Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

74results about How to "Yield easily" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

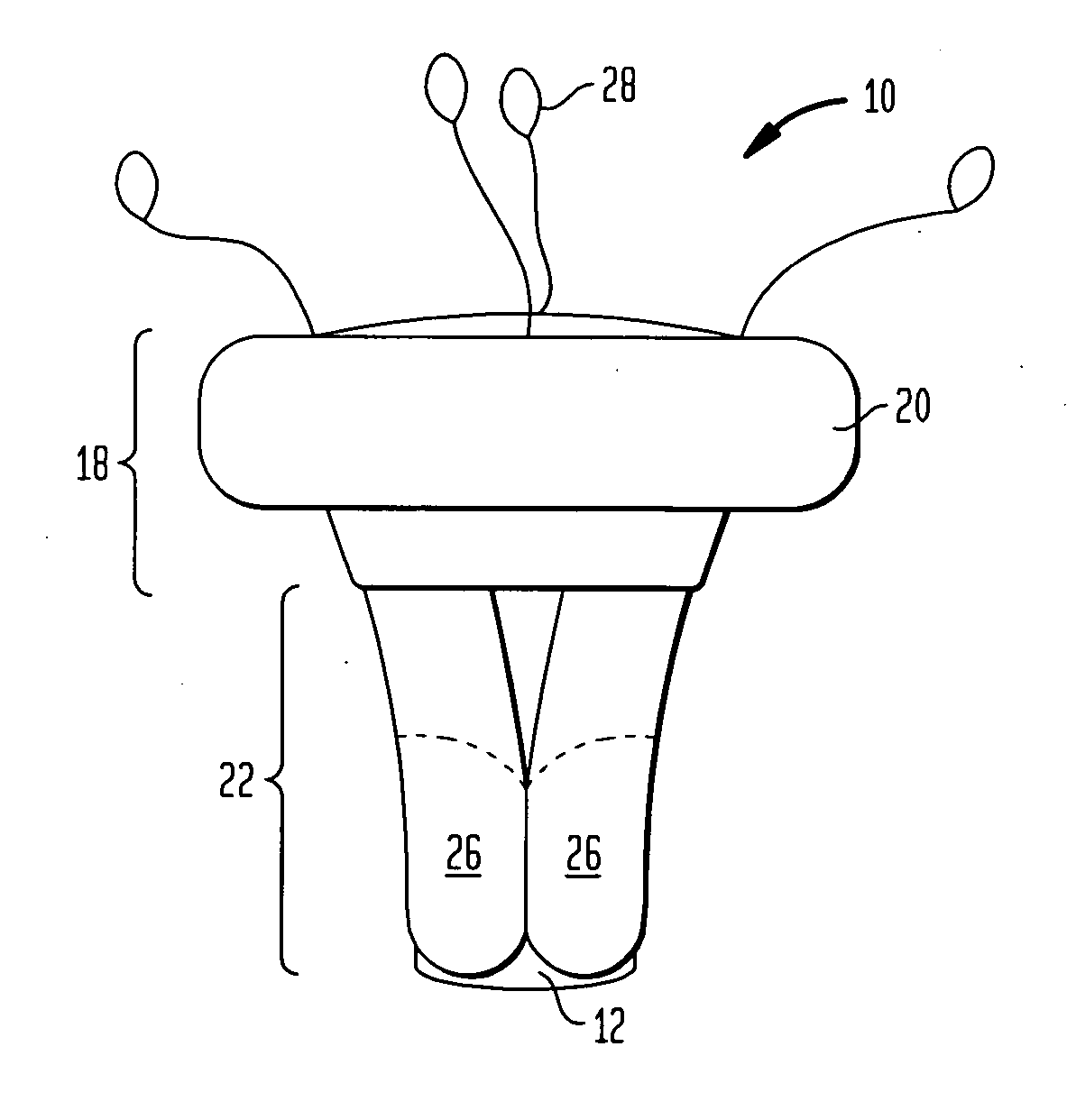

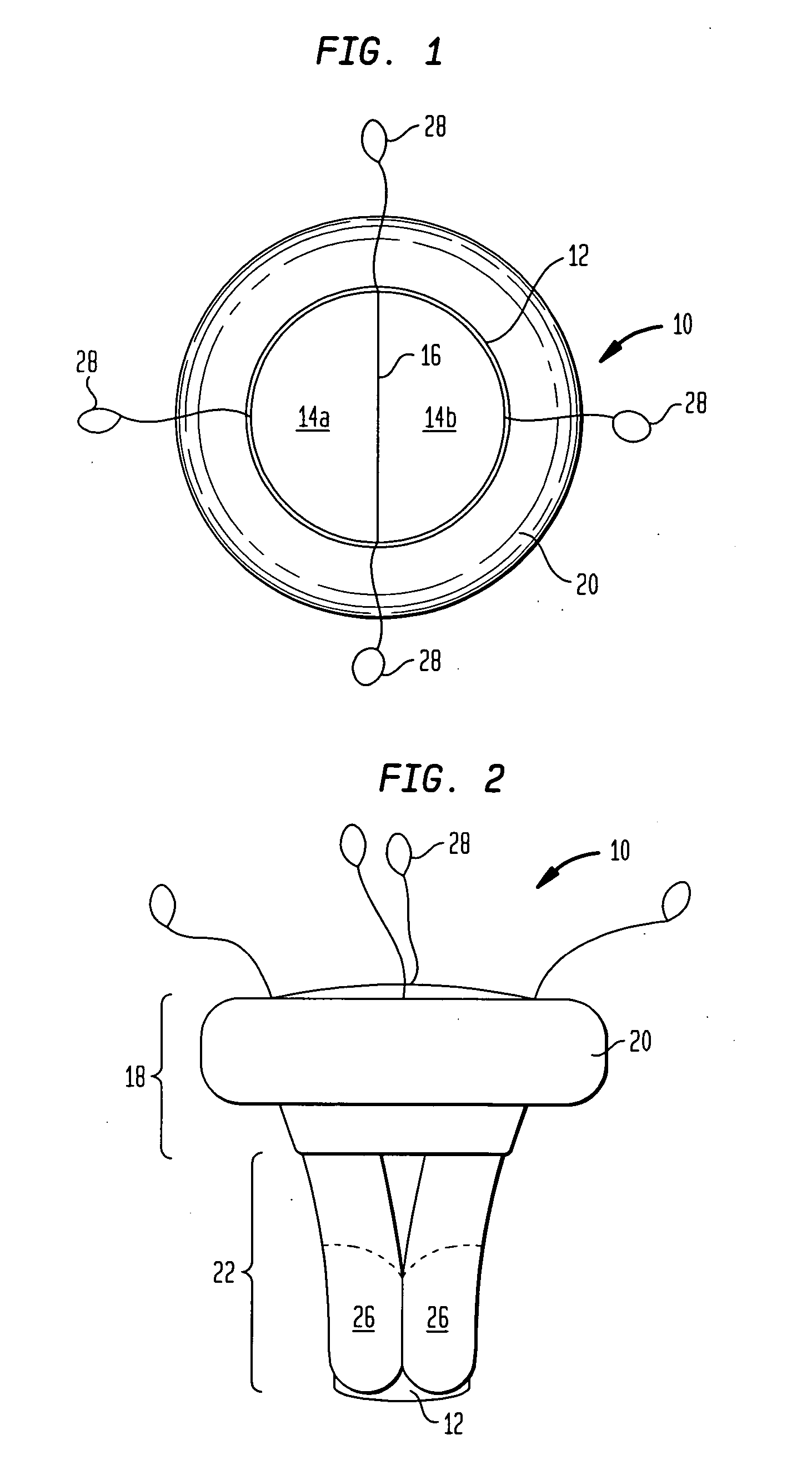

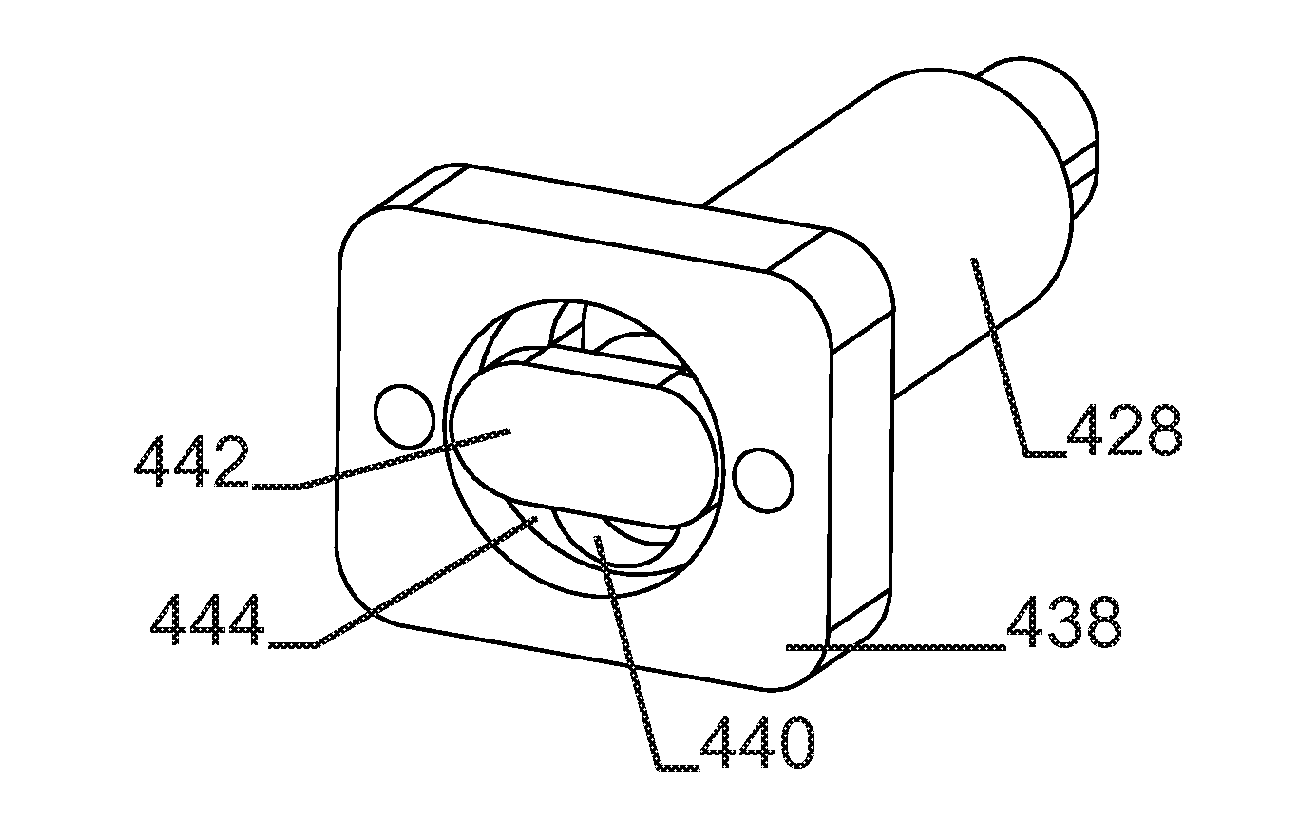

Gel based laparoscopic trocar

A gel based laparoscopic trocar having a shaft with upper and lower portions, the shaft having an interior dimension, a rigid gel casing surrounding the upper portion of the shaft, at least two resilient gel filled membranes filling the interior dimension of the upper portion of the shaft, a plurality of petals surrounding the external portion of the lower portion of the shaft, the petals having a first condition in which the petals are elongated along the length of the shaft and a second condition in which portions of the petals are permitted to curl upward and away from the shaft, and a release mechanism associated with the petals, the release mechanism adapted to permit the petals to move from the first condition to the second condition upon actuation. The petals may include a memory metal having a natural condition relating to the second condition of the petals.

Owner:EDRICH HEALTH TECH

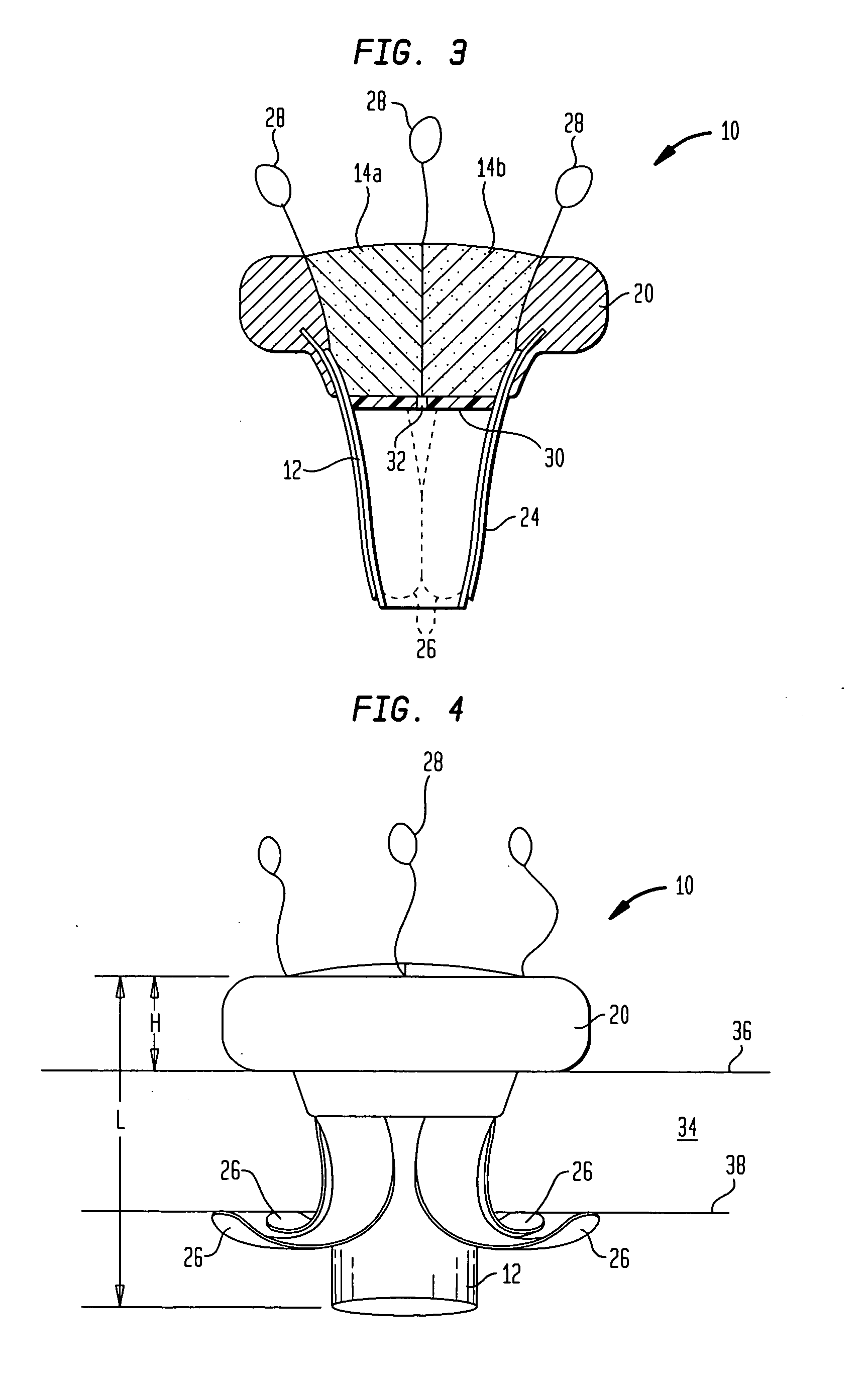

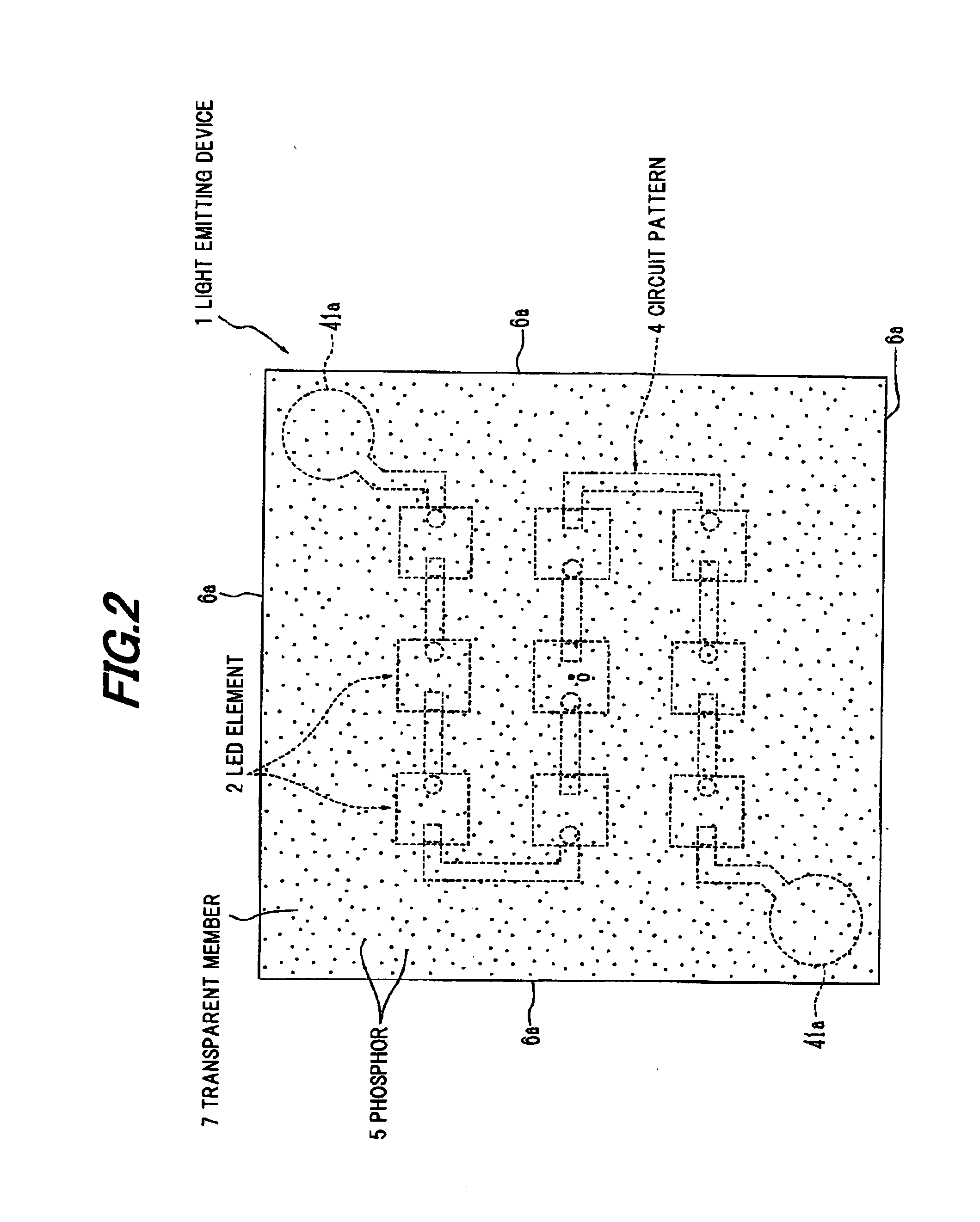

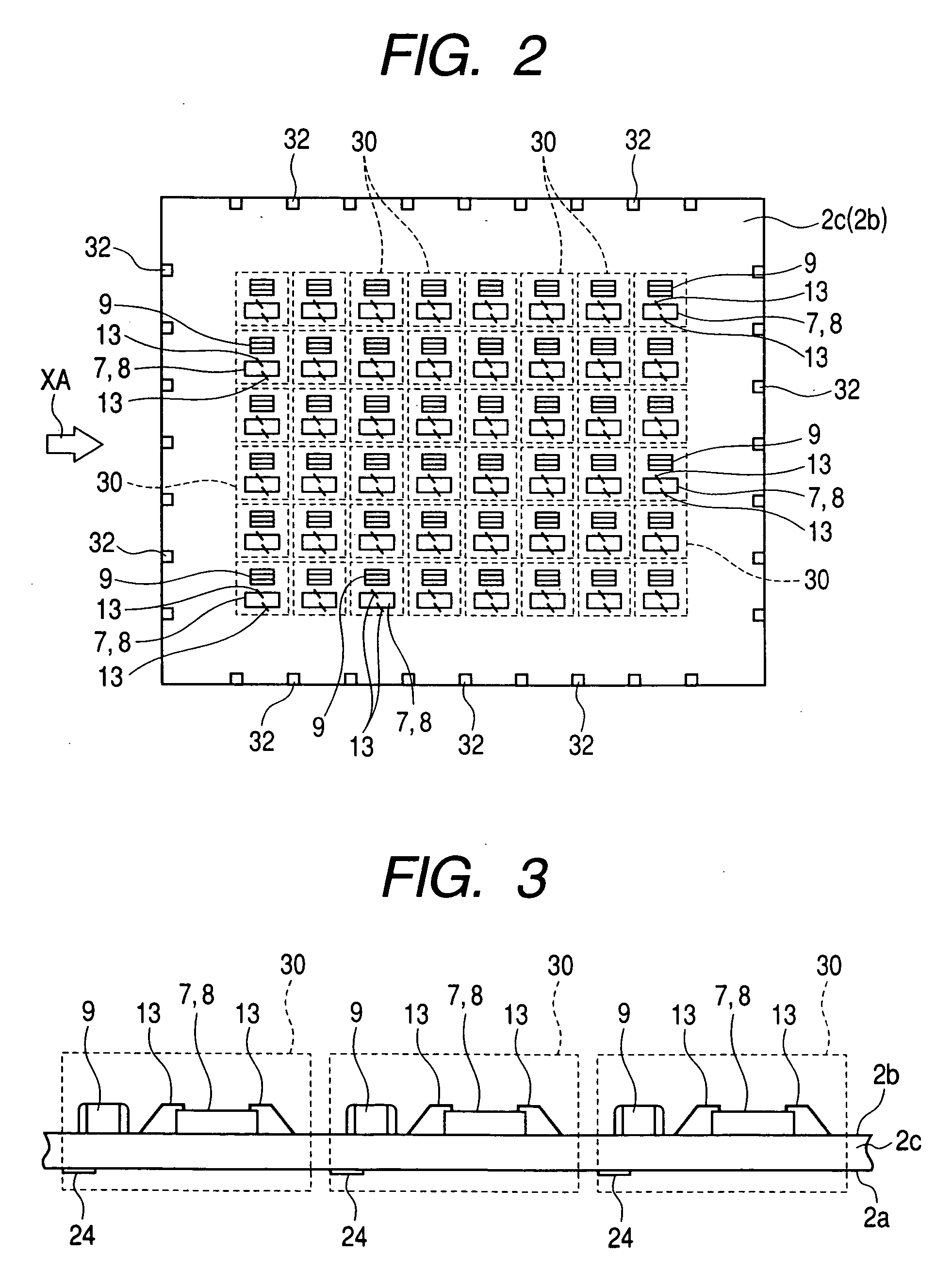

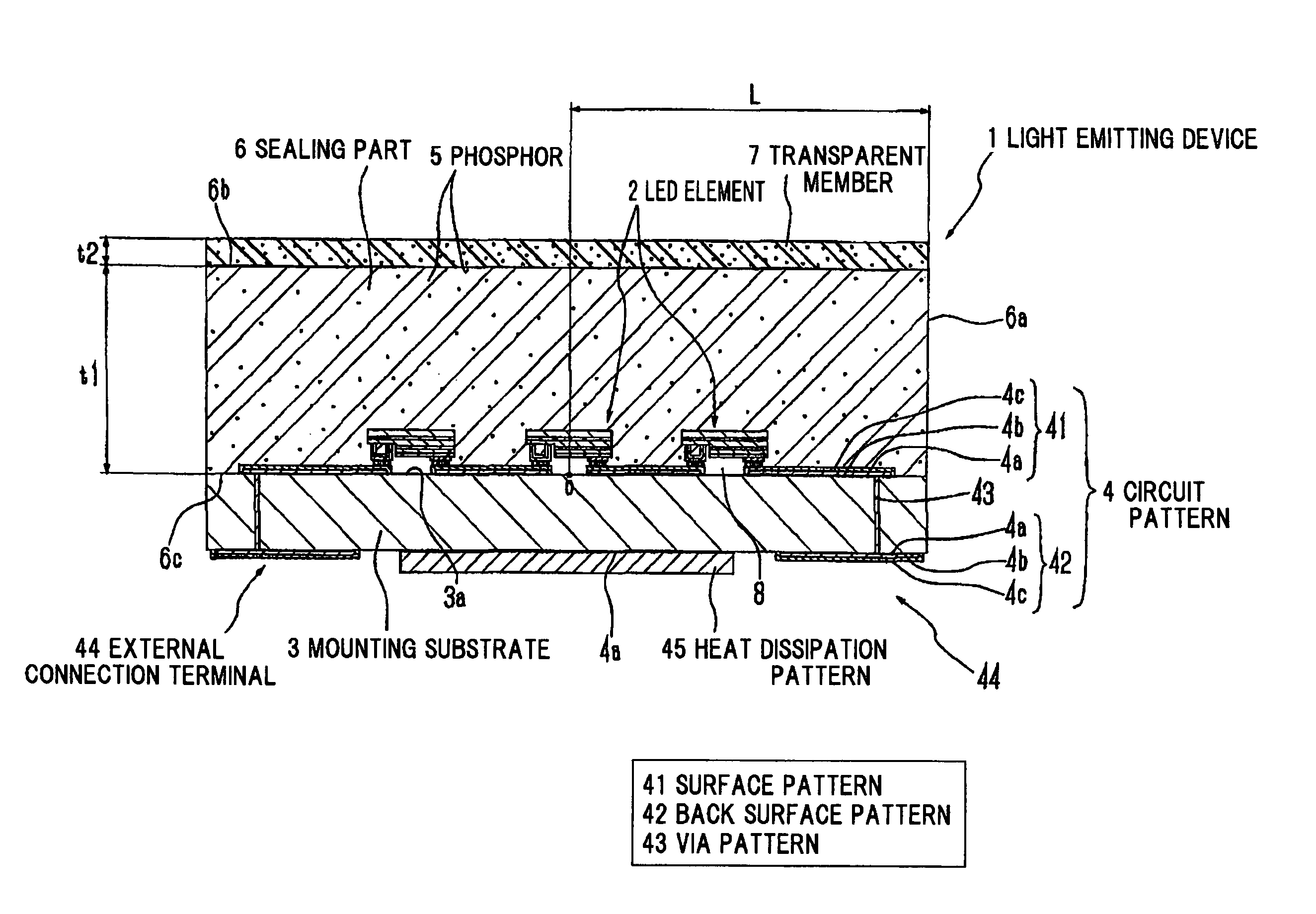

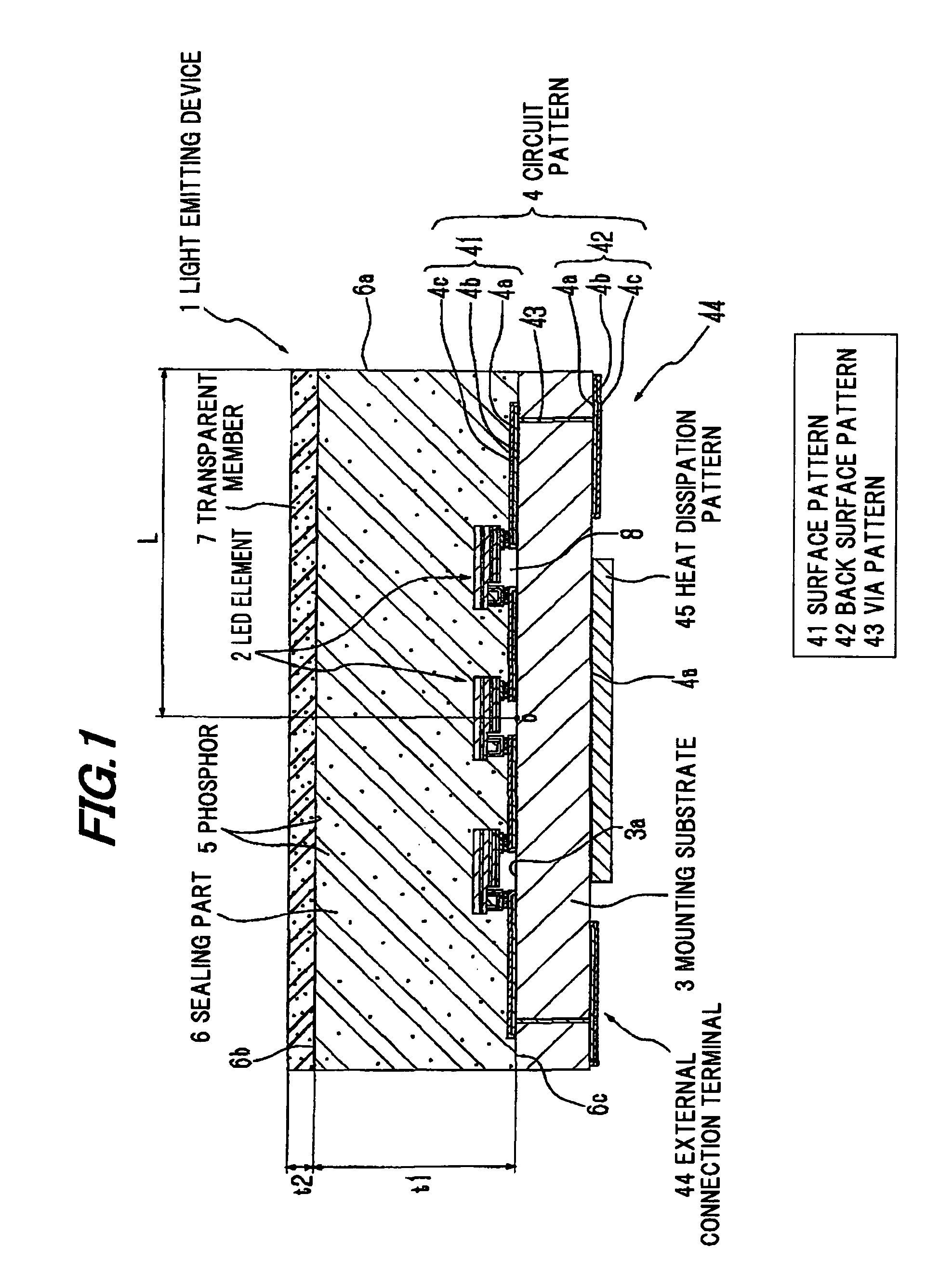

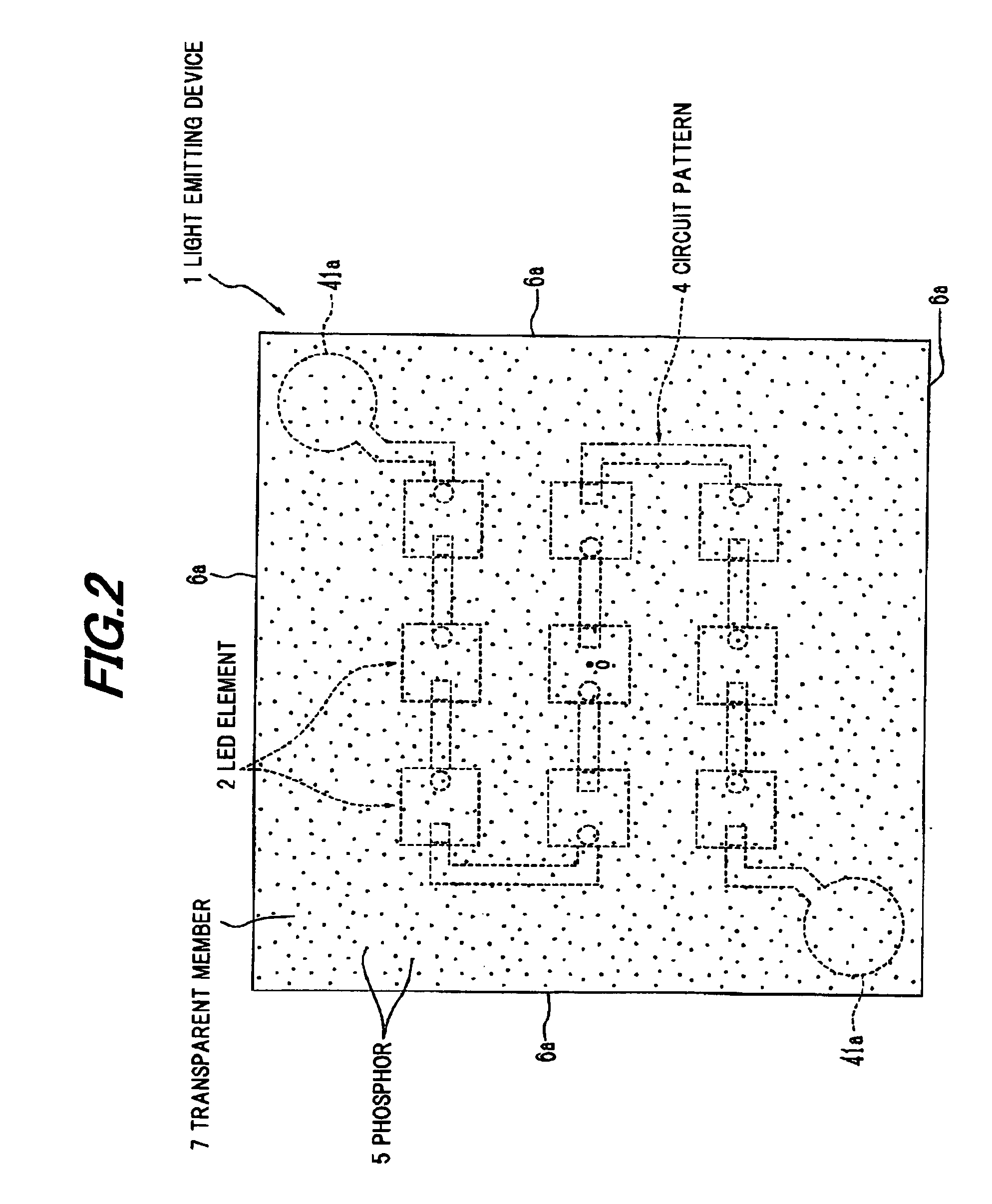

Light emitting device and light emitter

ActiveUS20080284315A1Sensitively sense unevenness in chromaticityReduce chroma differenceDischarge tube luminescnet screensLamp detailsPhosphorWavelength conversion

A light emitting device includes a light emitting element, a substrate with a flat mounting surface for mounting the light emitting element thereon, a sealing part for the light emitting element on the mounting surface of the substrate. The sealing part is formed of glass including a phosphor to be excited by light emitted from the light emitting element to radiate a wavelength conversion light. The sealing part is shaped like a rectangular solid wherein a lateral length is defined as a distance between a center of a bottom surface of the sealing part bonded to the mounting surface and a side face perpendicular to the mounting surface, a vertical length is defined as a distance between the mounting surface and a top surface of the sealing part, and at least one of the lateral length is longer than the vertical length. The device further includes a transparent member formed on the top surface of the sealing part. The transparent member includes the phosphor at a concentration higher than the sealing part.

Owner:TOYODA GOSEI CO LTD

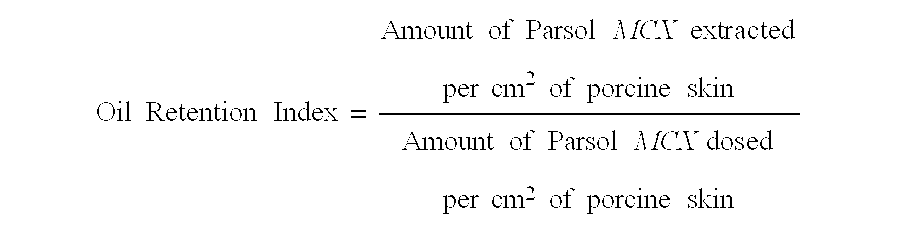

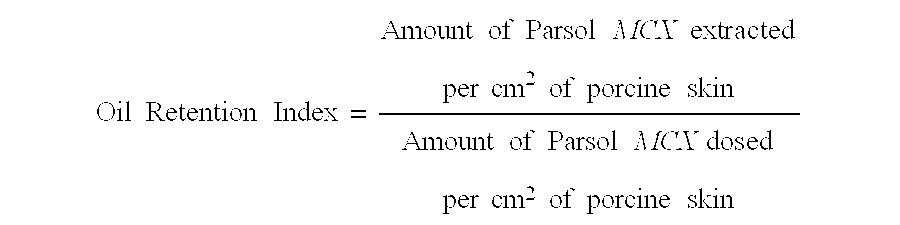

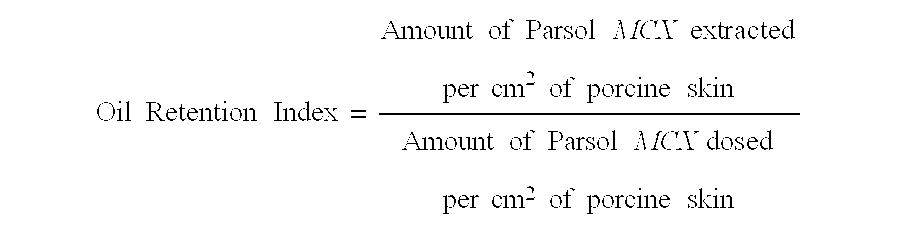

Method of enhanced moisture or reduced drying using wet-skin treatment compositions

InactiveUS20030049282A1Better behavedFast absorptionCosmetic preparationsToilet preparationsSkin treatmentsMoist skin

The invention provides methods of enhancing moisture or reducing drying using wet skin treatment composition. These compositions are activated by water and retained efficiently on skin. Thus, the compositions (and methods used) impart desirable benefits to skin, are perceived to absorb quickly on wet skin and leave the skin feeling clean, but non-greasy.

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

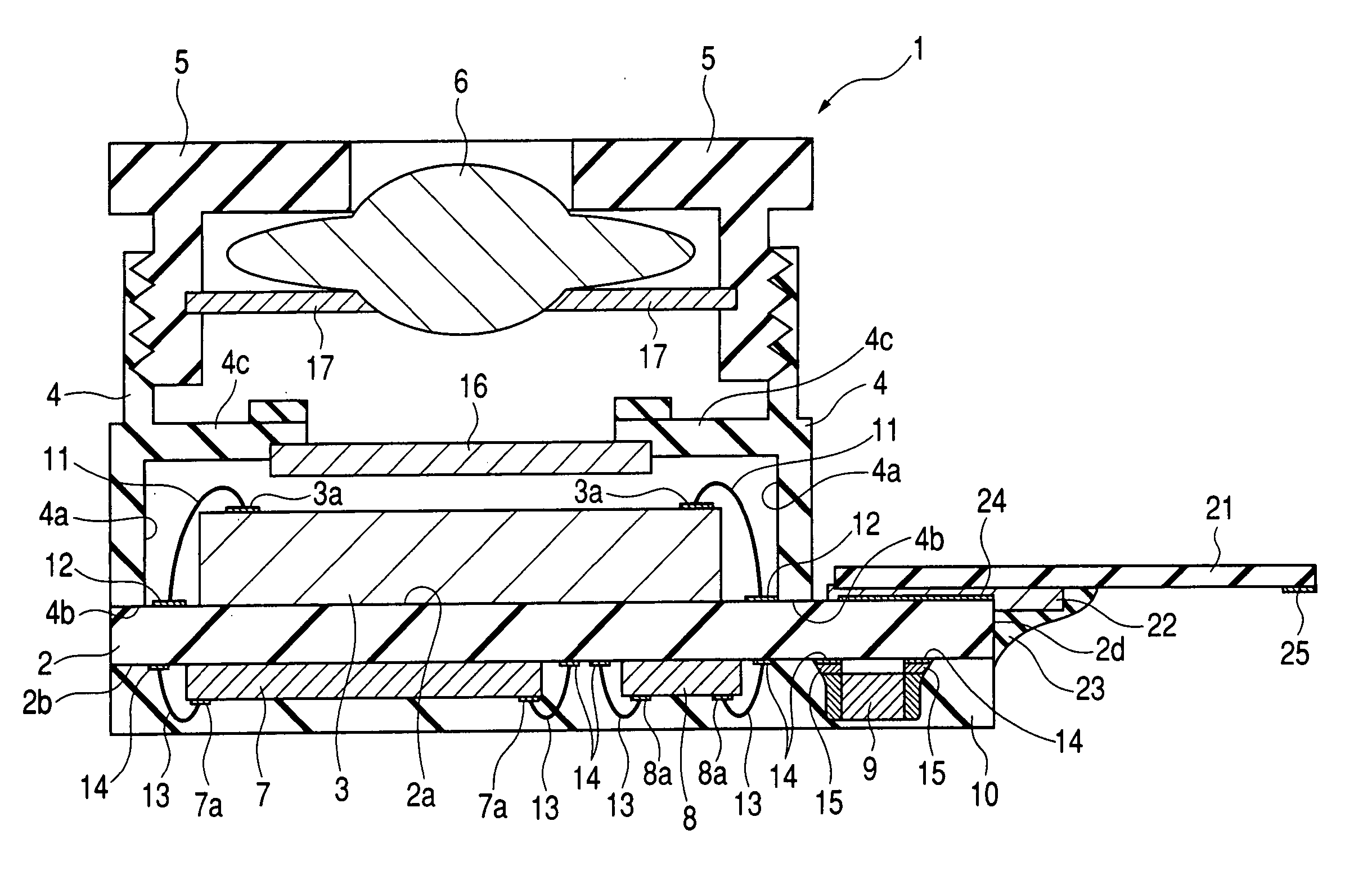

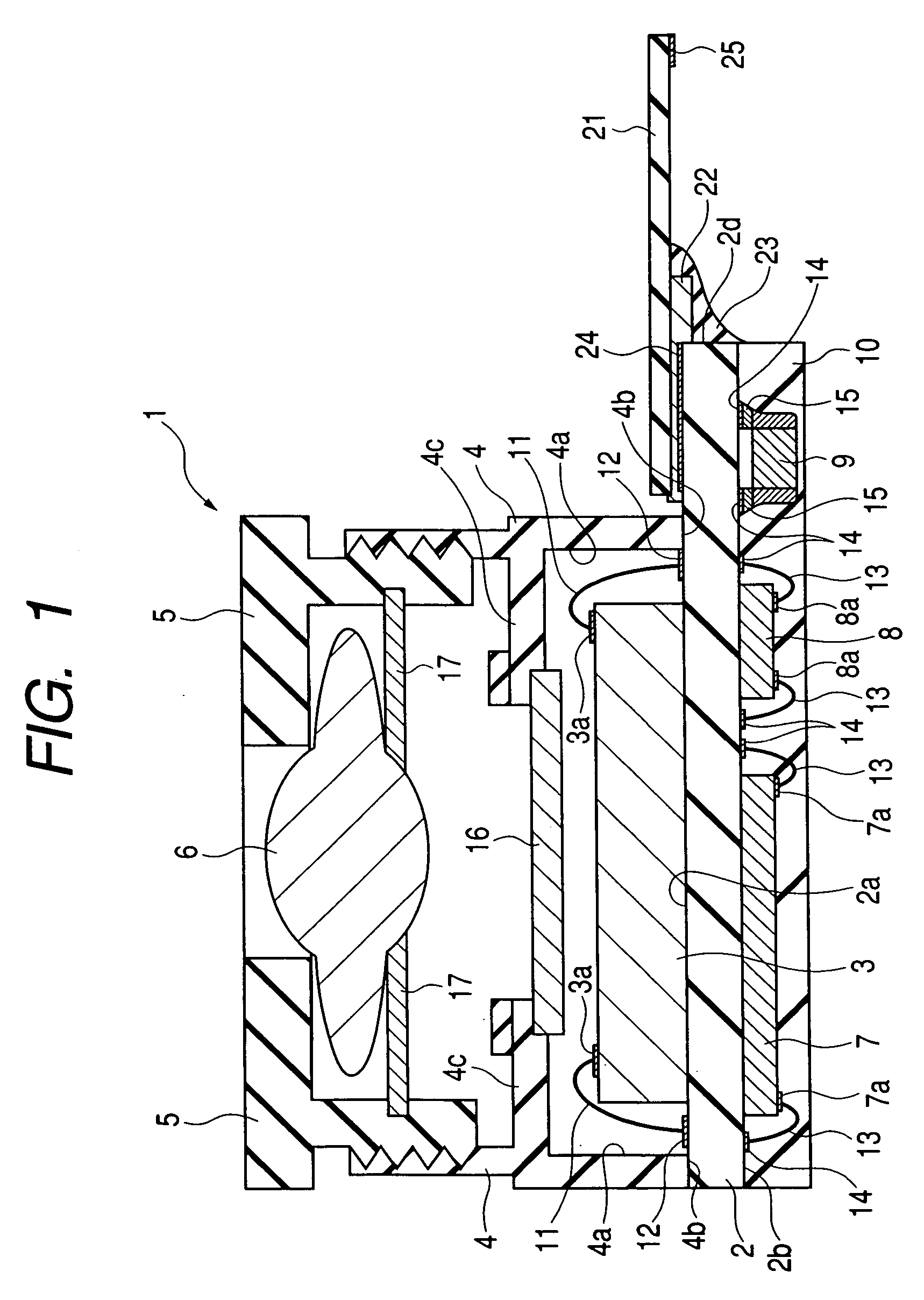

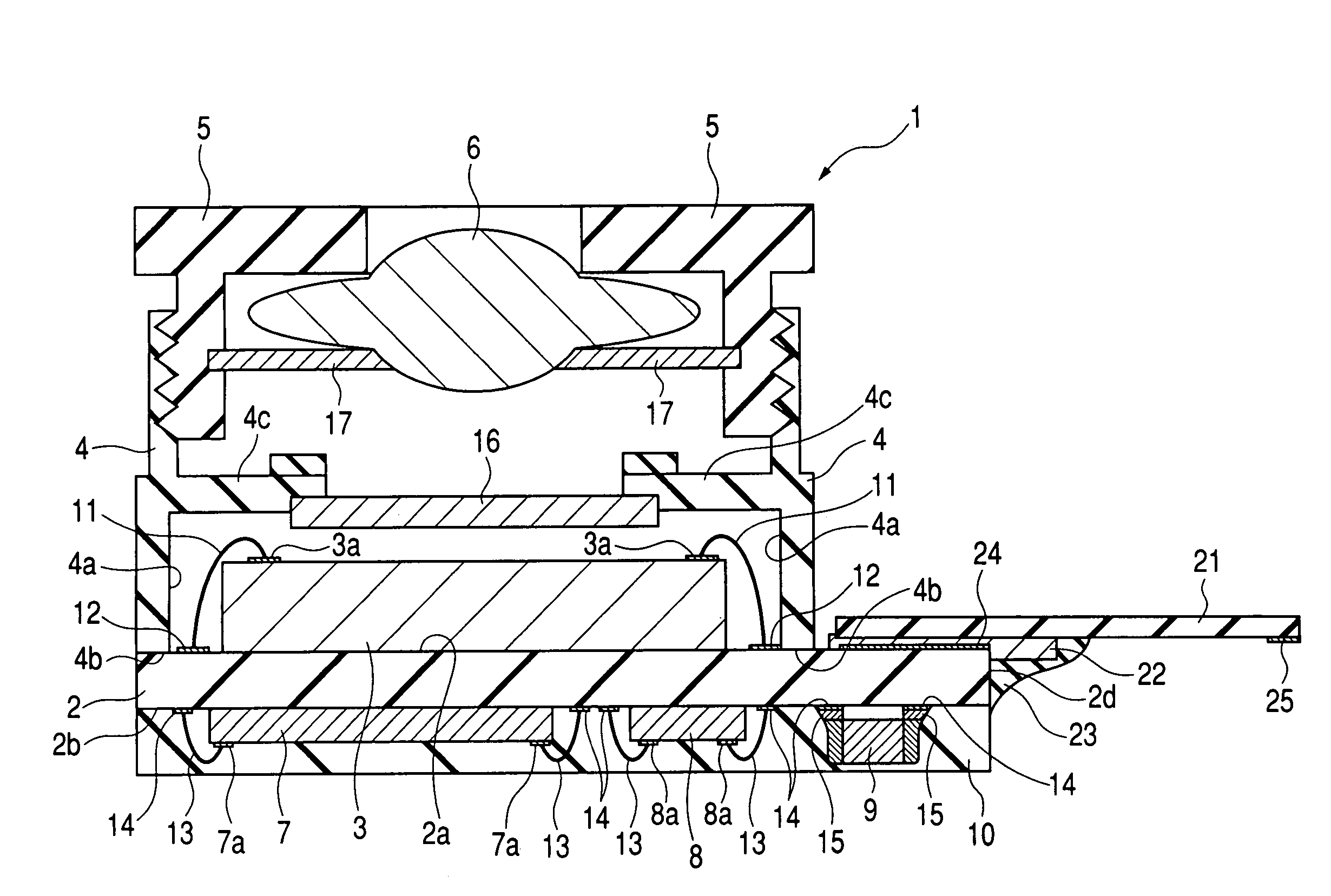

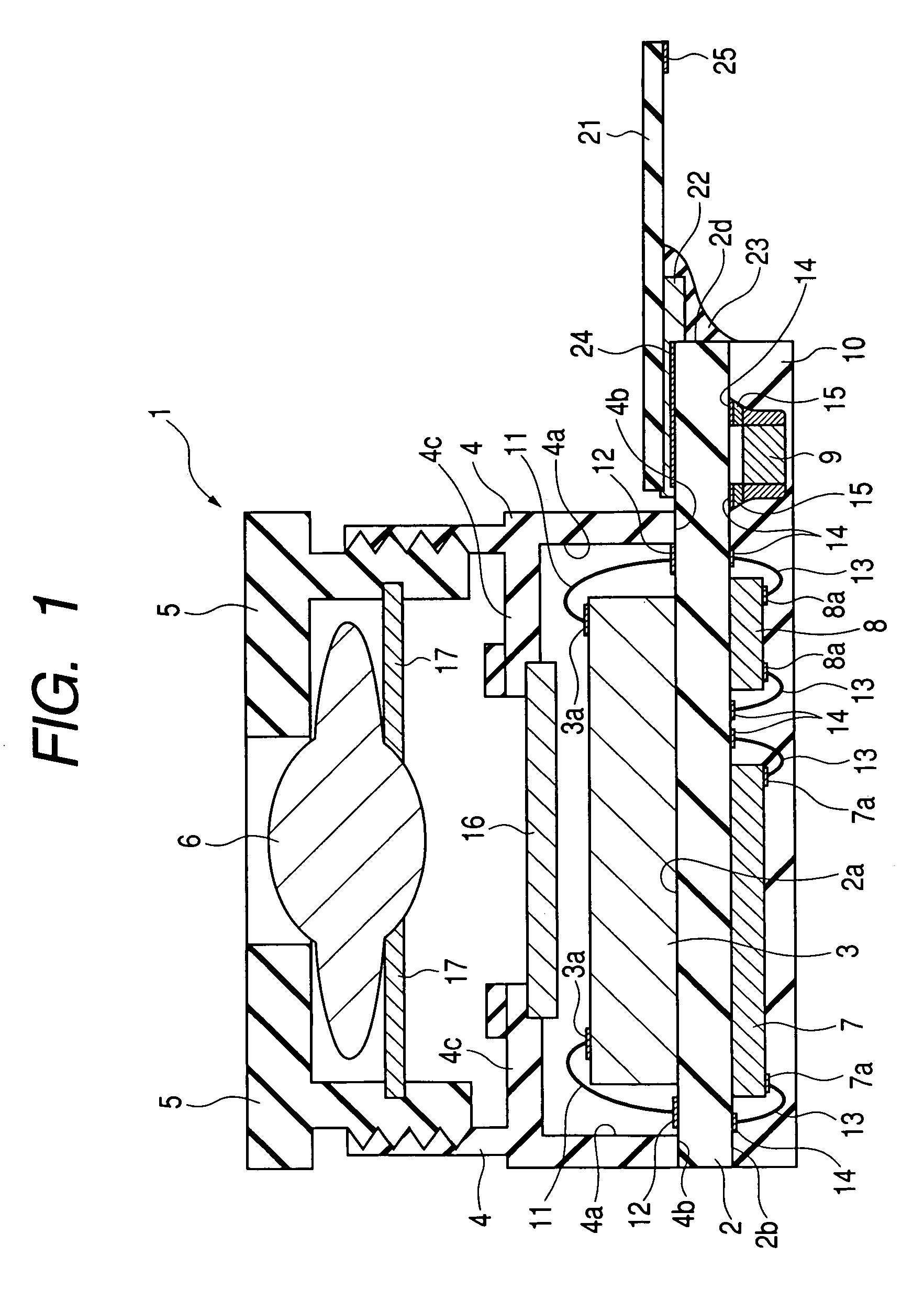

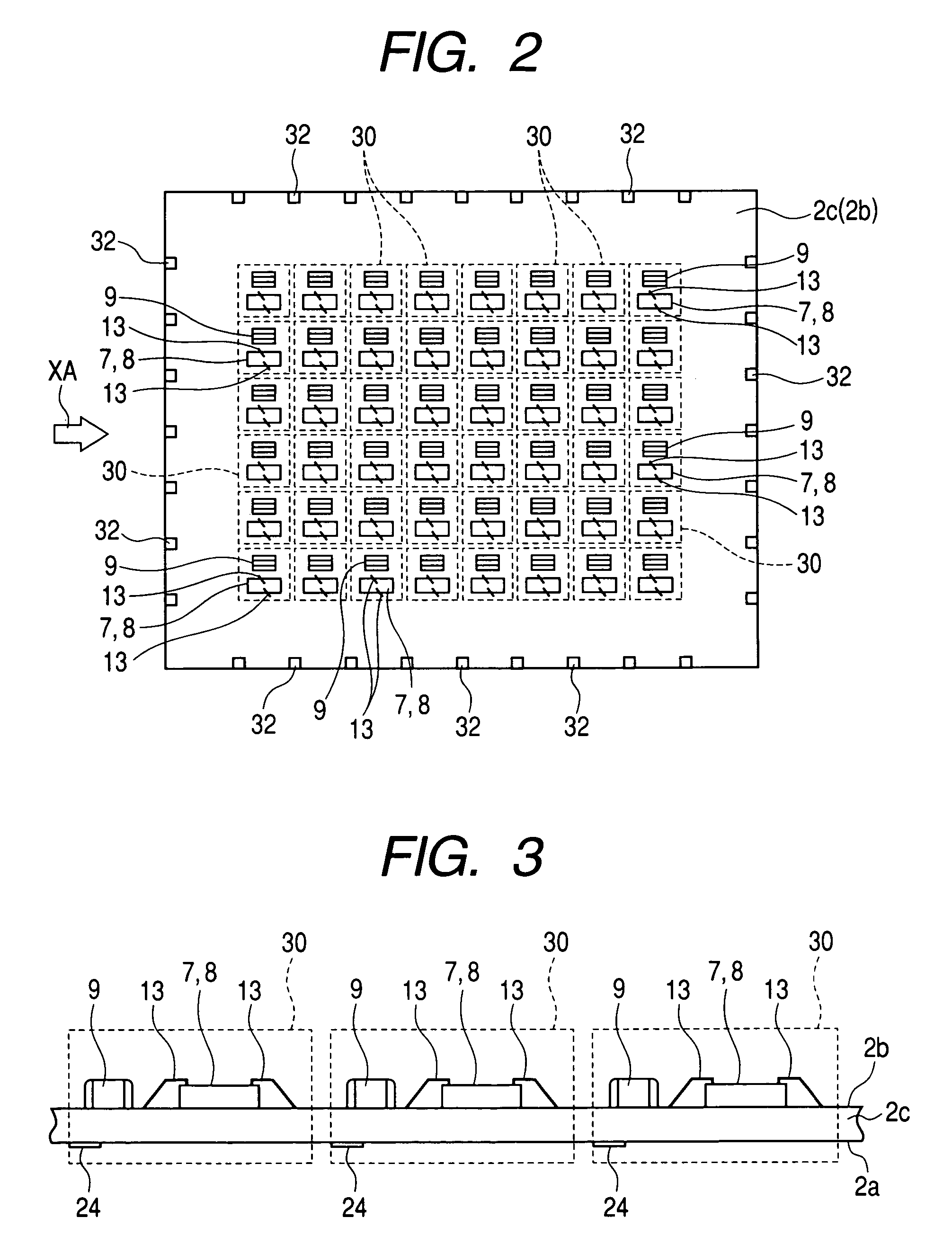

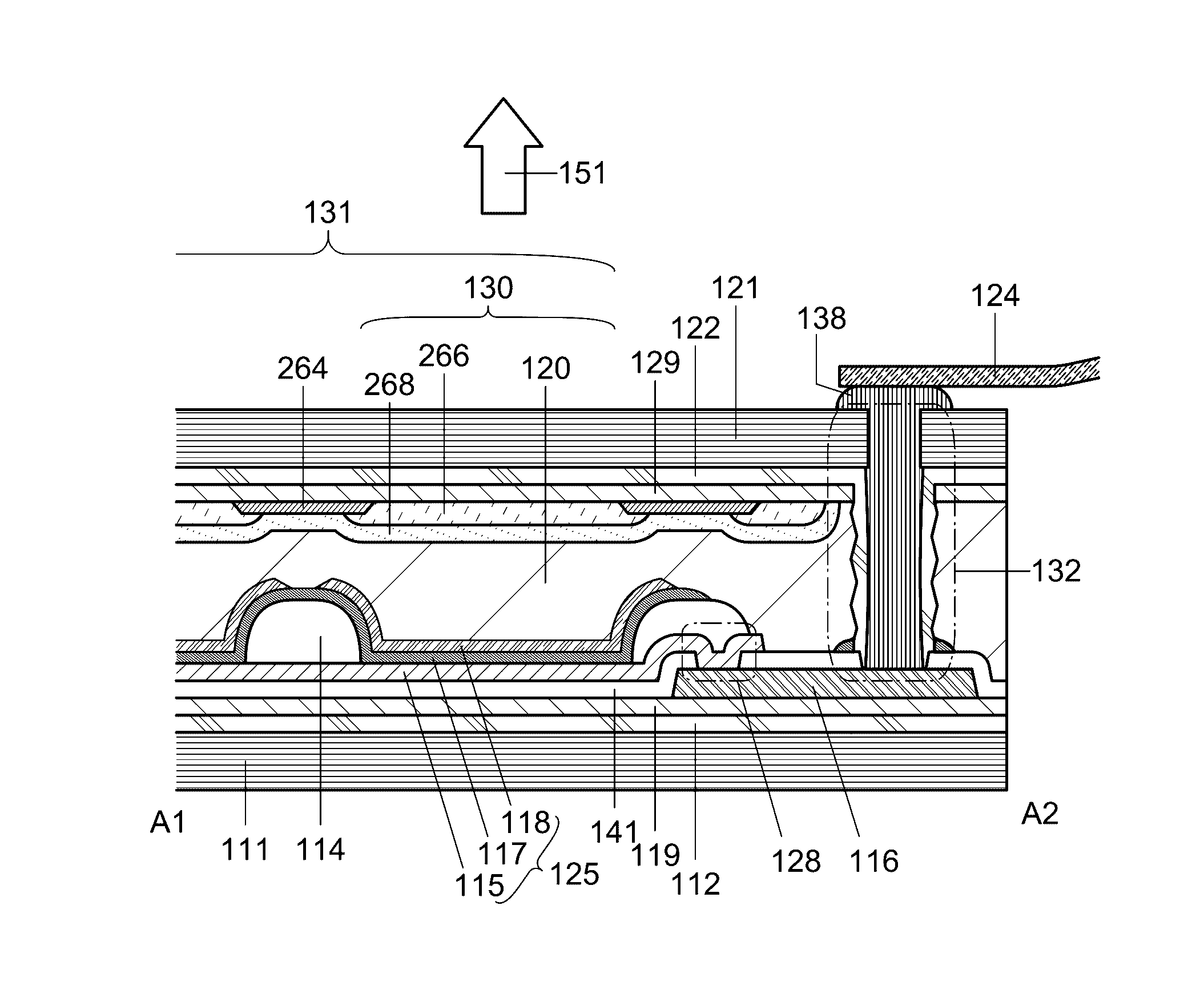

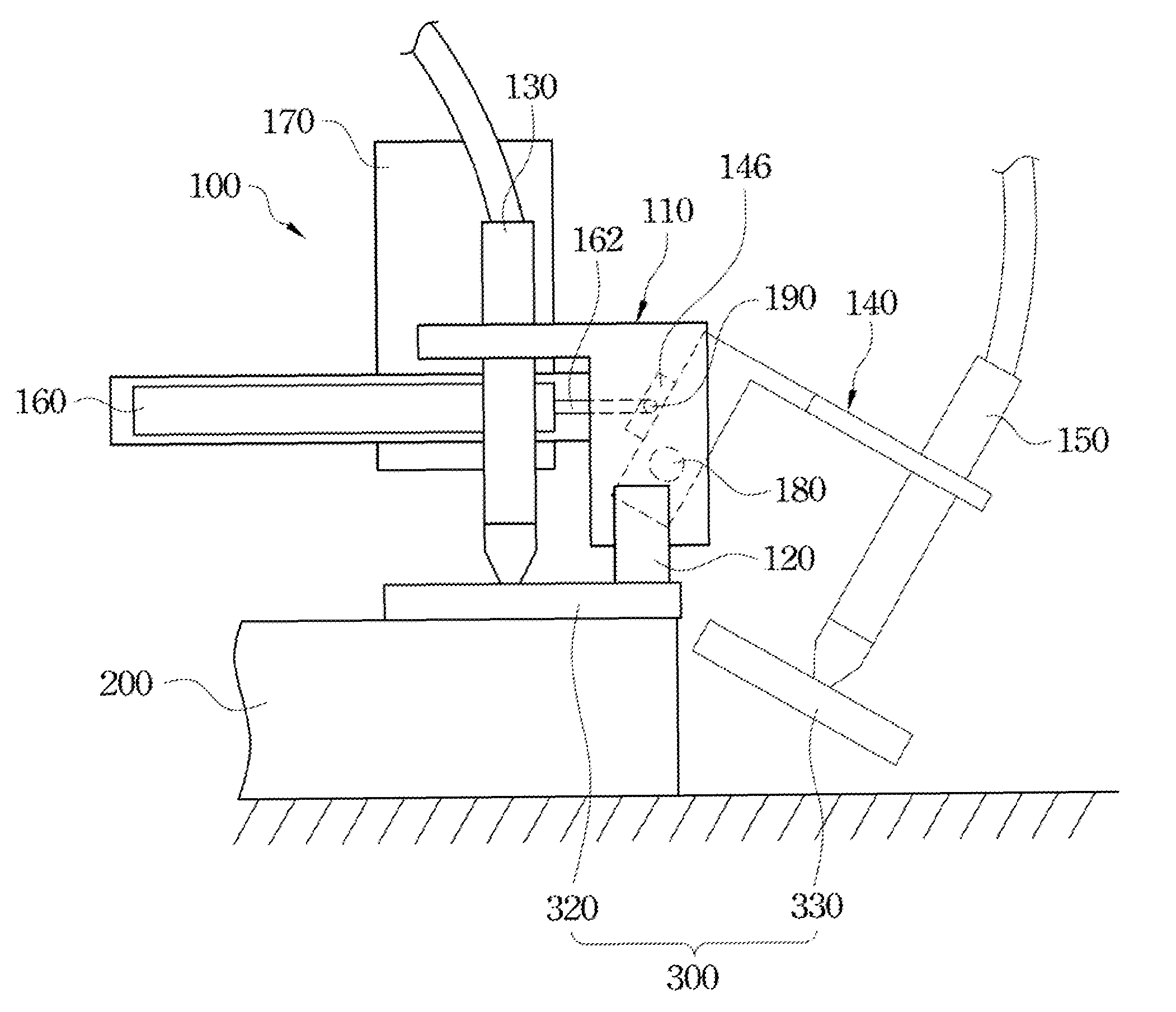

Manufacturing method of solid-state image sensing device

InactiveUS20060091487A1Improve manufacturing yieldYield easilyTelevision system detailsSolid-state devicesMemory chipAnisotropic conductive film

A sensor chip and a lens mount accommodating therein the sensor chip are mounted on a surface of a wiring substrate and a lens holder accommodating a lens therein is coupled with the lens mount. On a rear surface of the wiring substrate, a logic chip, a memory chip and a passive component are mounted and they are sealed with a seal resin. An electrode pad of the sensor chip is electrically connected to an electrode on the surface of the wiring substrate via a bonding wire but a stud bump is also formed on the electrode at the surface of the wiring substrate and this stud bump is connected with the bonding wire. On the surface of the wiring substrate, a flexible substrate is bonded with an anisotropic conductive film and a bonding material. When a camera module is to be manufactured, the surface side of the wiring substrate is assembled after the rear surface side of the wiring substrate is assembled.

Owner:RENESAS TECH CORP +1

Wet-skin treatment compositions

InactiveUS20030054019A1Better behavedFast absorptionCosmetic preparationsHair cosmeticsSkin treatmentsDermatology

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

Manufacturing method of solid-state image sensing device

InactiveUS7005310B2Improve manufacturing yieldYield easilyPrinted circuit assemblingTelevision system detailsMemory chipAnisotropic conductive film

A sensor chip and a lens mount accommodating therein the sensor chip are mounted on a surface of a wiring substrate and a lens holder accommodating a lens therein is coupled with the lens mount. On a rear surface of the wiring substrate, a logic chip, a memory chip and a passive component are mounted and they are sealed with a seal resin. An electrode pad of the sensor chip is electrically connected to an electrode on the surface of the wiring substrate via a bonding wire but a stud bump is also formed on the electrode at the surface of the wiring substrate and this stud bump is connected with the bonding wire. On the surface of the wiring substrate, a flexible substrate is bonded with an anisotropic conductive film and a bonding material. When a camera module is to be manufactured, the surface side of the wiring substrate is assembled after the rear surface side of the wiring substrate is assembled.

Owner:RENESAS ELECTRONICS CORP

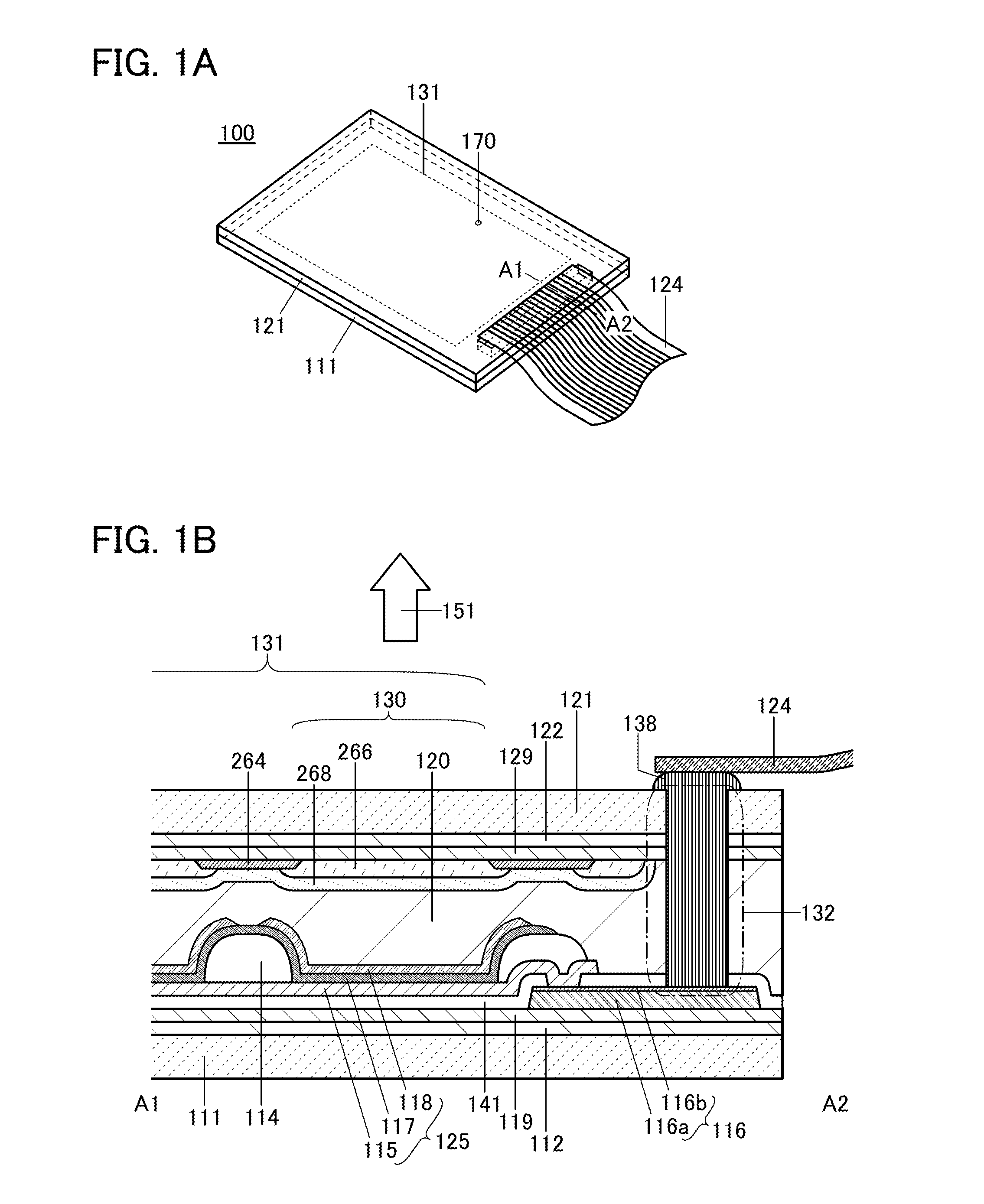

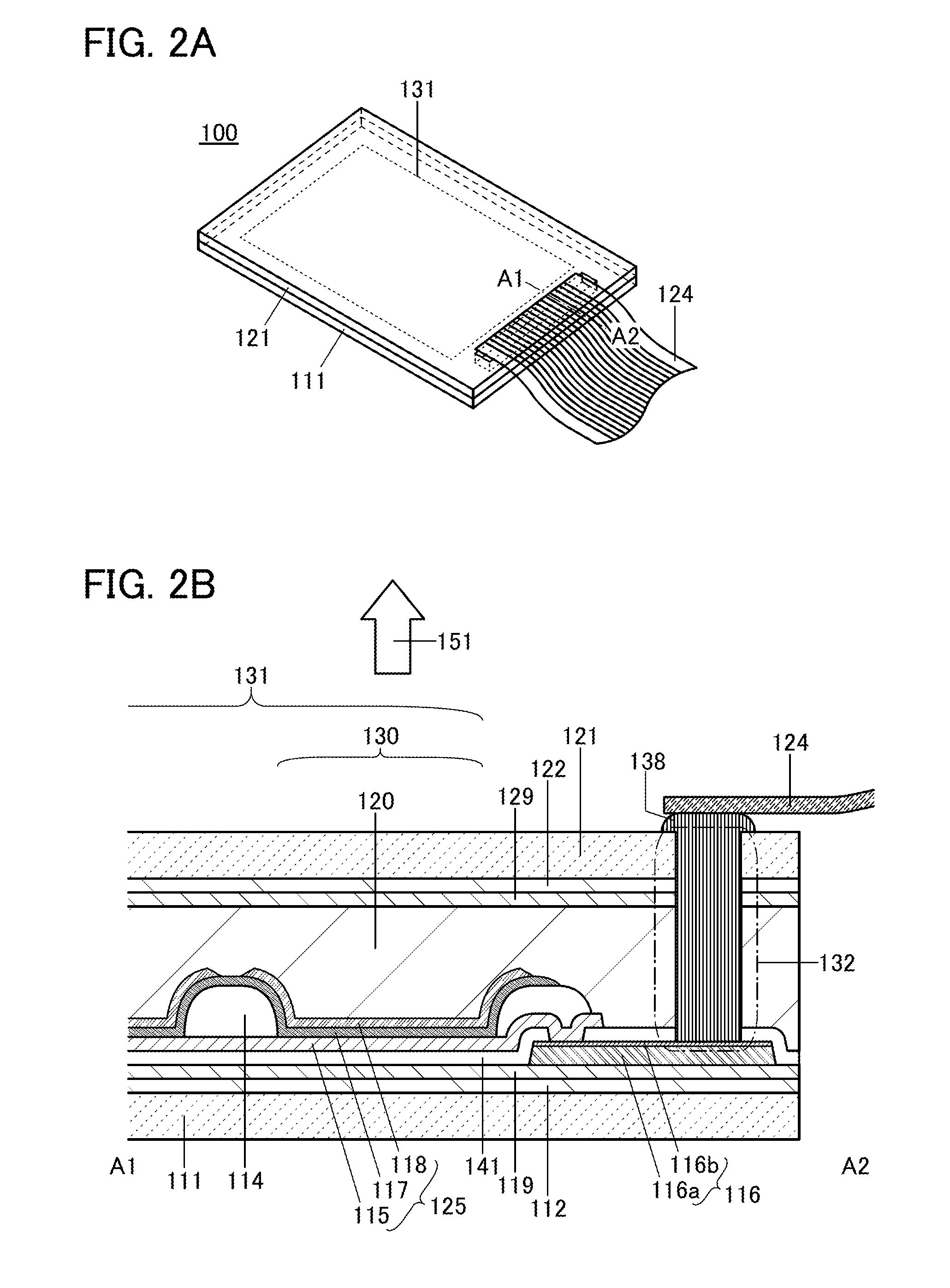

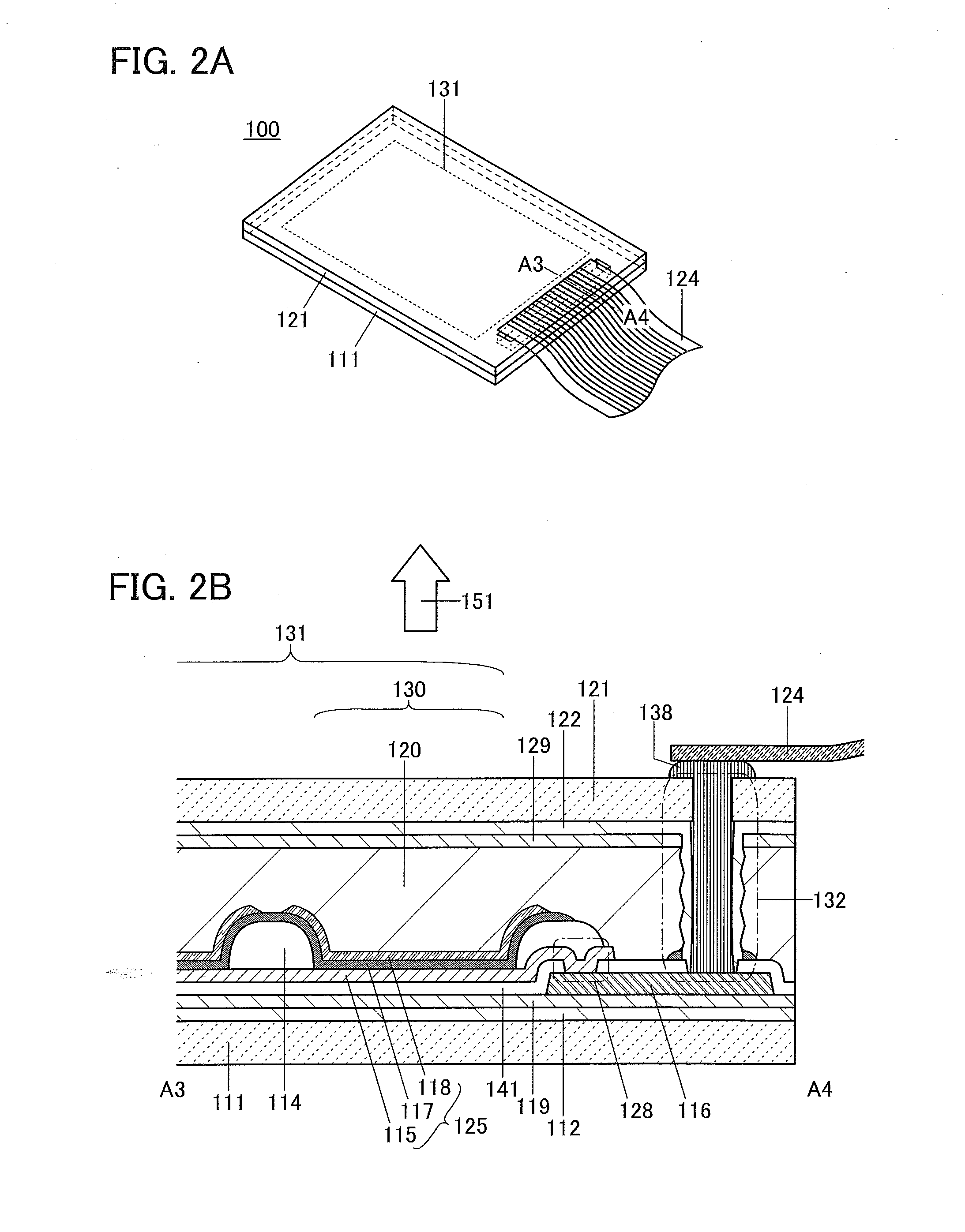

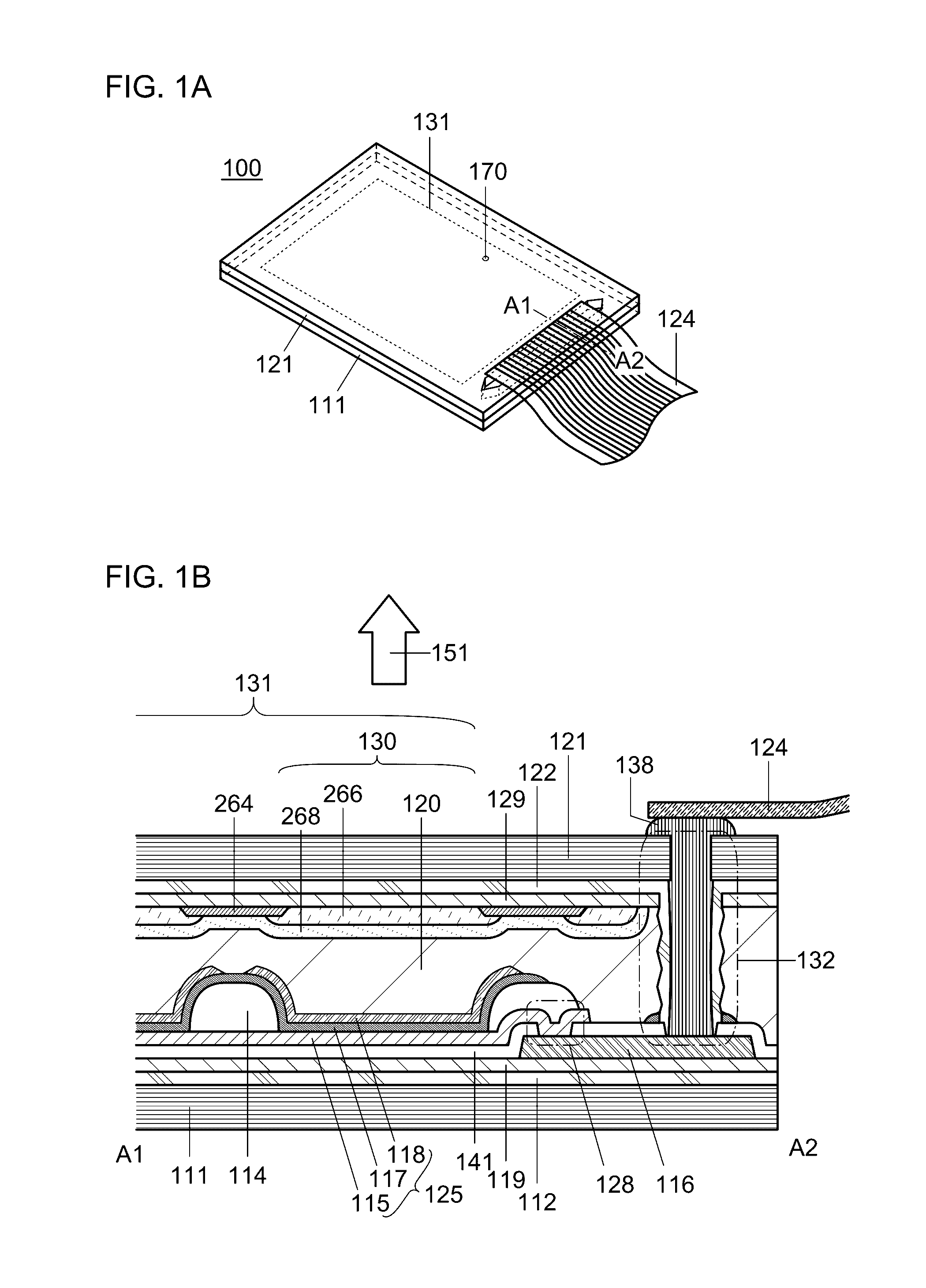

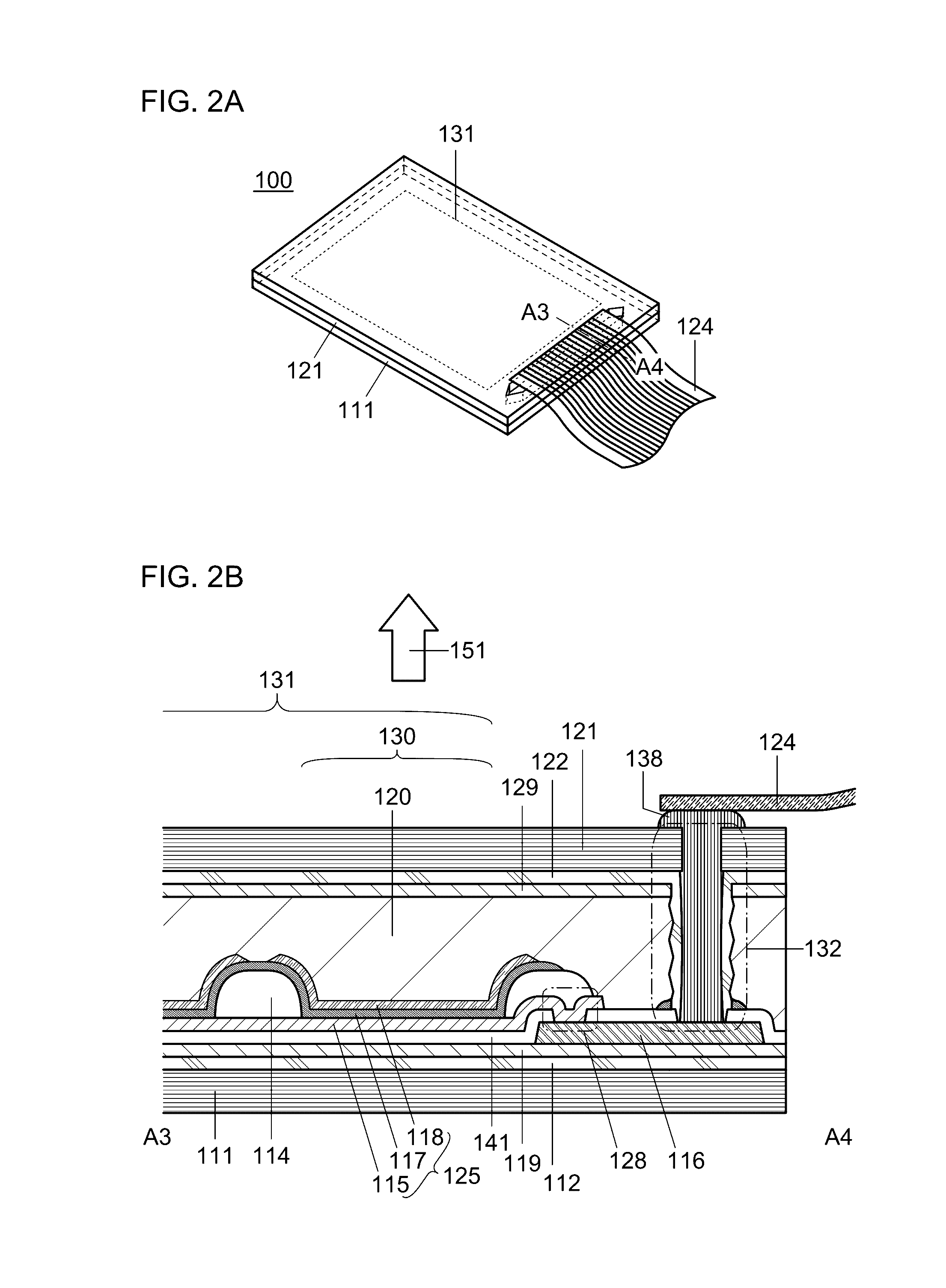

Method for manufacturing display device and method for manufacturing electronic device

ActiveUS20150250038A1Not easy to damageNot damage display regionLamination ancillary operationsLayered product treatmentDisplay deviceEngineering

A method for manufacturing a display device is provided. The method includes forming a display element interposed between a first substrate and a second substrate and peeling the second substrate from the first substrate so that an electrode, which is located between the first and second substrates and to be connected to an external electrode, is exposed simultaneously with the peeling of the second substrate.

Owner:SEMICON ENERGY LAB CO LTD

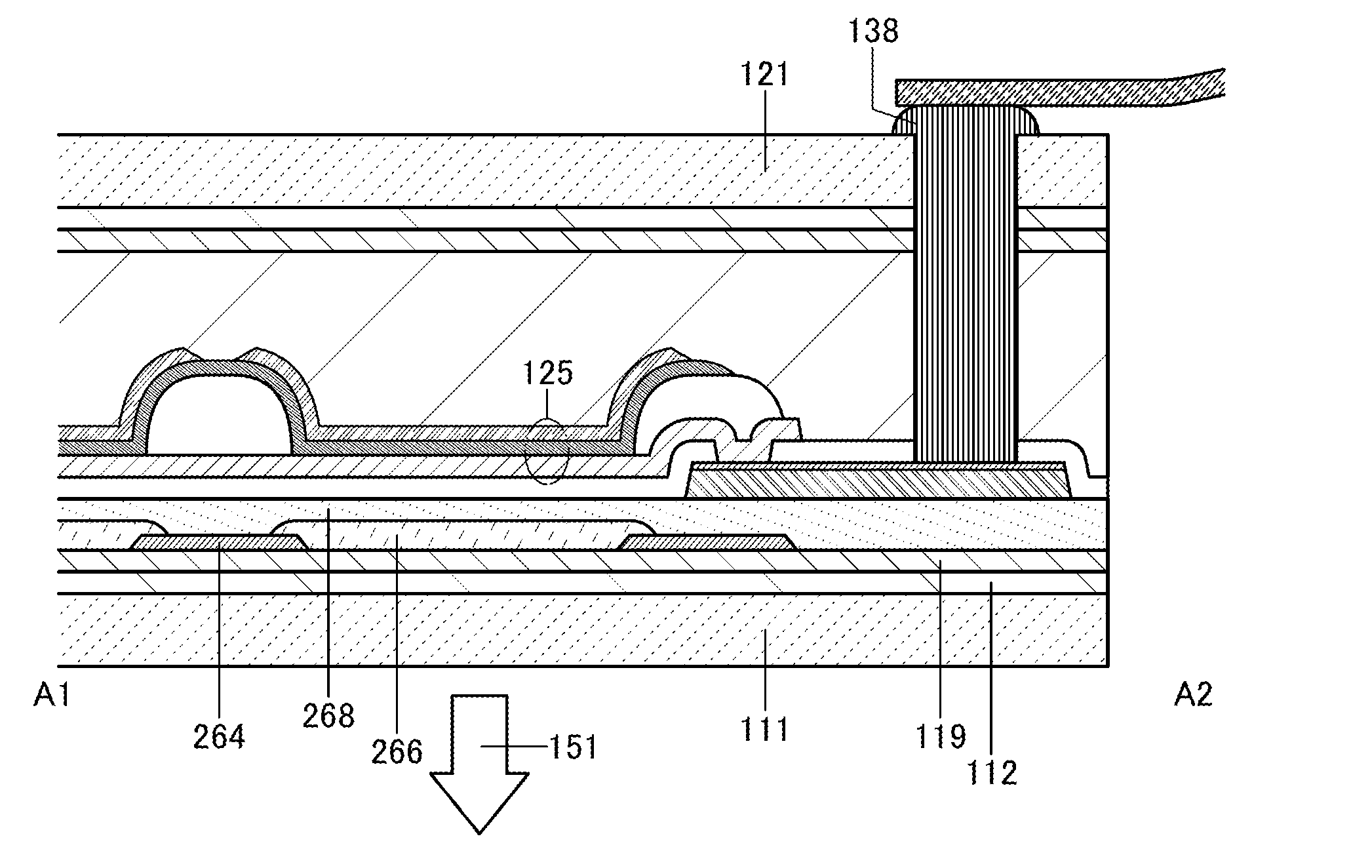

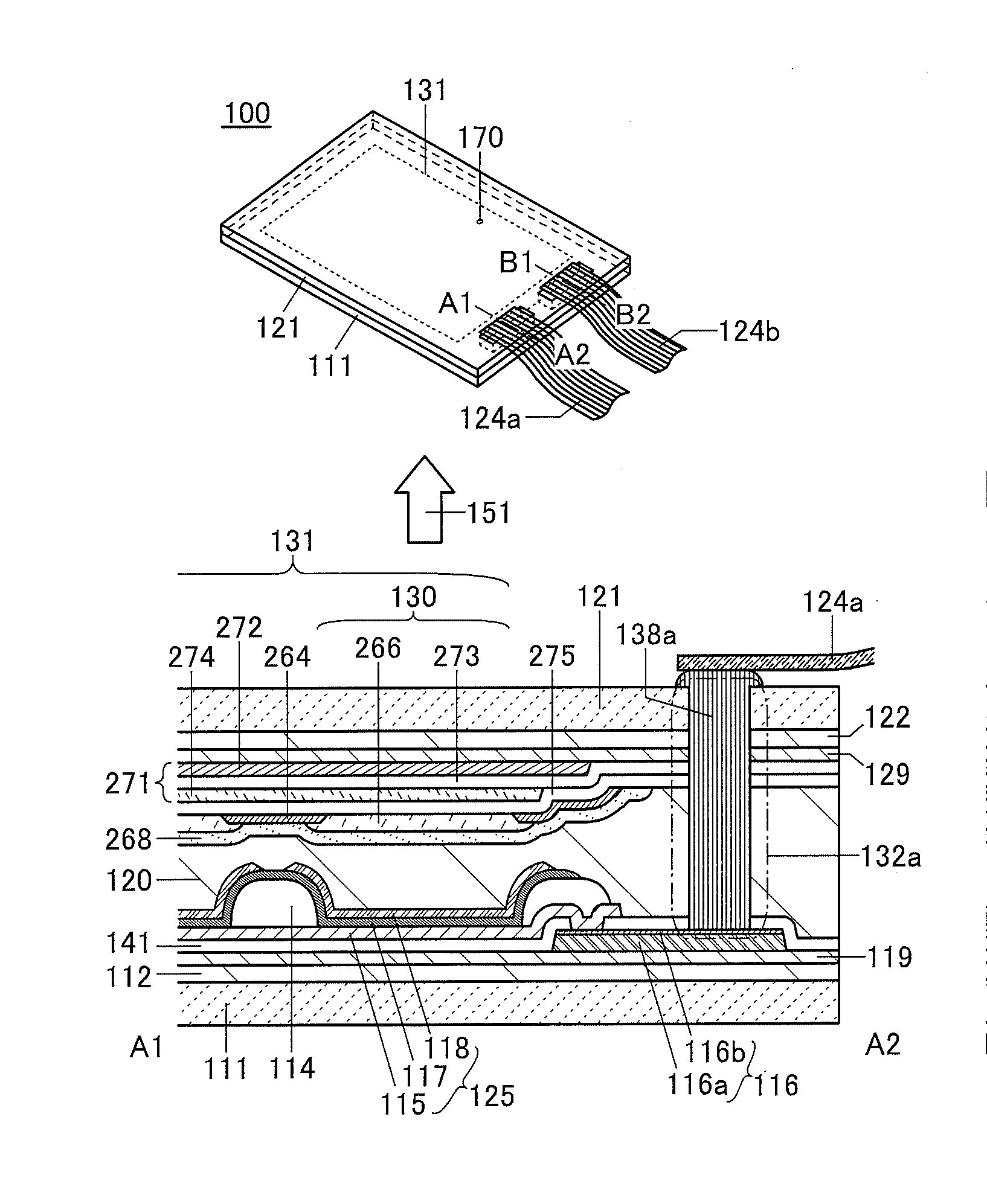

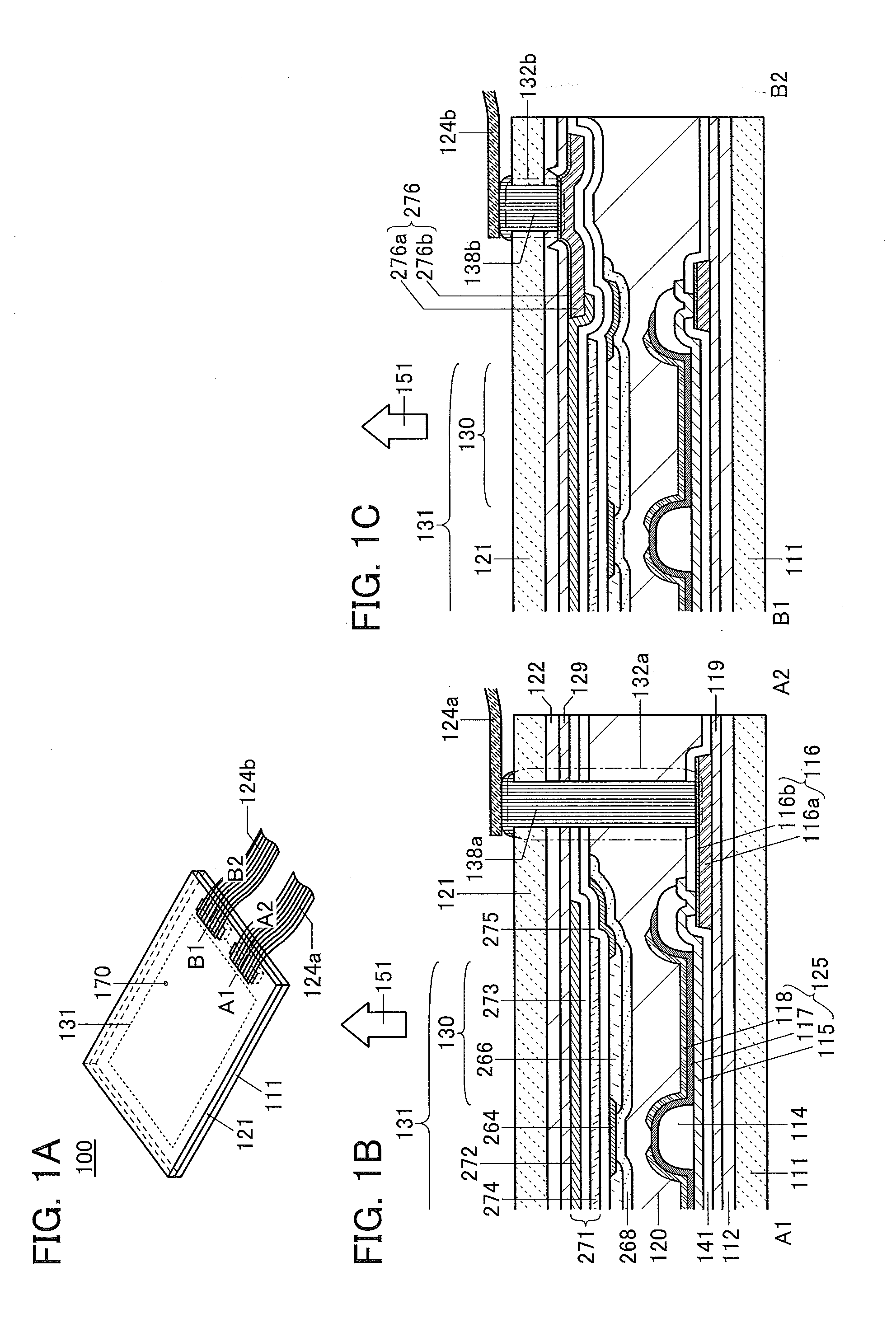

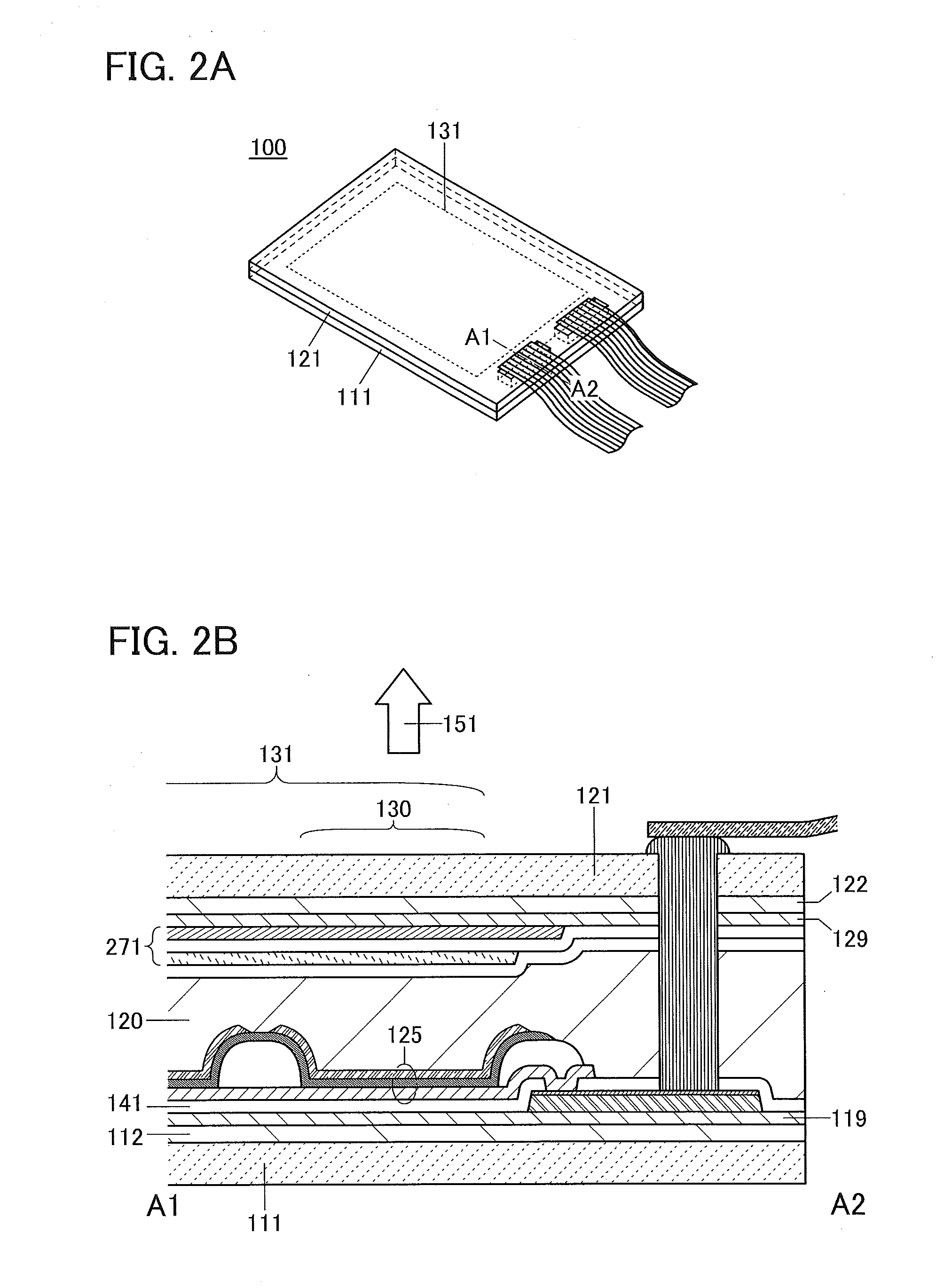

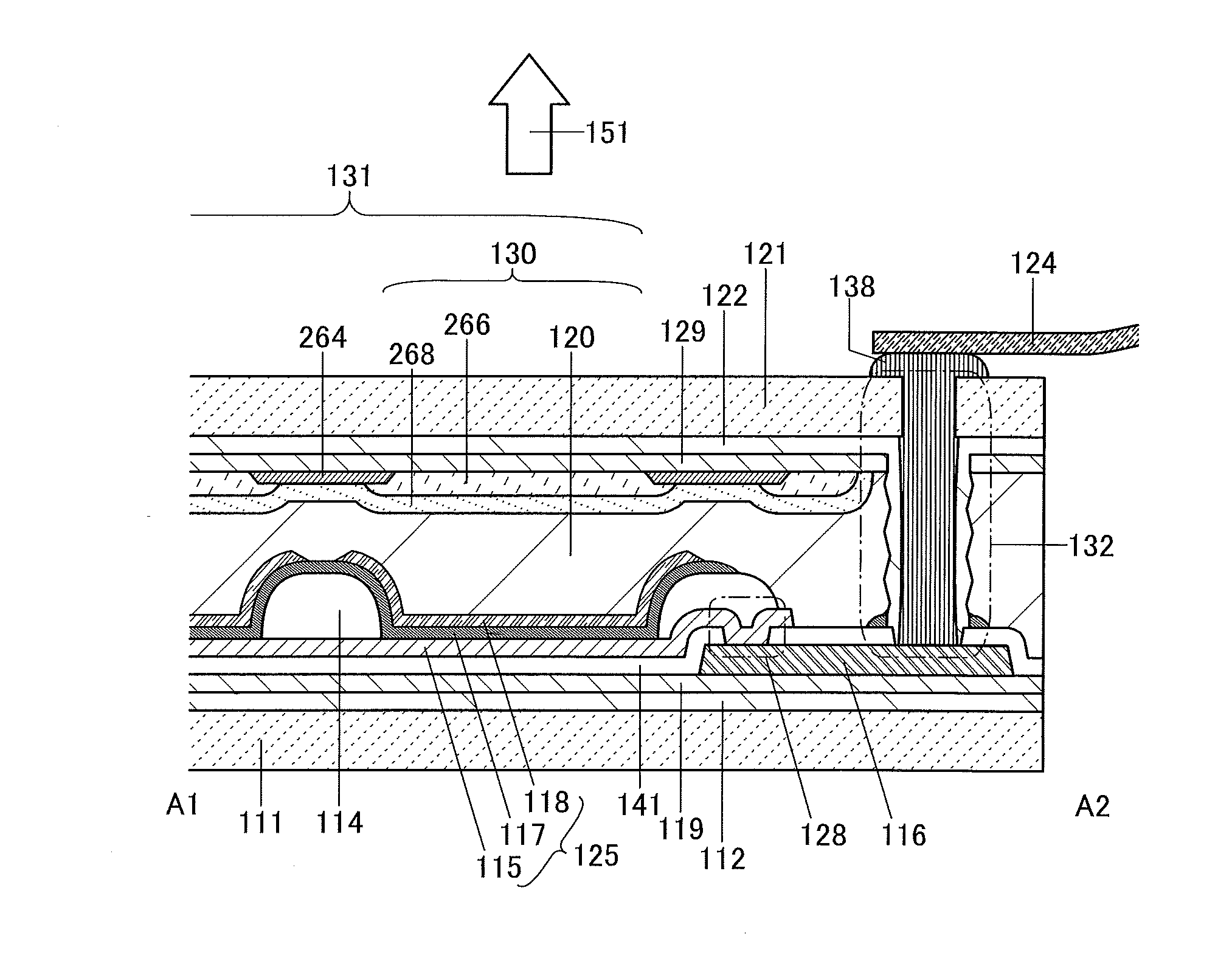

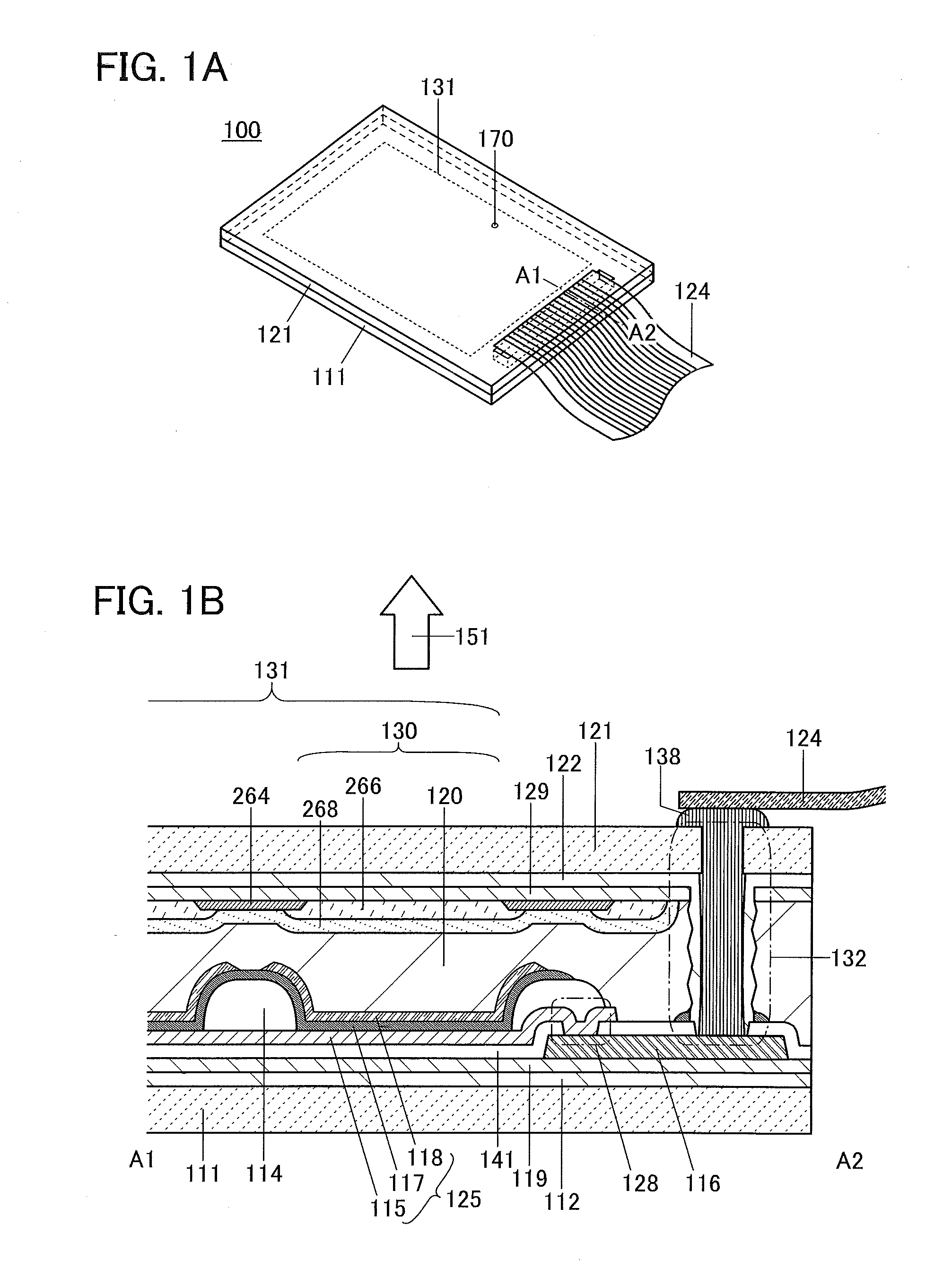

Display Device and Electronic Device

ActiveUS20150309637A1Not easy to damageImprove reliabilitySolid-state devicesNon-linear opticsDisplay deviceTransistor

A display device with high design flexibility is provided. The display device includes a display element, a touch sensor, and a transistor between two flexible substrates. An external electrode that supplies a signal to the display element and an external electrode that supplies a signal to the touch sensor are connected from the same surface of one of the substrates.

Owner:SEMICON ENERGY LAB CO LTD

Process for producing fiber-reinforced silicon carbide composites

InactiveUS6576076B1Easy to produceImprove toughnessLayered productsCeramic shaping apparatusPolyresinAtmosphere

A fiber-reinforced silicon carbide composite is produced by preparing a fiber prepreg containing a powdered silicon and a resin and molding the prepreg to yield a green body having a desired shape, or laminating a fiber prepreg containing a resin and a woven fabric prepreg containing a powdered silicon and a resin in alternate order and molding the laminate to yield a green body having a desired shape; carbonizing the green body at 900° to 1350° C. in an inert atmosphere; subjecting the carbonized body to reaction sintering at a temperature of 1300° C. or more in vacuo or in an inert atmosphere to form open pores; and infiltrating molten silicon into the sintered body having open pores at a temperature of about 1300° to 1800° C. in vacuo or an inert atmosphere.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Method for Manufacturing Display Device and Method for Manufacturing Electronic Device

ActiveUS20150263314A1High reliabilityHigh visibilityFinal product manufactureSolid-state devicesEngineeringDisplay device

A method for manufacturing a display device is provided. The method includes: forming, between a first substrate and a second substrate, a light-emitting element including an electroluminescence layer and a wiring over which a peeling layer formed by using the material of the electroluminescence layer is provided; and peeling whole of the second substrate from the first substrate so that the peeling layer over the wiring is simultaneously exposed.

Owner:SEMICON ENERGY LAB CO LTD

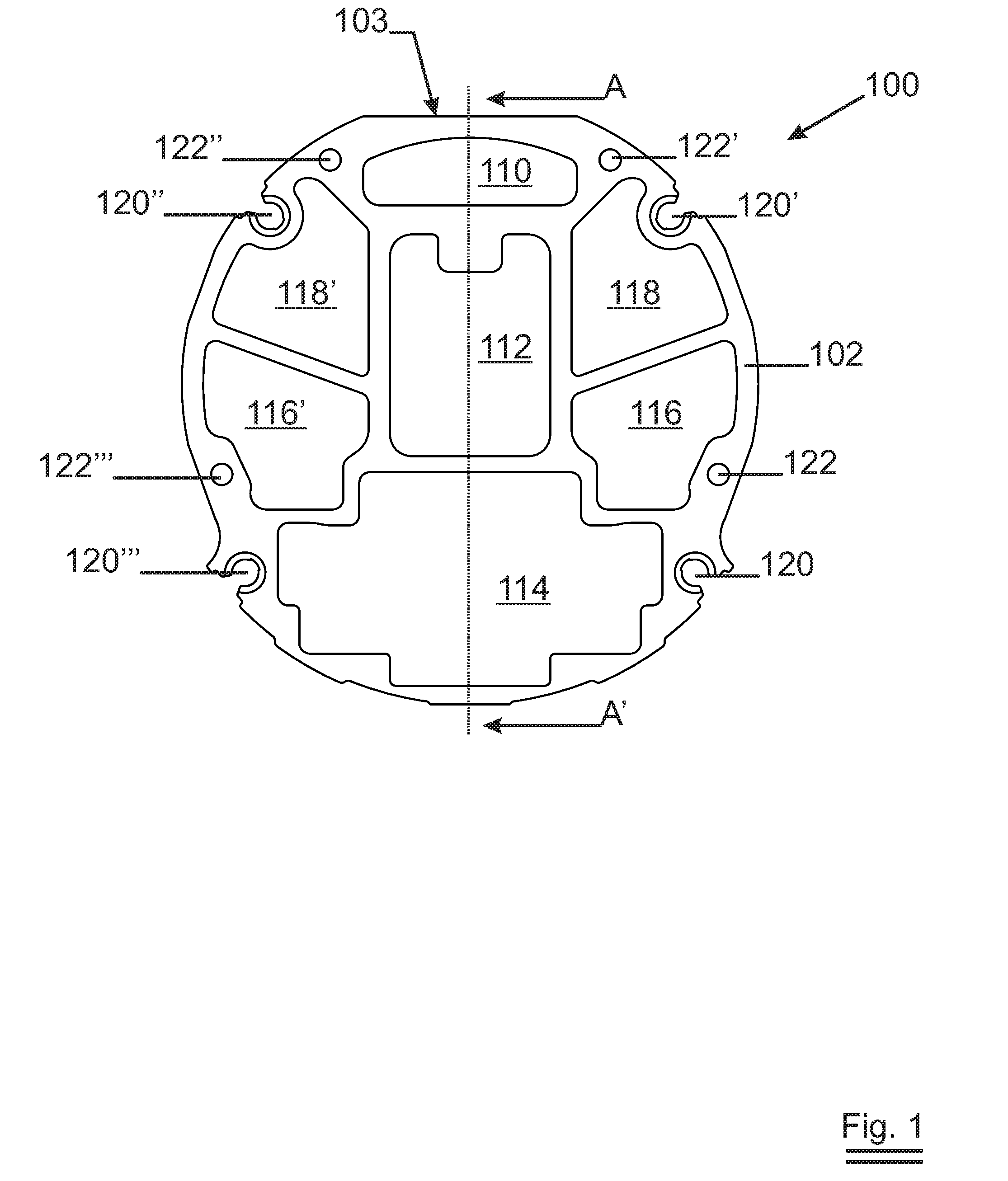

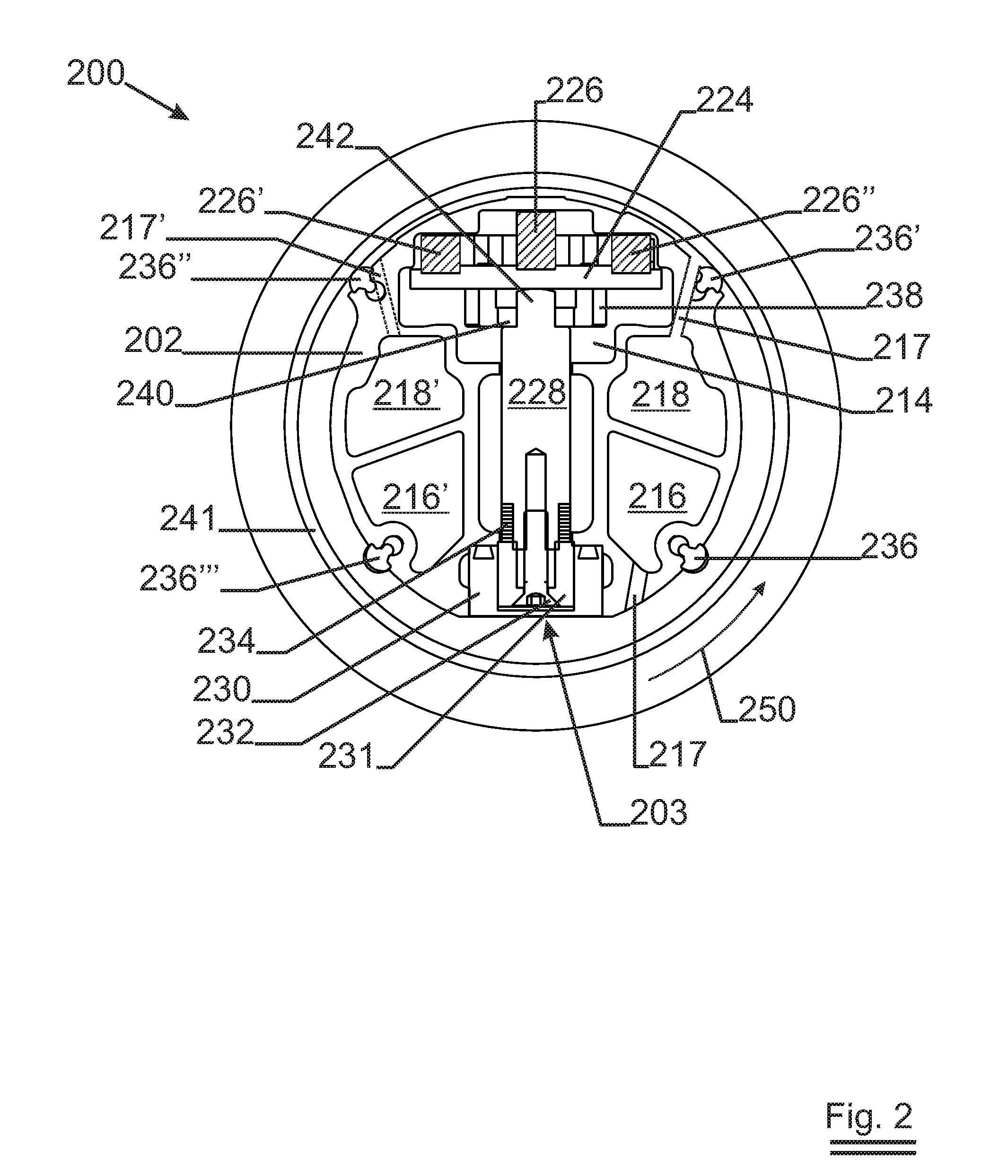

Rotatable sputtering magnetron with high stiffness

ActiveUS20110062022A1Less coolingImprove cooling efficiencyCellsElectric discharge tubesSputteringTarget surface

A sputtering magnetron (300) insertable in a rotatable target is described. The magnetron is designed around a single piece, multiwalled tube (102, 202) with compartments (316, 316′, 318, 318′) extending over the length of the tube. The multiwalled tube gives a much stiffer magnetron carrier structure compared to prior art magnetrons. As a result, the magnetic field generator can be mounted inside a compartment and the distance between magnets and target surface is easily adjustable as the tube is much stiffer than the generator. Additionally, the coolant channels can be incorporated inside the tube and close to the outer wall of the tube so that coolant can be supplied in the vicinity of the magnetic field generator. The increased stiffness of the magnetron allows the target tube to be carried by the magnetron—not the other way around—at least during part of the useful life of the target. As a result thin target carrier tubes can be used as they don't have to carry the magnetron anymore resulting in a longer use of the target.

Owner:SOLERAS ADVANCED COATINGS NV

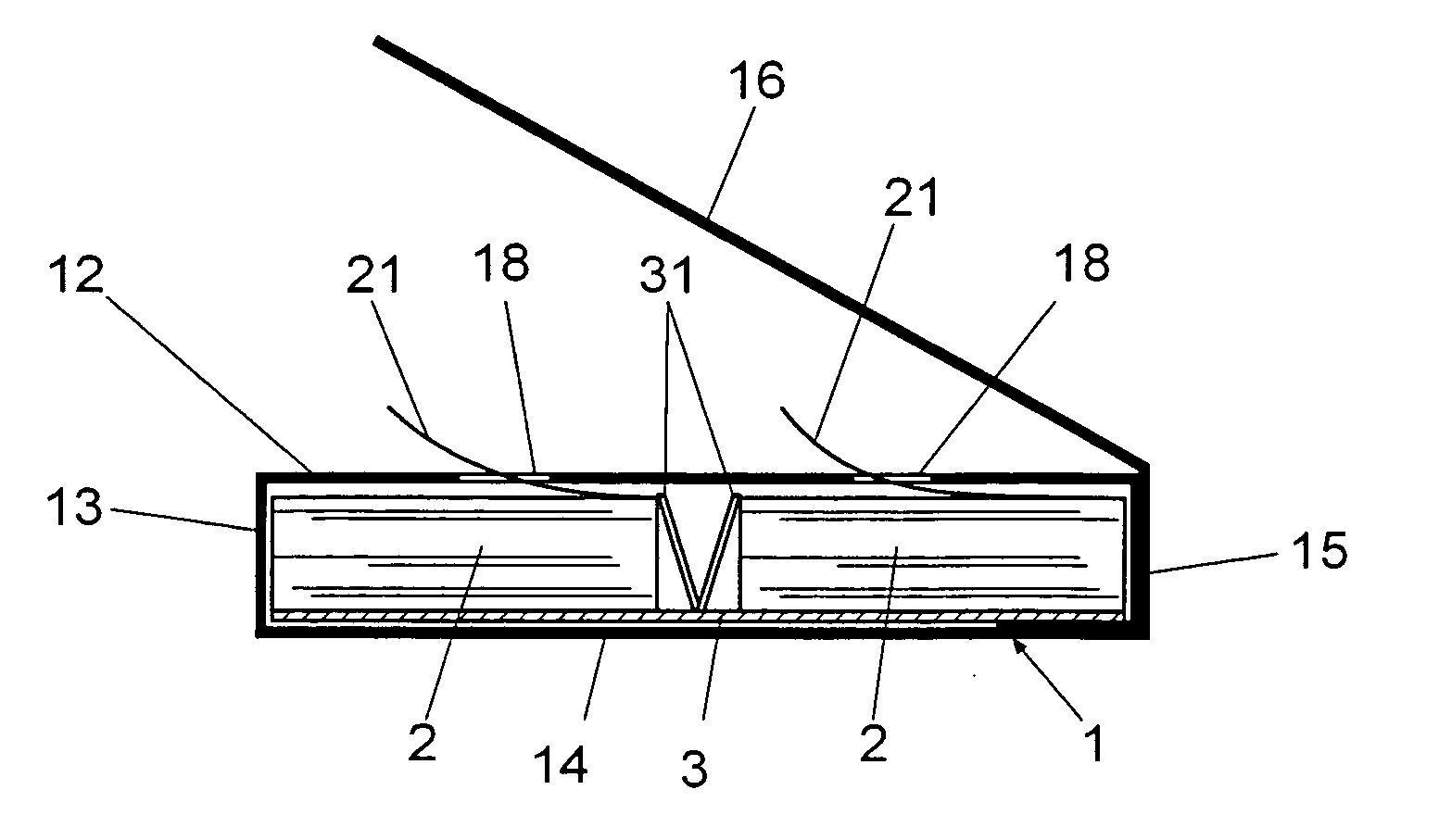

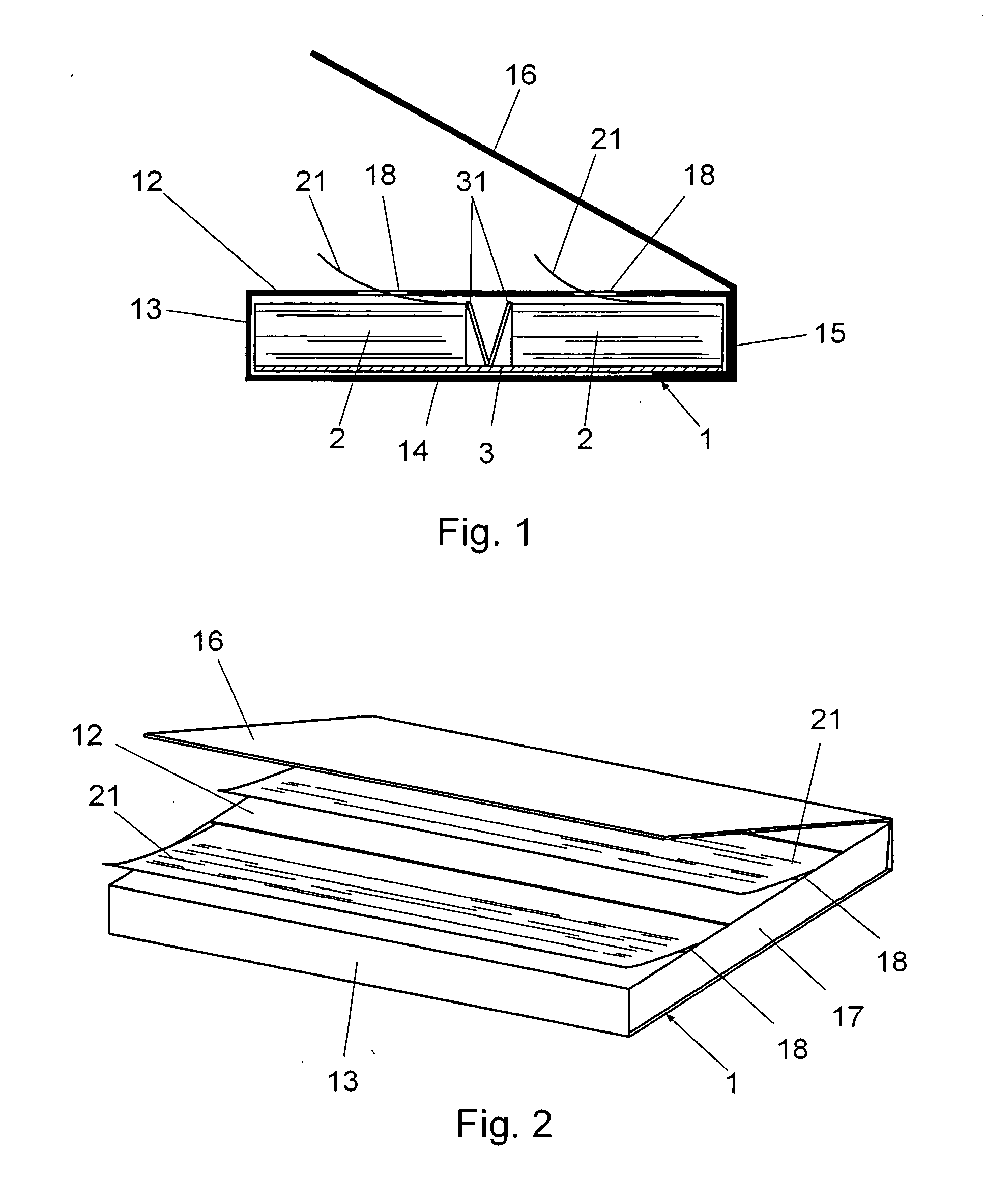

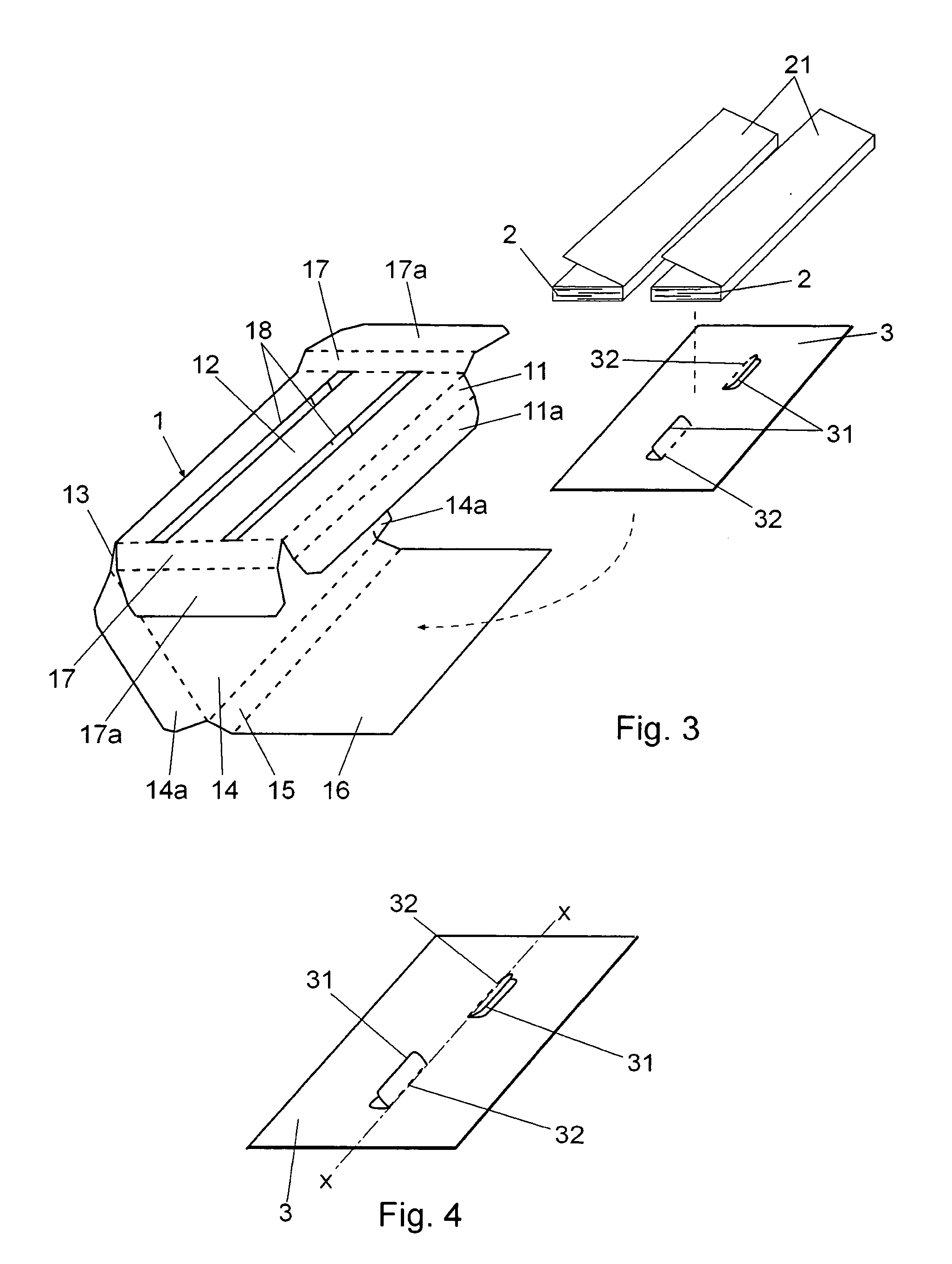

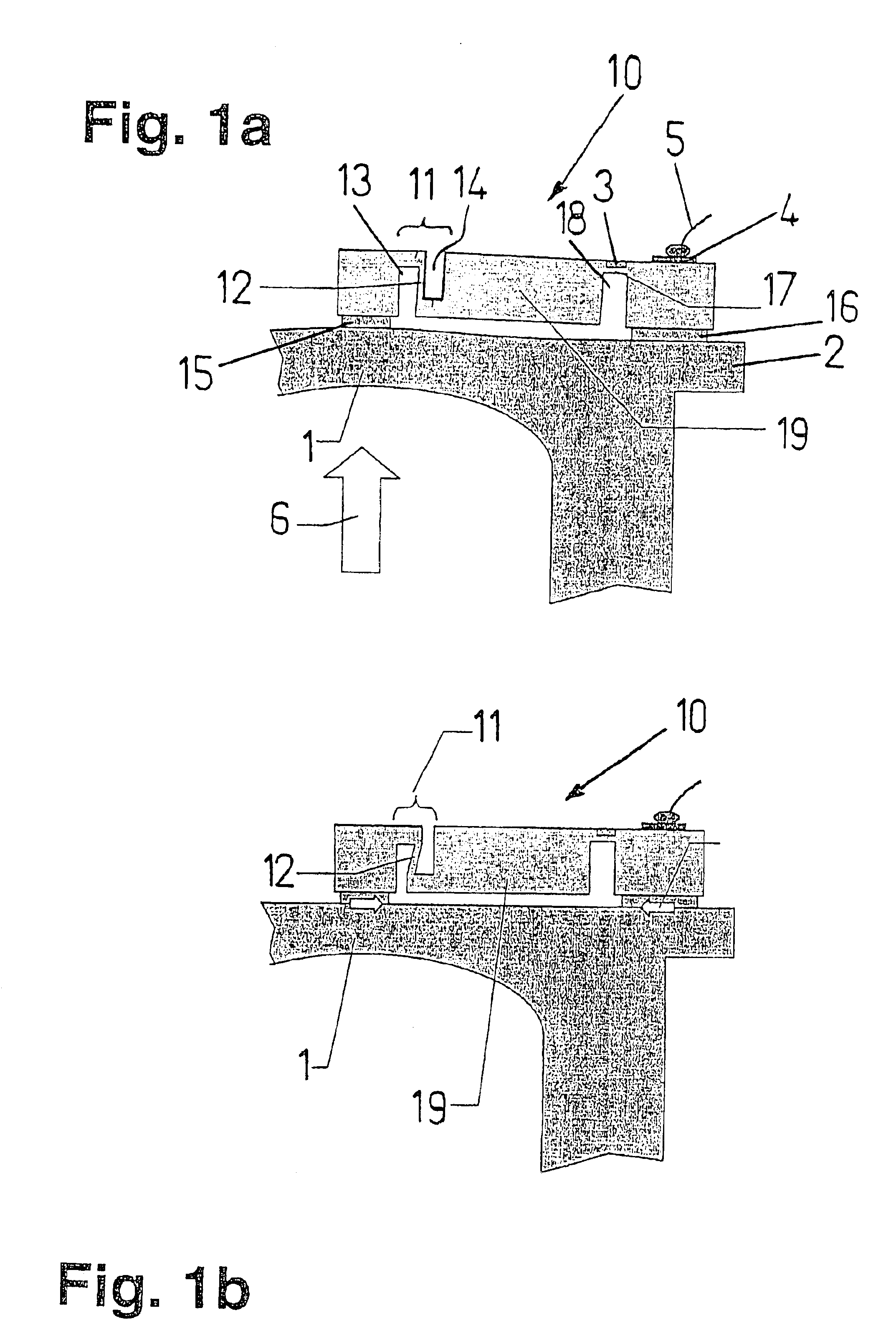

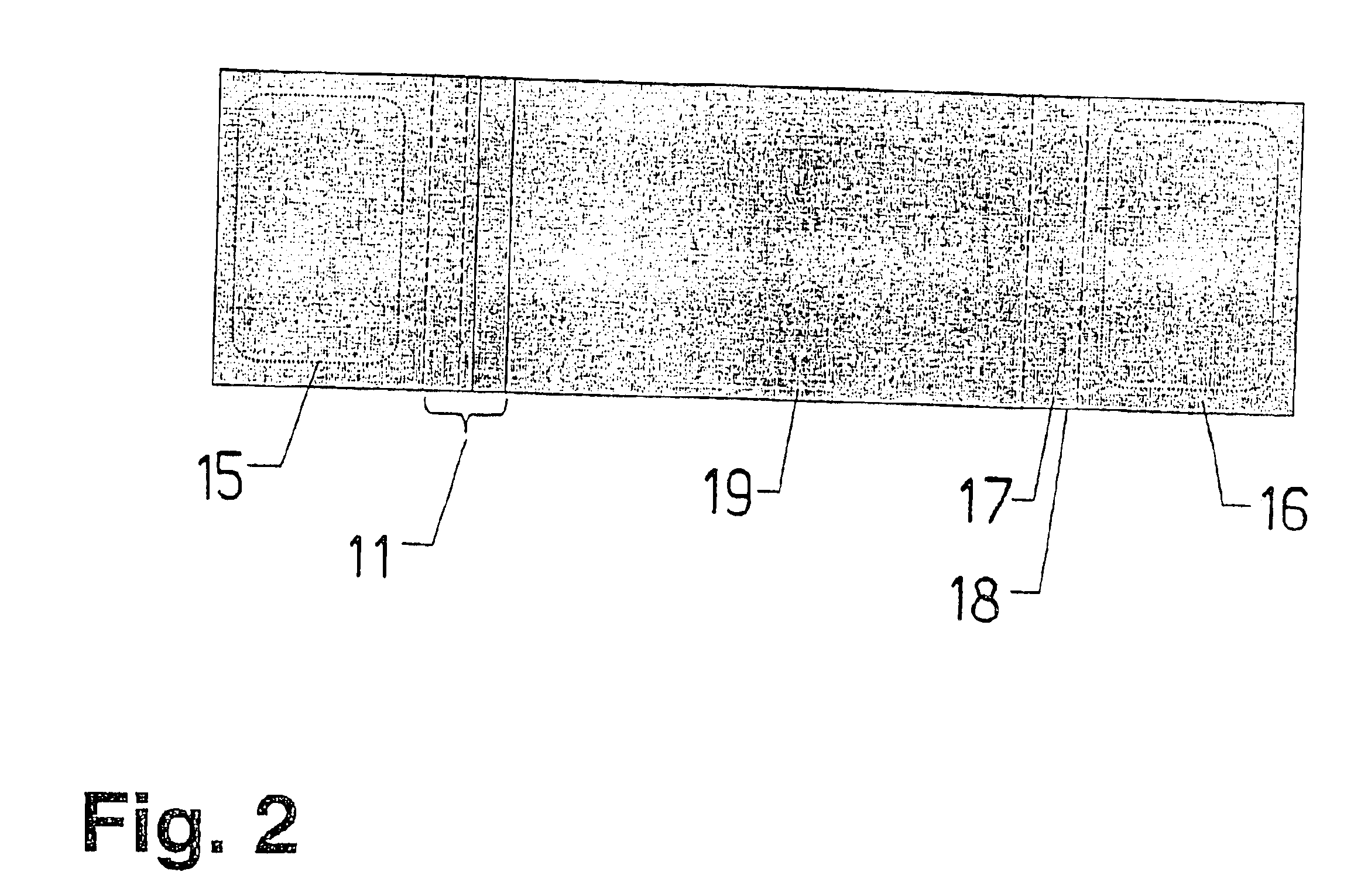

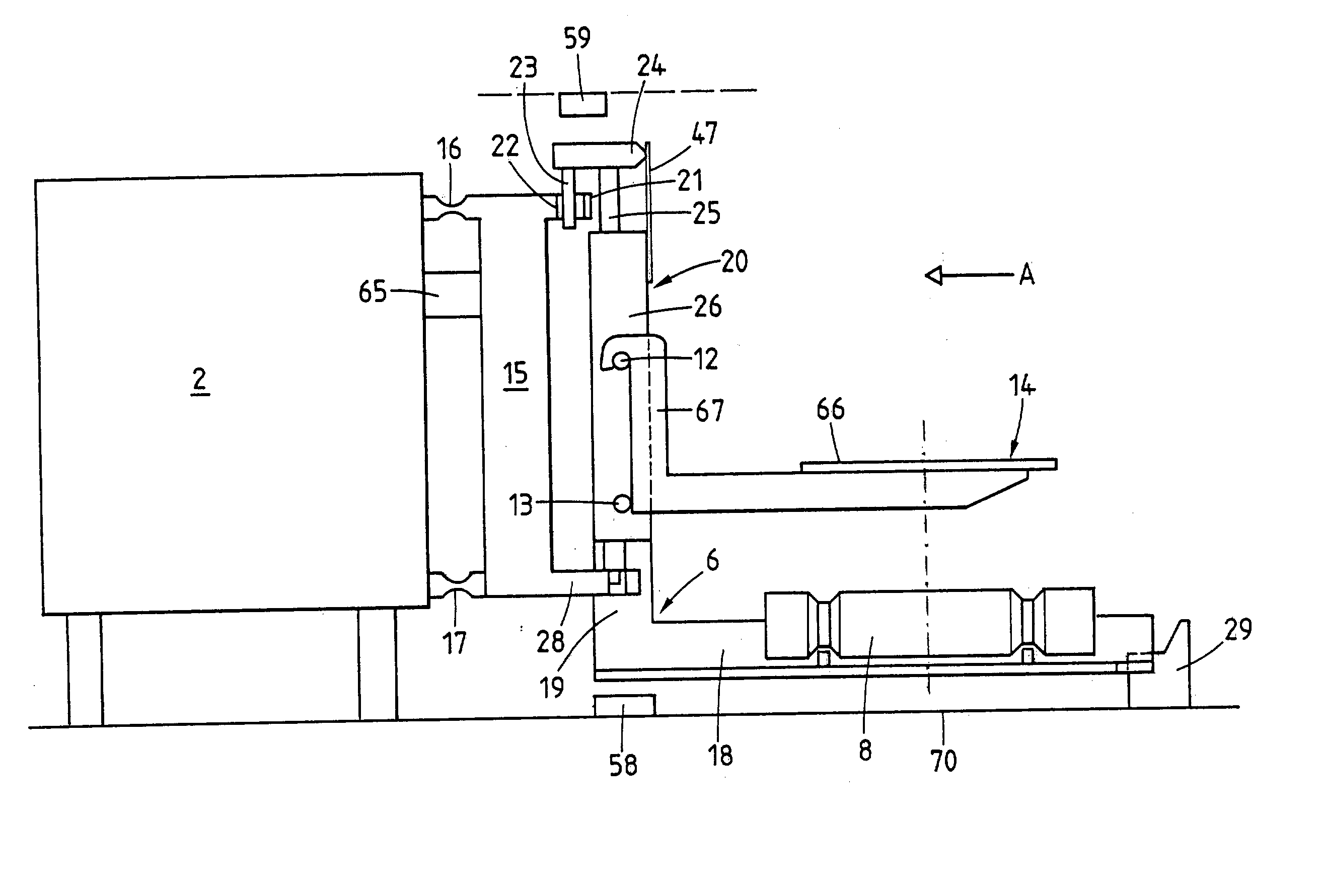

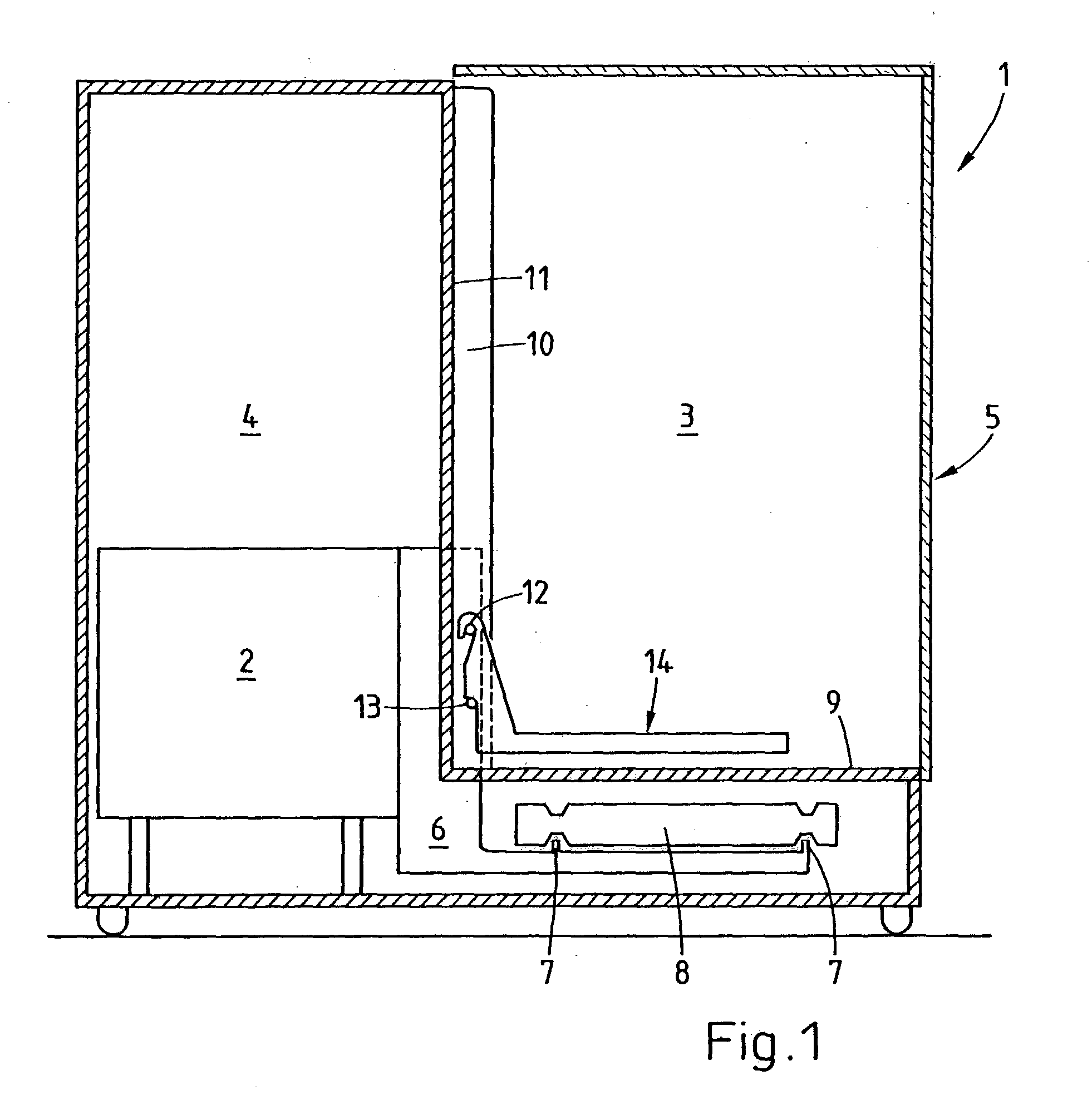

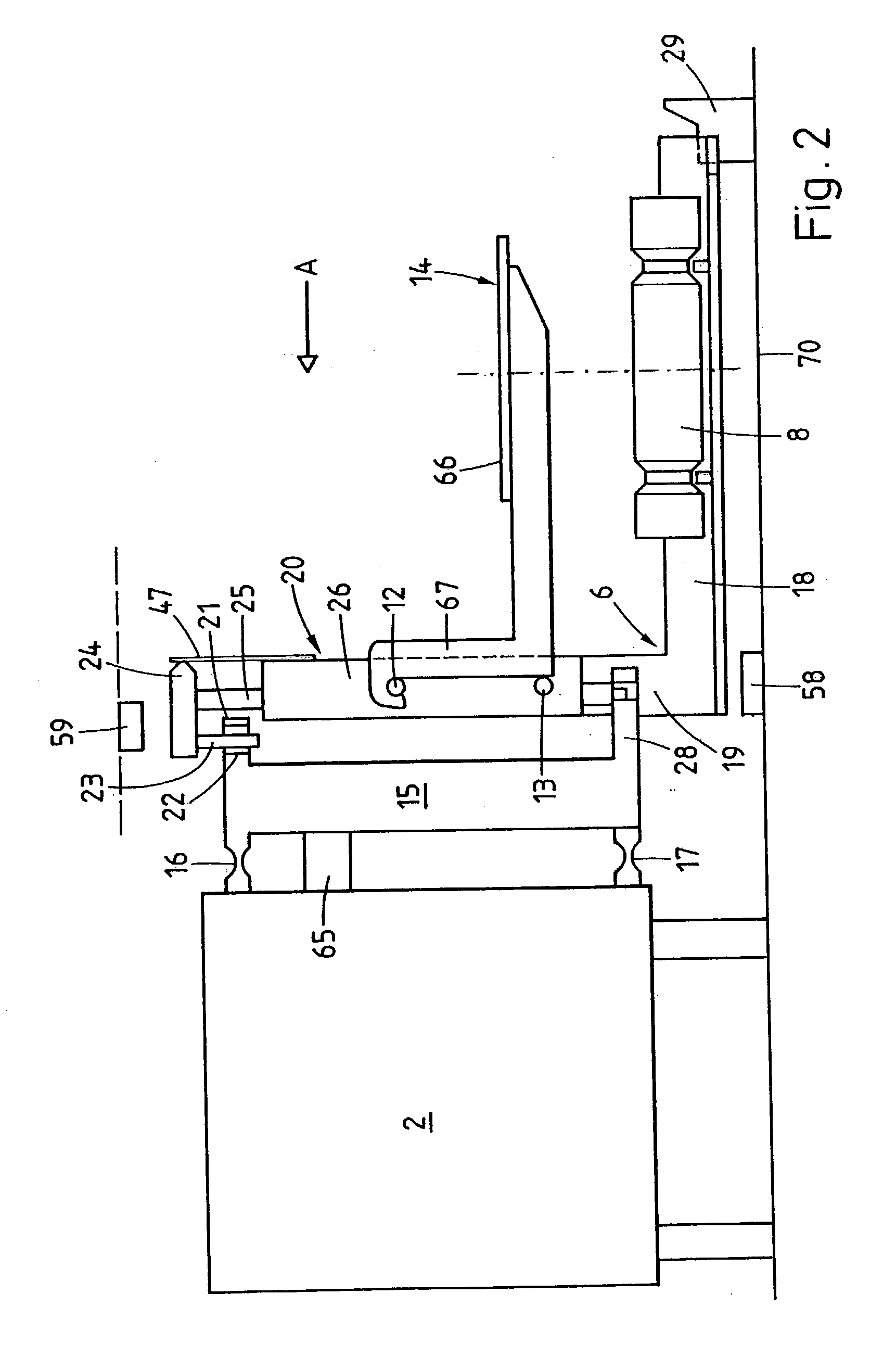

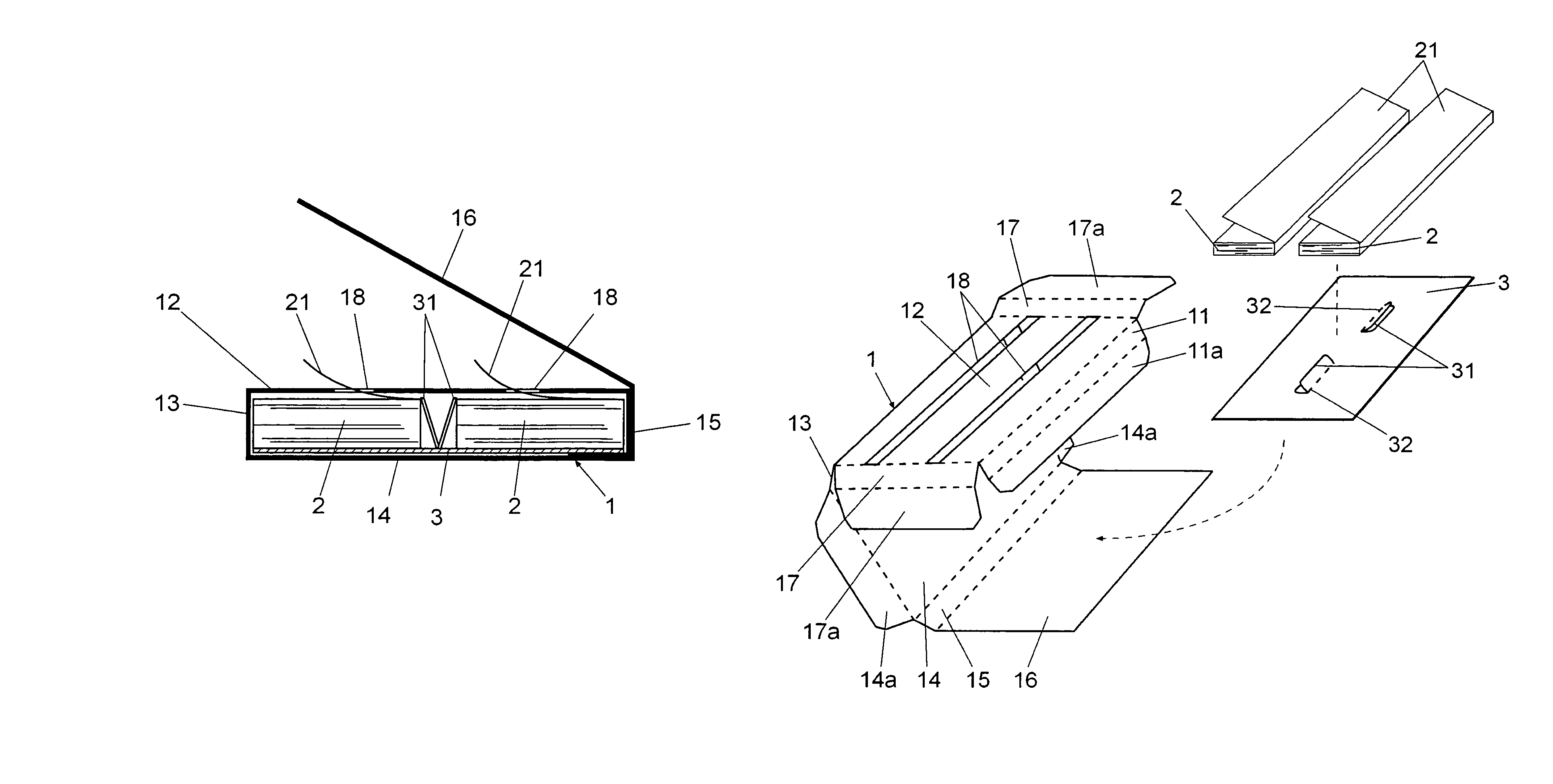

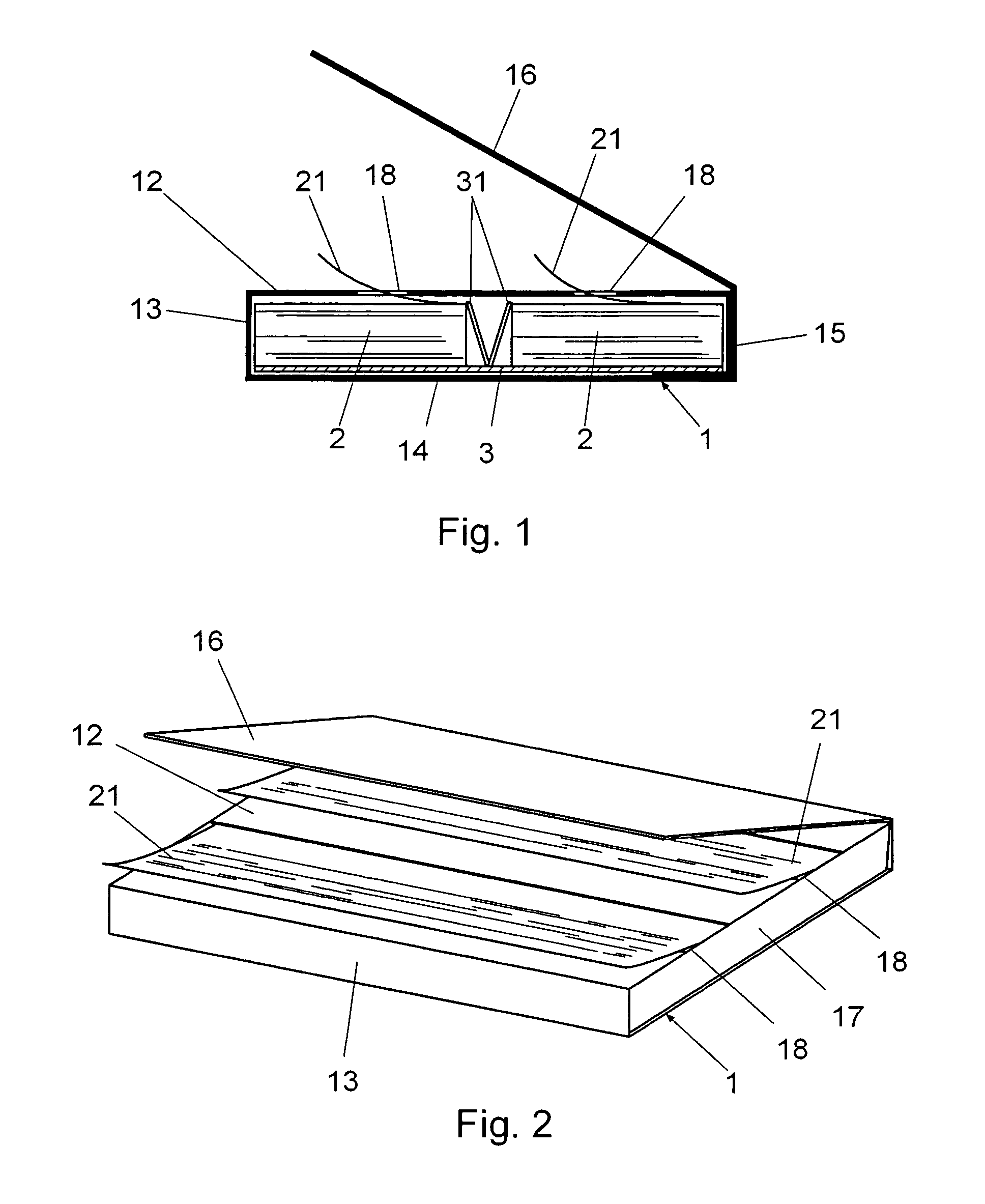

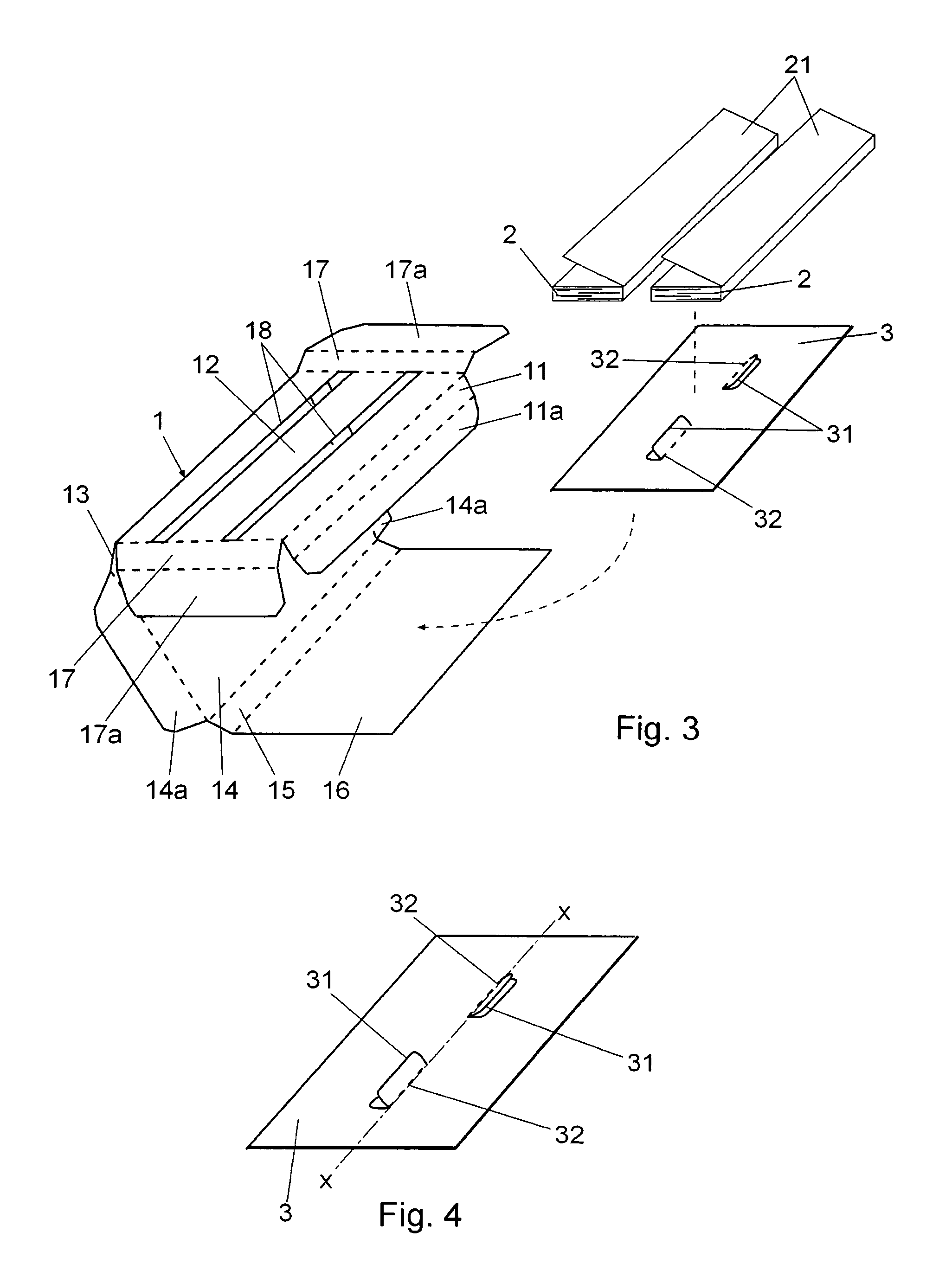

Package for cigarette rolling paper

InactiveUS20070221528A1Improve gripImproved additional holding effectContainers for flexible articlesCigar manufactureRolling paperEngineering

This package is made up of a sheet (1) that once having been die cut, folded and assembled, makes a prismatic rectangular shaped package that has longitudinal slots (18) for the successive extraction of the sheets of paper to roll cigarettes (21) that are stored in two or more wads of paper (2) housed on the inside of the package and supported on a reinforcing card (3) placed on the inner surface of the lower wall (14) of the package. This reinforcing card (3) has, at least two tabs (31) to retain the wads of paper (2), placed between the wads of paper (2), orientated towards the upper area, respectively inclined towards the front and rear walls of the package, and hinged on both fold lines (32) coinciding with a longitudinal X-X axis, parallel to the wads of paper (2) and the slots (18) for the extraction of the sheets of paper (21).

Owner:MIQUEL Y COSTAS & MIQUEL

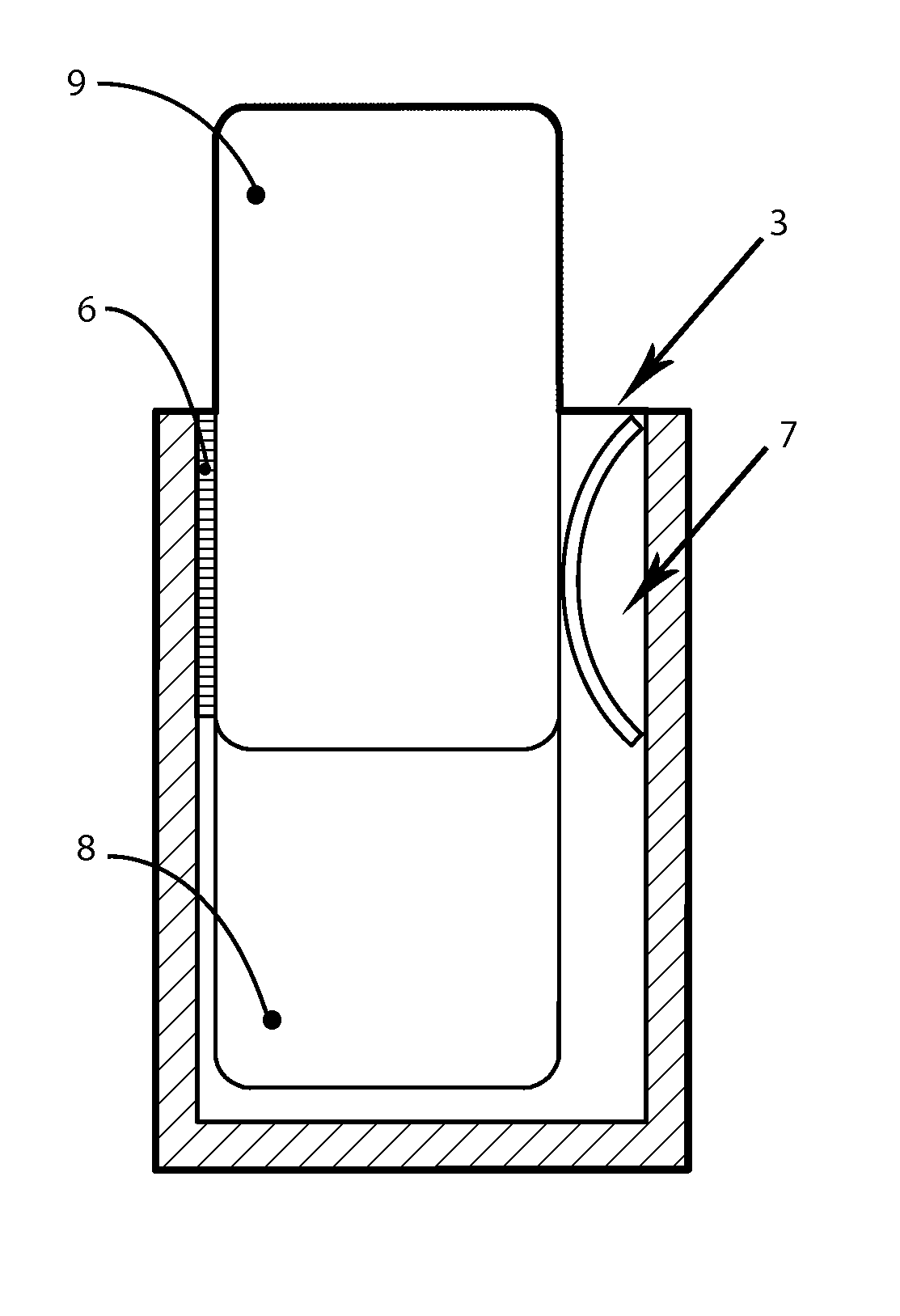

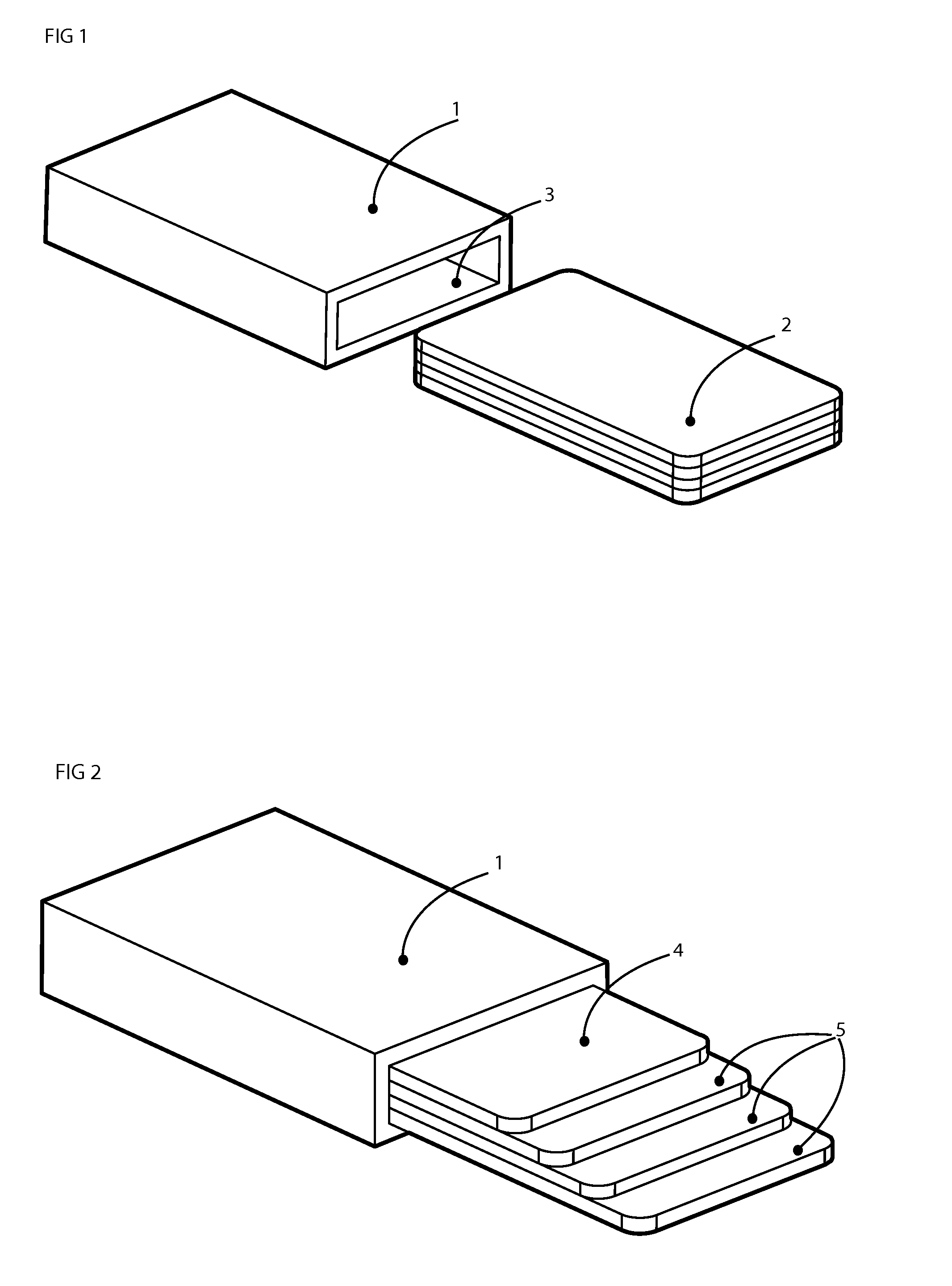

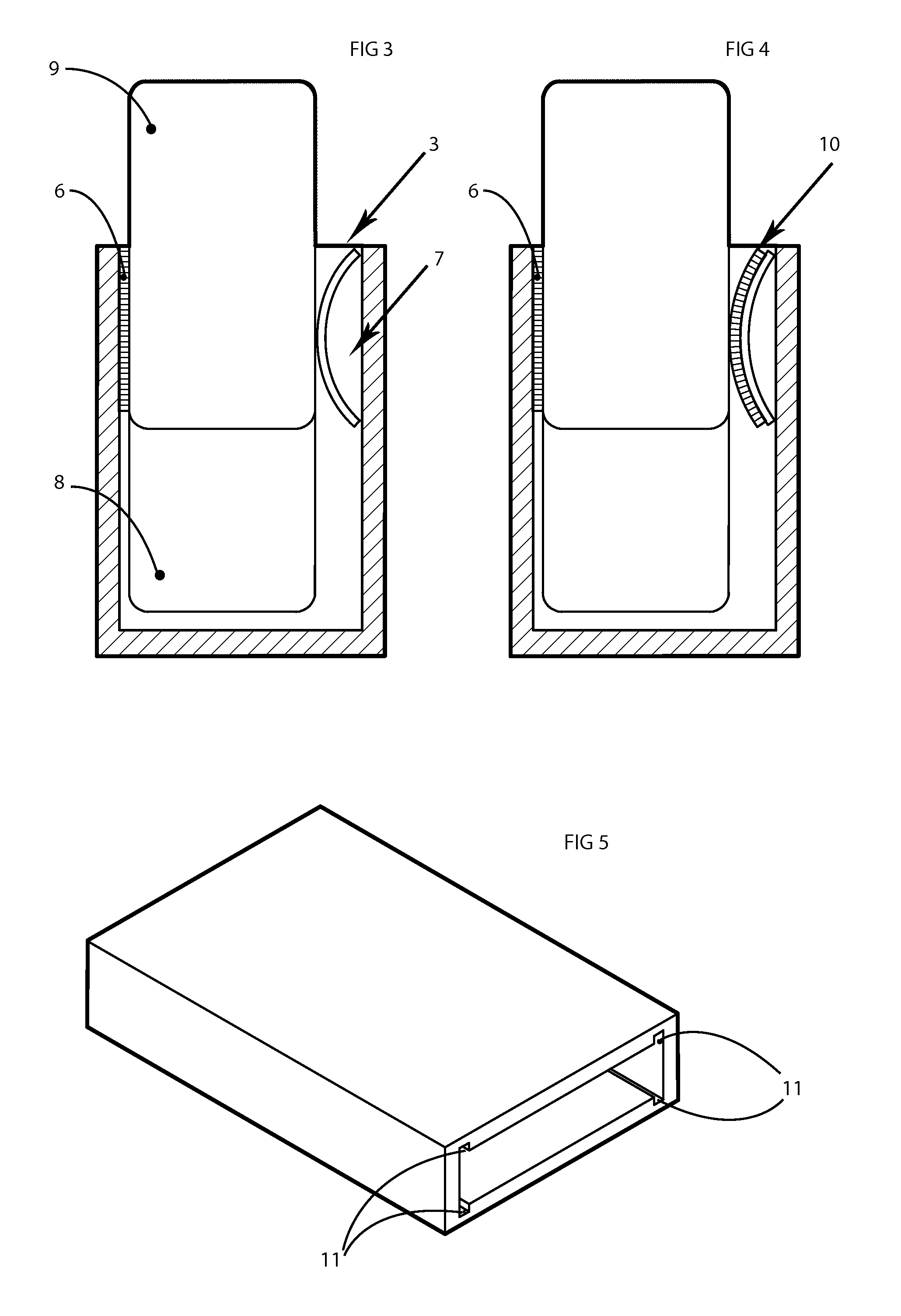

Holder for credit cards

A holder for cards, including a housing which tightly fits around a stack of at least three cards and has at least one card opening to locate and remove cards, while opposite the card opening in the housing there is a card remove feature through which the cards through the card opening can be slid out the housing, characterized in that at the inner side of the housing near the card opening at least one side a friction element is provided which exerts a friction force to the bearing side of each individual card which is at least partly contained in the housing, with the result that the card has such a stable position relative to the housing, that the card can not slide due to gravity, but indeed due to a with the finger tips exerted force.

Owner:R J VAN GEER BEHEER

Wet-skin treatment compositions

InactiveUS7192598B2Better behavedFast absorptionCosmetic preparationsToilet preparationsSkin treatmentsDermatology

Owner:UNILEVER HOME & PERSONAL CARE USA DIV OF CONOPCO IN C

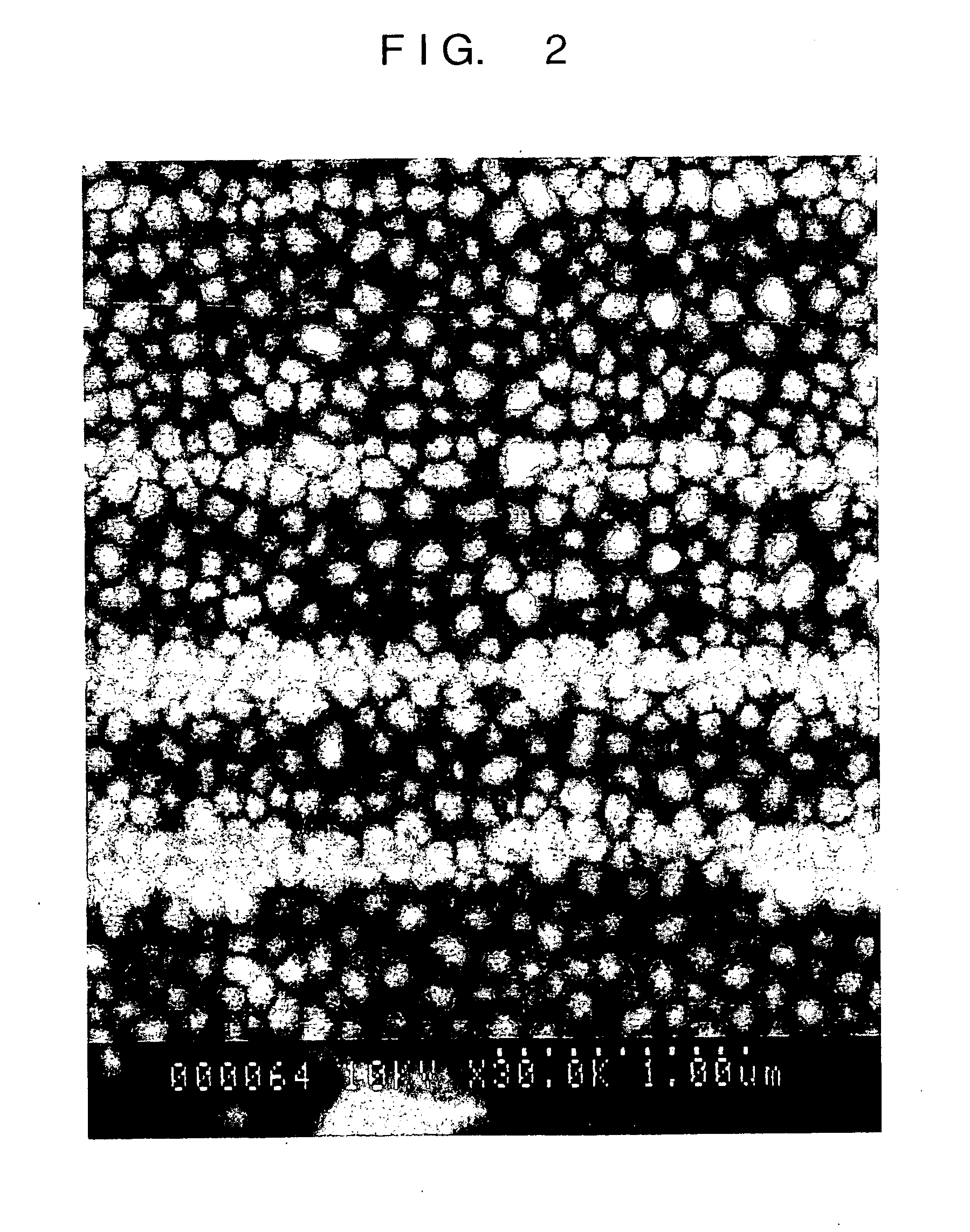

Resin product, production method for the same, and deposition method for a metallic coating

ActiveUS20070098967A1Improve productivityLow costVacuum evaporation coatingSputtering coatingProduction rateMetal coating

The present invention provides a metallic coating having a sheen and discontinuous structure and a resin product having the metallic coating by using a physical vapor deposition method at high productivity and low cost.

Owner:TOYODA GOSEI CO LTD

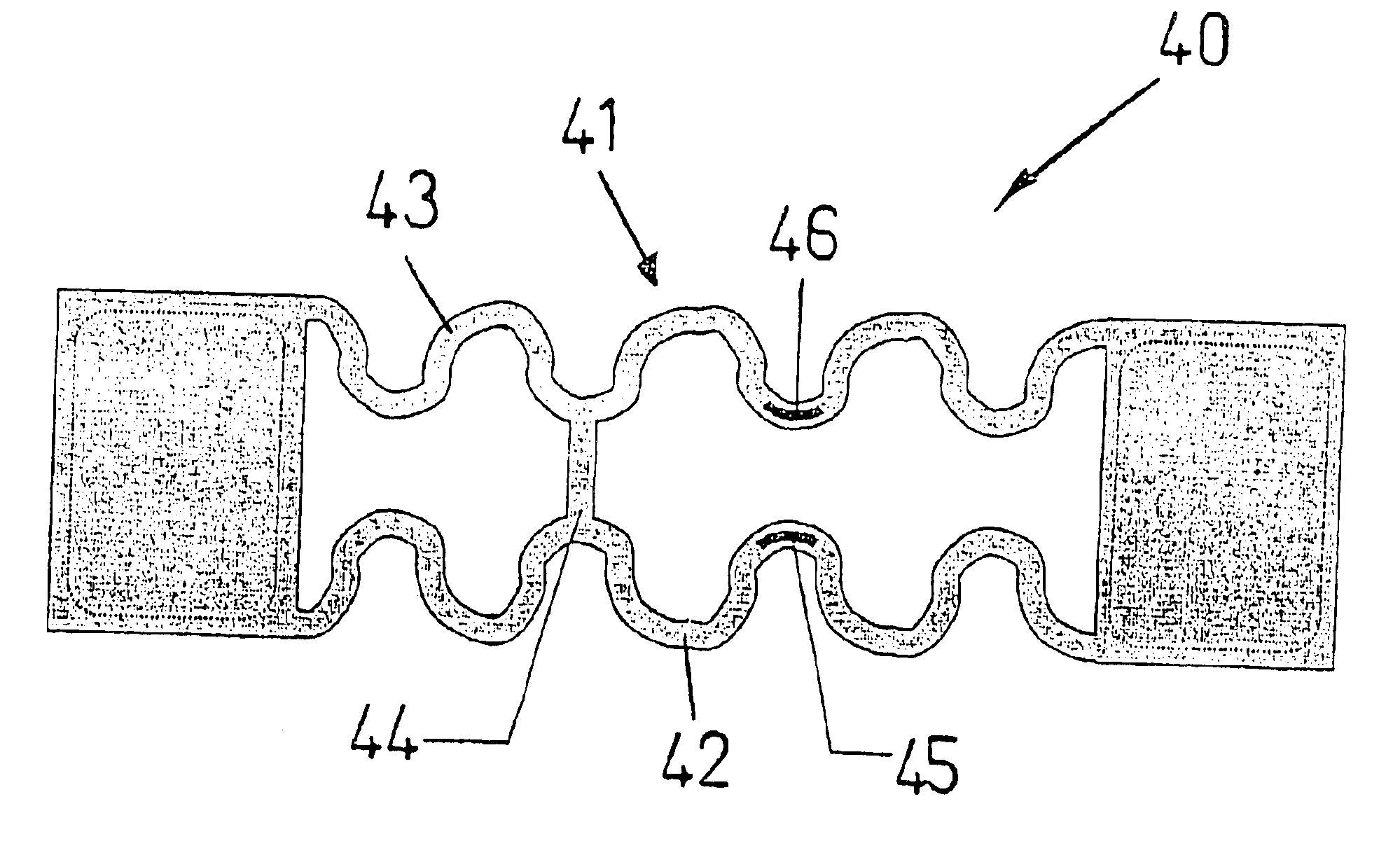

Micromechanical component and pressure sensor having a component of this type

InactiveUS6840111B2Decouple lateral and vertical stresses in the componentEasy to produceFluid pressure measurement using ohmic-resistance variationFluid pressure measurement using elastically-deformable gaugesEngineeringPressure sensor

A micromechanical component in which lateral deformations, i.e., deformations of the component parallel to its two main surfaces, are concentrated in a defined area of the component structure, making it possible to decouple lateral and vertical stresses in the component. The component structure includes at least one bellows-like structure in which lateral deformations of the component are concentrated. A pressure sensor having a micromechanical component of this type may be used, for example, for measured-value detection.

Owner:ROBERT BOSCH GMBH

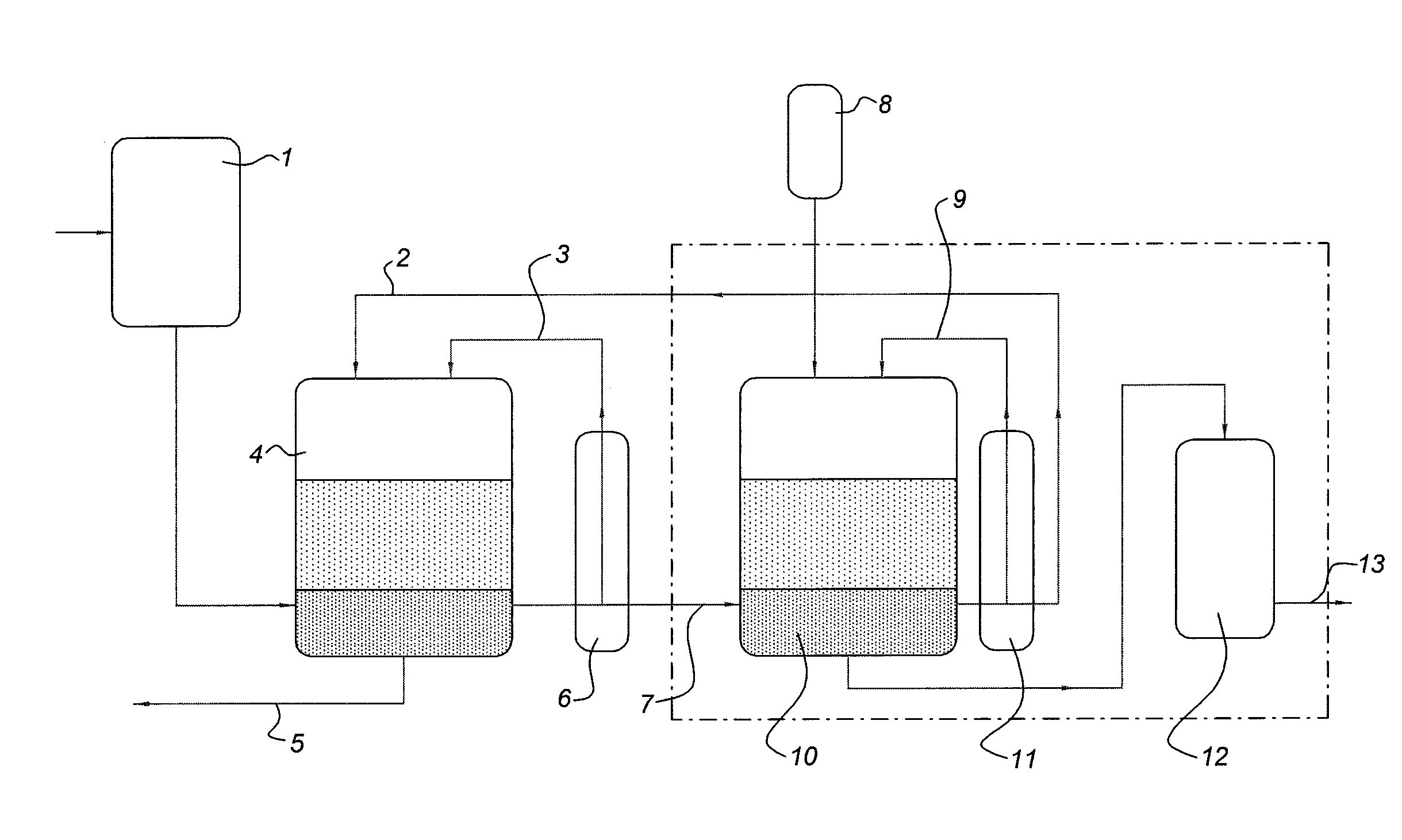

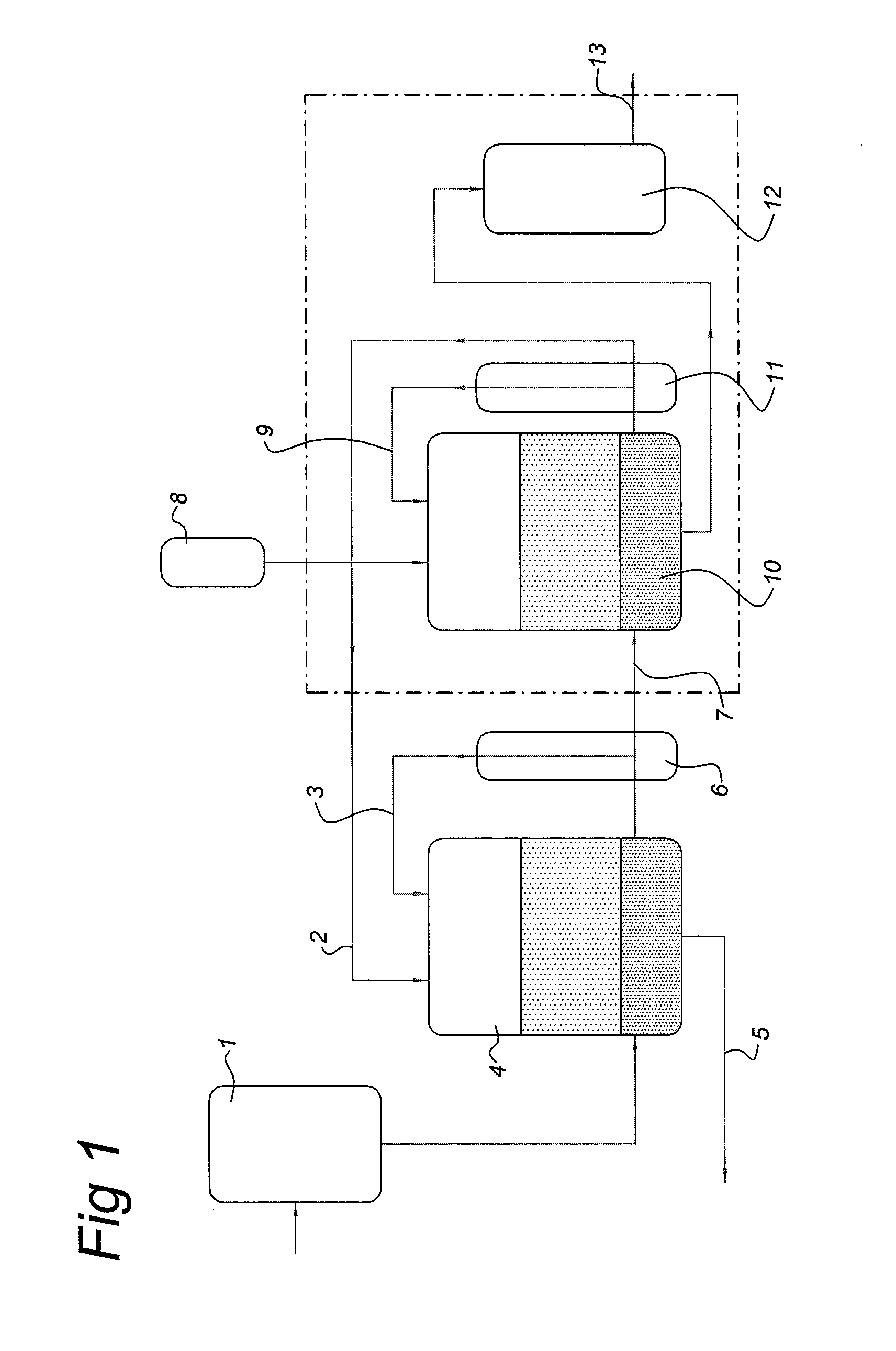

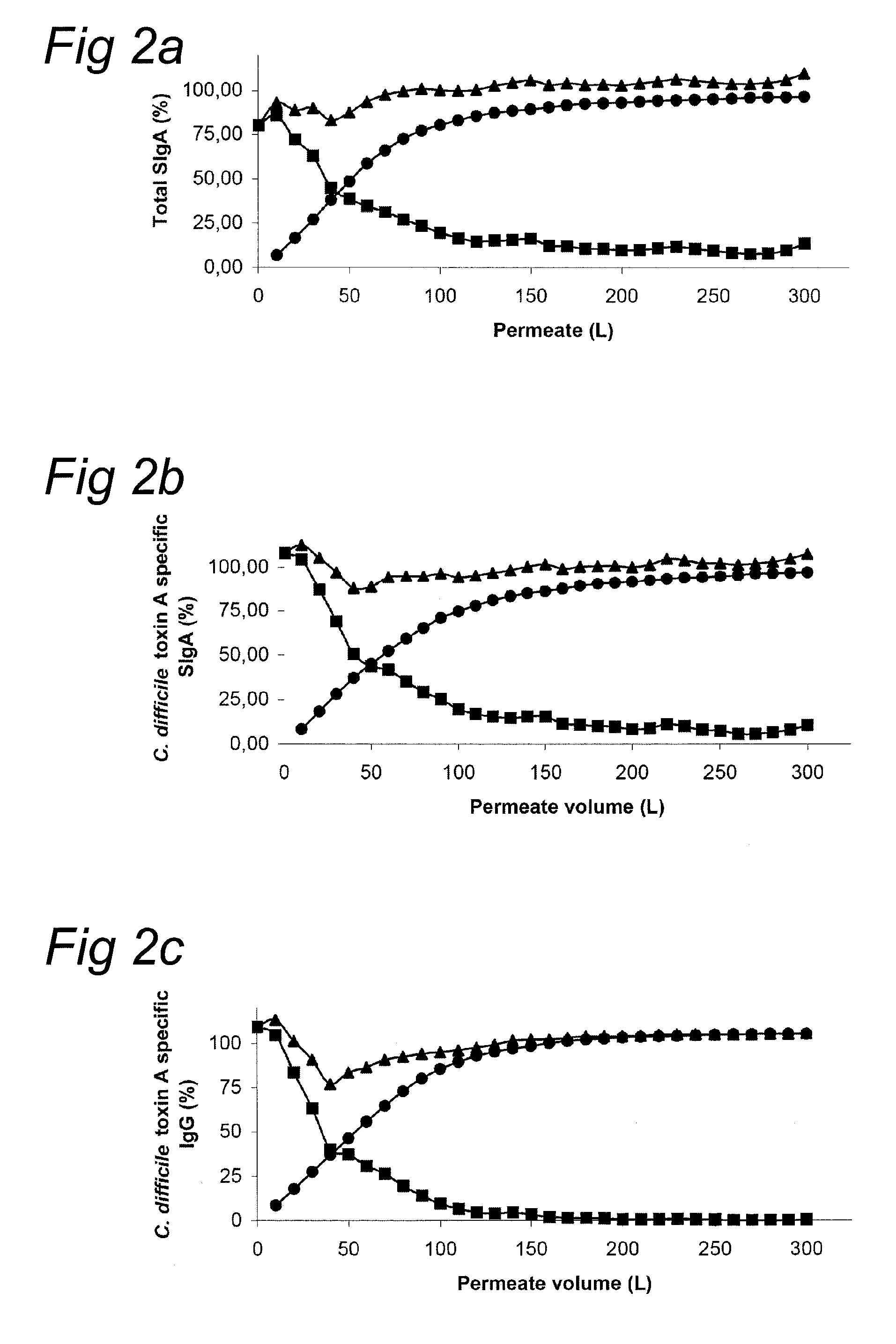

Process for producing milk fractions rich in secretory immunoglobulins

InactiveUS20110130545A1Yield easilyHigh yieldMilk preparationMetabolism disorderNasal cavityFiltration

The present invention concerns a process for producing compositions that are rich in secretory IgA (S-IgA) by fractionating milk containing S-IgA. Such compositions may be used in particular for treating and / or preventing infections and / or inflammation of the mucosal surfaces, e.g. the gastro-intestinal tract, urogenital tract, respiratory tract, nasal cavity or oral cavity, treating and / or preventing obesity and related diseases, or treating and / or preventing food allergies in subjects in need of such treatment. Briefly stated, the current invention provides a process for producing milk fractions rich in secretory Immunoglobulin A, using one or more microporous membrane filtration steps. A preferred protocol of the present process involves de-fatting, micro-filtration and ultrafiltration-concentration through a number of diafiltration cycles. The process of the invention, apart from the unexpectedly high yields achievable, offers advantages which are of particular interest in view of the scalability, application in existing diary factories and controllability of process parameters influencing the S-IgA quality and stability.

Owner:W HEALTH LP

Balance with a support element for coupling a weighing pan to a weighing cell

InactiveUS20030188897A1Yield easilyPrevent residual torquesWeighing apparatus using counterbalanceWeighing apparatus testing/calibrationCouplingCantilever

A balance includes a weighing cell with a vertically movable load receiver, a weighing pan to receive a weighing load, and a support element to couple the weighing pan to the vertically movable load receiver of the weighing cell. A cantilever arm with a seat for at least one calibration weight is solidly connected to the support element. The balance has a coupling arrangement that constrains the support element with low-friction mobility to the load receiver at three points forming a triangle in a plane that extends orthogonal to the symmetry plane of the weighing cell, wherein the triangle is symmetric to the symmetry plane of the weighing cell. Under the coupling arrangement, the support element is solidly supported on the load receiver in the direction in which the weighing load is acting.

Owner:METTLER TOLEDO GMBH

Process for producing fiber-reinforced silicon carbide composites

InactiveUS20030145934A1Easy to getEasy to produceCeramic shaping apparatusClaywaresCarbonizationUltimate tensile strength

A process produces a fiber-reinforced silicon carbide composite. The resulting composite has a high toughness where bundles of a reinforcing fiber are densely covered with glassy carbon derived from a resin to avoid deterioration of the strength, and it can easily be produced even in complicated shapes. Specifically, a fiber-reinforced silicon carbide composite is produced by preparing a fiber prepreg containing a powdered silicon and a resin and molding the prepreg to yield a green body having a desired shape, or laminating a fiber prepreg containing a resin and a woven fabric prepreg containing a powdered silicon and a resin in alternate order, and molding the laminate to yield a green body having a desired shape; carbonizing the green body at 900° C. to 1350° C. in an inert atmosphere; impregnating the carbonized body with a resin; firing the impregnated body again at 900° C. to 1350° C. in an inert atmosphere; performing the resin impregnation-carbonization procedure one to five times; subjecting the carbonized composite to reaction sintering at a temperature of 1300° C. or more in vacuo or in an inert atmosphere to form open pores, and finally infiltrating molten silicon into the sintered body having open pores at a temperature of about 1300° C. to 1800° C. in vacuo or in an inert atmosphere.

Owner:NAT INST OF ADVANCED IND SCI & TECH

Conductive coating composition

InactiveUS20110135939A1Simple compositionYield easilyConductive layers on insulating-supportsConductive materialColloidal silicaOrganic solvent

Disclosed is a conductive coating composition containing an organic solvent dispersion of an intrinsically conductive polymer such as a doped polyaniline or a doped polythiophene, and a binder. The conductive coating composition is characterized in that the binder contains a polymerizable monomer-dispersed silica sol, which is obtained by dispersing a colloidal silica into a polymerizable organic compound monomer. The composition provides a conductive thin film having high transparency and excellent strength.

Owner:NISSAN CHEM IND LTD

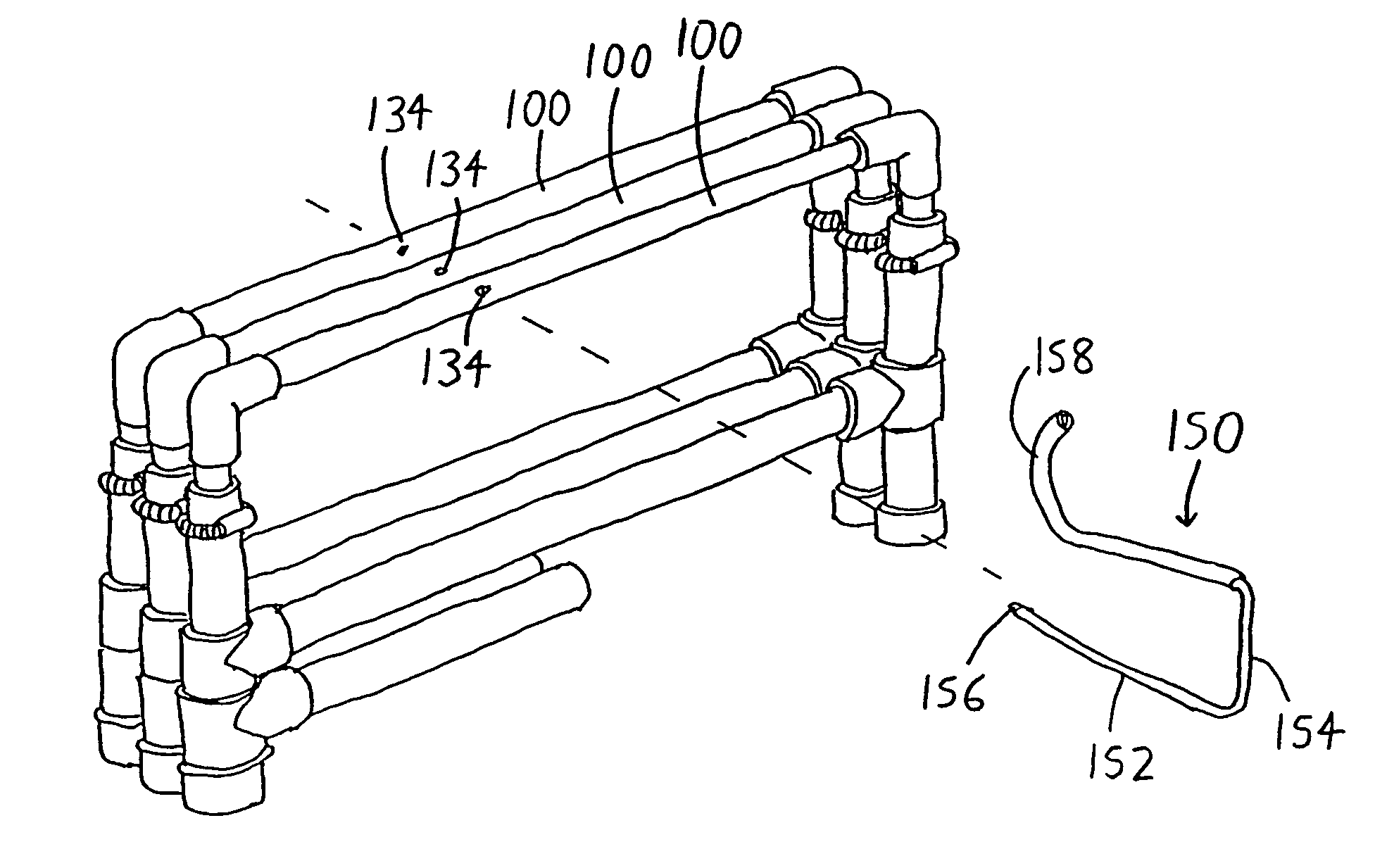

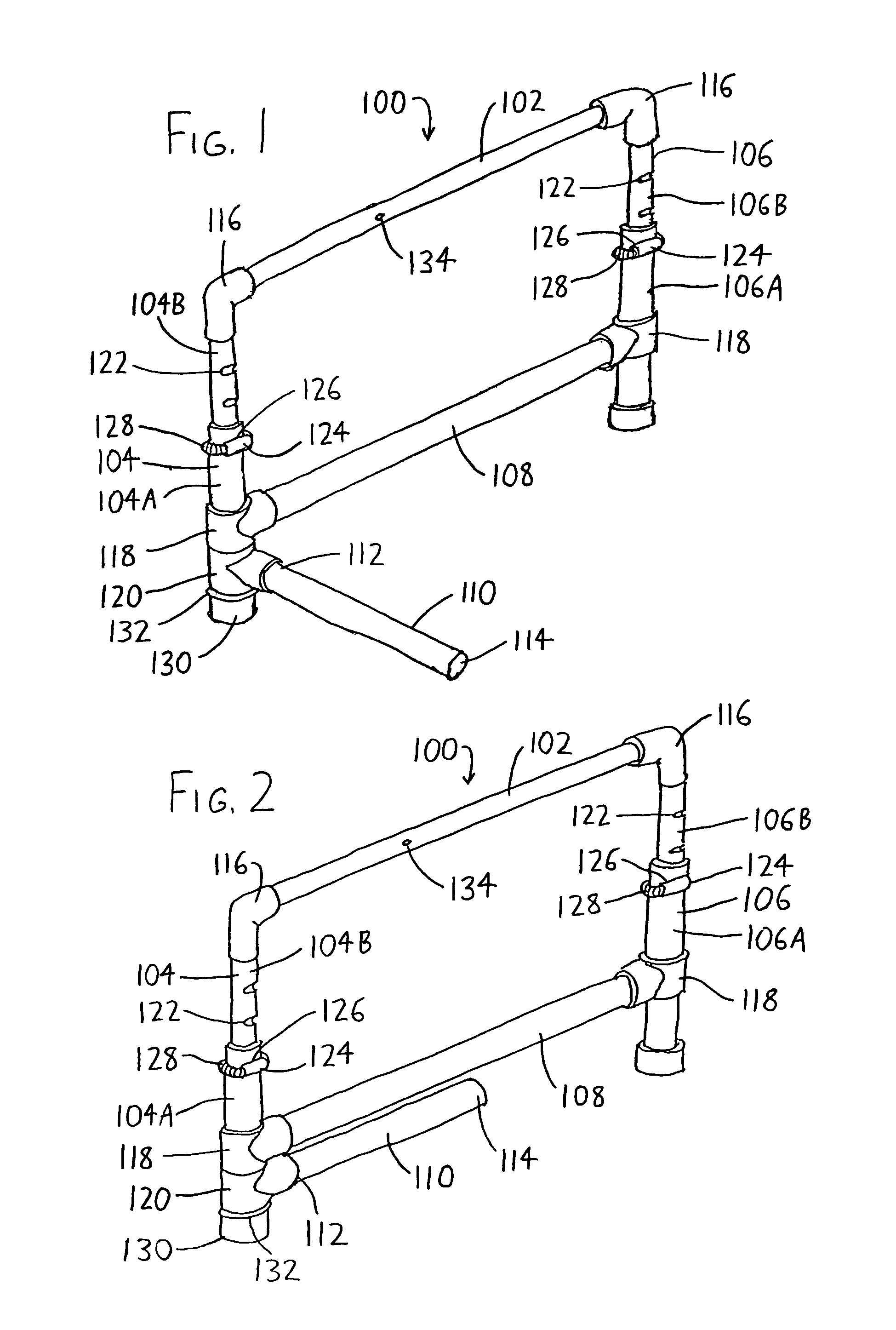

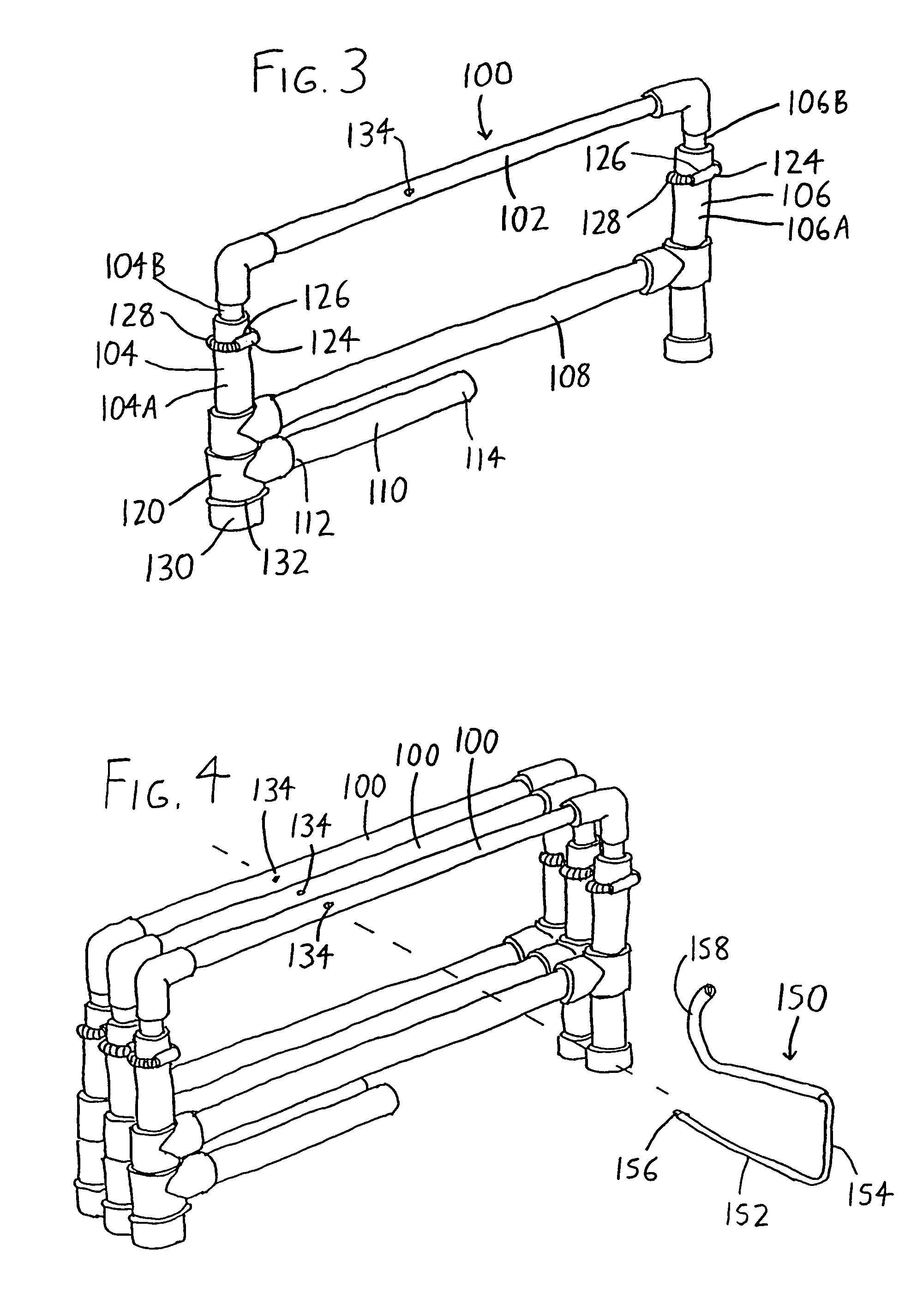

Hurdle for sport and training use

A hurdle which may be readily converted between an erect / in-use state and a collapsed / readily storable state includes a crossbar having adjustable height, and the ability to be converted between a supporting state where one or more support legs maintain the hurdle in an erect position, and a folded state wherein the support legs are folded within the plane of the hurdle so that it will not readily stand erect. Thus, the crossbar may be collapsed to a lowest-height position and the hurdle may be put in its folded state for easy transport and storage, or the support leg(s) may be unfolded to its supporting state and the crossbar may be raised to a desired height so that the hurdle is ready for use. A handle may also be provided for allowing easy collection and transport of multiple hurdles.

Owner:PRISM FITNESS

Method for manufacturing display device and method for manufacturing electronic device

ActiveUS20170033287A1Not easy to damageImprove reliabilityFinal product manufactureSolid-state devicesSecondary layerEngineering

Provided is a method for manufacturing a highly reliable display device. The method includes steps of providing a first layer, a first insulating layer, an electrode, and a second insulating layer over a first surface of a first substrate; removing a part of the second insulating layer to provide a first opening; providing a display element and a second layer over the second insulating layer; providing a third layer and a third insulating layer over a second surface of a second substrate; removing part of the third layer and part of the third insulating layer to provide a second opening; overlapping the first substrate and the second substrate with a bonding layer positioned therebetween such that the first surface and the second surface face each other and the first opening and the second opening have an overlap region; separating the first substrate and the first layer from the first insulating layer; providing a third substrate such that the first insulating layer and the third substrate overlap with each other; separating the second substrate, part of the bonding layer, part of the second layer, and the third layer from the third insulating layer; and providing a fourth substrate such that the third insulating layer and the fourth substrate overlap with each other.

Owner:SEMICON ENERGY LAB CO LTD

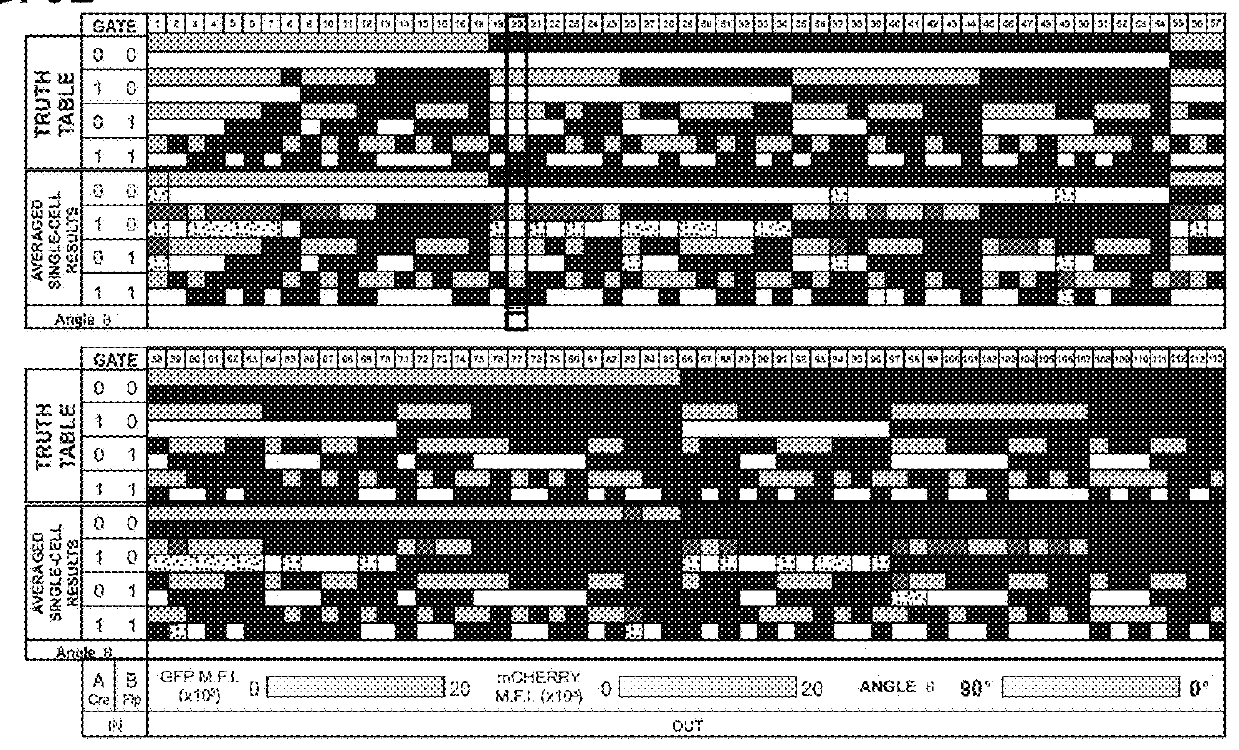

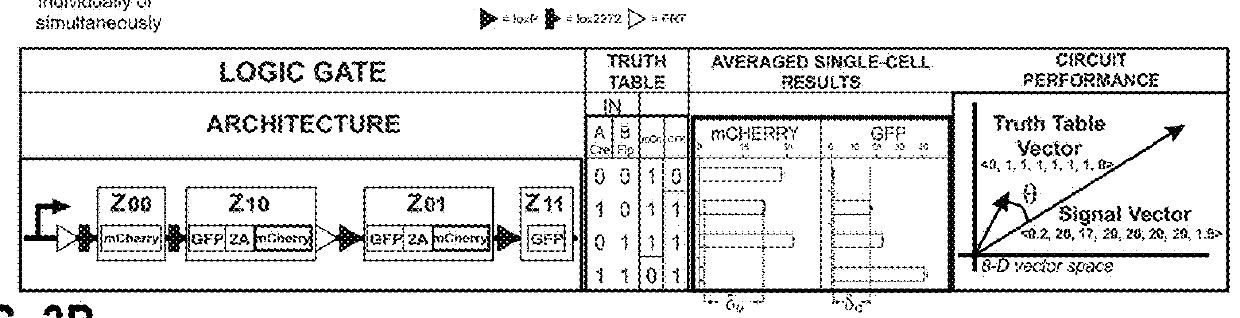

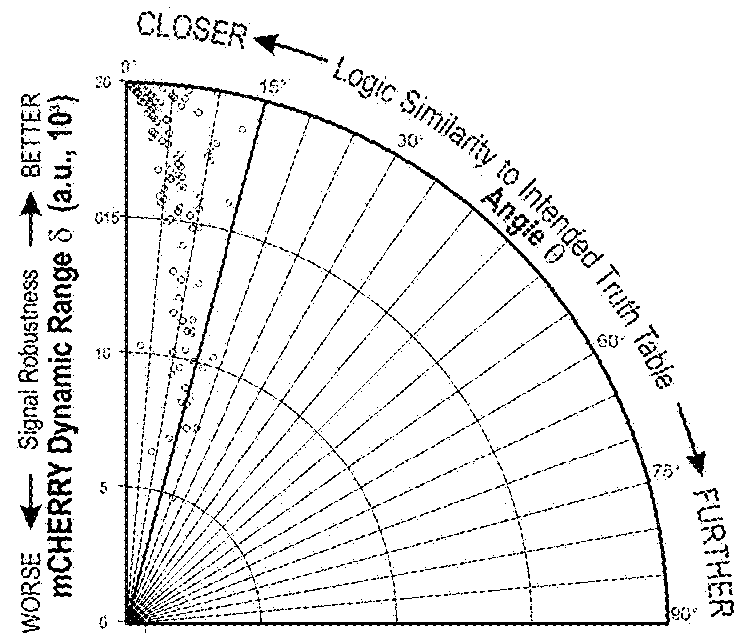

Inducible dimerization of recombinases

PendingUS20180163195A1Reduce the impactIncrease spacingEnzyme stabilisationT cellChemically induced dimerization

The technology described herein relates to controlled chemically- or light-induced rejoinder of split-recombinases. In some embodiments, compositions, methods, kits and systems are provided that relate to a split-recombinase system, whereby protein complementation or rejoinder of split-recombinases is mediated by chemical-induced dimerization domains (CIDDs) or light-induced dimerization domains (LIDD) and rejoinder of the split-recombinases occur in the presence of one or more chemical inducers or light inducers, respectively. The split-recombinases systems as disclosed herein can be used in gene therapy, integrated logic and memory in living cells such as mammalian cells. The nucleic acid cassettes, switches, and systems described herein allow for controlled gene expression or gene regulation. The controlled chemically- or light-induced rejoinder of split-recombinases can be used in, for example, adopted T-cell therapy.

Owner:TRUSTEES OF BOSTON UNIV

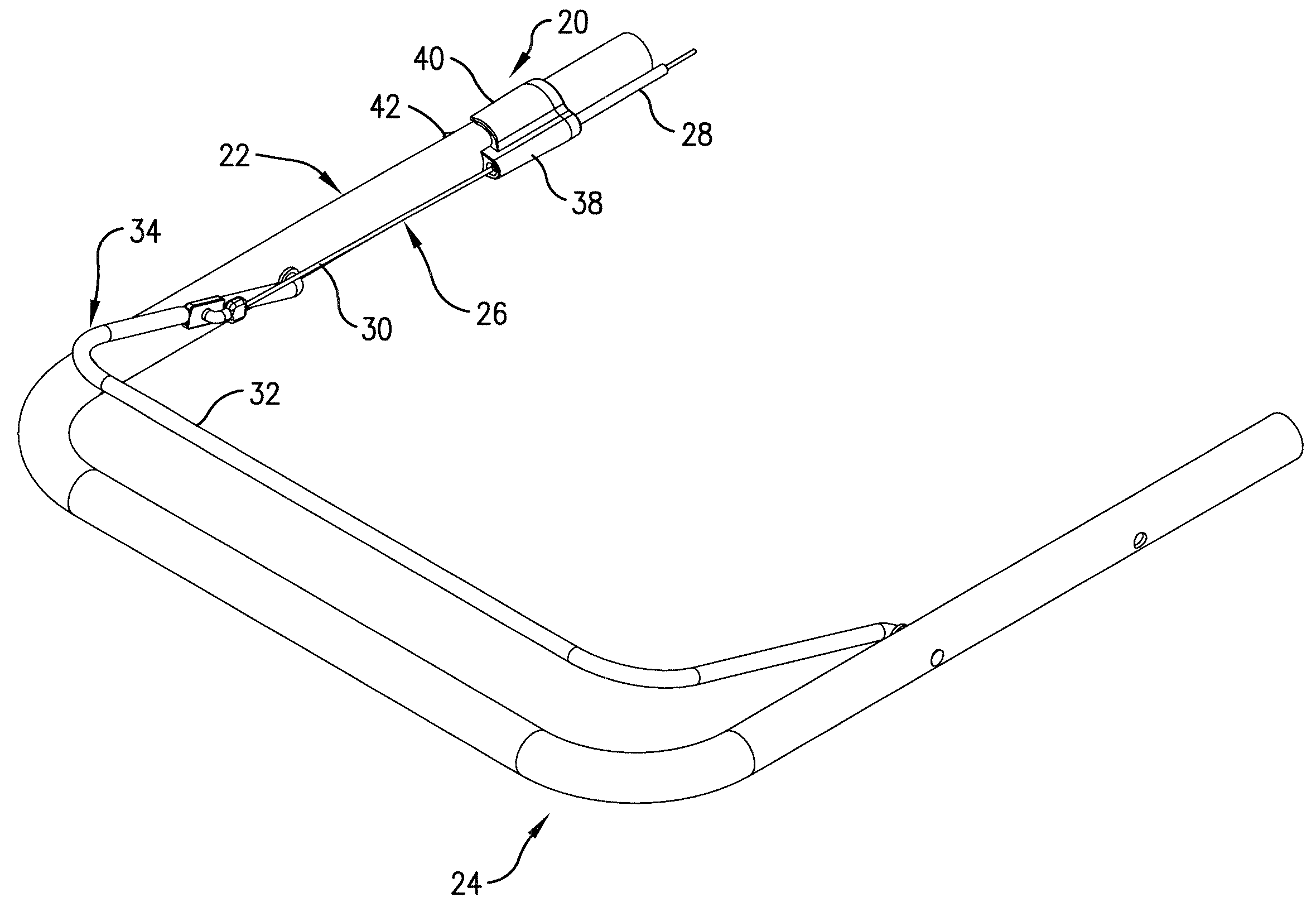

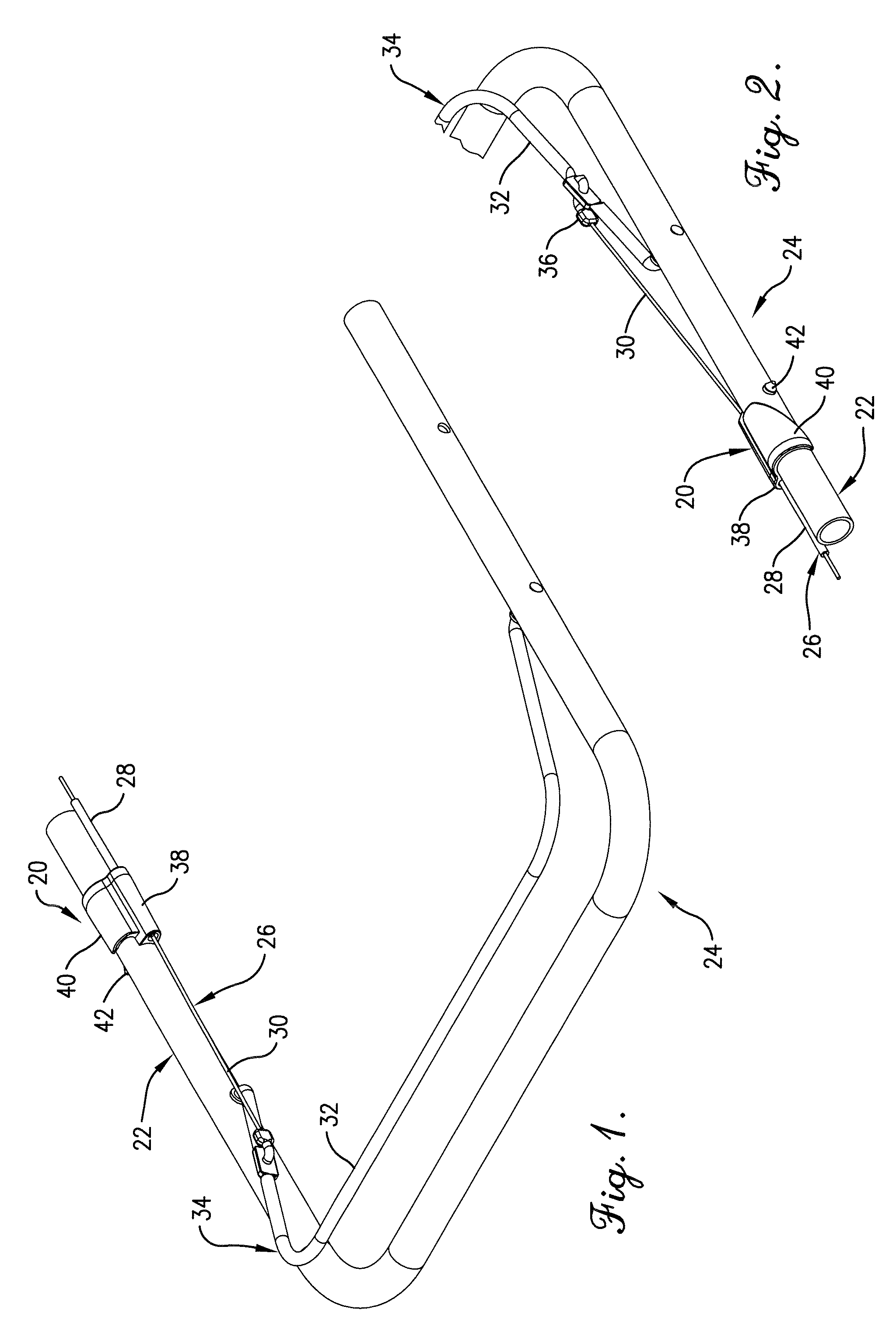

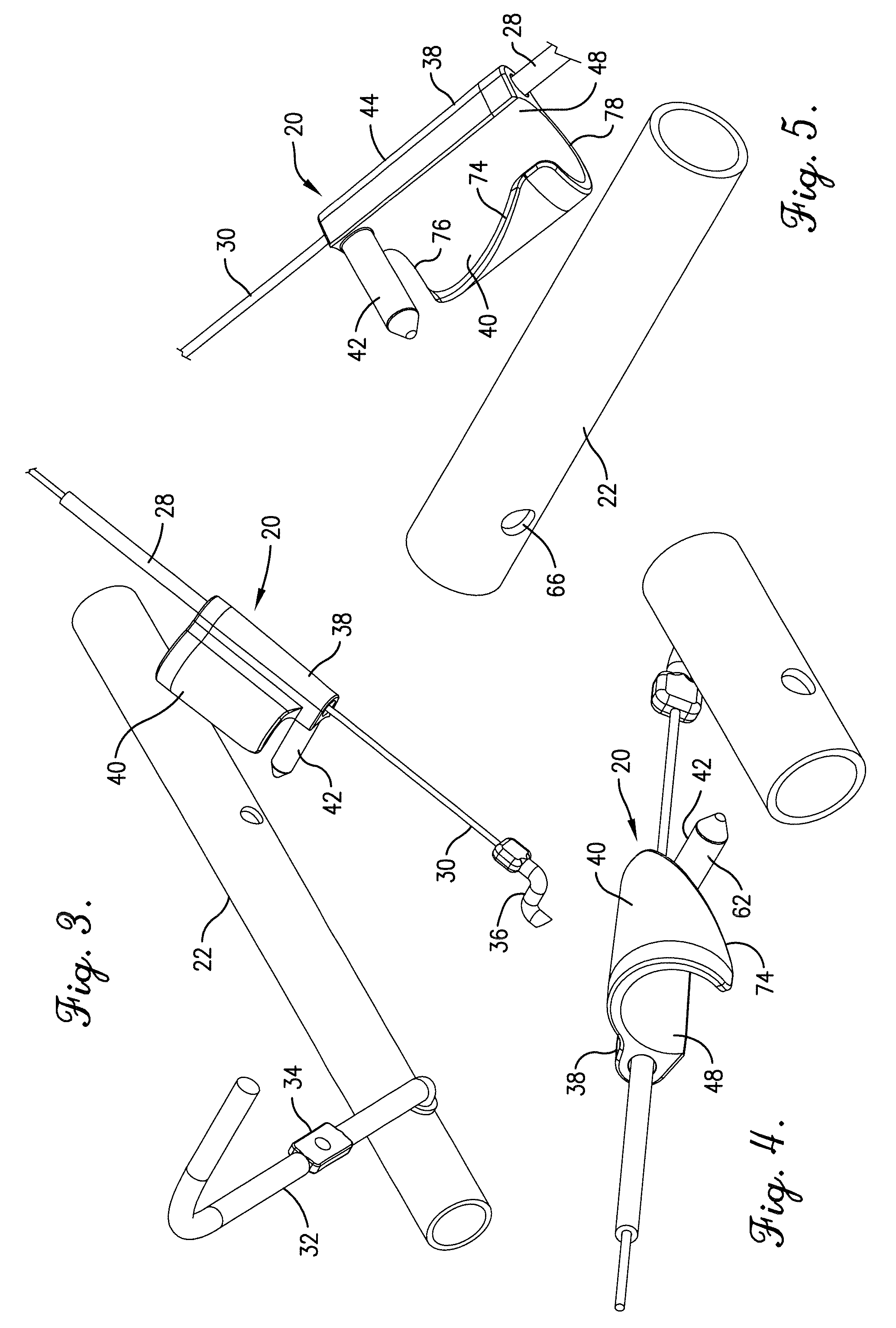

Conduit guide clip

Owner:WESCON CONTROLS

Light emitting device and light emitter

ActiveUS7872410B2Unevenness in emission color can be significantly suppressedInhomogeneous suppressionDischarge tube luminescnet screensLamp detailsPhosphorLight emitting device

Owner:TOYODA GOSEI CO LTD

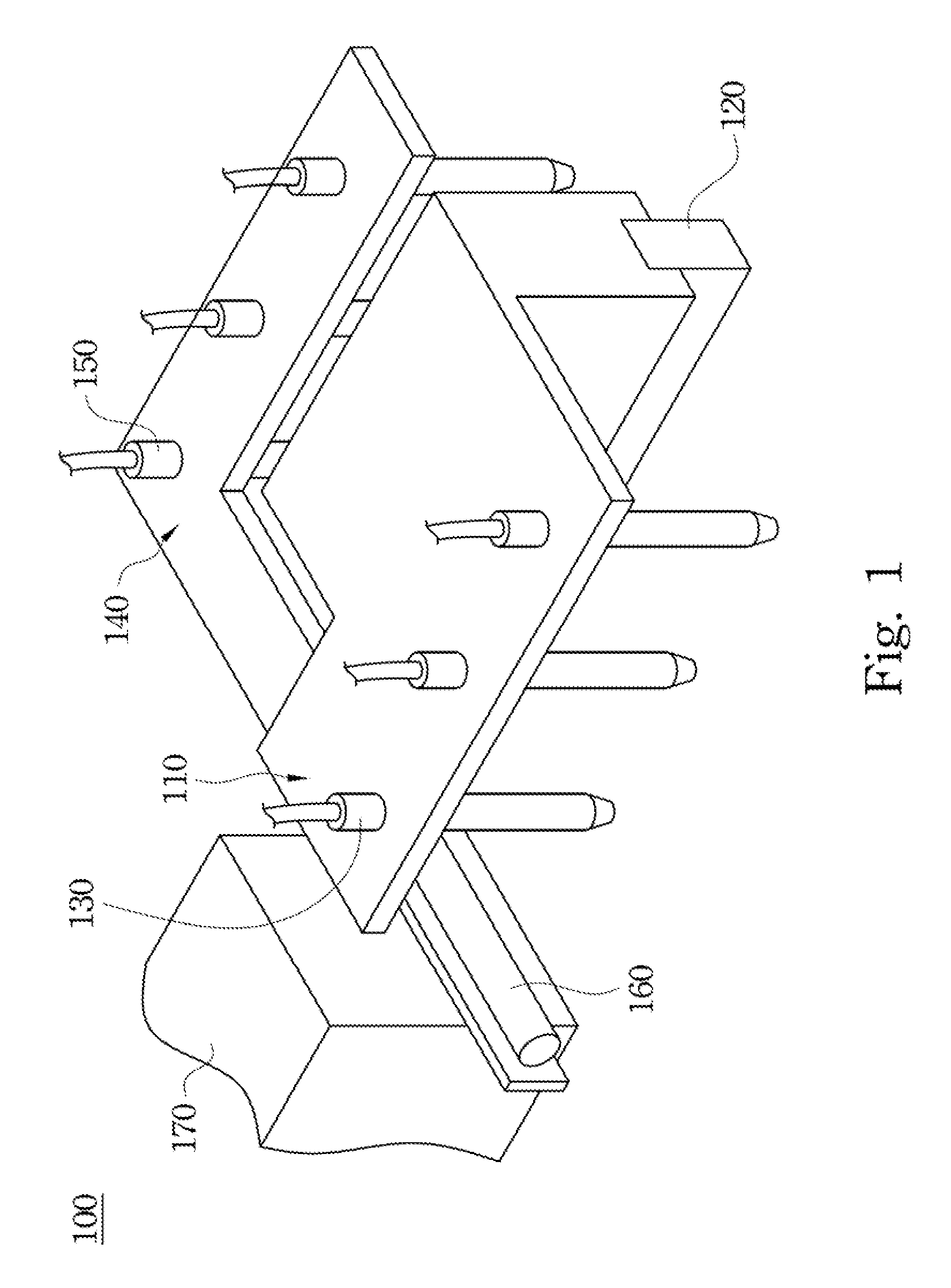

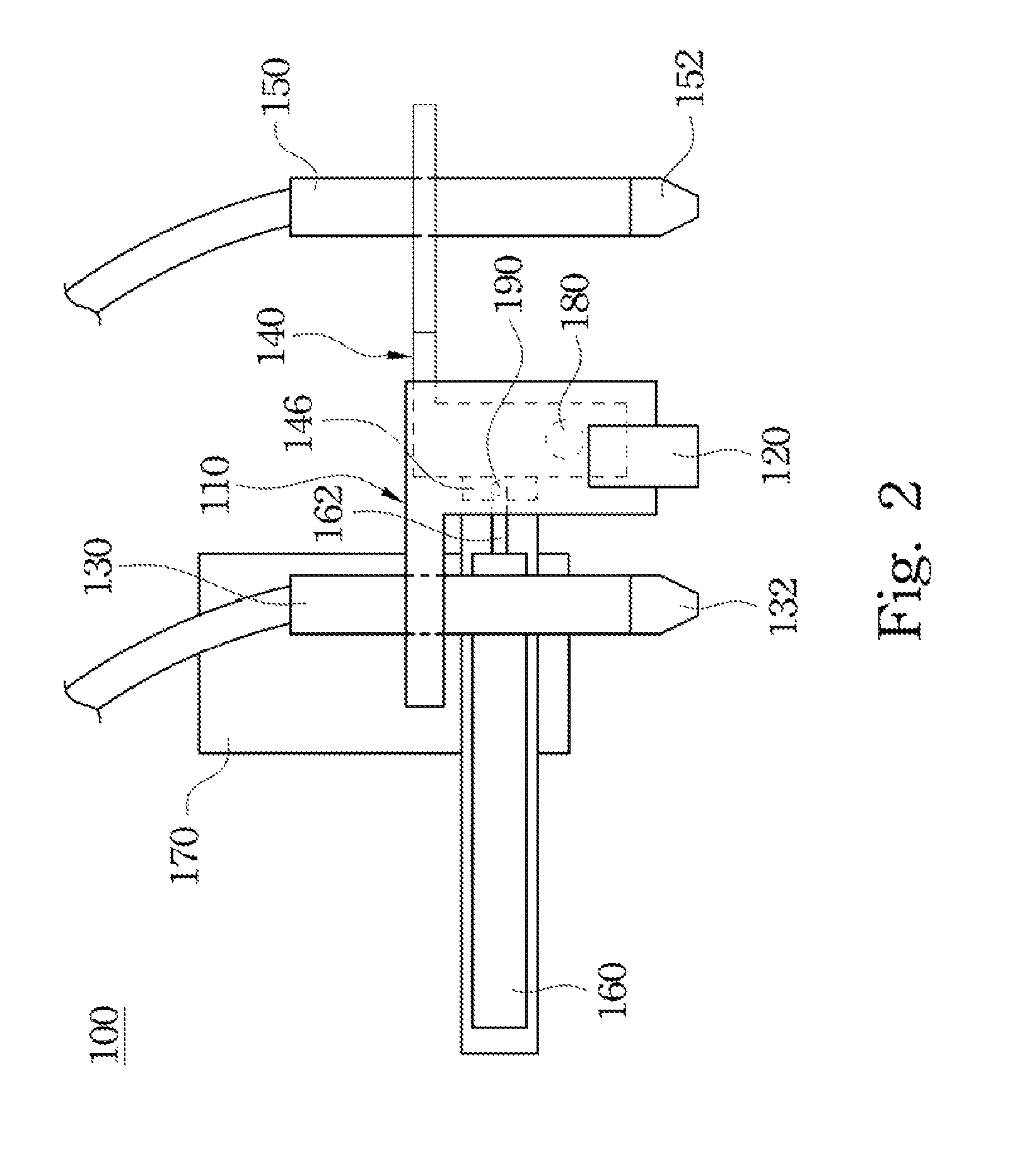

Fracturing apparatus

InactiveUS8584918B2Easy qualityYield easilyMetal working apparatusArticle deliveryEngineeringMechanical engineering

A fracturing apparatus is provided. The fracturing apparatus includes a first board portion, a pressing element, a first suction device, a second board portion, a second suction device, and a cylinder. The first suction device is secured to the first board portion. The second board portion is rotatably connected to the first board portion. The second suction device is secured to the second board portion. The pressing element is secured to the first board portion and disposed between the first board portion and the second board portion. The cylinder is located on the first board portion and includes a piston rod rotatably connected to the second board portion. When the piston rod extends, the second board portion is pressed by the piston rod and swiveled about the first board portion.

Owner:RYTEC CORP

Resin composition capable of laser marking method, and marked molded article

InactiveUS6586518B1Uniform contrastWithout deterioration in workability and mechanical characteristicFibre treatmentSpecial tyresElastomerPolyolefin

A resin composition capable of laser marking according to the present invention includes a polyolefin resin in combination with a laser-sensitive component such as a carbon black or metallic compound white pigment and a dispersing aid such as a higher fatty acid compound. The polyolefin resin includes, for example, a polypropylene. The resin composition may further include about 0.5 to 30 parts by weight of an elastomer relative to 100 parts by weight of the polyolefin resin. By irradiating an surface of a molded article obtained from the resin composition with a laser, a mark having a sharp and uniform contrast can be formed on the surface of the molded article.

Owner:DAICEL CHEM IND LTD

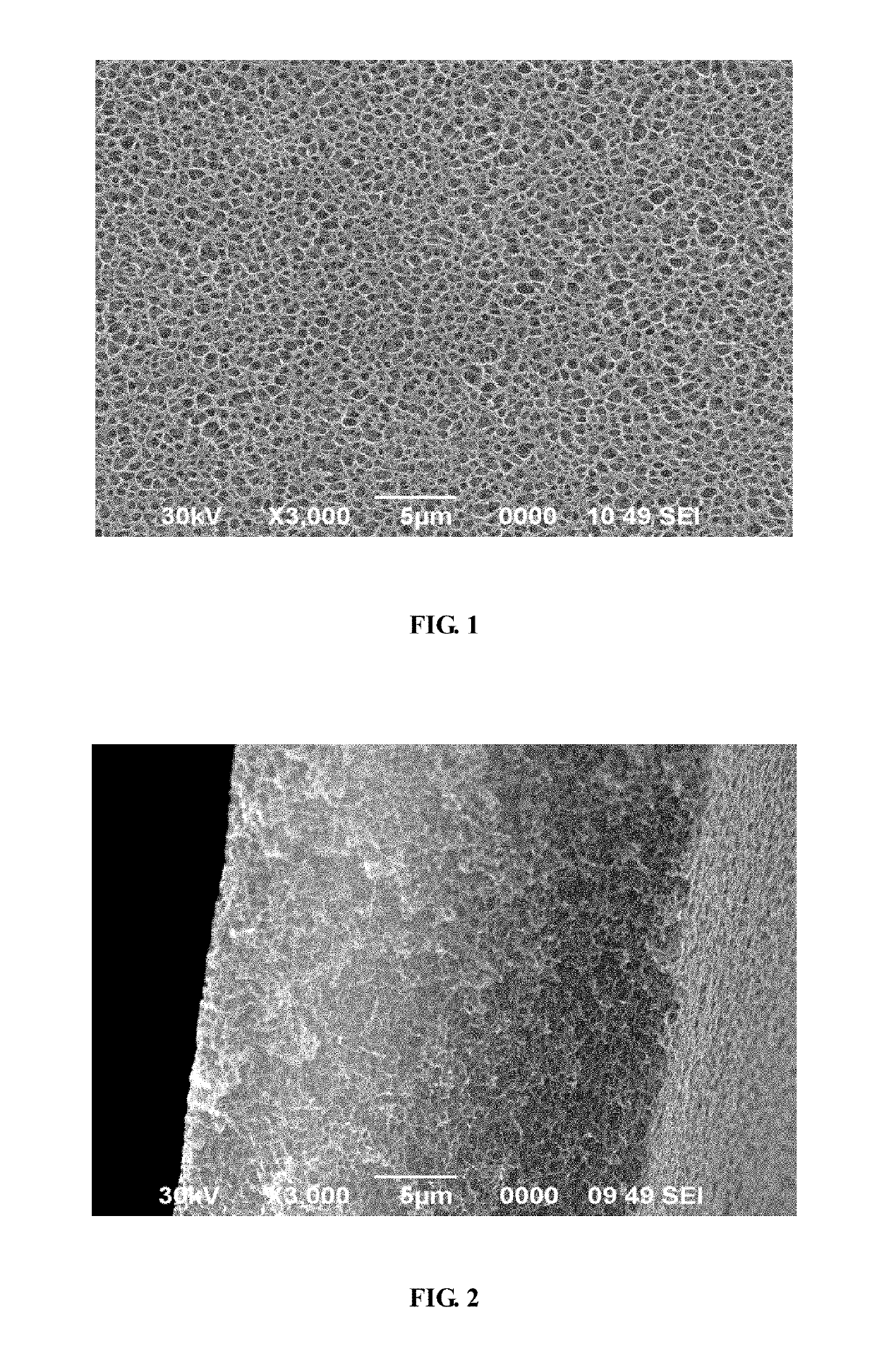

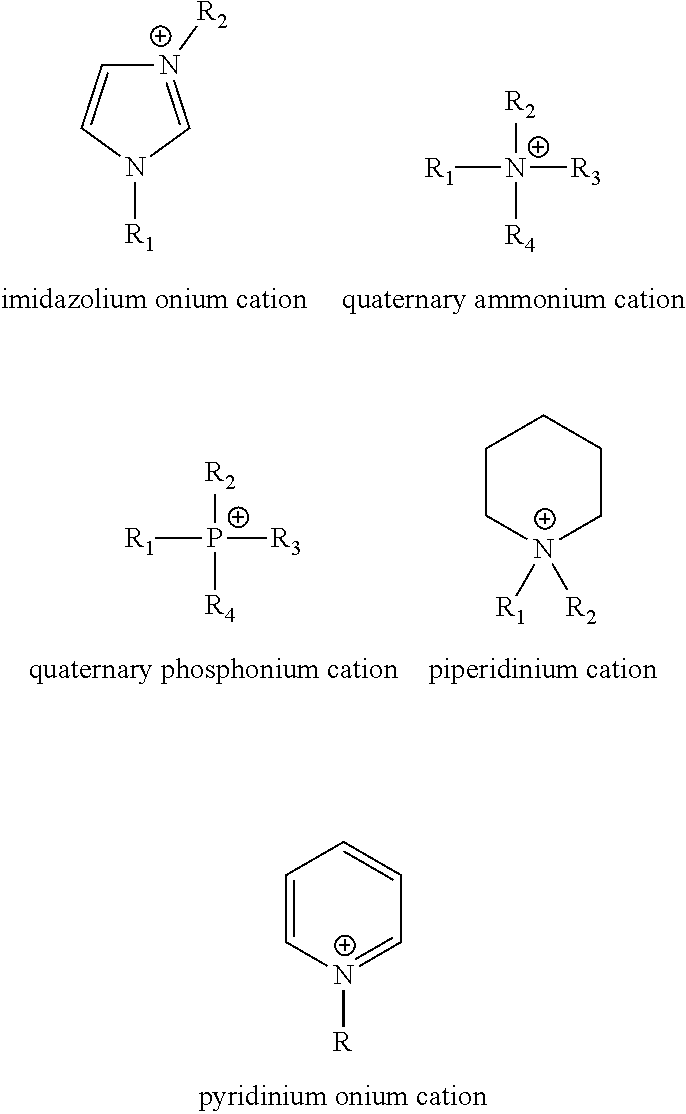

Method for preparing aromatic polyamide porous membrane and aromatic polyamide porous membrane prepared thereby

ActiveUS20190097196A1Easy to controlYield easilyMembranesSemi-permeable membranesAramidesPorous membrane

The present invention provides a method for preparing an aromatic polyamide porous membrane and an aromatic polyamide porous membrane prepared by the above method. The method for preparing an aromatic polyamide porous membrane includes the following steps: mixing an ionic liquid with an aromatic polyamide into a solvent to form a mixed solution; the mixed solution forming a membrane in a coagulation bath; and extracting with an extractant to remove the solvent and the ionic liquid from the membrane to yield a porous membrane. In the method of the present invention, the application of the ionic liquid would greatly reduce the application of additives; further, the ionic liquid has a high stability and is easy to be separated from other solvents and be recycled, which assures the safety during the usage and recycle thereof.

Owner:MICROVAST ADVANCED MEMBRANE INC

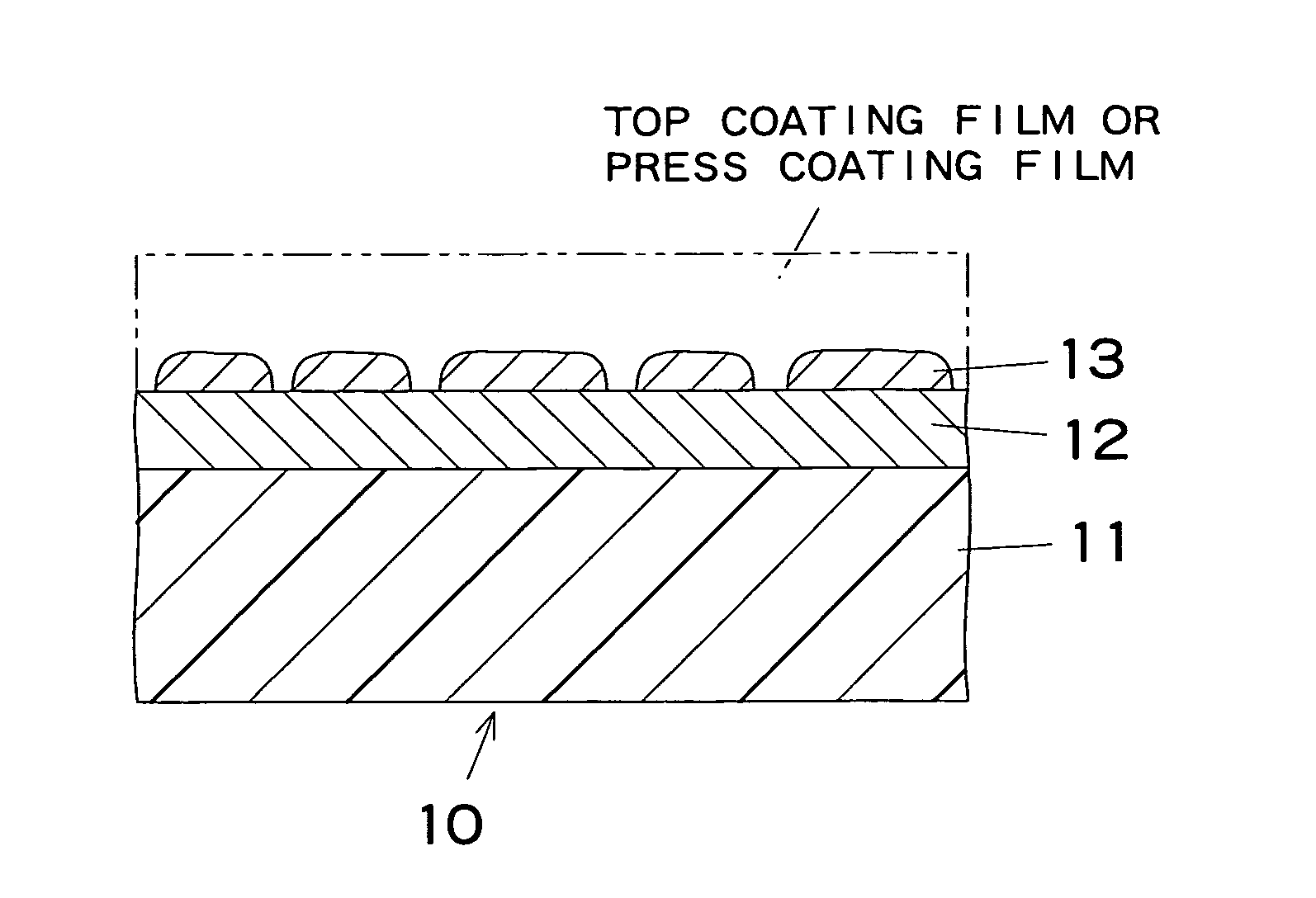

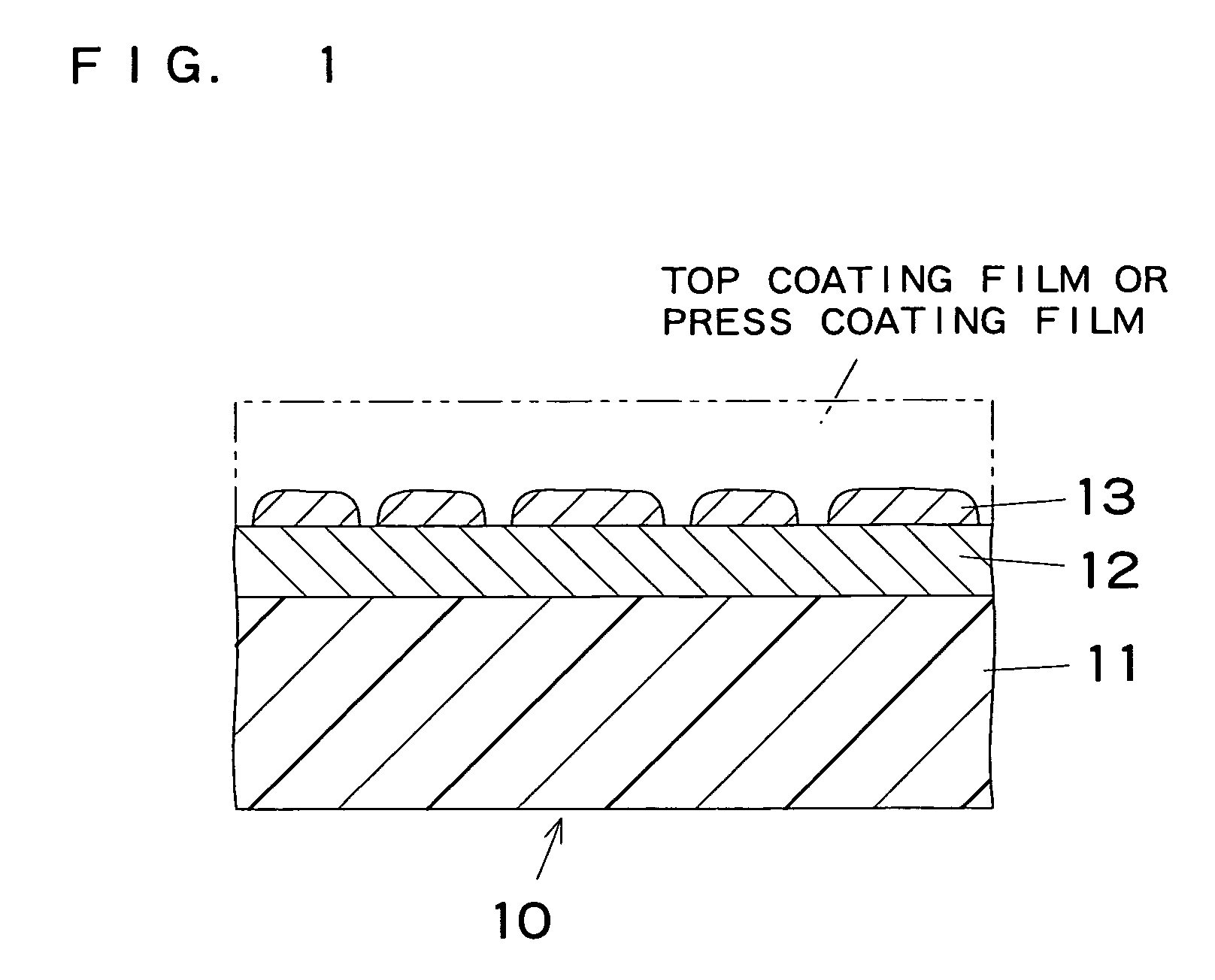

Film and labeled plastic container

InactiveUS20150247017A1Yield easilyDifficult for ink can be transferredDecorative surface effectsDomestic containersPolymer sciencePorous layer

A thermoplastic resin film that has an excellent heat insulating property, and a labeled plastic container produced by attaching the thermoplastic resin film by in-mold molding are provided. The film comprises at least one porous layer that satisfies the following conditions (A) and (B). (A) The porous layer includes 25 to 65 pts. mass of thermoplastic resin and 35 to 75 pts. mass of inorganic fine powders. (B) A pore length L of the porous layer as expressed by L=d×(ρ0−ρ) / ρ0 is 20 μm or longer. L denotes the pore length [μm] of the porous layer, d denotes a thickness [μm] of the porous layer, p denotes a density [g / cm3] of the porous layer, and ρ0 denotes a true density [g / cm3] of the porous layer.

Owner:YUPO CORP

Package for cigarette rolling paper

InactiveUS7611014B2Yield easilyContainers for flexible articlesCigar manufactureRolling paperEngineering

This package is made up of a sheet (1) that once having been die cut, folded and assembled, makes a prismatic rectangular shaped package that has longitudinal slots (18) for the successive extraction of the sheets of paper to roll cigarettes (21) that are stored in two or more wads of paper (2) housed on the inside of the package and supported on a reinforcing card (3) placed on the inner surface of the lower wall (14) of the package. This reinforcing card (3) has, at least two tabs (31) to retain the wads of paper (2), placed between the wads of paper (2), orientated towards the upper area, respectively inclined towards the front and rear walls of the package, and hinged on both fold lines (32) coinciding with a longitudinal X-X axis, parallel to the wads of paper (2) and the slots (18) for the extraction of the sheets of paper (21).

Owner:MIQUEL Y COSTAS & MIQUEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com