Boosting slurry-supply system for combusting water coal slurry

A coal-water slurry and combustion water technology, applied in the direction of fuel supply, combustion method, combustion equipment, etc., can solve the problems of serious wear of pump wearing parts, short continuous operation time, and influence on continuous operation of boilers, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

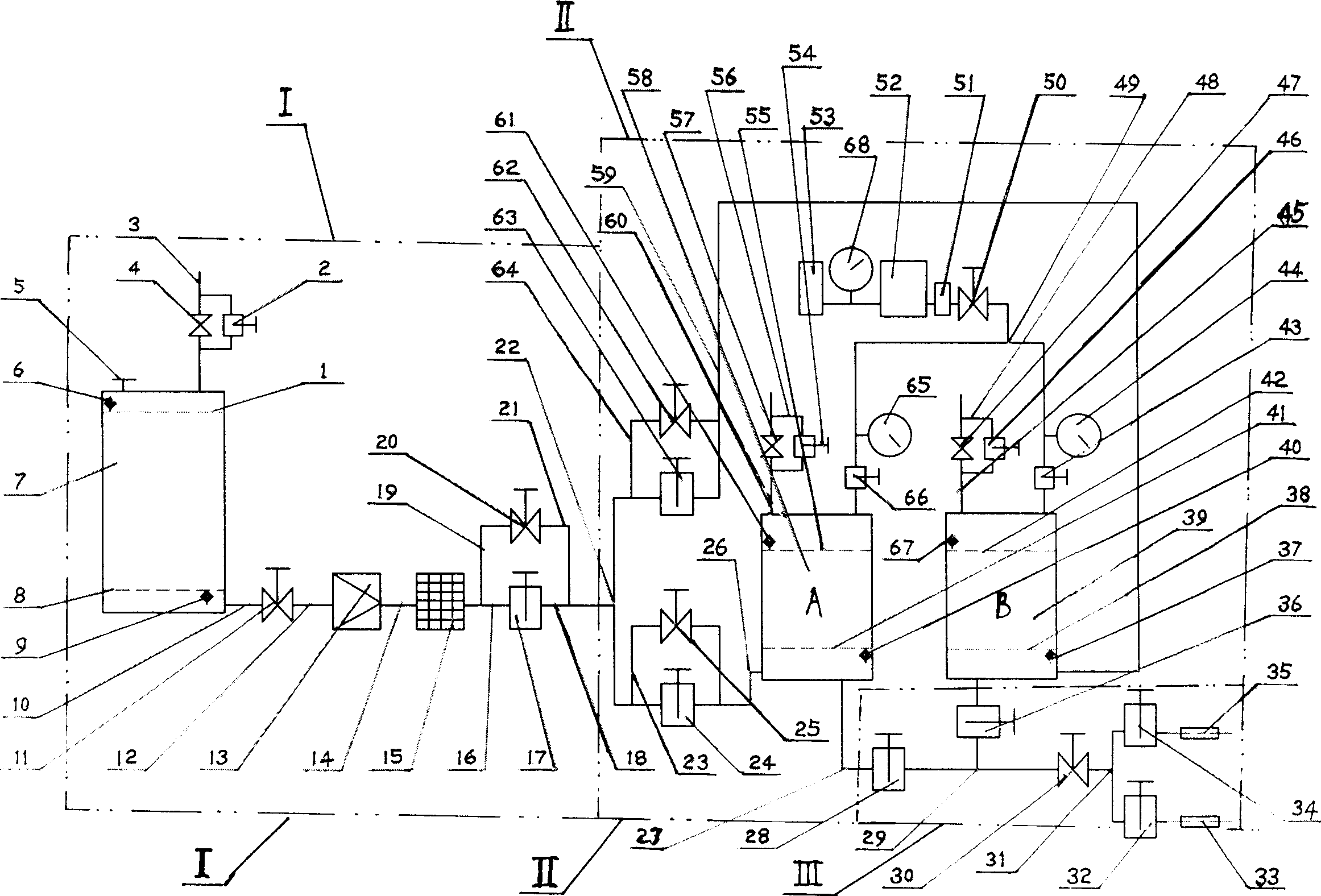

[0009] In the present embodiment, in the coal-water slurry input device (1), comprise the slurry storage tank (7) of storage fuel and fuel delivery pipeline, on the fuel delivery pipeline, there are low-pressure slurry delivery pump (13), filter (15) and The control valve on the pipeline and the delivery of the coal-water slurry are replaced by the low-pressure slurry delivery pump (13) by the original high-pressure slurry supply pump. This fuel delivery pipe is connected with A pressurized slurry supply tank (58). In the pressurized slurry supply device (II), two pressurized slurry supply tanks (39, 58) of A and B have been adopted, and the two pressurized slurry supply tanks are connected with the compressed air source, and two pressurized slurry storage tanks ( 58, 39) switch between each other through the control of the central control cabinet to deliver high-pressure coal-water slurry to the coal-water slurry spray guns (33, 35) in turn. A booster slurry supply tank fuel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com