Clean heating air stove with water-coal slurry fuel

A technology of hot air furnace and coal-water slurry, applied in combustion chamber, combustion method, combustion equipment, etc., can solve the problems of difficult to remove hot air ash, reduce air flow rate, reduce dust, etc., achieve less dust, reduce dust, complete burn effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

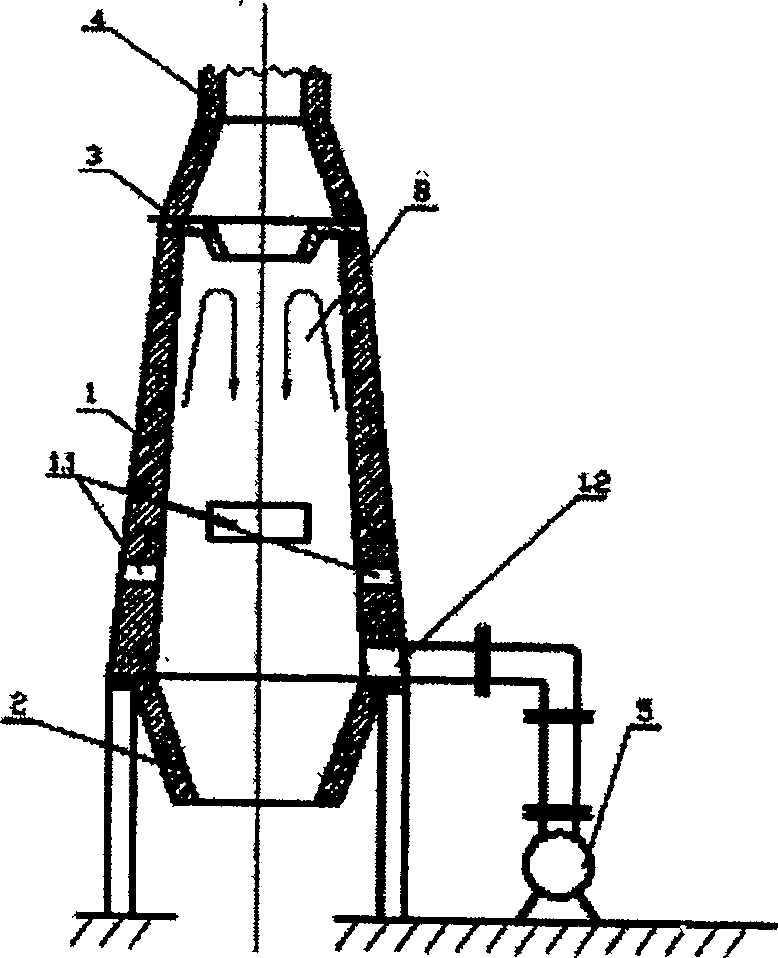

[0022] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings.

[0023] Such as figure 1 As shown, the coal-water slurry fuel clean hot air furnace of the present invention contains a body of furnace, and the body of furnace mainly includes a conical hearth 1, a dust deflector 3, a furnace cover 4, an ash hopper 2 and a blower 5, and the lower end of the conical hearth 1 There are several coal-water slurry nozzles 1.1, and the present invention also includes an ash settler 7; the lowermost end of the conical furnace 1 is connected to the ash collecting hopper 2, the uppermost end is connected to the dust deflector 3, and the top of the dust deflector 3 is connected to the furnace cover 4 , the furnace cover 4 is connected with the ash settler 7 through the hot air pipe 6; the blower 5 is connected with the conical furnace 1 through the conical furnace 1 through the secondary nozzl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com