Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

30 results about "Coal-water slurry fuel" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Coal-water slurry fuel is a combustible mixture of fine coal particles suspended in water. It can be used to power boilers, gas turbines, diesel engines and heating and power stations.

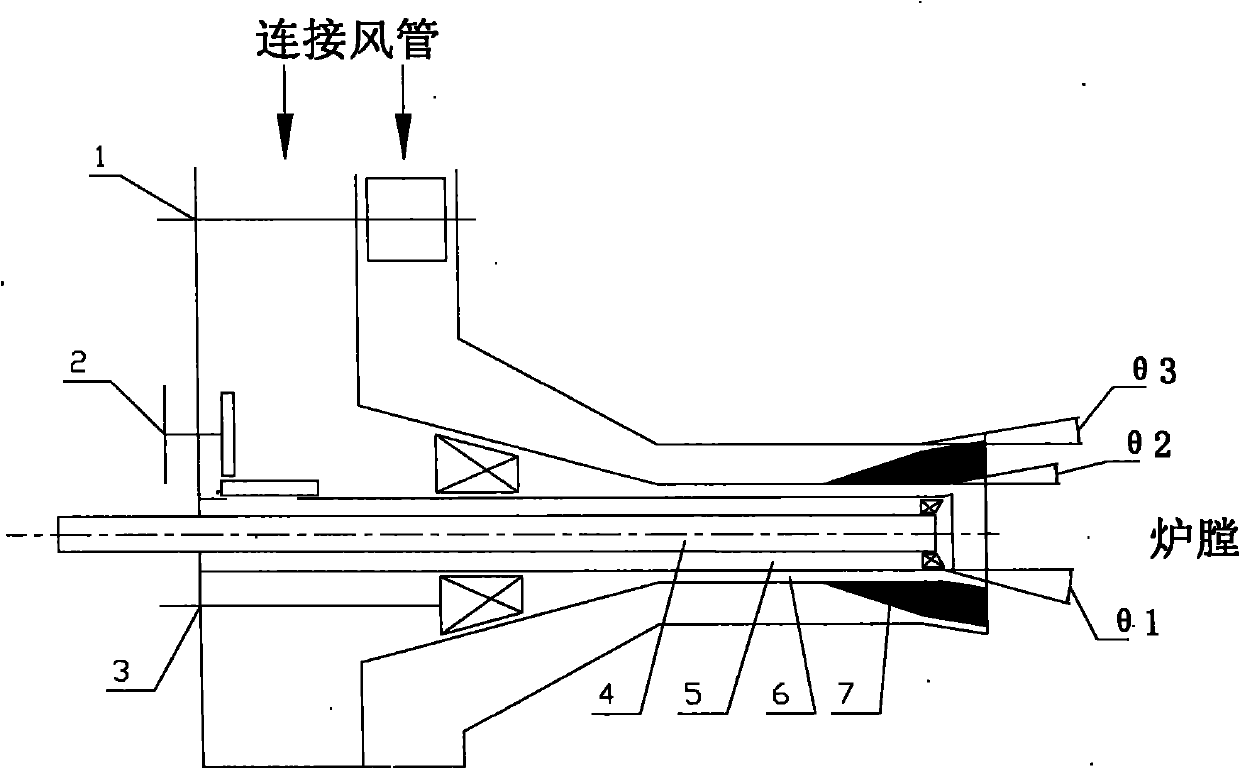

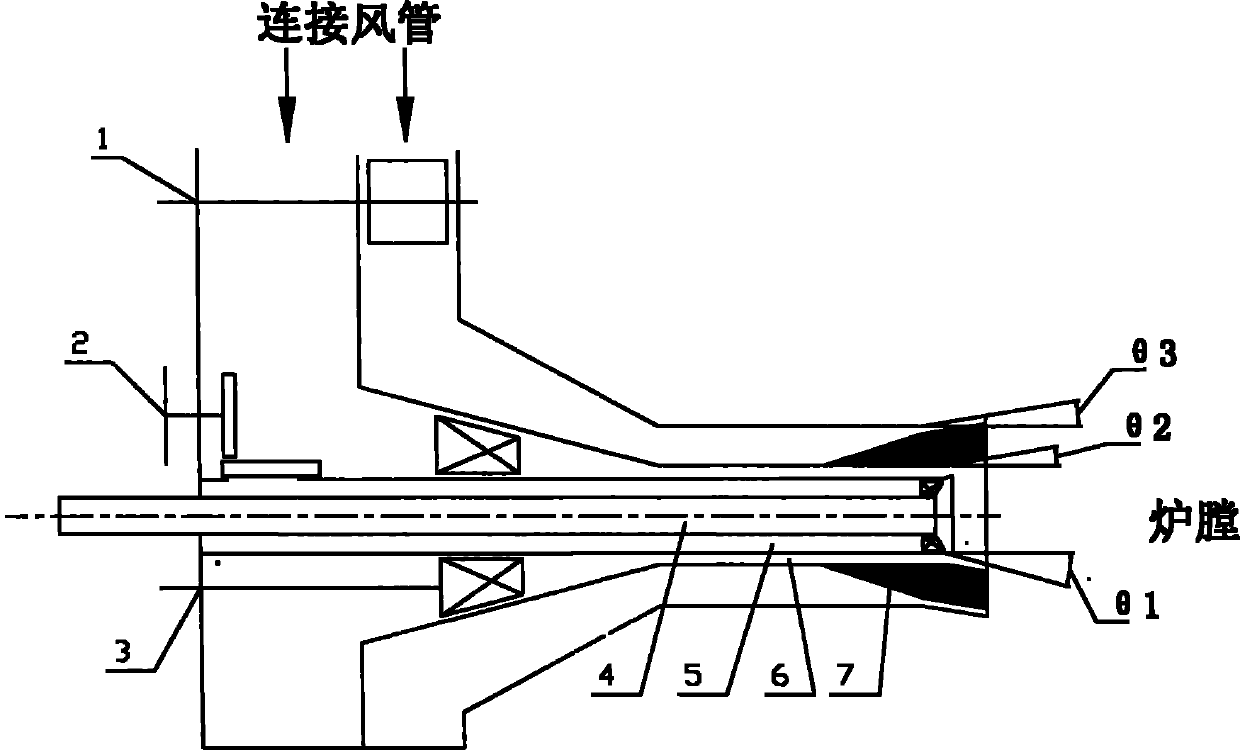

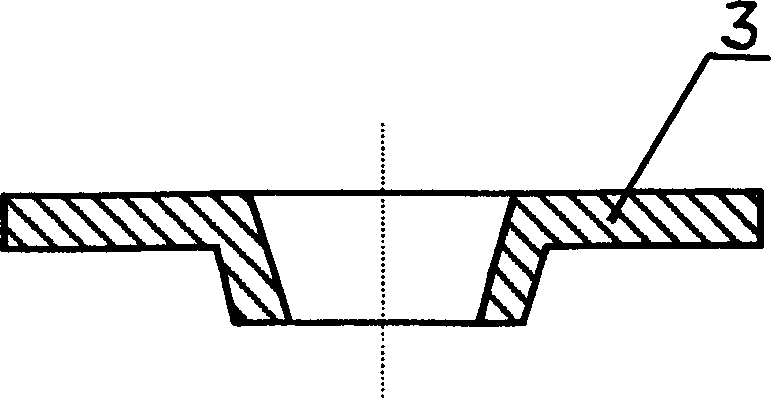

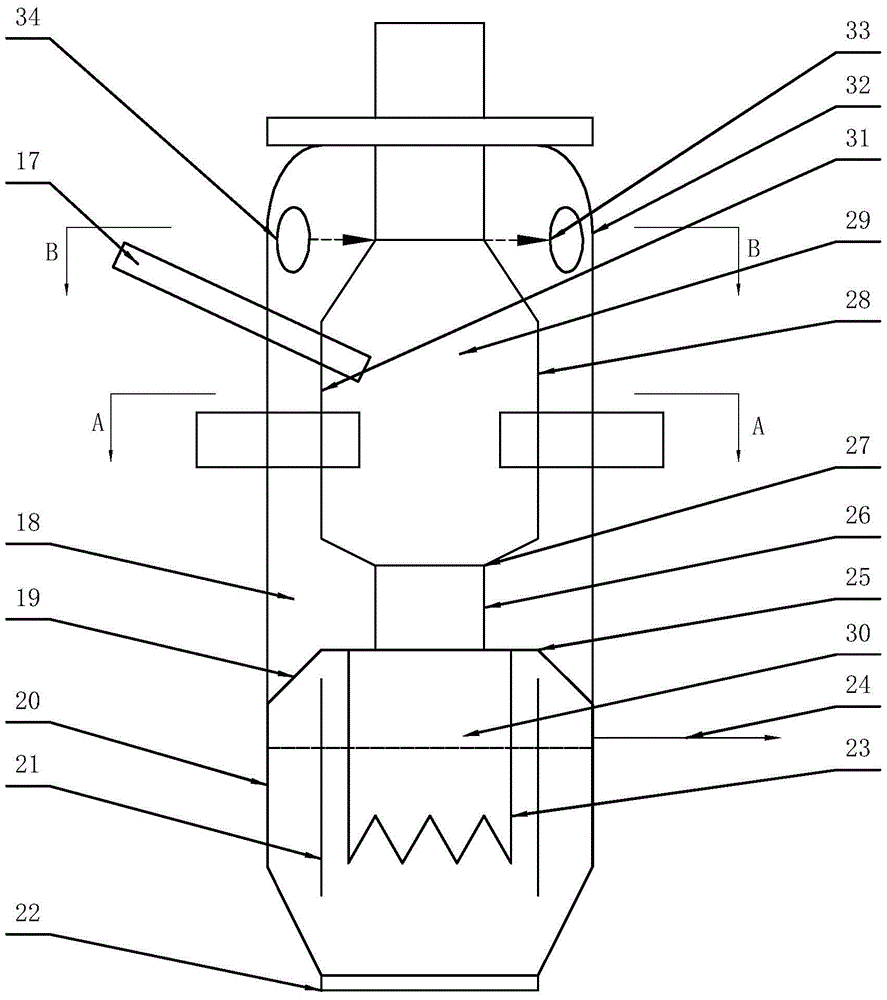

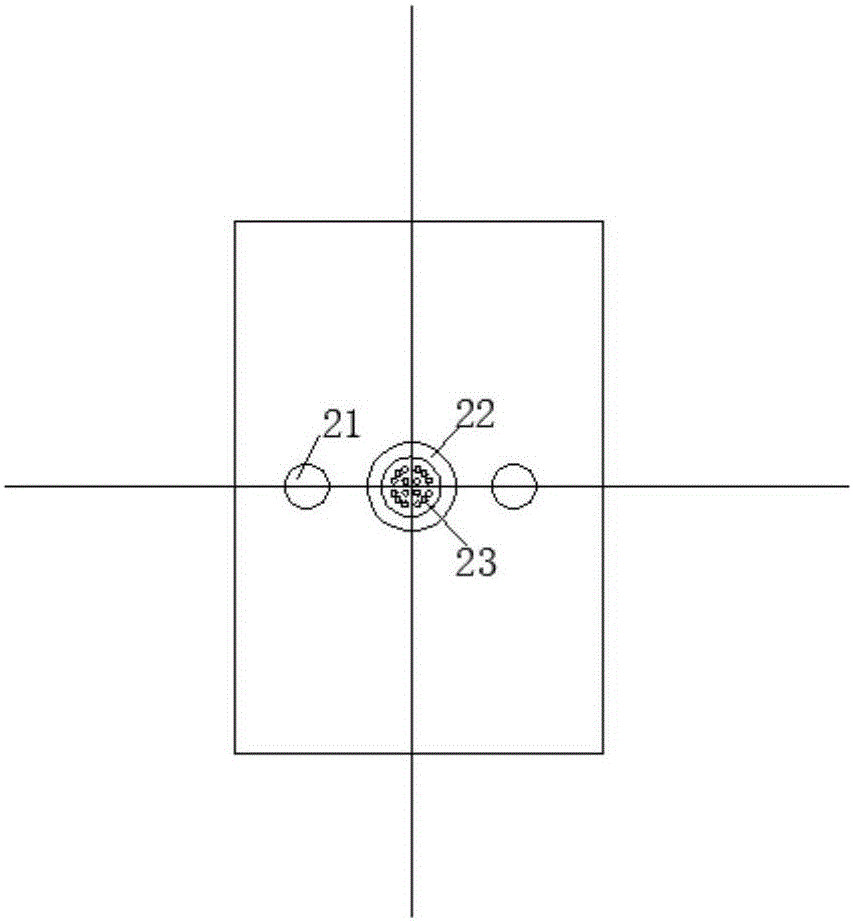

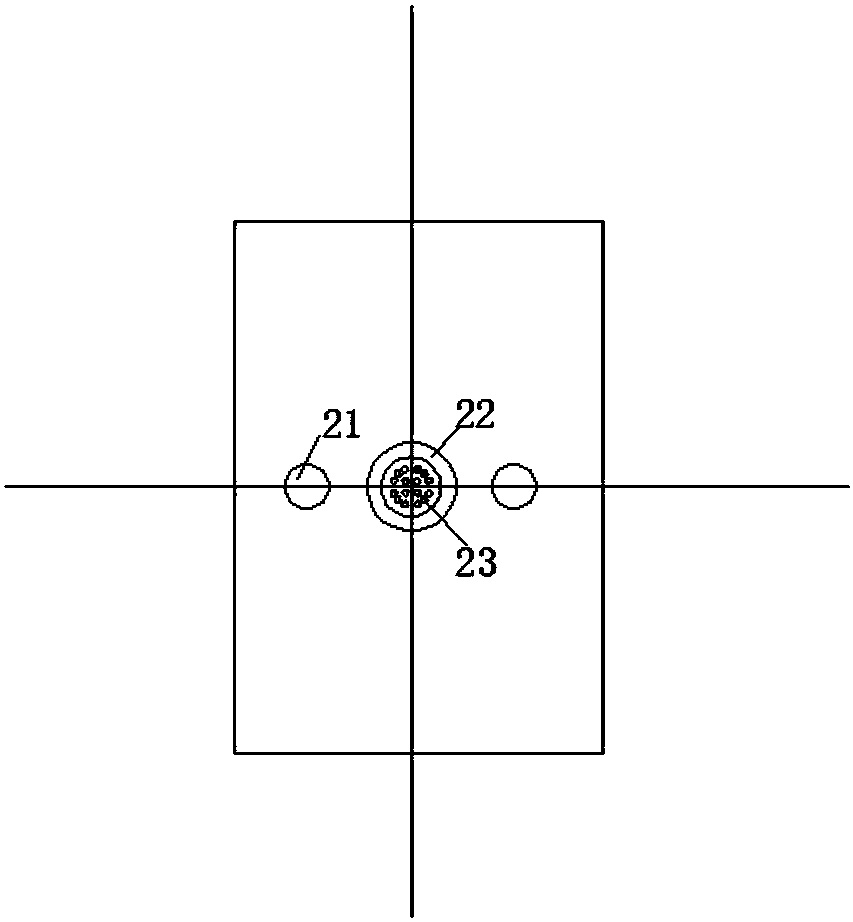

Low-NOx combustor for combusting coal water slurry and combustion method

The invention relates to a combustor and aims to provide a low-NOx combustor for combusting coal water slurry and a combustion method. The combustor comprises a coal water slurry gun sleeve, a primary air pipe and a secondary air pipe which are sequentially and coaxially arranged from inside to outside, wherein the outside of the secondary air pipe is at least provided with a coaxially sleeved combustion air pipe for controlling NOx. In the invention, combustion-supporting air is sent into a combustion chamber by multiple layers (whiffs) to control the mixing of the combustion-supporting air and the coal water slurry so as to control the oxygen concentration of the coal water slurry in the whole combustion process; gaps are preserved between various whiffs of combustion-supporting air according to the combustion characteristics of the coal water slurry so as to delay the mixing of the combustion-supporting air and the coal water slurry; a part of the combustion-supporting air is distributed by adopting direct current, which has the effect of stopping external combustion-supporting air from mixing with flames; and the flaring angles of all nozzles of the combustor are different so that the mixing of all air layers and the flame length are reasonably controlled.

Owner:浙江百能科技有限公司 +1

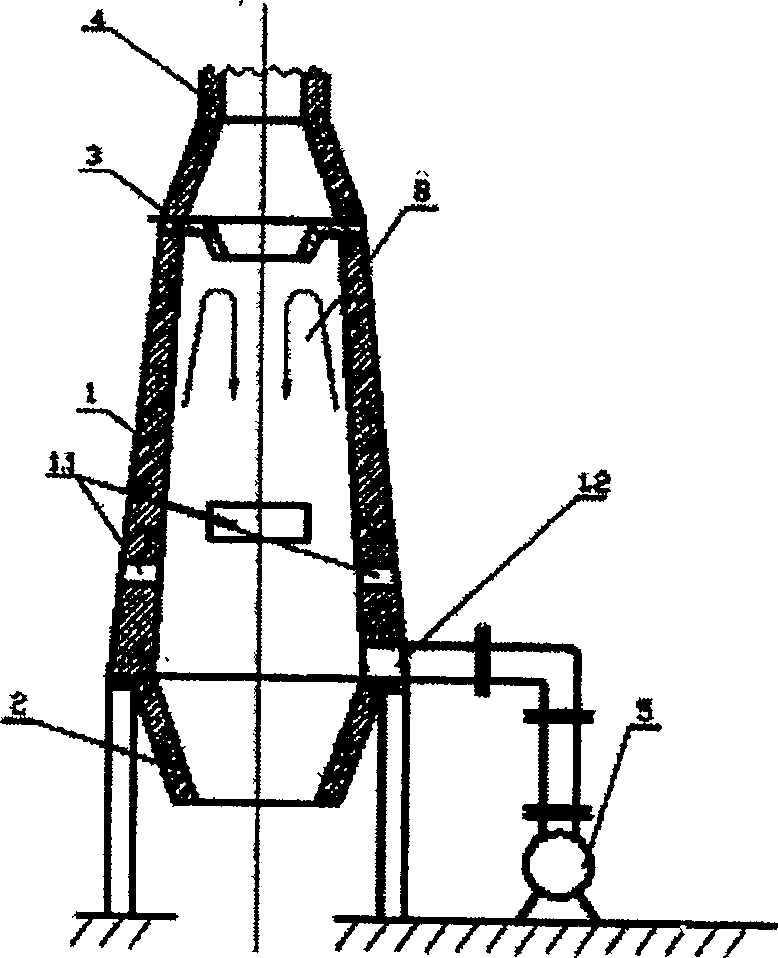

Clean heating air stove with water-coal fluid fuel

The invention discloses coal water slurry fuel cleaning warm air furnace. It includes furnace body. The furnace body includes furnace chamber, dust guide plate, furnace mantle, dust collecting bucket, and air blower. The bottom end of the furnace chamber has many coal water slurry jets. The invention also has ash settler. The furnace chamber is cone. And its bottom end is connected to ash collecting bucket. Its top end is connected to ash guide plate. The ash guide plate is connected to the furnace mantle. It is connected to the ash setter. The air blower is connected to the cone furnace chamber. Because of adopting cone furnace body, ash guide plate, and ash setter, the invention can make the fuel burn more completely, dust much less. And its reliability is high. It can be used in the place which needs cleaning warm air.

Owner:SOUTH CHINA UNIV OF TECH

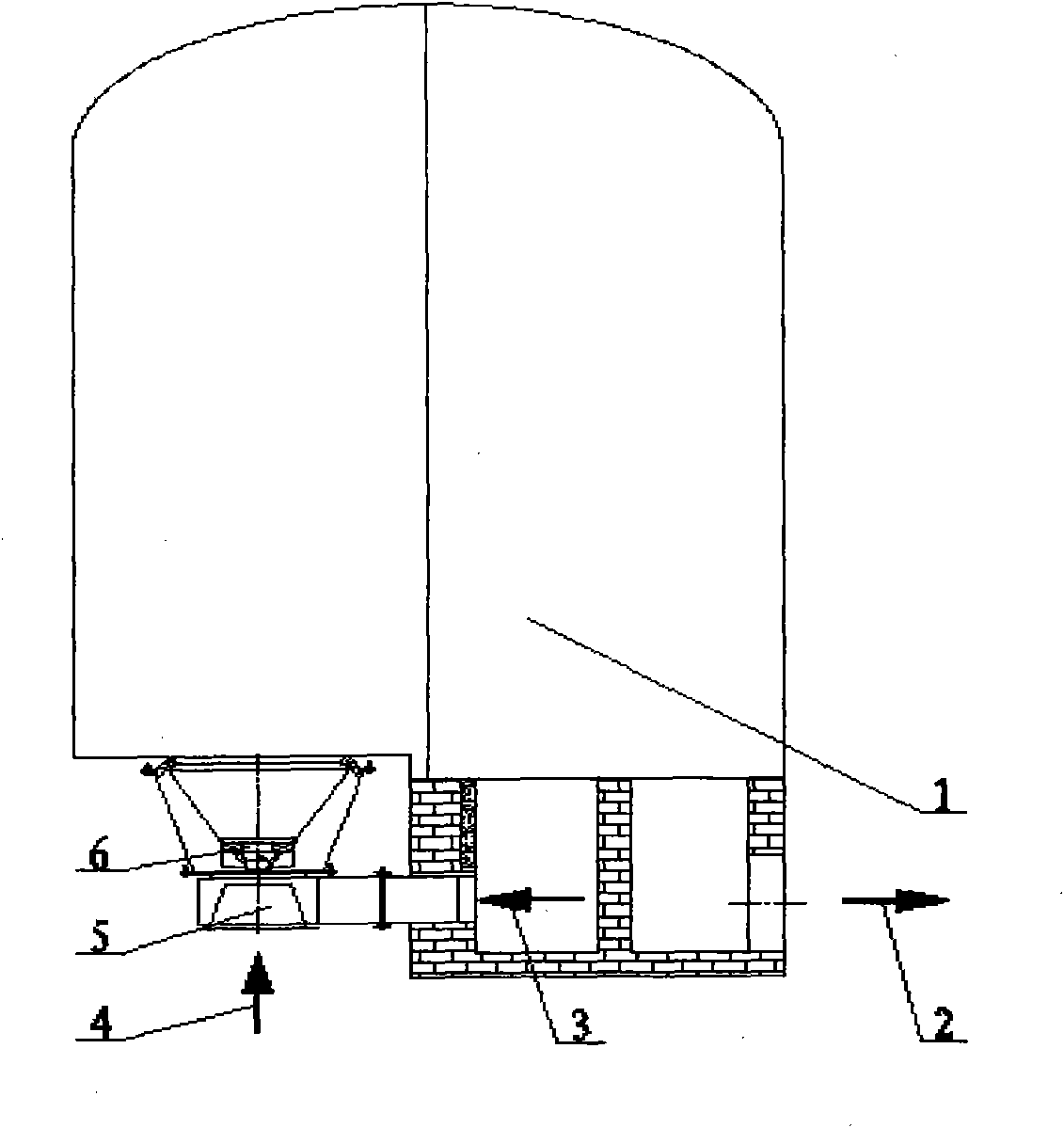

Boosting slurry-supply system for combusting water coal slurry

InactiveCN1553078AAvoid long-standing and difficult technical problems that are easy to wearLong-term continuous normal workLump/pulverulent fuel preparationGas cylinderEngineering

A water-coal slurry boost feeding system consists of a feeding unit, an outputting the slurry to the nozzle, a boosting device between them. The boosting device consists of a boost-feeding tank, a high pressure compressed gas cylinder connected with the boost feeding tank and an air compressor. Furthermore, two or more boost feeding tanks are connected in parallel with their outlets connected with the nozzle in parallel either. A low-pressure slurry-feeding pump can be used to replace the high pressure one and to have multiple boost-feeding tanks in parallel to boost in turn, so that it prevents the high pressure slurry-feeding pump from wear-out easily, lower cost and works normally long and continuously.

Owner:邓立新

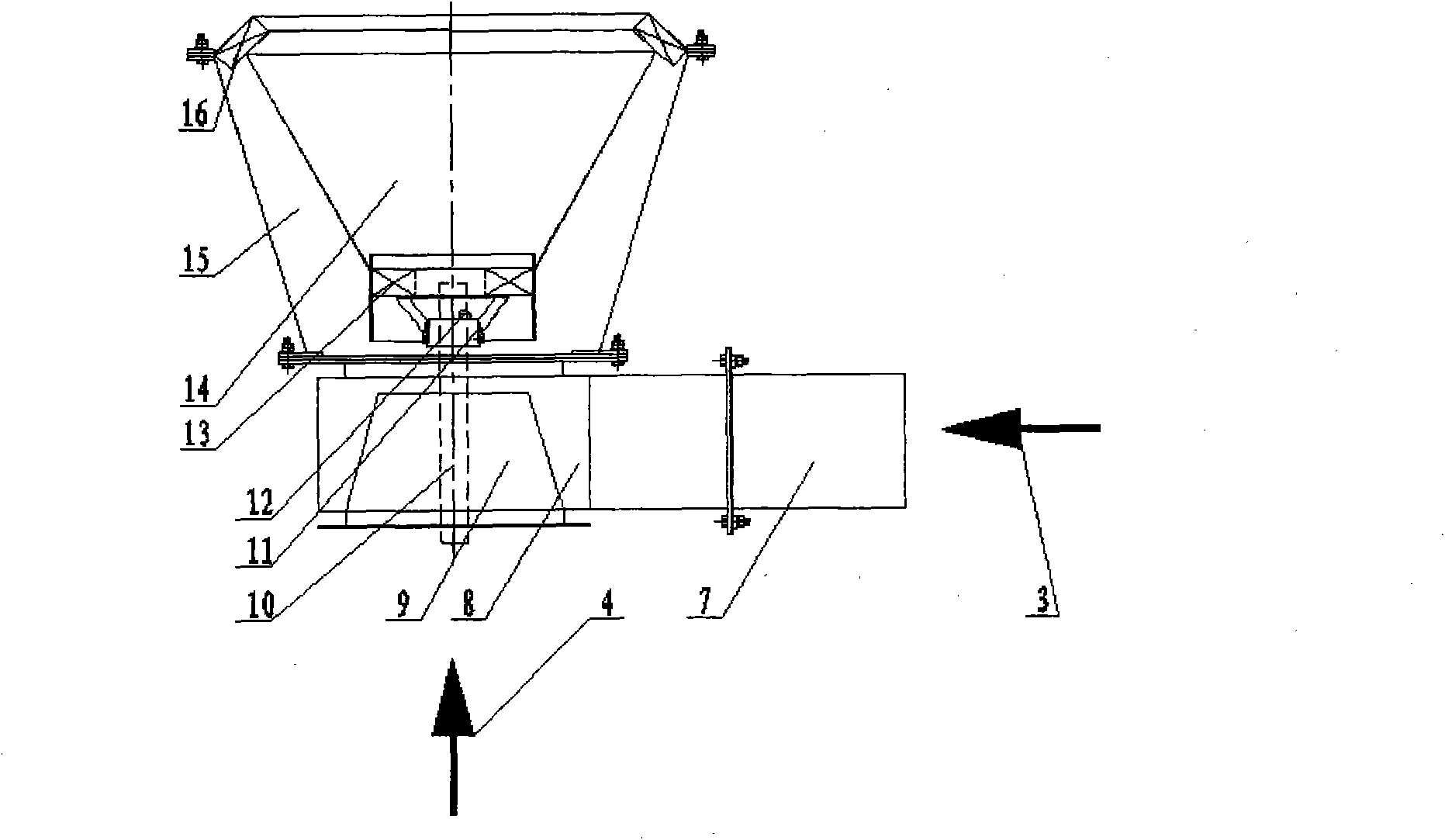

Coal-water slurry combustion method and its combustion equipment

InactiveCN101070956AIncrease burn rateContinuous mixed combustionSolid fuel combustionCombustion apparatusAir volumeCombustion chamber

The invention relates to a methods and combustion equipment for burning coal water mixture, the method is that atomized coal water mixture is spurted in combustion chamber for suspension combustion, combustion flame gradually form high temperature gas in process of flowing forward, make the combustion-supporting air form a suspension combustion-supporting air driving field in hearth and return some proper high temperature gas to suspension combustion chamber burning again. After exchanging heat the gas is exhausted by chimney. The combustion equipment consists of hearth and coal water mixture jet combustion engine, the combustion chamber is in the hearth, the hearth at the injection end of coal water mixture are installed with main air duct, damper as well as many air doors. The method and equipment can combust the coal water mixture completely, and automatic discharge ash, increasing combustion ratio of coal water mixture to the ultimate can save energy and protect environment.

Owner:邓立新

Coal-water slurry fuel and preparation method thereof

InactiveCN102746912ASave resourcesImprove utilizationLiquid carbonaceous fuelsFly ashEnergy consumption

The invention discloses a coal-water slurry fuel and a preparation method thereof. The coal-water slurry fuel includes components of charcoal, water and additives, wherein the additives comprise a dispersant and a stabilizing agent. The preparation method for the coal-water slurry fuel comprises a first step of performing hydro-thermal charing to the raw material biomass to get a mixture of the charcoal and water, and a second step of adding the additives to the mixture of the charcoal and water to obtain a crude product of the coal-water slurry fuel. According to the invention, the biomass, especially the agriculture residue, is used as a raw material to preparing the novel coal-water fuel which has the properties of environmental protection, high caloric value, and large caloric power. The preparation method for the fuel is low in energy consumption, economical and cheap, and easy for operation. The coal-water slurry product has low sulfur content, and has the advantages of few black smoke, big fire, full burning, no flying ash, clean burning, etc. in use.

Owner:北京雷恩新材料科技有限公司

CWS (Coal Water Slurry) hot water boiler system

InactiveCN105091320AGuaranteed normal ignitionGuaranteed stable combustionCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberSpray nozzle

The invention relates to a CWS (Coal Water Slurry) hot water boiler system. The CWS hot water boiler system is characterized in that four corners of a combustion chamber are all provided with low nitrogen type combustors specially using CWS; refractory belts are additionally arranged at the peripheries of elevation sections of CWS spraying nozzles of the combustors; the lower ends of water walls stretch downwards to form an ash cooling hopper; the upper end of one water wall at the rear side of the combustion chamber stretches into and protrudes out of a furnace to form a furnace arch; the furnace arch stretches upwards to form two branches, one of the branches vertically and upwards enters a collection box, and a film type water wall is formed by the other branch so as to form an oblique furnace bottom of the bottom part of a horizontal flue; one water wall at the front side of the combustion chamber stretches backwards to form a rear roof tube. The CWS hot water boiler system disclosed by the invention has the following advantages that (1) CWS fuel is creatively used on a large-capacity hot water boiler; (2) ignition and stable combustion of the boiler during low load are ensured; (3) water circulation of the boiler is forced circulation, simplicity and reliability are obtained, the four water walls at the front side, the rear side, the left side and the right side of the combustion chamber are risen at one step, the temperature is uniform and reasonable, the temperature deviation is reduced, and the combustion stability is ensured.

Owner:南通万达能源动力科技有限公司

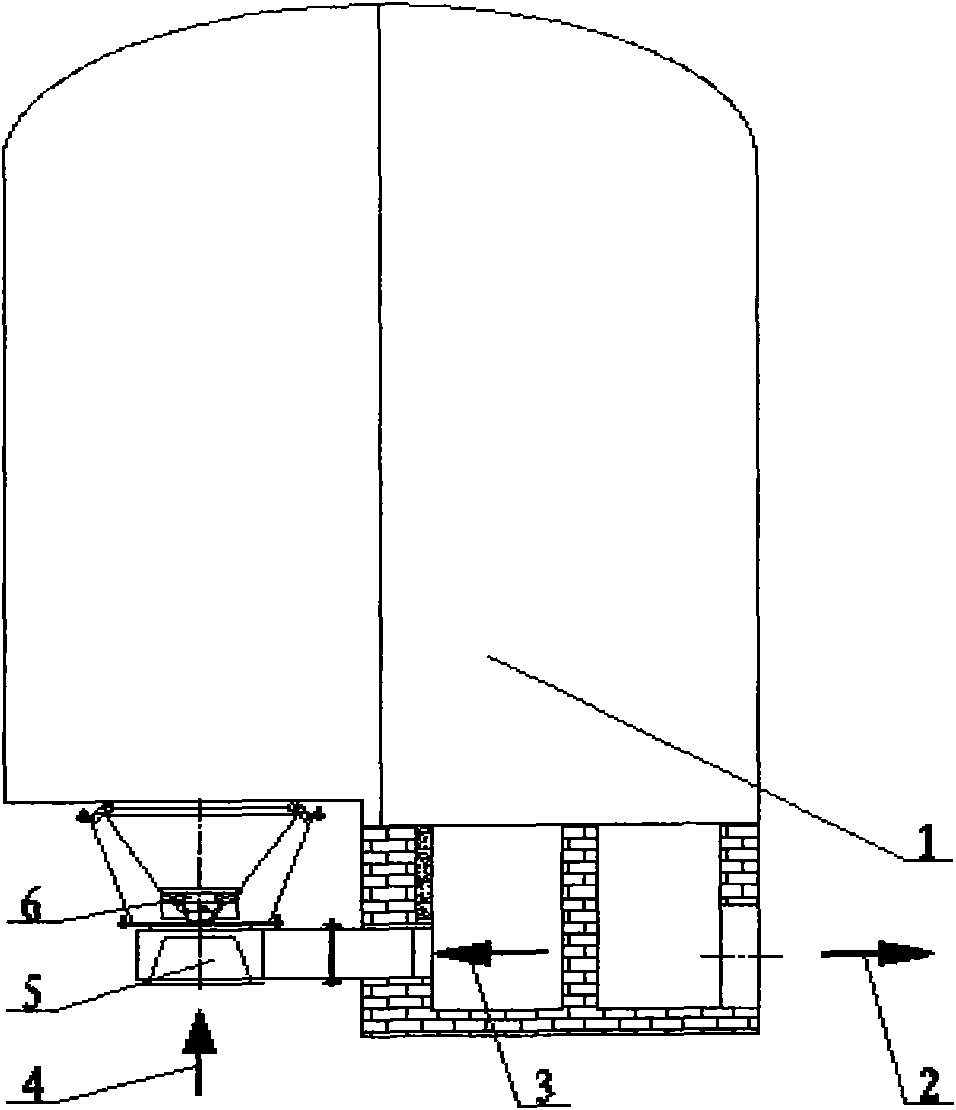

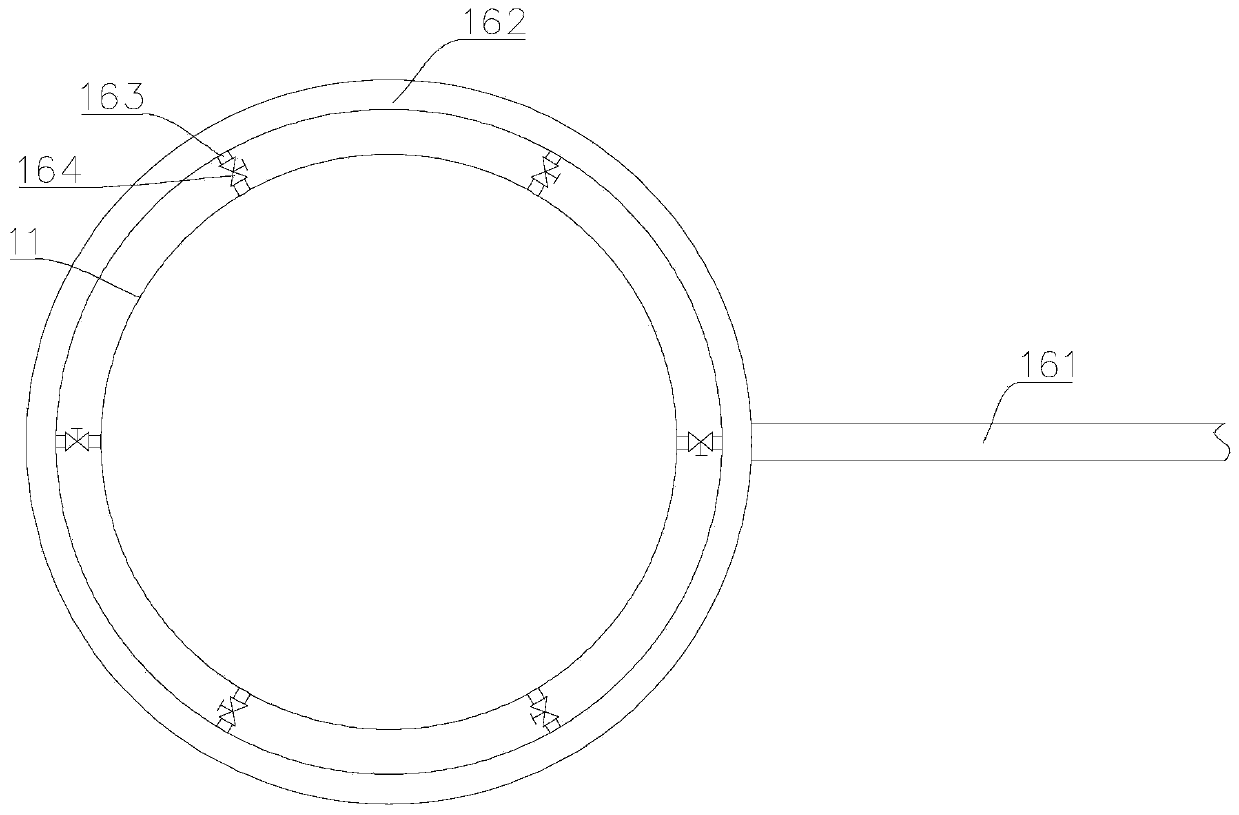

Low volatile coal water slurry combustion device

InactiveCN102374526ASimple structureEasy to use and maintainCombustion using gaseous and pulverulent fuelBurnersCombustion chamberEvaporation

The invention relates to a low volatile coal water slurry combustion device. The device mainly comprises a loop-shaped combustion chamber 1, an ejector 5, a combustion head 6 and the like. When combustion air provided by main air flow 4 enters an ejector mixing chamber at high speed from an ejector nozzle, the high temperature fuel gas is sucked in a combustion head mixing chamber, wherein the high temperature fuel gas flows in the ejector mixing chamber from a high temperature reflow fuel gas pipeline; the high temperature fuel gas in the combustion head mixing chamber enters a primary combustion chamber by ejecting with a primary swirler, such that the temperature of the air flow is increased. A fuel oil combustion system of the combustion head starts to ignite, and a nozzle injects oil to burn. When the air flow temperature inside the whole combustion chamber reaches (exceeds) the temperature for coal water slurry evaporation, firing and burning, a coal water slurry lance is started to inject the coal water slurry fuel to the primary combustion chamber. When the coal water slurry fuel burns stably, the work of the fuel system is stopped, and the coal water slurry continuously burns.

Owner:GUIZHOU AERONAUTICAL ENGINE INST

A pressurized gasification process for simultaneously gasifying pulverized coal and coal-water slurry

ActiveCN104531219BSimple structureHigh failure rateGasification apparatus detailsGranular/pulverulent flues gasificationFire brickProcess engineering

The invention relates to a pressure gasification process for simultaneously gasifying powdered coal and coal water slurry. The pressure gasification process is characterized in that a purpose-made gasification furnace is used, the gasification furnace is provided with a purpose-made powdered coal burner and a start-up burner and capable of simultaneously processing the coal water slurry and the powdered coal; gasification comprises the following steps of carrying out ignition start-up, igniting the powdered coal burner, increasing the temperature and pressure of the gasification furnace and a carbon washing tower, igniting a coal water slurry burner, increasing the pressure inside a gasification chamber, and controlling continuous gasification under a specific reaction condition. The pressure gasification process disclosed by the invention can be used for solving the problems of low effective component, high requirement on the quality of coal fed into the furnace, short life of the coal water slurry burner, short operation time of a single furnace, short life of a refractory brick, low coal slurry concentration and the like of a synthetic gas obtained through the traditional coal water slurry and solving the problems of large investment, complex equipment, high comprehensive energy consumption and the like of the traditional powdered coal gasification process.

Owner:SINOPEC NINGBO ENG +2

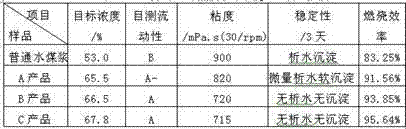

Coal tar and coal water slurry mixed fuel and preparation method thereof

InactiveCN103666609ALow viscosityImprove combustion efficiencyLiquid carbonaceous fuelsCoal tar productPetroleum engineering

The invention relates to mixed coal water slurry fuel, in particular to coal tar and coal water slurry mixed fuel and a preparation method thereof. The coal tar and coal water slurry mixed fuel comprises the following raw materials in parts by weight: 55-65 parts of superfine pulverized coal, 10-25 parts of coal tar, 10-25 parts of water, 2-5 parts of flame accelerator, 2-5 parts of dispersing agent and 4-10 parts of emolsifier. The mixed fuel has the benefits that: (1) a finish product is low in viscosity, the combustion efficiency of coal water slurry is effectively improved, the combustion is more completely and sufficiently, (2) the stability of the coal water slurry is improved, the coal water slurry can be stored for a long term, (3) the mixed fuel is in a liquid slurry shape, can be pumped, atomized, stored and transported like oil and is convenient to transport, and (4) the combustion is sufficient, the carbon smoke pollution is greatly reduced, and the mixed fuel is environment-friendly and energy-saving.

Owner:JINAN DEV ZONE XINGHUO SCI & TECH RES INST

Coal water slurry flame-free oxygen-enriched combustion system

ActiveCN105757651ASolve the problem of high capture costEmission reductionBurnersIndirect carbon-dioxide mitigationGas heaterOxygen tank

The invention discloses a coal water slurry flame-free oxygen-enriched combustion system. The system comprises a hearth, a high-speed atomization combustor, a slurry supply system, an oxygen supply system, a flue gas circulating system and a flue gas discharging and recycling system. The high-speed atomization combustor comprises a primary air nozzle, a secondary air nozzle and a coal water slurry atomization nozzle; the slurry supply system comprises a slurry storage tank, a slurry conveying pump, a stirring filter and a slurry supply pump; the oxygen supply system comprises an oxygen tank, a gas heater and a gas pressurizing pump; the flue gas circulating system comprises a flue gas heat exchanger, a dust remover, a circulating draught fan and a condenser; and the flue gas discharging and recycling system comprises a CO2 compression and storage device and a chimney. According to a coal water slurry flame-free oxygen-enriched combustion technology provided by the invention, oxygen is pressurized and heated and is mixed with circulating flue gas, and mixed gas is sprayed into a furnace to form volume combustion; coal water slurry is subjected to heat exchange through the flue gas heat exchanger, so that the initial temperature is improved and ignition heat is reduced; and the problems of a current coal water slurry boiler that the combustion efficiency is relatively low, the emission of NOx is high and the capturing cost of CO2 is high and the like can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Combustion system with coal water slurry fired boiler

InactiveCN102997228AAvoid heavy polluting processes with insufficient combustion at low temperaturesThe furnace heats up rapidlyCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion systemFuel tank

The invention relates to a combustion system with a coal water slurry fired boiler. The combustion system comprises a coal water slurry storage tank, a stirrer, a slurry supply pump, a filter, a combustor and the boiler which are sequentially connected with one another, wherein the combustor is respectively provided with an air-blast system and an ignition oil way which are used for atomizing coal water slurry, the air-blast system comprises an air storage tank and an air compressor acting on the air storage tank, the air storage tank is connected with the combustor, and the ignition oil way comprises a daily oil tank and an ignition oil tank which are sequentially connected with the combustor. The combustion system totally adopts flow conveying and atomization of pipelines, can implement automatic ignition of oil in a short time, is simple and convenient to operate and high in safety, and requires labor intensity which is much less than that required by a coal-fired boiler.

Owner:CHANGZHOU OLYMSPAN THERMAL ENERGY EQUIP

In-furnace denitrification method and device

InactiveCN106318515ARealize resource utilizationNo coking phenomenonCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCycloneCombustion chamber

The invention discloses an in-furnace denitrification coal water slurry making and combusting system integrated method and equipment. The method comprises the following steps: on the basis of the traditional slurry making process, adding a denitrification reducing agent, and preparing coal water slurry fuel containing the denitrification reducing agent; spraying the coal water slurry fuel into a boiler for burning, controlling the combustion temperature of the hearth to be stabilized in an optima reduction reaction temperature range and controlling the oxygen content of the flue gas, so that high-efficiency low-cost in-furnace SNCR denitrification of the coal water slurry is realized. The whole device comprises a coal water slurry combustion boiler, wherein the coal water slurry combustion boiler adopts the design of a primary combustion chamber and a secondary combustion chamber and is respectively provided with an axial cyclone primary combustor and a secondary combustor; a fire barrier is arranged at the tail of the primary combustion chamber, an air door is arranged below the primary combustion chamber, the rear upper part of the primary combustion chamber is connected with a dust remover through a pipeline, and the combusted smoke dust is discharged through an induced draft fan connected with the dust remover; and the axial cyclone primary combustor and the secondary combustor are respectively connected with a coal water slurry tank through a screw pump via pipelines, and are also respectively connected with an air compressor at the coal water slurry inlet through pipelines.

Owner:HUNAN UNIV OF TECH +1

Coal water slurry oxygen-rich combustion system

InactiveCN105910098ASolve the problem of high capture costEmission reductionIndirect carbon-dioxide mitigationStationary tubular conduit assembliesOxygen tankHearth

The invention discloses a coal water slurry oxygen-rich combustion system. The coal water slurry oxygen-rich combustion system comprises a hearth, a combustor, a slurry supply system, an oxygen supply system, a flue gas circulation system and a flue gas discharging and recovering system; the slurry supply system comprises a slurry storage tank, a slurry conveying pump, a stirring filter and a slurry supply pump; the oxygen supply system comprises an air separation device compressor and an oxygen tank; the flue gas circulation system comprises a flue gas heat exchanger, a deduster, a circulation fan and a condenser; and the flue gas discharging and recovering system comprises a CO2 compression and storage device and a chimney. Coal water slurry exchanges heat with high temperature flue gas, so the initial temperature is improved, and the ignition heat is reduced; and pure oxygen jet combustion is used in the igniting stage to reduce the igniting temperature of the coal water slurry and rapidly improve the combustion rate of the coal water slurry, and an oxygen-rich combustion technology is combined to solve the problems of difficult ignition, low combustion efficiency, high discharge of NOx and high CO2 capture cost of present coal water slurry boilers.

Owner:HUAZHONG UNIV OF SCI & TECH

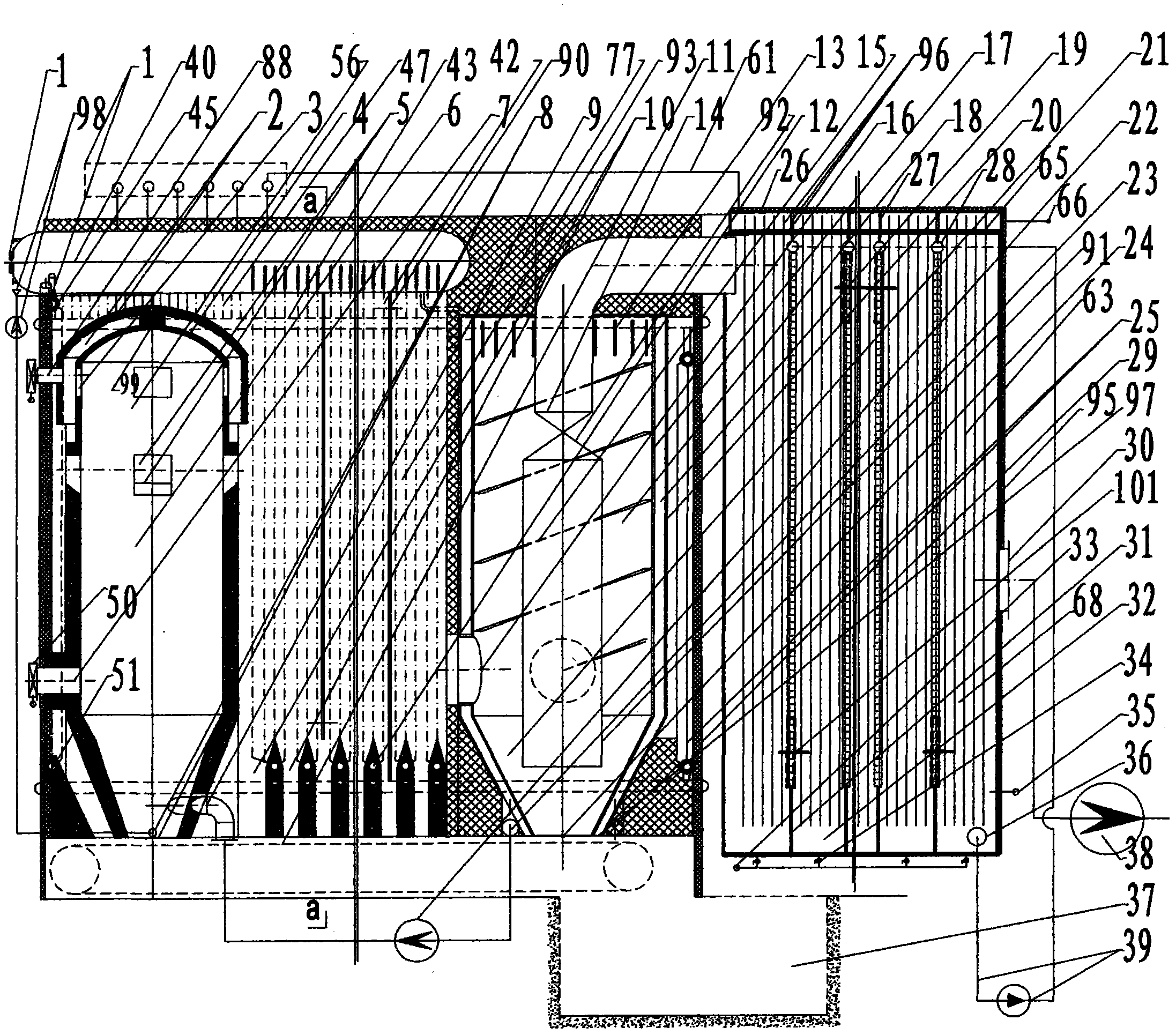

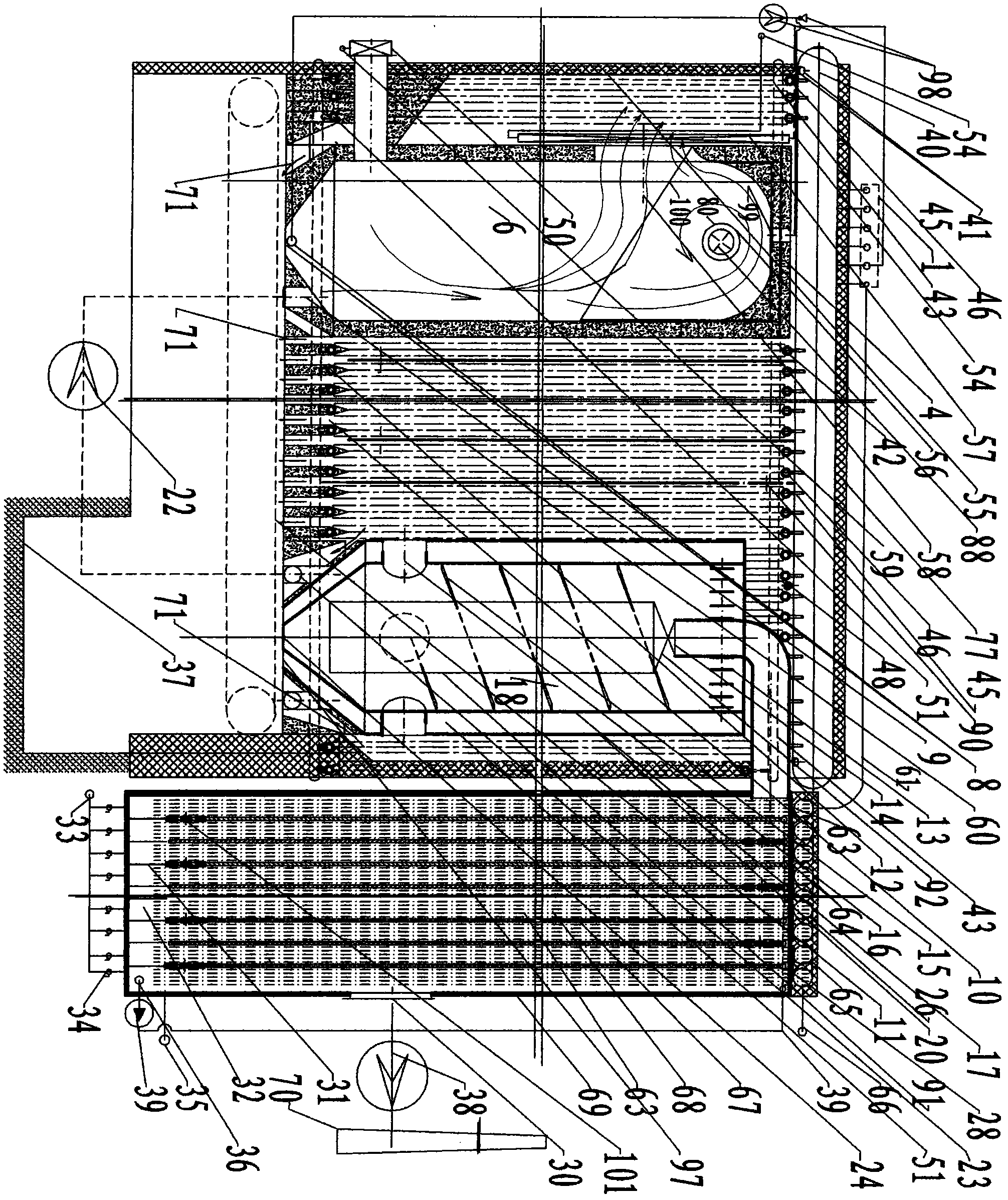

A self-purifying dust removal low noxsox condensate type super-efficient four-chamber three-circulation coal-water slurry boiler

InactiveCN102287811AImprove the level of environmental protectionHigh thermal efficiencyFluid heatersCombination devicesEngineeringDry heat

A self-cleaning and dust-removing low NOxSOx condensate type super-efficient four-chamber three-circulation coal-water slurry boiler, especially equipped with a dry-heat furnace, the chamber is equipped with a coal-water slurry burner, a temperature-controlled sewage burner, a convective heat exchange chamber, and an ash separator. The four-chamber structure of the chamber and the condensate-type heat-absorbing superconductor bundle chamber realizes the energy saving of about 25% compared with the current coal-water slurry boiler. The functional configuration of "waste heat recovery" will fundamentally solve the problem of coal-burning pollution in my country and even the world and the current coal-water slurry technology is restricted by the water content of 35-45% and cannot reuse latent heat, providing coal-water slurry boilers for the whole country The real possibility that the economy of life, industry and power generation operation comes first.

Owner:管理

Direct current low-nitrogen combustion device of coal water slurry boiler

InactiveCN106765062AReduce carbon contentAvoid cokingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelLow nitrogenFlue gas

The invention discloses a direct current low-nitrogen combustion device of a coal water slurry boiler. The direct current low-nitrogen combustion device comprises device combustors which are arranged at the positions of four corners of a hearth, coal water slurry guns arranged on the device combustors, secondary air inlet devices, primary air inlet devices, and ignition air inlet devices, wherein the secondary air inlet devices and the primary air inlet devices are alternately arranged in the longitudinal direction of the device combustors at intervals. The ignition air inlet devices are arranged at the bottoms of the device combustors. The low-nitrogen combustion device further comprises over fire air separation combustor devices arranged on the tops of the device combustors. Each set of coal water slurry gun comprises the coal water slurry large slurry guns and the small coal water slurry small slurry gun located between the two vertically-adjacent coal water slurry large slurry guns, wherein the coal water slurry large slurry guns and the coal water slurry small slurry gun are arranged at the positions of air inlets of the primary air inlet devices. By the adoption of the designed low-nitrogen combustion device, the concentration of nitric oxide of flue gas of an outlet of the boiler can be smaller than 300 mg / m<3>, the boiler can meet the requirement for ultraclean discharging (smaller than or equal to 50 mg / m<3>, the consumption of ammonia injection is reduced, and the environment-friendliness effect and the economic benefits are obvious.

Owner:武汉武锅能源工程有限公司

Coal water slurry and coal water slurry powder combusting hybrid boiler

InactiveCN102032554AReduce cokingAvoid cokingCombustion using gaseous and pulverulent fuelCombustion using liquid and pulverulent fuelCombustion chamberCoal slurry

The invention provides a coal water slurry and coal water slurry powder combusting hybrid boiler which comprises a combustor, a combustion chamber and a boiler body, wherein the combustor is fixedly arranged outside the combustion chamber and comprises a precombustion chamber and and after-combustion chamber which are communicated with each other, the precombustion chamber is adjacent to the combustor, and the length ratio of the precombustion chamber to the after-combustion chamber is 0.4-0.9. The coal water slurry and coal water slurry powder combusting hybrid boiler also comprises a first longitudinal jet blast pipe and a second longitudinal jet blast pipe, wherein the first longitudinal jet blast pipe and the second longitudinal jet blast pipe are fixedly arranged in after-combustion chamber respectively in a direction perpendicular to the spraying direction of the combustor, a plurality of first air ports are arranged on the first longitudinal jet blast pipe, and the first air ports face toward the combustor; a plurality of second air ports are arranged on the second longitudinal jet blast pipe, and the air outlet direction of the second air ports is upward. Thus, the usable range of the coal water slurry and coal water slurry powder combusting hybrid boiler is increased.

Owner:QINGDAO HAIZHONG ENVIRONMENTAL PROTECTION BOILER

Biomass coal water slurry prepared by combining phenolic wastewater and biomass charcoal, and production method and production system for biomass coal water slurry

PendingCN110846093AReduce processing costsReduce pollutionLiquid carbonaceous fuelsFuel additivesWastewaterCoal chemical industry

The invention provides a biomass coal water slurry prepared by combining phenolic wastewater and biomass charcoal, and a production method and a production system for the biomass coal water slurry, belonging to the technical field of coal water slurry fuel. The biomass coal water slurry adopts the biomass charcoal, coal and the phenolic wastewater as slurrying raw materials, has the advantages ofbiomass fuel, and realizes direct recycling of the phenolic wastewater in the coal chemical industry at the same time; meanwhile, the biomass coal water slurry utilizes the phenolic wastewater to replace water as a pulping raw material, makes up for the defect of low calorific value of the biomass charcoal, increases the calorific value of fuel, and has important social benefits and economic benefits. The biomass coal water slurry provided by the invention comprises the following components in parts by weight: 20-60 parts of pulverized coal, 10-50 parts of biomass charcoal powder, 30-50 partsof the phenolic wastewater, 0.3-0.7 part of a dispersant and 0.3-0.7 part of a stabilizing agent.

Owner:QINGDAO CLEAR ENVIRONMENT PROTECTION BOILER ENG

Coal water slurry compression-ignition internal combustion engine

InactiveCN104061072AReduce vibrationReduce frictionCombustion enginesEngine controllersExternal combustion engineRotary engine

A coal water slurry compression-ignition internal combustion engine relates to the fields of coal water slurry fuels, internal combustion engines, and air compressor components. The important components of the compression-ignition internal combustion engine are pistons 1, a round notched crank shaft 2, a crankshaft 3 and cylinder bodies 4, wherein the pistons 1 as well as the cylinder bodies 4 are arranged opposite horizontally; the round notched crank shaft 2 is embedded in the circular interior of the round notched crank hole 1-1 of the pistons 1; the notched crank groove 2-2 of the round notched crank shaft 2 is connected with the crankshaft 3 through a crank 3-1; the notched crank shaft 2 and the crankshaft 3 are integrally embedded in the cylinder bodies 4. The compression-ignition internal combustion engine adopts the design concept of an eccentric crankshaft of a rotary engine, so as to reduce vibration and friction of the crankshaft, and reduce length and diameter of the crankshaft by half, reduce the size of the internal combustion engine, and improve fuel economical efficiency to reduce fuel cost. The compression-ignition internal combustion engine is long in stroke, can realize the compression-ignition technology for various fuels to a diesel mode, and is particularly suitable for compression-ignition combustion of fuels such as gasoline, diesel oil, methanol and coal water slurry, thereby greatly improving combustion efficiency of the internal combustion engine.

Owner:王萍 +2

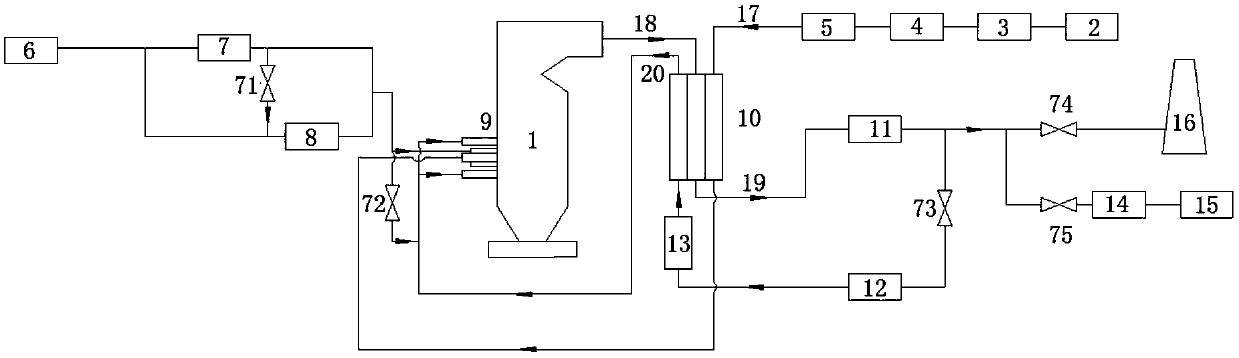

A Coal Water Slurry Flameless Oxygen-enriched Combustion System

ActiveCN105757651BSolve the problem of high capture costEmission reductionBurnersIndirect carbon-dioxide mitigationGas heaterOxygen tank

The invention discloses a coal water slurry flame-free oxygen-enriched combustion system. The system comprises a hearth, a high-speed atomization combustor, a slurry supply system, an oxygen supply system, a flue gas circulating system and a flue gas discharging and recycling system. The high-speed atomization combustor comprises a primary air nozzle, a secondary air nozzle and a coal water slurry atomization nozzle; the slurry supply system comprises a slurry storage tank, a slurry conveying pump, a stirring filter and a slurry supply pump; the oxygen supply system comprises an oxygen tank, a gas heater and a gas pressurizing pump; the flue gas circulating system comprises a flue gas heat exchanger, a dust remover, a circulating draught fan and a condenser; and the flue gas discharging and recycling system comprises a CO2 compression and storage device and a chimney. According to a coal water slurry flame-free oxygen-enriched combustion technology provided by the invention, oxygen is pressurized and heated and is mixed with circulating flue gas, and mixed gas is sprayed into a furnace to form volume combustion; coal water slurry is subjected to heat exchange through the flue gas heat exchanger, so that the initial temperature is improved and ignition heat is reduced; and the problems of a current coal water slurry boiler that the combustion efficiency is relatively low, the emission of NOx is high and the capturing cost of CO2 is high and the like can be solved.

Owner:HUAZHONG UNIV OF SCI & TECH

Waste metal processing liquid coal water slurry fuel

The invention discloses waste metal processing liquid coal water slurry fuel which comprises a waste metal processing liquid, coal water slurry as well as a dispersing agent and a coupling agent, wherein the waste metal processing liquid, the coal water slurry, the dispersing agent and the coupling agent are mixed up to prepare a coal water slurry mixture applicable to combustion. Therefore, the waste metal processing liquid can be effectively treated, the heat amount of the coal water slurry is improved, a good combustion property is achieved, the energy waste is effectively avoided, the problem about stability of a conventional organic waste liquid coal water slurry product is substantially solved, good flowbility is achieved, and the waste metal processing liquid coal water slurry fuel is easy to load, unload, store, convey in pipelines, combust in atomization spaces and the like.

Owner:AMER TECH CO LTD

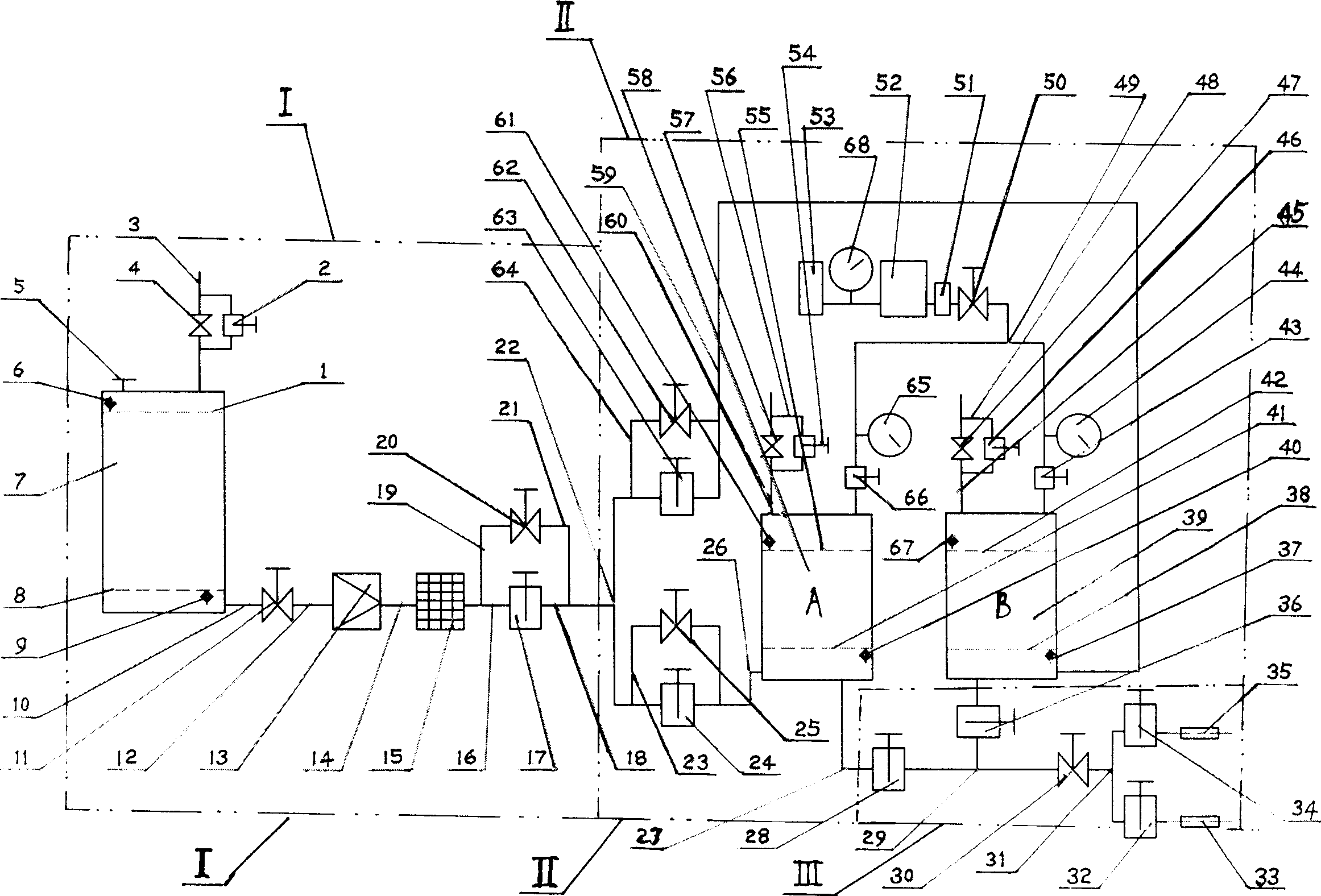

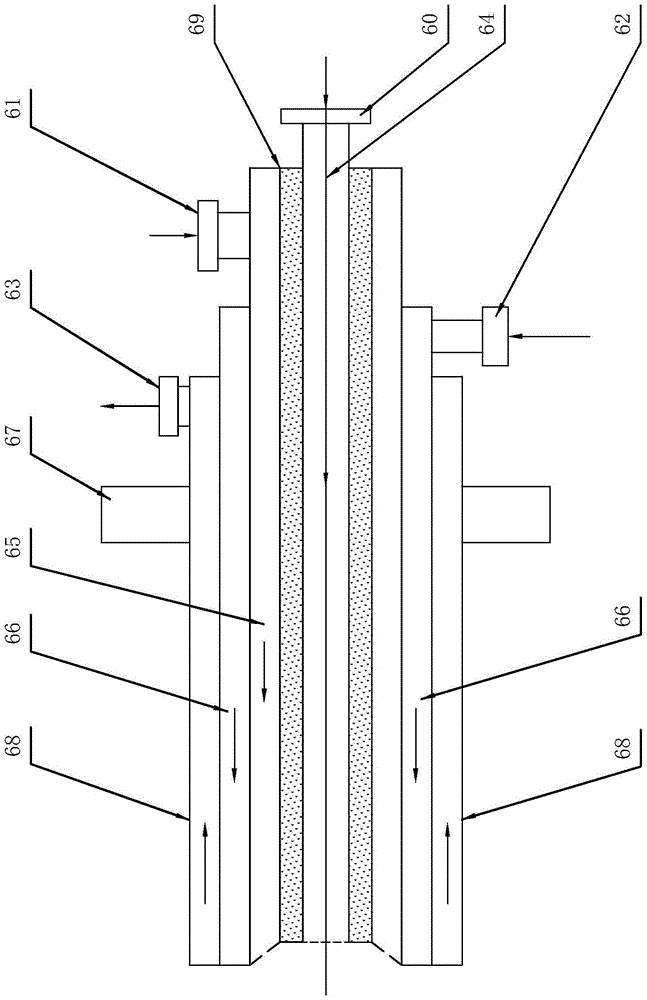

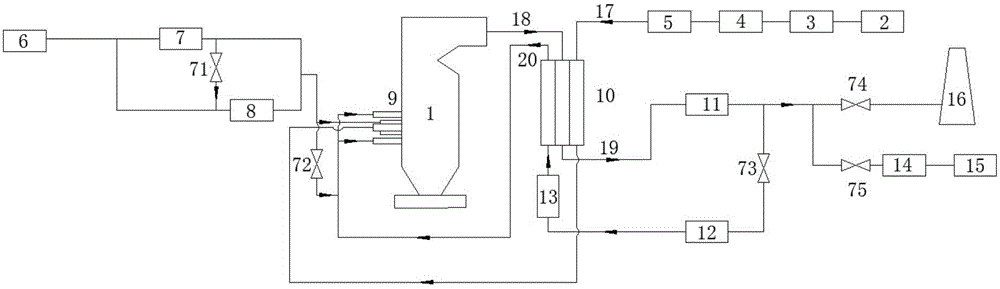

Supercharging pulp feeding system of coal water slurry fuel and method thereof

The invention discloses pressurization slurry supply system and method for coal-water slurry fuel. The pressurization slurry supply system for coal-water slurry fuel comprises an air compressor, a balance tank, a slurry supply tank connected in turn, the slurry supply tank is provided with a pressure meter, also an electric control box and a frequency convertor, signal of the pressure meter is inputted into the electrical control box which outputs frequency signal to the frequency convertor, the frequency signal controls rotation speed of the air compressor. The pressurization slurry supply method for coal-water slurry fuel comprises: driving the slurry tank to transfer high-pressure water-coal slurry by pressurizing air, altering frequency of the input apparatus of pressurizing the air to adjust the pressure of inputted pressurized air. Because the supplied slurry is determined by the pressurized air in the slurry supply tank, the pressure of the pressurized air is controlled by the frequency convertor, such that the slurry supply amount is adjusted by controlling the frequency convertor with the electrical control box, thus the equipment abrasion is reduce because screw pumps are unnecessary, slurry supply is stable, energy consumption cost is reduced thereby being convenient for chief stoker worker to operate.

Owner:付帮太

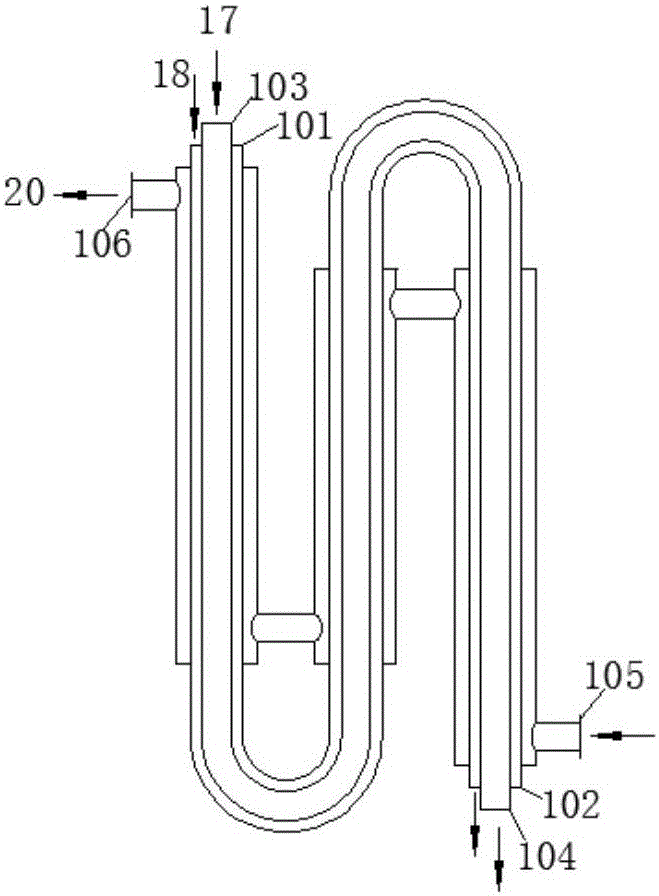

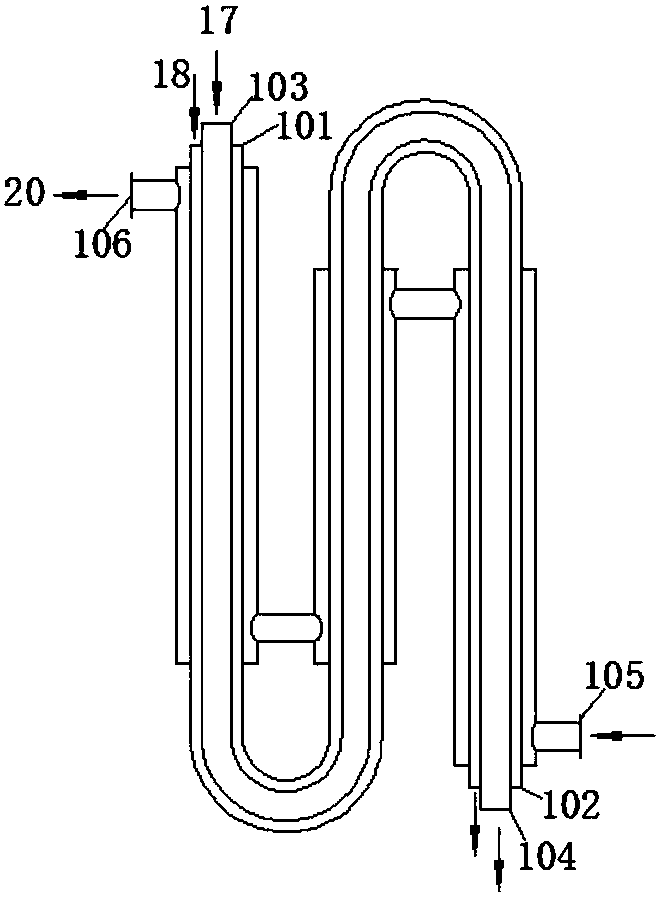

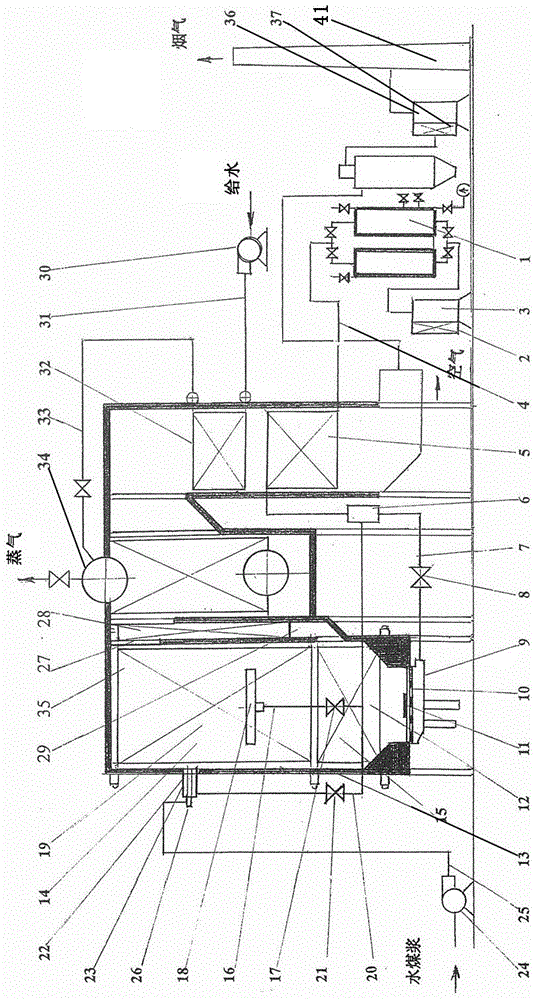

Water-coal-slurry steam injection boiler in oilfields

PendingCN106642045AAvoid fightingCompact and reasonable structureSteam generation using pressureSteam boilersAir preheaterSlag

The invention relates to the technical field of steam injection boilers for heavy oil wells in oilfields, in particular to a water-coal-slurry steam injection boiler in oilfields. The water-coal-slurry steam injection boiler comprises a boiler body, an upper water cooling wall, a lower water cooling wall, a superheater and an air preheater, an inverted-U-shaped flue is arranged in the boiler body and comprises a left vertical flue body, an upper horizontal flue body and a right vertical flue body, and a left flue slag-drip opening is formed in the bottom of the boiler body at the lower end of the left vertical flue body. The water-coal-slurry steam injection boiler has the advantages that the water-coal-slurry steam injection boiler is reasonable and compact in structure and convenient to use; a combustor in the steam injection boiler takes water coal slurry as fuel, and air is preheated by the air preheater and then is delivered to the water-coal-slurry combustor, so that flame extinguishing caused by low air temperatures is avoided, and reliability and stability in combustion are improved; combustion wastes can be discharged via the slag-drip opening, long-term continuous running and substituting the water coal slurry fuel for natural gas fuel can be achieved, and accordingly clean combustion, energy saving and emission reduction are achieved; the steam injection boiler is high in heat utilization ratio and convenient to move and transport.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Clean heating air stove with water-coal slurry fuel

The invention discloses coal water slurry fuel cleaning warm air furnace. It includes furnace body. The furnace body includes furnace chamber, dust guide plate, furnace mantle, dust collecting bucket, and air blower. The bottom end of the furnace chamber has many coal water slurry jets. The invention also has ash settler. The furnace chamber is cone. And its bottom end is connected to ash collecting bucket. Its top end is connected to ash guide plate. The ash guide plate is connected to the furnace mantle. It is connected to the ash setter. The air blower is connected to the cone furnace chamber. Because of adopting cone furnace body, ash guide plate, and ash setter, the invention can make the fuel burn more completely, dust much less. And its reliability is high. It can be used in the place which needs cleaning warm air.

Owner:SOUTH CHINA UNIV OF TECH

Emulsifier, tar coal water slurry fuel and preparation method thereof

PendingCN114456860ALow costGood emulsifying oil effectLiquid carbonaceous fuelsAluminium chlorideAluminium chlorohydrate

The invention provides an emulsifier, a tar coal water slurry fuel and a preparation method of the tar coal water slurry fuel, and relates to the technical field of preparation of tar coal water slurry emulsifiers. The emulsifier provided by the invention comprises the following components in percentage by mass: 50-90% of polyaluminum chloride, 5-30% of sodium carbonate and 5-20% of sodium chloride. The emulsifier provided by the invention has the characteristics of good dispersity, emulsibility and stability, can effectively improve the uniformity of tar coal water slurry fuel slurry, and does not generate precipitates. And the emulsifier provided by the invention is low in cost. Results of the embodiment show that the tar coal water slurry fuel prepared by the invention is uniform in slurry, is not layered, and does not generate precipitates within 48 hours.

Owner:佛山市天亿化工有限公司

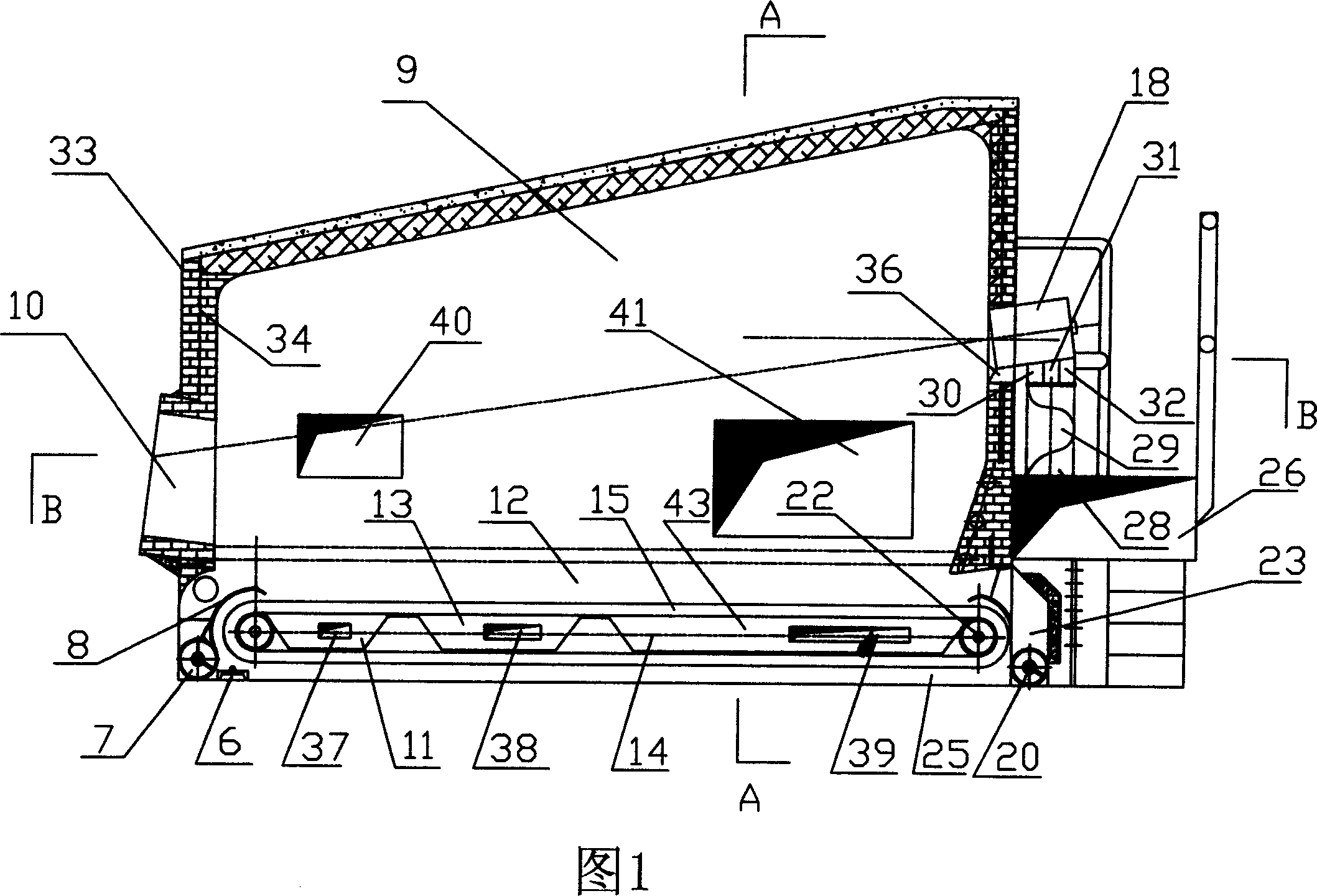

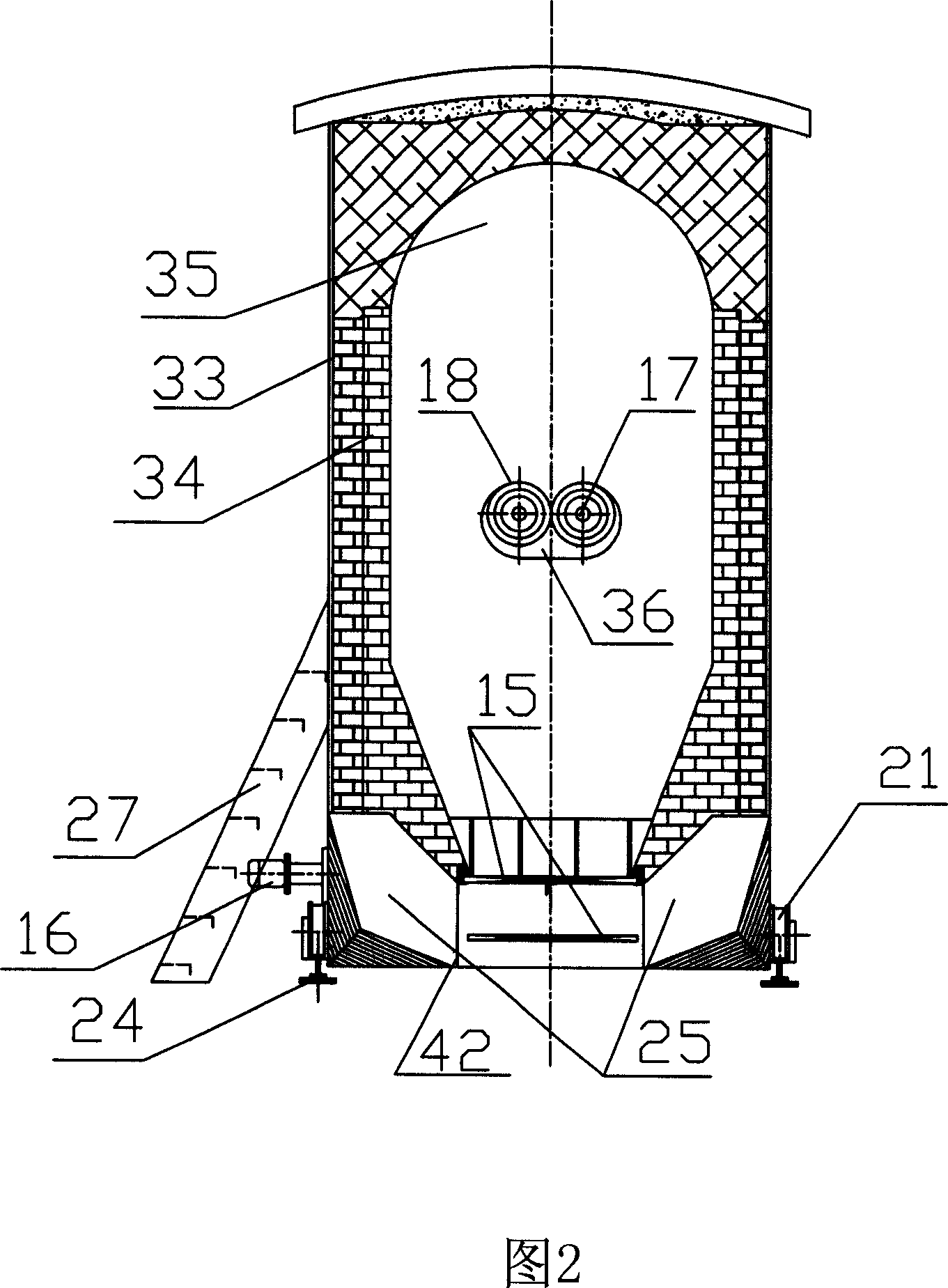

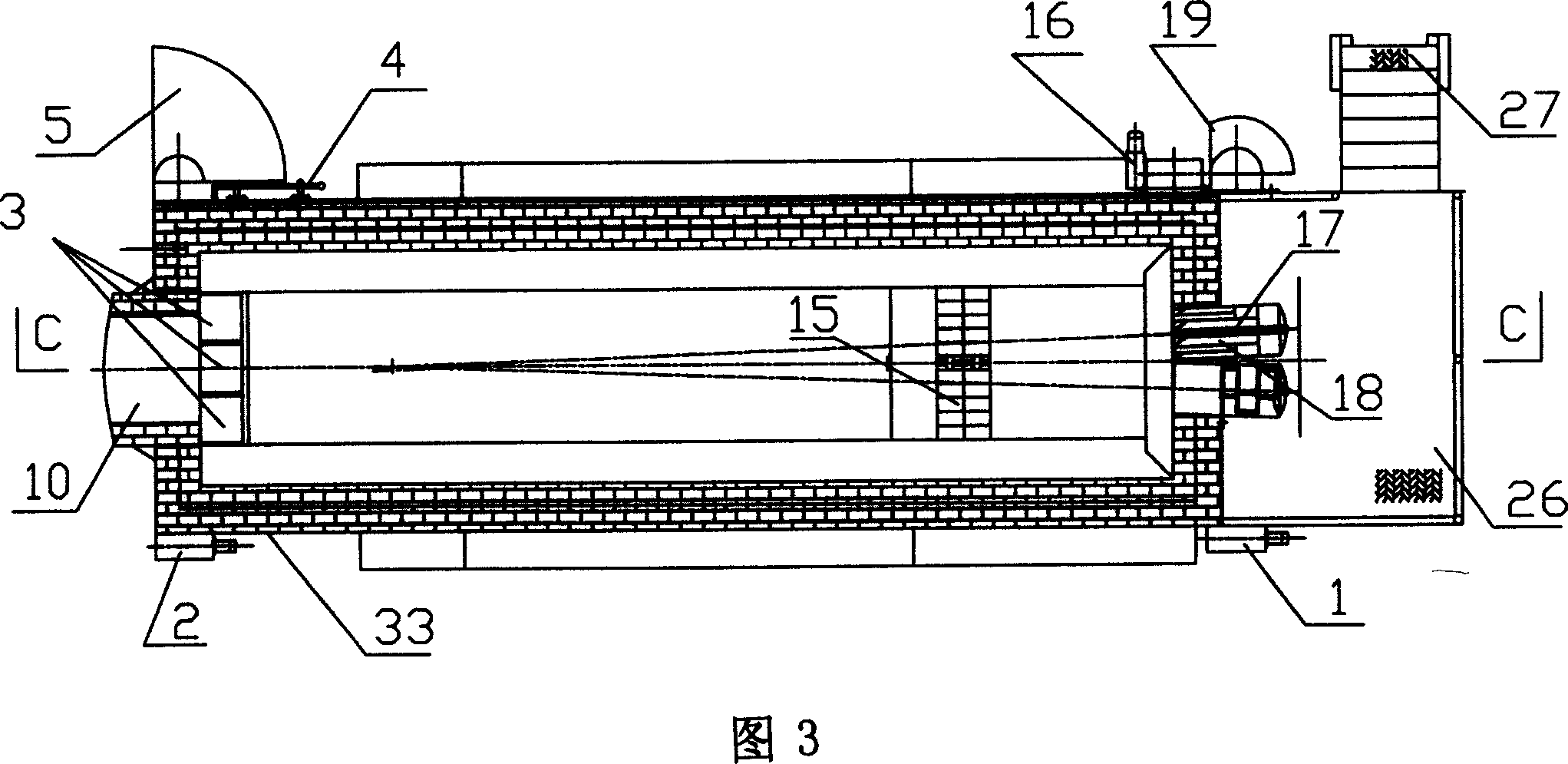

Layer combustion method for coal water slurry and equipment therefor

InactiveCN1271366CLow one-time investment costLow running costSolid fuel combustionCombustion apparatusGratingColloid

Owner:王安徽

Metal processing waste liquid coal water slurry fuel

InactiveCN103849441BEasy to handleHigh calorific valueLiquid carbonaceous fuelsMetalworkingLiquid fuel

The invention discloses waste metal processing liquid coal water slurry fuel which comprises a waste metal processing liquid, coal water slurry as well as a dispersing agent and a coupling agent, wherein the waste metal processing liquid, the coal water slurry, the dispersing agent and the coupling agent are mixed up to prepare a coal water slurry mixture applicable to combustion. Therefore, the waste metal processing liquid can be effectively treated, the heat amount of the coal water slurry is improved, a good combustion property is achieved, the energy waste is effectively avoided, the problem about stability of a conventional organic waste liquid coal water slurry product is substantially solved, good flowbility is achieved, and the waste metal processing liquid coal water slurry fuel is easy to load, unload, store, convey in pipelines, combust in atomization spaces and the like.

Owner:AMER TECH CO LTD

Low-energy coal water slurry gasification system and coal water slurry heating method

The invention discloses a low-energy coal water slurry gasification system. The system comprises a coal storage bucket, the discharge port of the coal storage bucket is connected with a coal weighingfeeder, the coal weighing feeder is connected with the inlet of a coal mill, the coal mill is connected with a mill discharge tank, the outlet of the mill discharge tank is connected with a mill discharge tank pump, the mill discharge tank pump is connected with a coal slurry tank, the coal slurry tank is connected with a coal slurry feeding pump, the coal slurry feeding pump is connected with a gasification furnace through a coal slurry conveying tube, the coal slurry conveying tube is provided with a heating device, and the coal slurry conveying tube is further provided with a temperature detecting device. The invention also discloses a coal water slurry heating method. A coal water slurry in the coal slurry conveying tube can be heated, and the temperature of the coal water slurry in the conveying tube can be kept within a certain temperature range, so the coal consumption and the oxygen consumption are reduced, and the discharge amount of carbon dioxide is reduced.

Owner:CHINA COAL SHAANXI YULIN ENERGY & CHEM

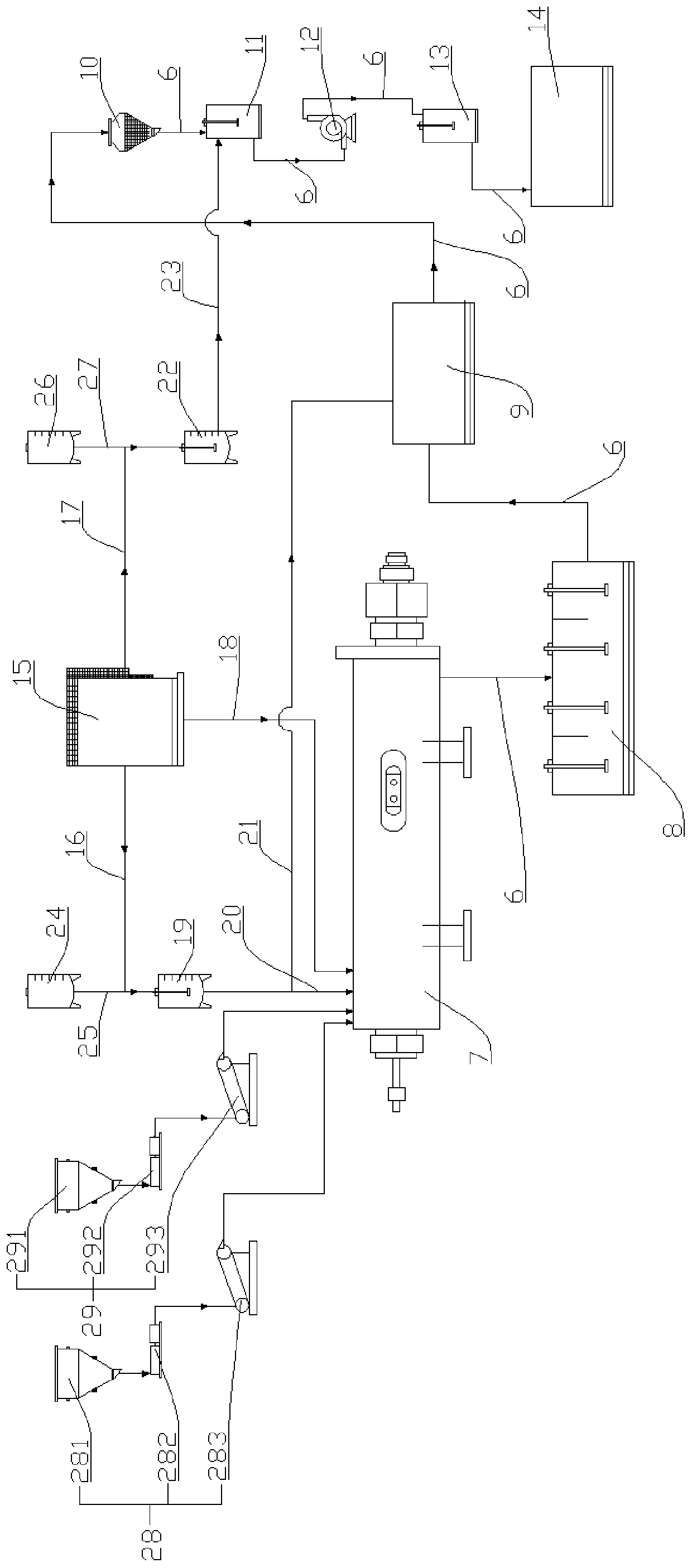

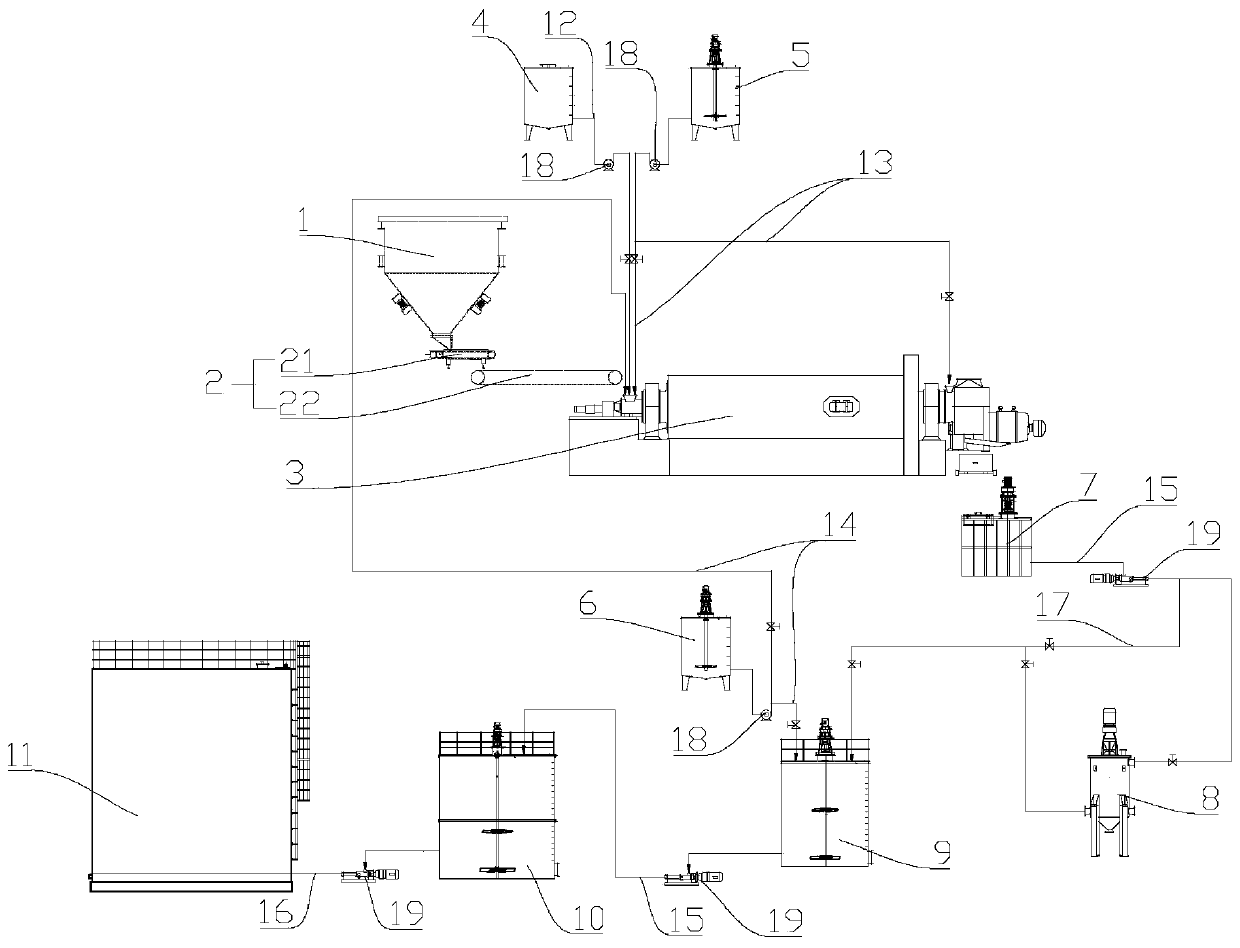

Production method and production system of high-stability coal water slurry fuel

PendingCN110527570AImprove liquidityImprove stabilityLiquid carbonaceous fuelsFiltrationMaterials science

The invention provides a production method and production system of high-stability coal water slurry fuel, and belongs to the technical field of coal water slurry production. A coal water slurry product produced by the production method has better particle size gradation and better stability and fluidity. The production method comprises the following steps: determining the total amount of a dispersant and the total amount of a stabilizer; adding all feed coal, water, part of the dispersant and part of the stabilizer into a mill from the inlet end of the mill for grinding; adding the residual dispersant into slurry flowing out of the outlet end of the mill from the outlet end of the mill to obtain primary slurry; collecting the primary slurry, performing stirring, performing refined filtration, and conveying the product into a stirring tank; adding the residual stabilizer into the stirring tank, and uniformly mixing the residual stabilizer and the slurry in the stirring tank under stirring to obtain secondary slurry; and conveying the secondary slurry to a homogenizing tank for homogenizing and curing, and conveying finished-product slurry into a finished-product slurry storage tankfrom the bottom of the finished-product slurry storage tank for storage.

Owner:青岛特利尔科技有限公司

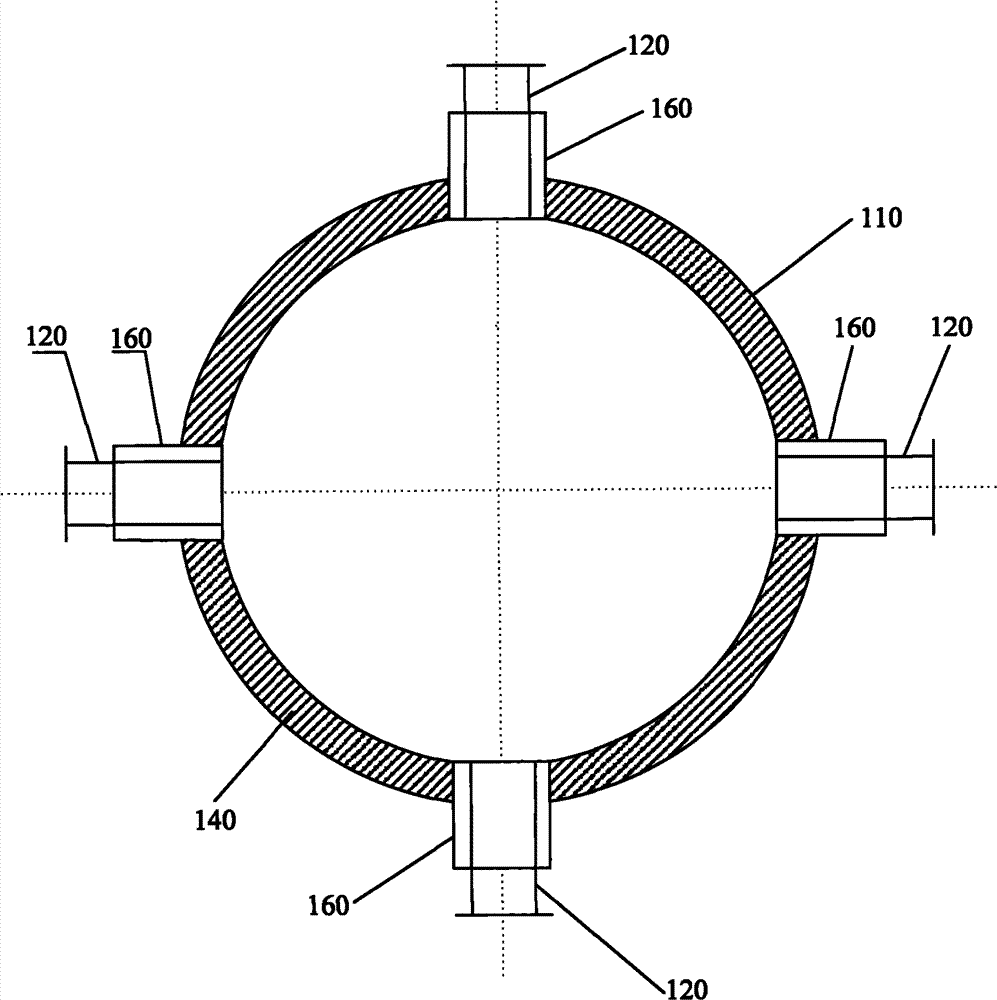

Coal water slurry gasification furnace for gasifying coal water slurry

ActiveCN101892086BFully atomizedImprove gasification efficiencyCombined combustion mitigationGranular/pulverulent flues gasificationCombustion chamberBrick

The invention provides a coal water slurry gasification furnace for gasifying coal water slurry, which comprises a combustion chamber and a chilling chamber, and is characterized in that: the combustion chamber further comprises a quasi-elliptic large-diameter combustion chamber shell, at least two coal water slurry and oxygen three-channel process nozzle chambers which are symmetrically arrangedat the large diameter of the combustion chamber shell and slightly incline downwards, at least two coal water slurry and oxygen three-channel nozzles which slightly incline downwards and are detachably arranged in each coal water slurry and oxygen three-channel process nozzle chamber and of which the openings face the inside of the combustion chamber, a fireproof brick which is lined in the combustion shell, at least two oxygen nozzle chambers which are positioned at the periphery below each coal water slurry and oxygen three-channel process nozzle chamber and incline upwards, at least two oxygen nozzles which incline upwards and are detachably arranged in each oxygen nozzle chamber and of which the openings face the inside of the combustion chamber, and a combustion chamber slag hole which is formed at the bottom of the combustion chamber, wherein the chilling chamber is arranged on the lower part of the combustion chamber and below the combustion chamber slag hole.

Owner:CHNA ENERGY INVESTMENT CORP LTD +2

A low-concentration oxygen-enriched fluidized suspension combustion method of coal-water slurry and its boiler device

ActiveCN104197321BPromote fireImprove combustion conditionsFluidized bed combustionEnergy inputAir preheaterMolecular sieve

The invention relates to a coal water slurry low-concentration oxygen enrichment fluidization suspension combustion method and boiler device. Zeolite molecular sieve oxygen enrichment devices are adopted to manufacture 24 to 30 percent of low-concentration oxygen enrichment air, the air is heated through an air preheater, primary air, secondary air and graining air pass through a fluidized bed, a secondary air opening and a coal water slurry granulator respectively to enter a combustion chamber, fluidization suspension combustion is achieved, the ignition and combustion condition of the coal water slurry boiler is improved, the ignition temperature of fuel is reduced, the combustion temperature, the combustion rate and the combustion-off rate are improved, the ignition and combustion stability of the fuel is improved, the adaption range of the coal water slurry boiler to the coal water slurry fuel is widened, and the boiler can be suitable for combusting coal water slurry made of inferior coal and also suitable for combusting sludge-coal blending coal water slurry fuel and sludge-coal slurry mixing coal water slurry fuel. The fuel cost and the production cost are reduced, the significant economic value is achieved, and the great social significance in improving the environment is achieved.

Owner:HANGZHOU FUDING ENERGY SAVING TECH SERVICE +1

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com