Welding surface and near-surface crack depth detection device

A technology of depth detection and welding surface, which is applied in the direction of measuring device, analysis of solids by using sound wave/ultrasonic wave/infrasonic wave, and material analysis by using sound wave/ultrasonic wave/infrasonic wave, etc. and other problems to achieve the effect of avoiding missed detection, reducing work intensity and improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

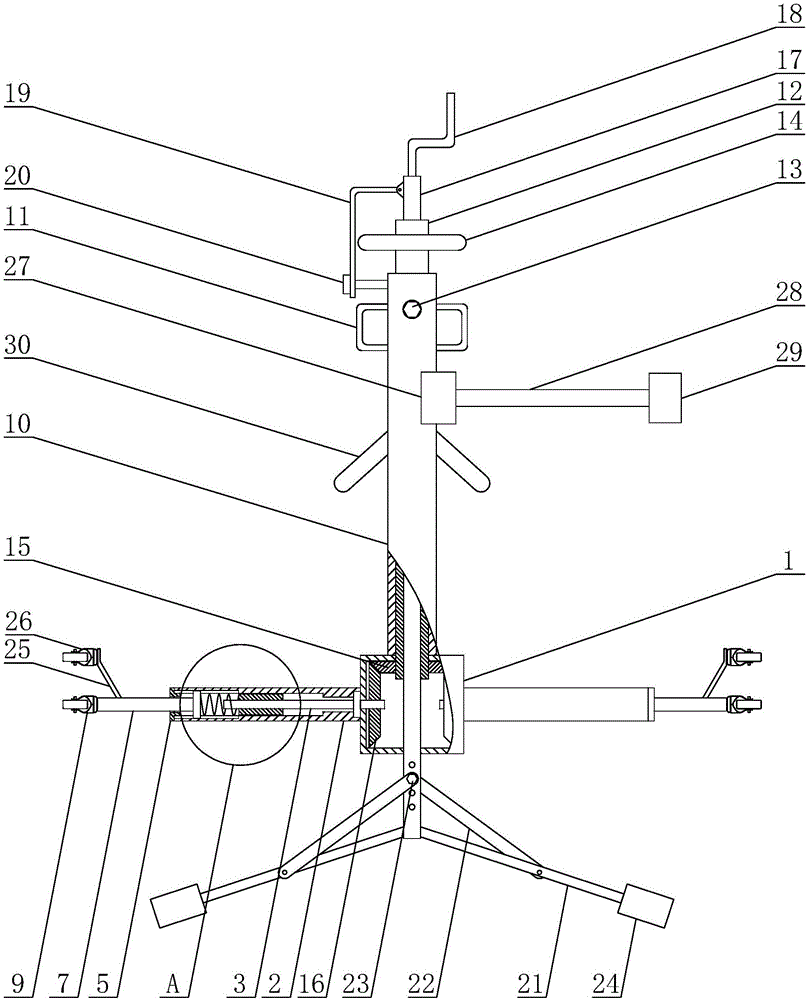

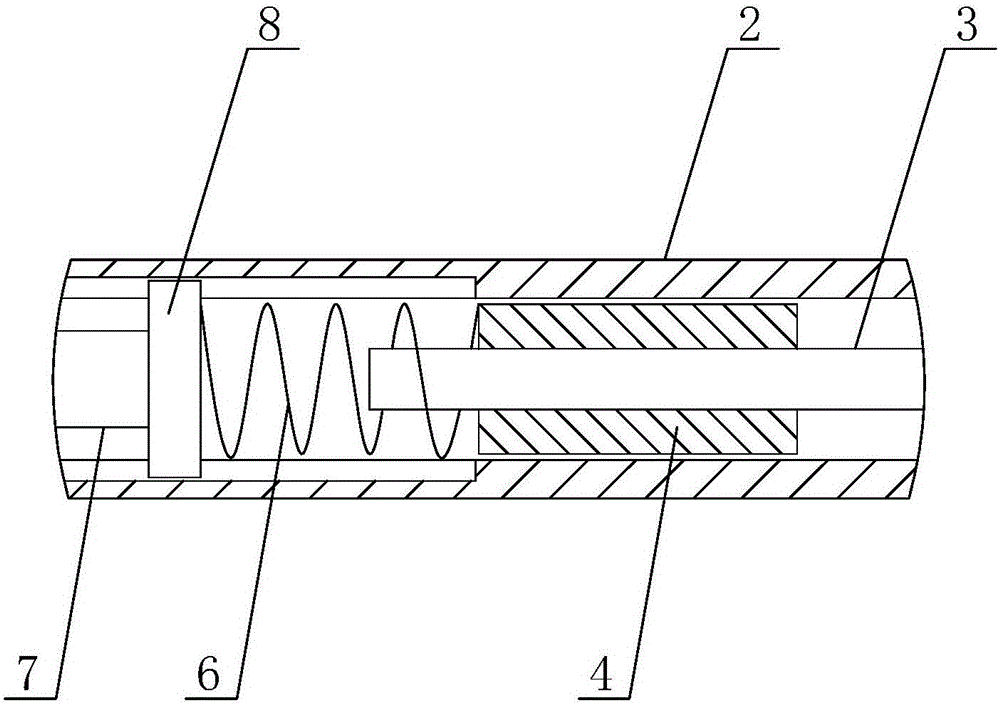

[0022]Embodiment: The present invention is a welding surface and near-surface crack depth detection device, including a support base 1, a cavity is provided in the support base 1, a support cylinder 2 is arranged on the support base 1, and the support base 1 The cylinder 2 communicates with the cavity, the number of the support cylinders 2 is three, the axes of the three support cylinders 2 are on the same plane, and the angle between adjacent support cylinders 2 is 120°, The invention can be stably fixed in chemical containers and pipelines. A screw 3 is arranged inside the support cylinder 2, and the screw 3 is rotationally connected with the support cylinder 2 through a bearing. The outer wall of the transmission tube 4 is provided with a slider, the inner wall of the support tube 2 is provided with a chute suitable for the slider, the transmission tube 4 is slidably connected with the support tube 2, and the screw rod 3 rotates It can drive the transmission pipe 4 to move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com