Method for detecting welding seam of resistance weld pipe through creeping wave and creeping wave probe for method

A technology for creeping wave probes and resistance welded pipes, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measuring devices. Inadequate problems, to achieve the effect of reducing the workload of scanning, high detection sensitivity, and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings.

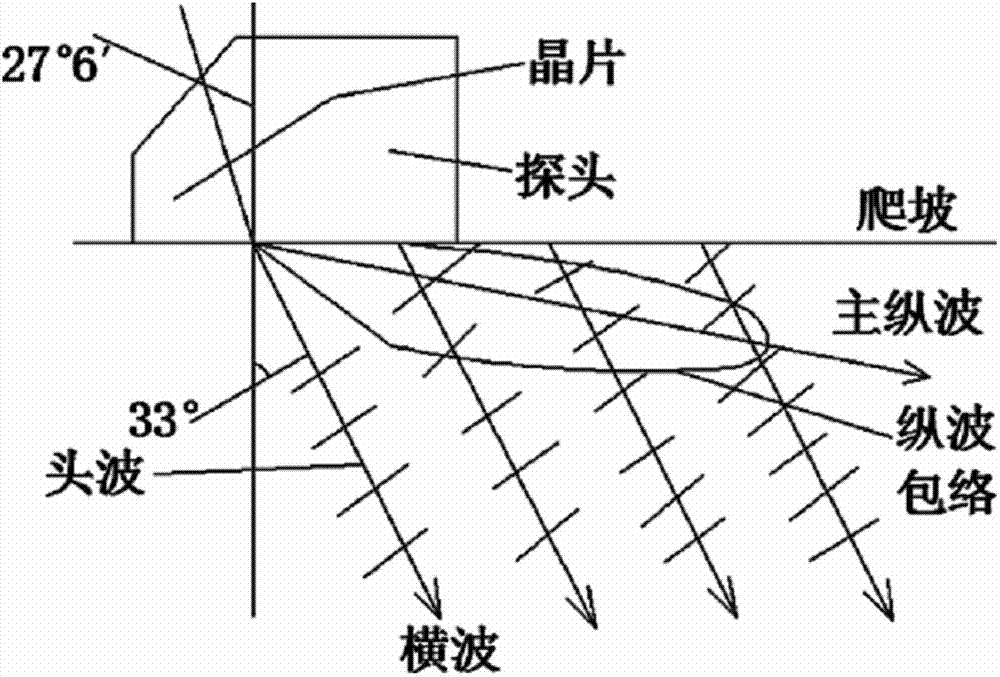

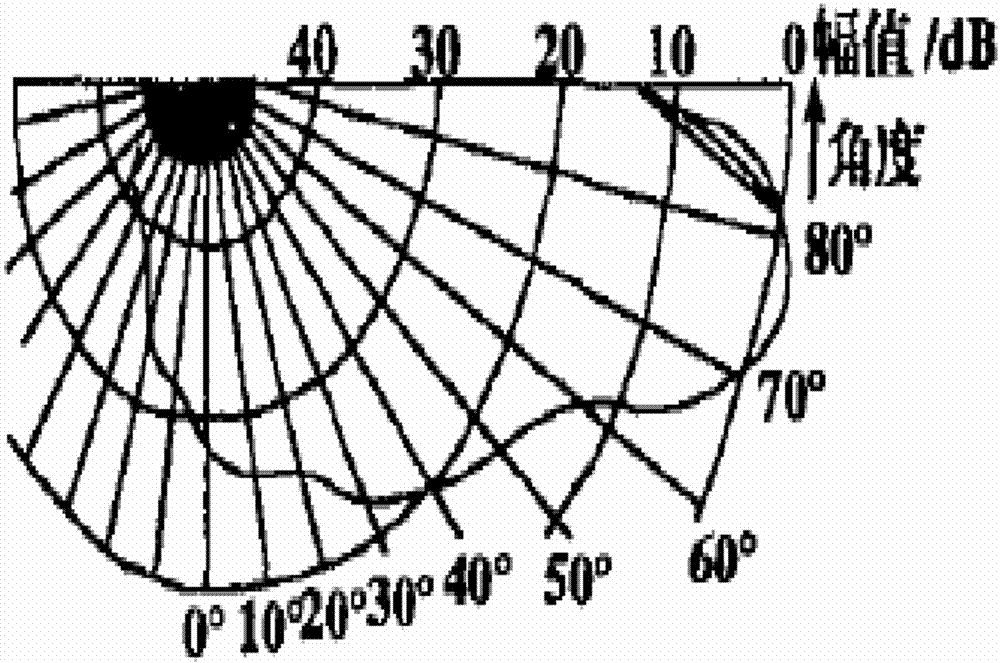

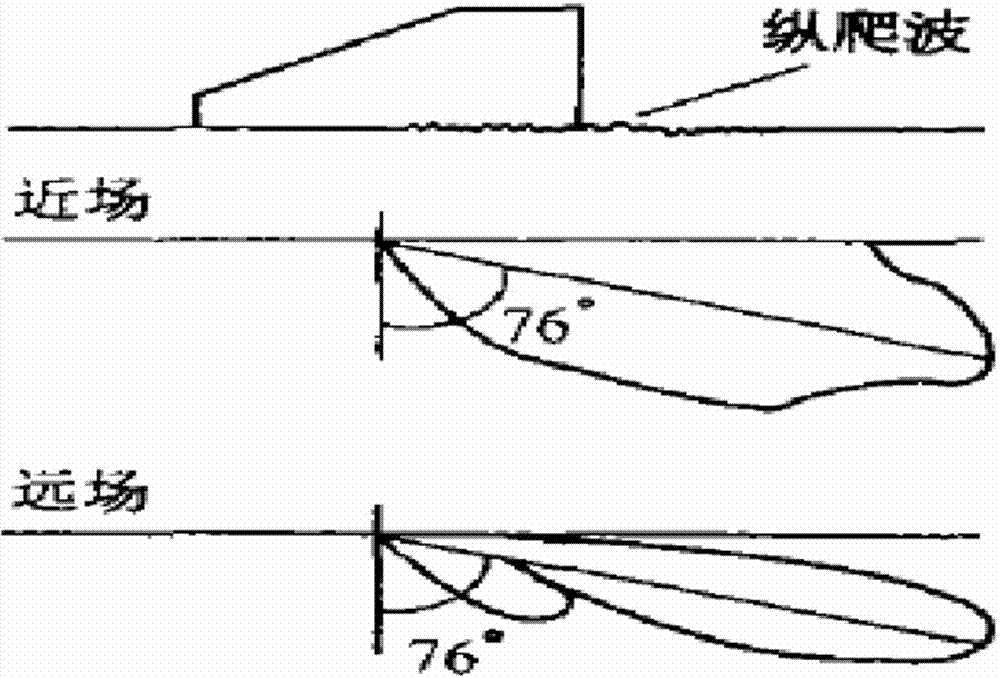

[0029] Climbing wave, also known as subsurface longitudinal wave, is a longitudinal wave that propagates close to the surface. It can detect defects near the surface and is insensitive to surface roughness. The probe whose incident angle is near the first critical angle (in plexiglass) can be used in steel A creeping wave is generated, and the probe is called a creeping wave probe. The schematic diagram of the sound field of the creeping wave probe is shown in figure 1 , The sound field excited by the creeping wave probe has the characteristics of multi-wave types, and the shear wave and head wave of about 33° are also generated while the climbing wave is generated. Under the condition that the probe is fixed, the creeping wave and the shear wave radiate outward from the vicinity of the incident point; while the head wave is a shear wave that is continuously radiate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com