Detection method of double-metal composite material seabed pipeline circumferential welding seam phased array partitioning method

A technology for composite materials and submarine pipelines, which is applied in the direction of material analysis, analysis materials, and measuring devices using sound waves/ultrasonic waves/infrasonic waves, which can solve problems such as undetectable, attenuation, and difficulty in ensuring quantitative accuracy, so as to avoid radiation hazards and improve The effect of detecting efficiency and improving laying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

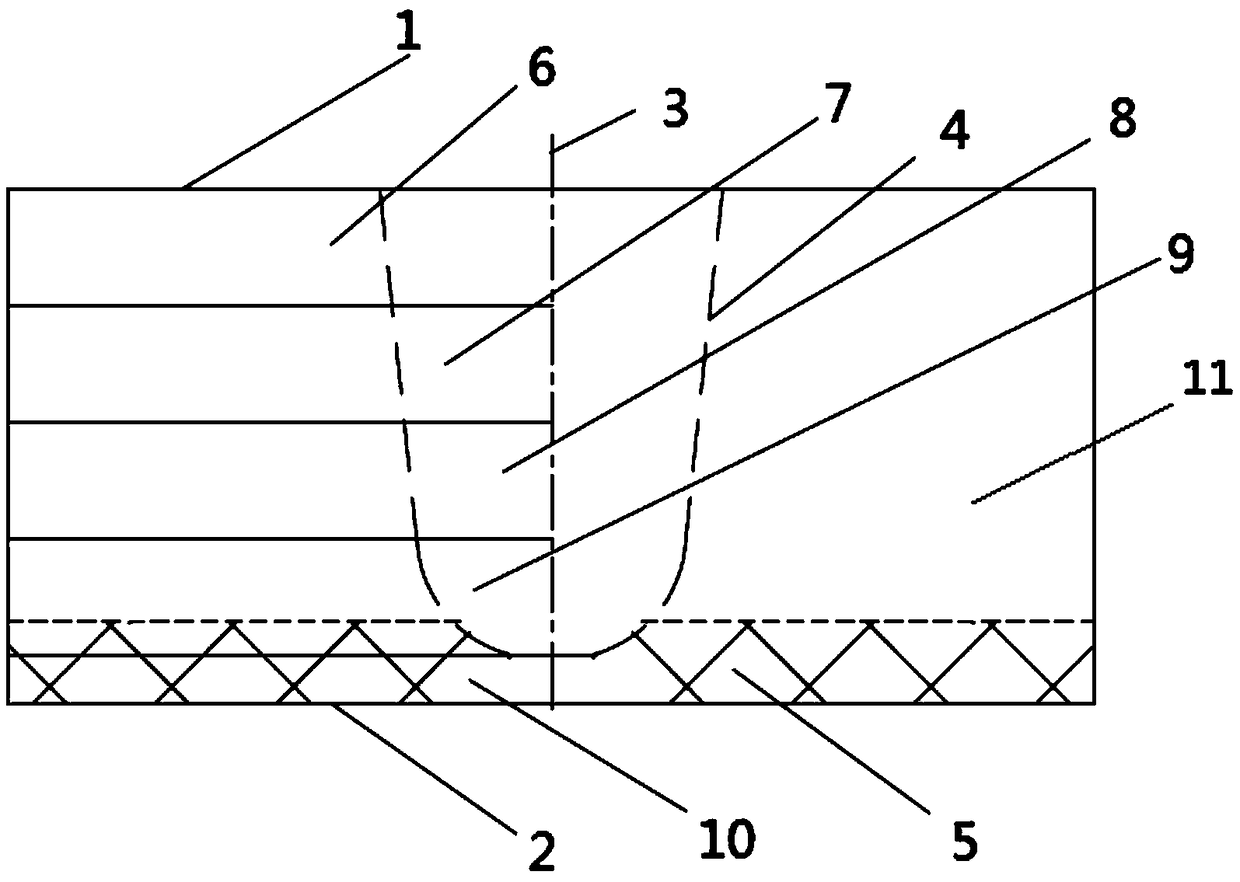

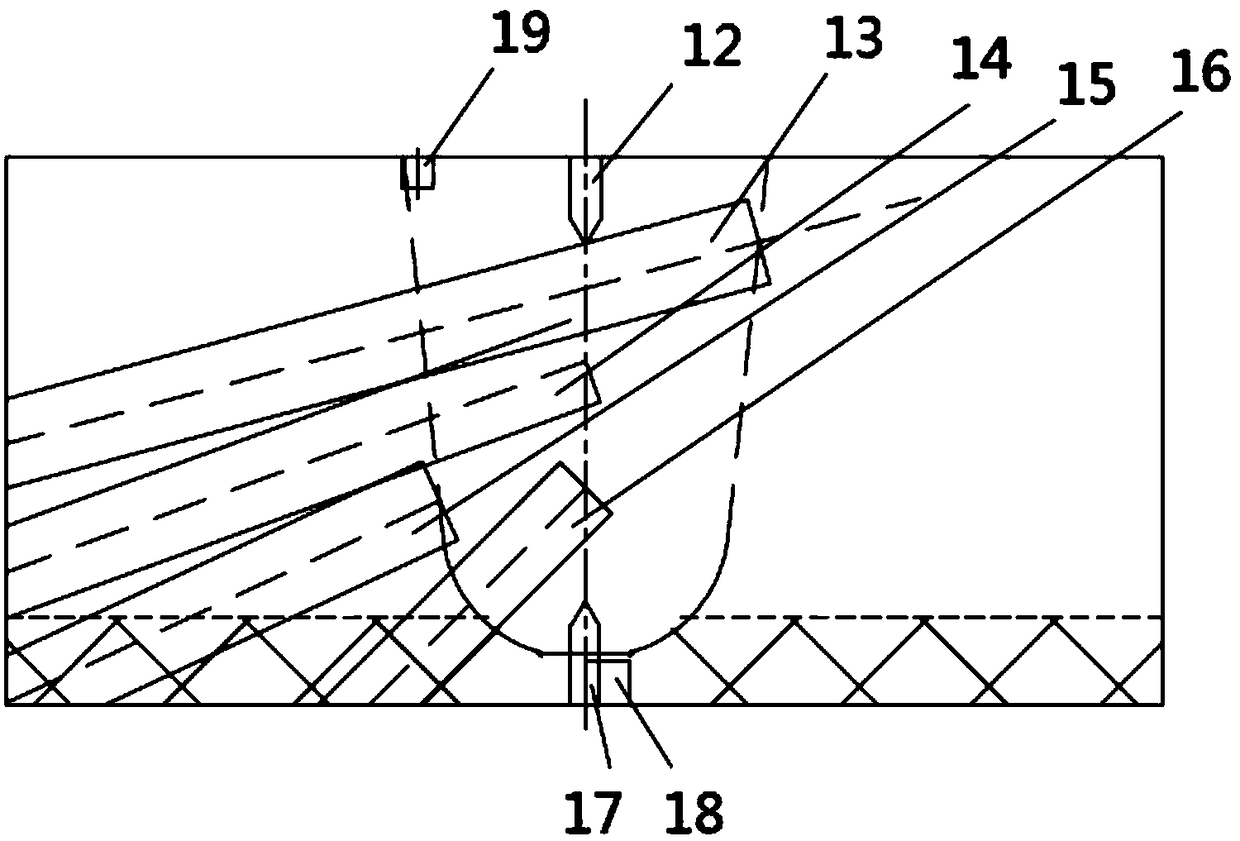

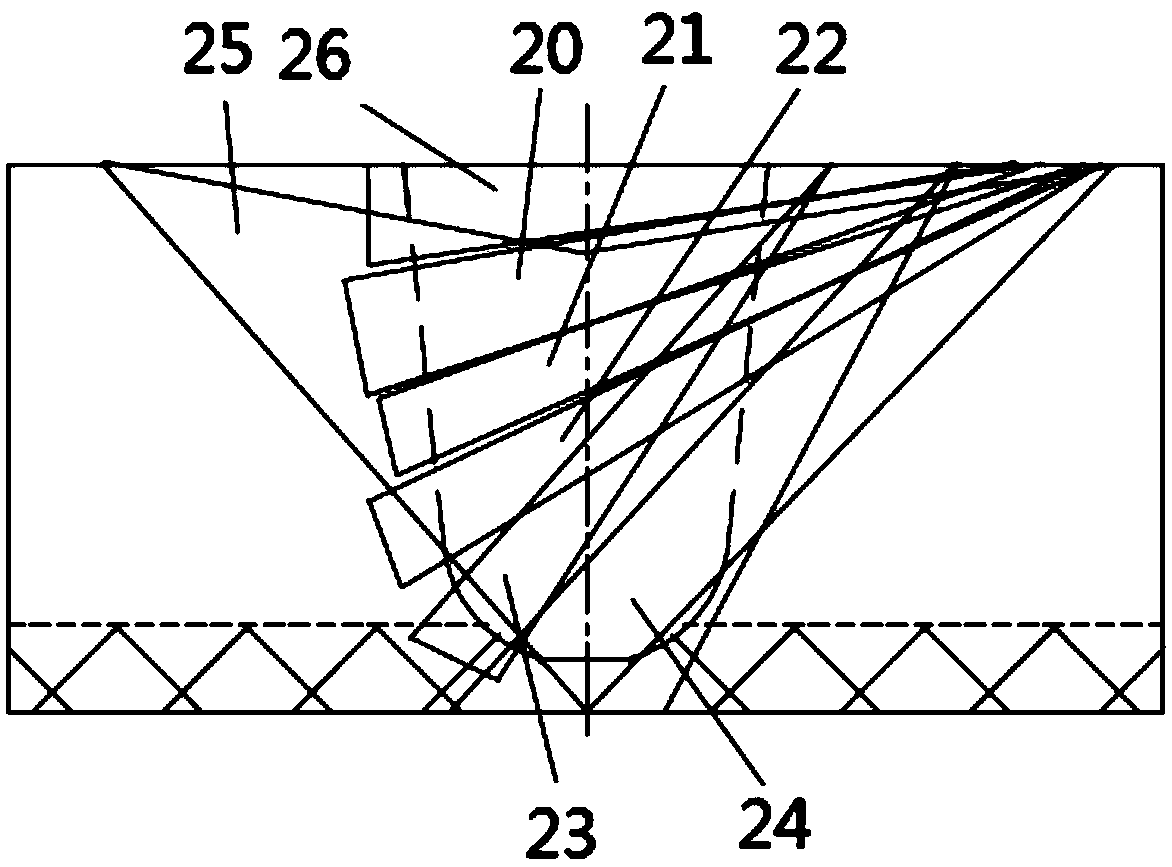

[0025] Such as figure 1 As shown, the selected pipeline size is: 10”x18.9mm, the groove type is: J-shaped groove, the detection material is bimetallic composite material, the material of carbon steel base material 11 is: API 5L X65, and the inner lining layer 5 The thickness is: 3mm stainless steel, the material of the weld filling area is: nickel-based 625, and the metallurgical bonding is used for detection within 100mm of the pipe end. The specific steps of the detection are as follows:

[0026] The first step: if figure 1 As shown, the probe is placed on the upper surface 1 of the weld, and the lower surface 2 of the weld is a non-probe placement surface. According to the form of the weld groove, several weld partitions are respectively set on the weld groove surface 4 (this embodiment It is: the first weld zone 6, the second weld zone 7, the third weld zone 8, the fourth weld zone 9, the fifth weld zone 10), wherein the height of several weld zones is controlled at 1- 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com