waveParallel computing

The invention discloses a comparison test block for creeping wave fault detection, wherein the comparison test block has a column structure, in addition, one end of the comparison block is provided with at least one detection surface (10), the first detection surface (10) is a part of the cylindrical surface and is outwards projected, the bus line direction of the first detection surface (10) is the same as the length direction of the comparison test block, in addition, first detection grooves (11) are arranged in the first detection surface (10) and are grooves with the same depth, and in addition, the first detection grooves (11) extend in the circumference direction of the first detection surface (10). The first detection surface of the comparison test block can simulate the surface of an object to be tested, after a creeping wave probe is pasted with the first detection surface of the comparison test block, the first detection grooves arranged in the first detection surface can be used for determining the sensitivity during the creeping wave detection, and in addition, the reflection equivalent weight during the creeping wave fault detection can be determined.

Owner:CHINA SHENHUA ENERGY CO LTD +2

A Ray Tracing Method for Dynamic Adjustment of Cutting Surfaces Under Triangular Mesh Surfaces

ActiveCN106126794BStrong engineering versatilityFacilitates electromagnetic calculationsSpecial data processing applicationsCreeping waveComputer science

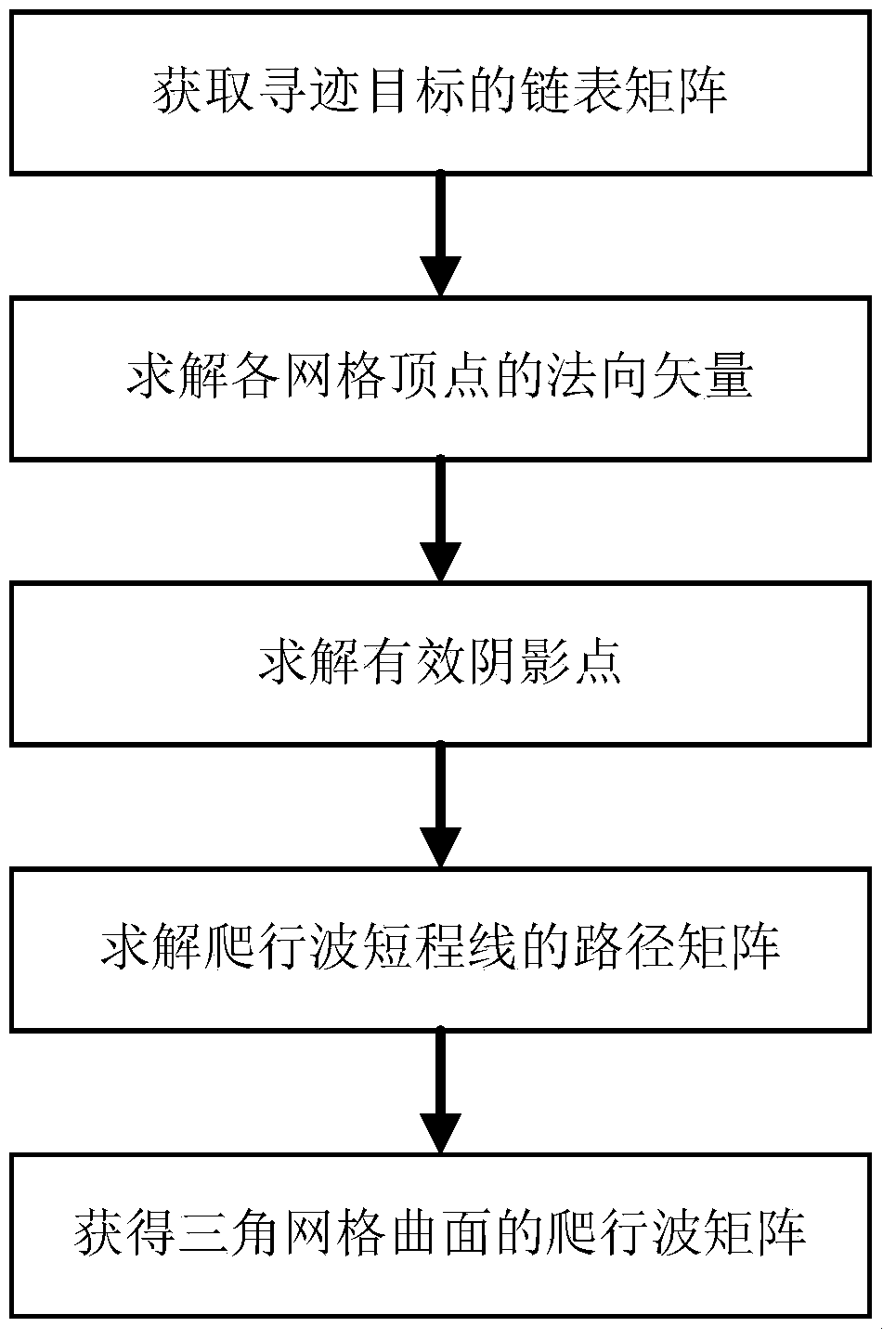

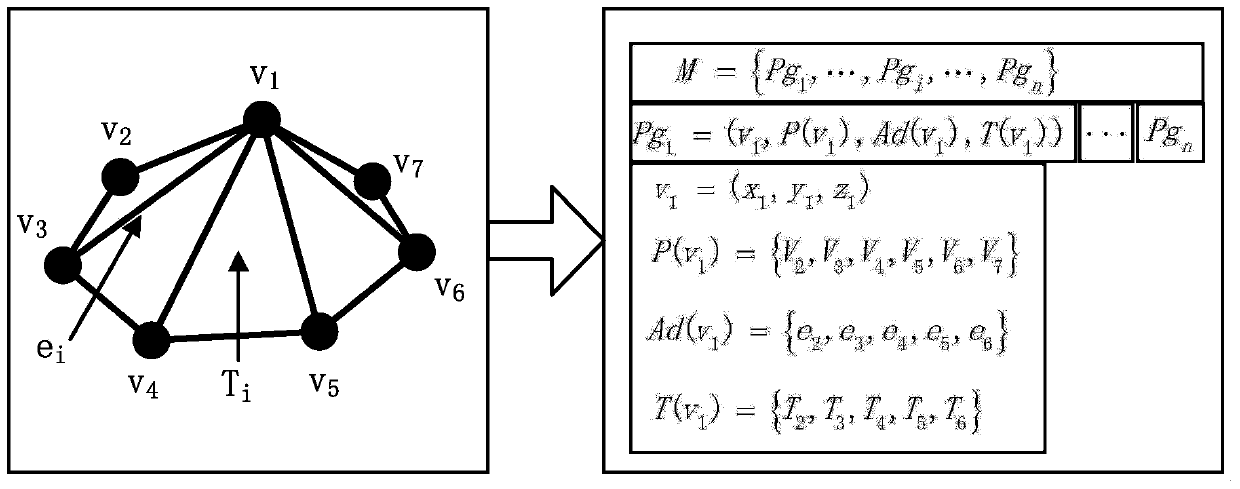

The invention discloses a radial trailing method with a dynamically adjustable cut surface for a triangular mesh surface. The method comprises the steps of firstly parsing a triangular mesh file in an NAS format, and thus acquiring a chain table matrix of the triangular mesh surface; implementing an area-angular rate weighting method on the chain table matrix to acquire a normal vector of each node of the mesh; acquiring a valid shadow point of a target according to the normal vector of each node of the mesh, a radial trailing source point and an initial incident direction; and using the valid shadow point as a start, acquiring the cut surface based on a propagation direction and the normal vector of a current triangular mesh apex, continuously cutting until a trailing ending condition is met, acquiring a path matrix of creeping wave geodesic lines, and at last acquiring a creeping wave arc by using a fitting method. According to the method of the invention, the complex optimization problem is avoided, the trailing speed is enhanced, in addition, a creep wave tailing model adopts pure analytical geometry for computation, and thus the method has no numerical error and no optimization error, and is good in trailing accuracy and stability.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com