Ultrasonic TOFD technology detection method for butt seam of different thickness plates

A butt weld and technical inspection technology, which is applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids and other directions, can solve problems such as the inability to detect thick plate weld parts, and achieve the effect of broadening the range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In conjunction with the content of the method of the present invention, the following numerical simulations and experimental tests are provided:

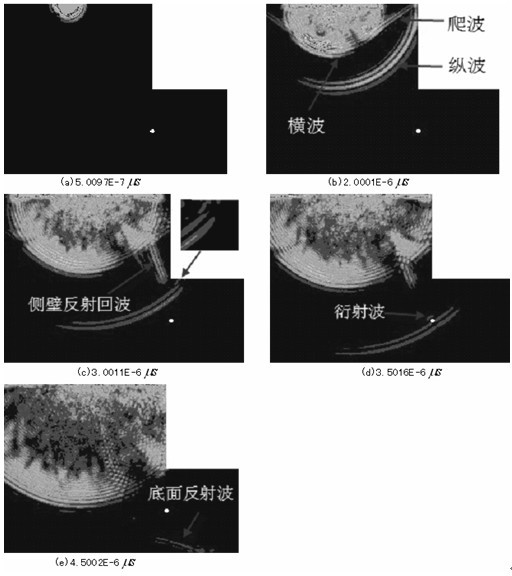

[0017] 1) Numerical simulation example

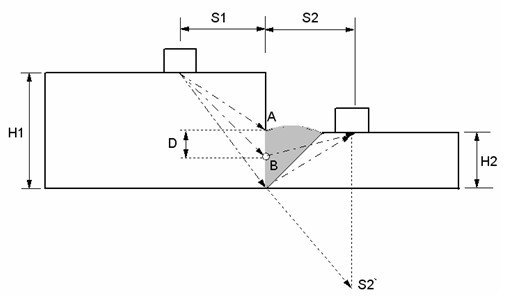

[0018] 1) Build as figure 1 The finite element model of the ladder-type test block shown is used for TOFD detection of welded joints of unequal thickness plates. The geometric parameters of the finite element model corresponding to the test block are shown in Table 1, and the material of the finite element model is steel. The diameter of the transverse through hole at the depth D=5mm from the surface of the thin plate at the butt joint is 1mm.

[0019] Table 1

[0020]

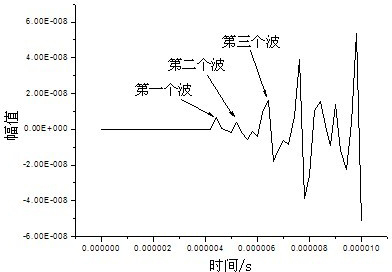

[0021] For this method, a stepped artificial defect test block is made, with a high plane thickness 20mm, bottom plane thickness is 10mm, and the defect depth is 5mm. Choose a probe with a longitudinal wave refraction angle of 60°, and the lengths S1 and S2 between the probe and the step are both 10mm. The r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com