Ultrasonic detection method for defects of welding position of through-wall pipe of peak shaving unit

A detection method and a technology of a peak-shaving unit, which are applied in the use of sound waves/ultrasonic waves/infrasonic waves to analyze solids, use sound waves/ultrasonic waves/infrasonic waves for material analysis, and measurement devices, etc. Defect detection and other issues to achieve the effect of improving the fit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Include the following steps:

[0028] (1) Use the same batch of original pipes to be inspected to make test blocks;

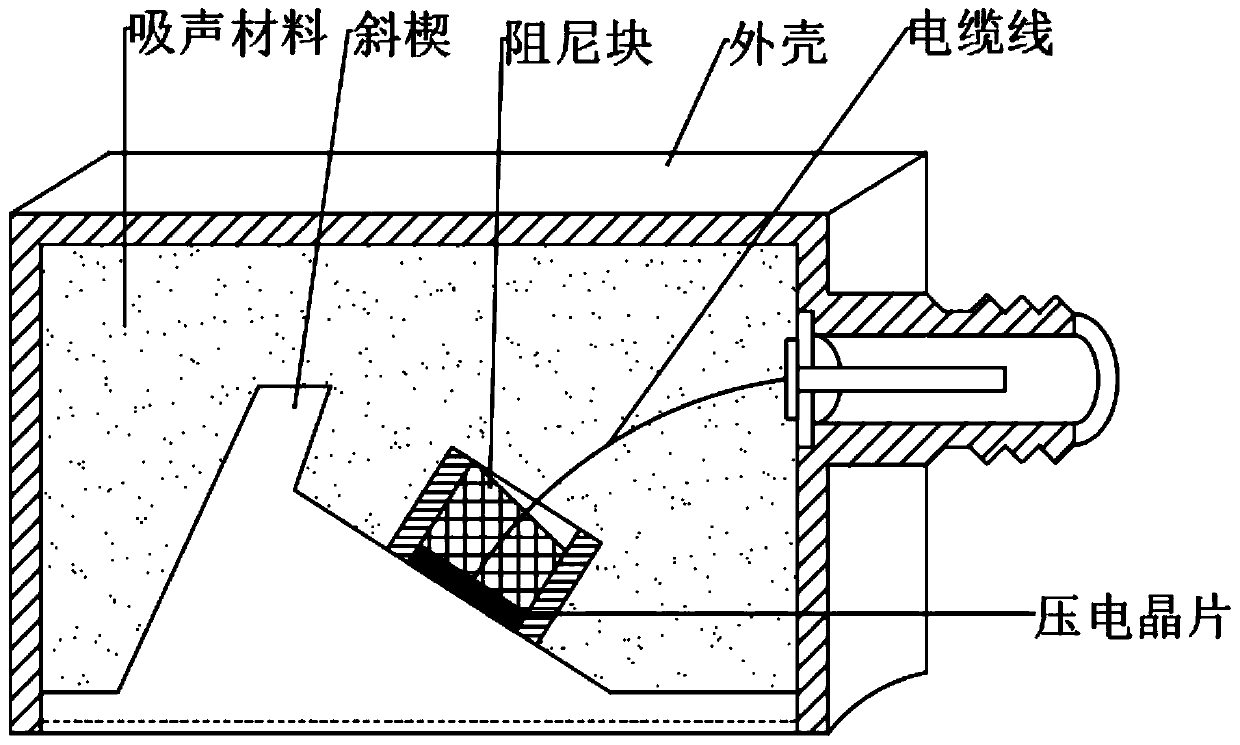

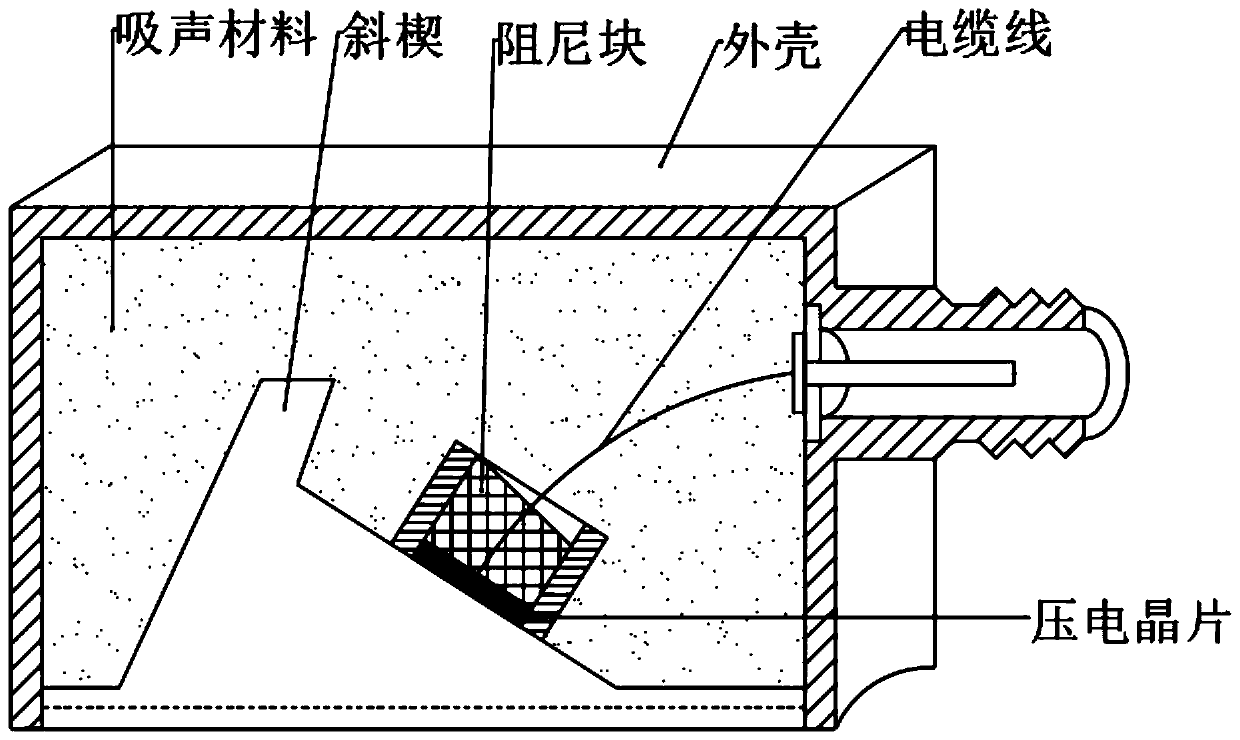

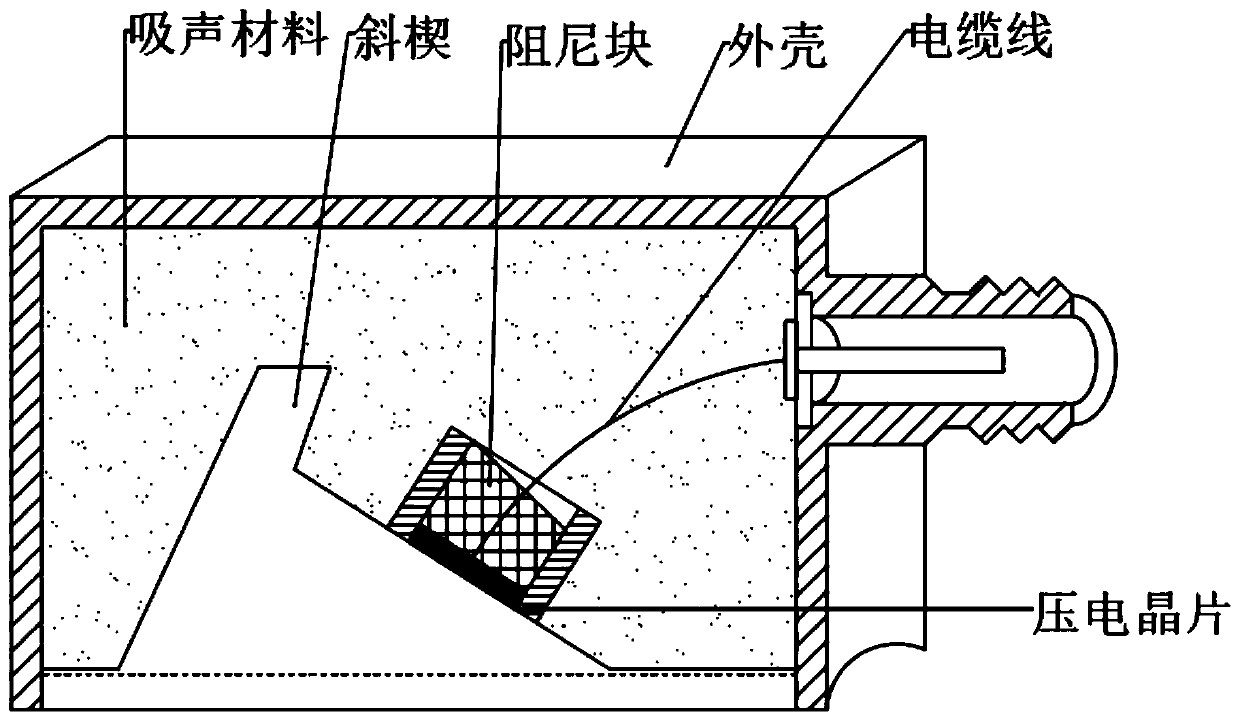

[0029] (2) Design a detection probe with a radian to improve the fit between the probe and the pipeline;

[0030] (3) Select a suitable couplant to ensure that the ultrasonic energy can pass into the sample to be tested;

[0031] (4) Use the test block to adjust the sensitivity, and measure the AVG curve and DAC curve;

[0032] (5) Select the K1 probe and use the secondary wave to detect the weld and butt weld at the connection between the wall pipe and the casing;

[0033] (6) Select the K2 probe and use the primary wave to detect the weld and butt weld at the connection between the wall pipe and the casing;

[0034] (7) Select the creeping wave probe to detect the butt weld of the wall-piercing pipe, and detect the weld at the joint between the wall-piercing pipe and the casing with defects to determine whether the defect extends to the wall of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com