Ultrasonic testing method for butt-jointed seam of steel tube tower in electric transmission line

A technology for butt welds and power transmission lines. It is applied in the direction of using sonic/ultrasonic/infrasonic waves to analyze solids. It can solve the problems of environmental pollution, high cost, personal injury, etc., and achieve high detection sensitivity, high work efficiency and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

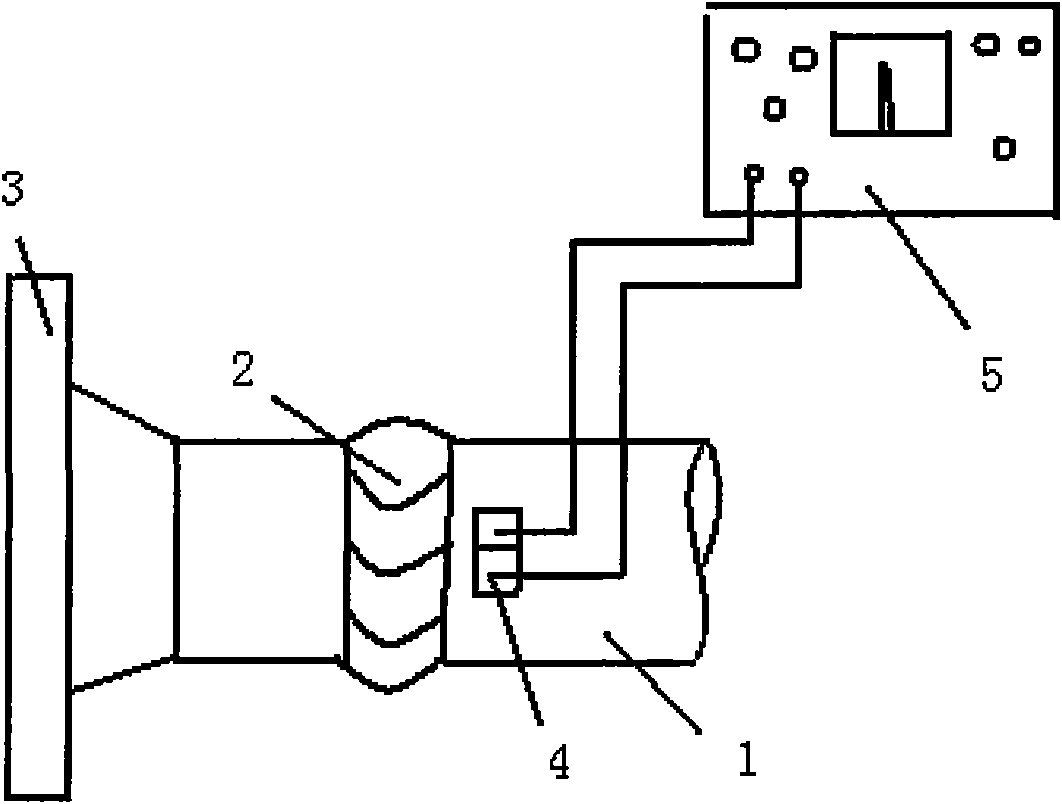

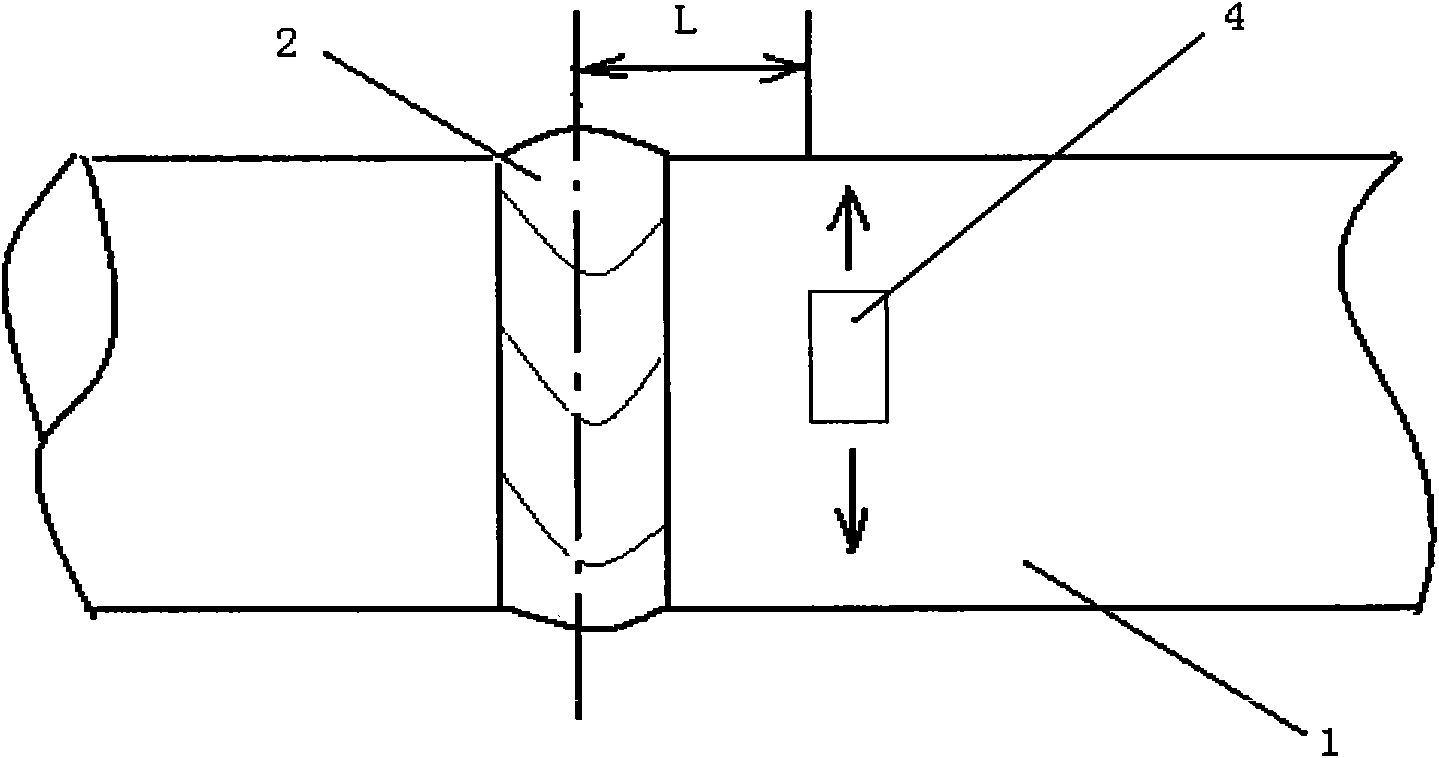

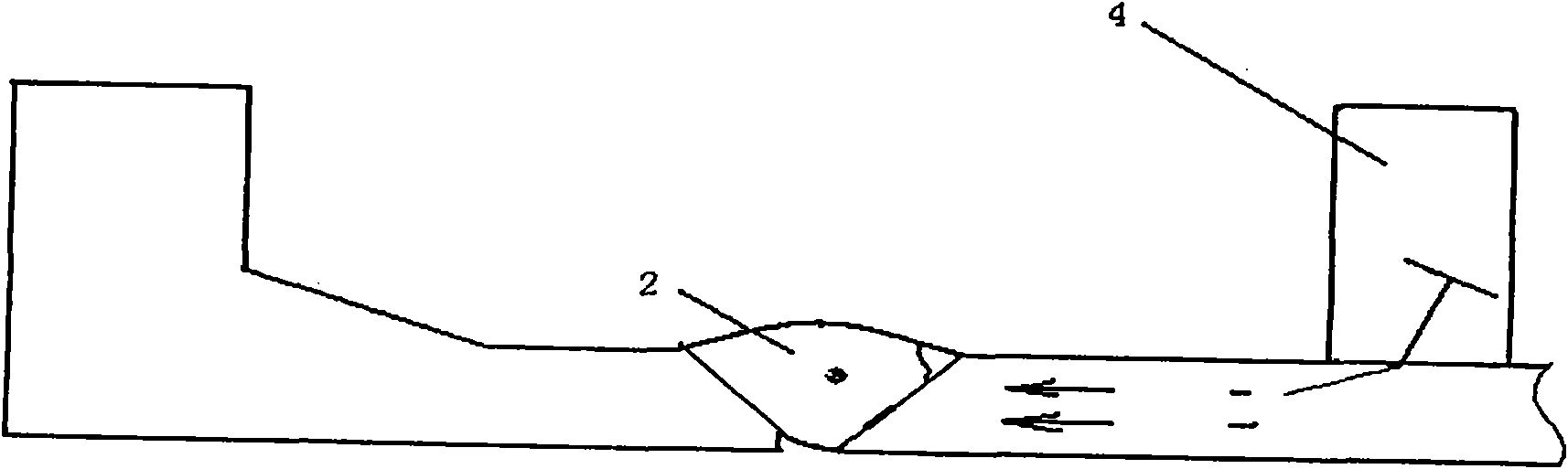

[0029] The preferred embodiment of the present invention is described in more detail below with reference to the accompanying drawings of the present invention.

[0030] 1. Preparation before ultrasonic testing

[0031] (1) Clarify the calibration of weldment material, specification, welding process, heat treatment, groove type and center position of welded joint;

[0032] (2) The surface quality and appearance dimensions of welded joints shall pass the inspection;

[0033] (3) The steel pipe side of the welded joint should remove spatter, rust, oxide and oil, and the surface should be polished smooth, with a grinding width of 30mm;

[0034] (4) For the base metal on both sides of the welded joint, the thickness of the pipe wall should be measured before ultrasonic testing, at least every 90. measure a little;

[0035] (5) The coupling agent has good wetting ability and sound permeability, and uses machine oil or water-based cellulose derivatives;

[0036] (6) The selected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com