Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

126results about How to "Uniform extrusion force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

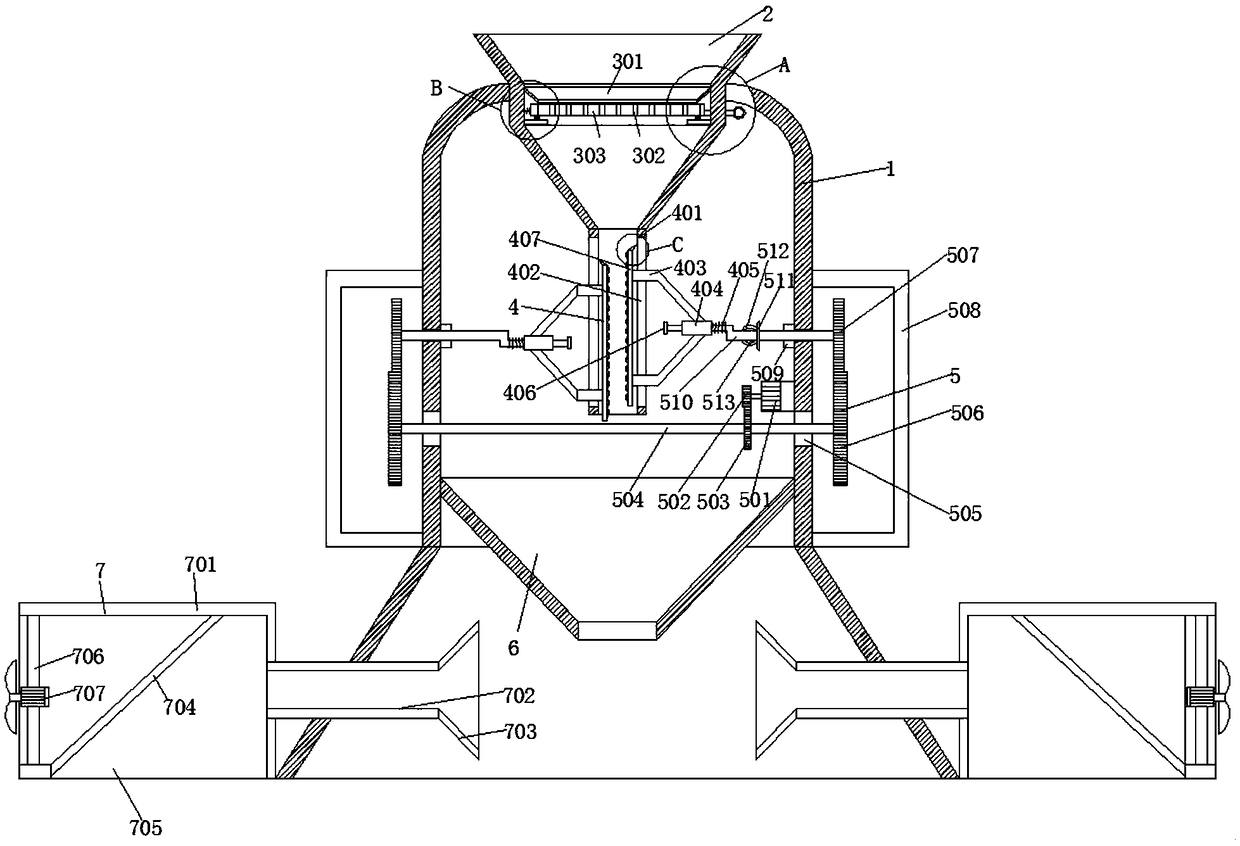

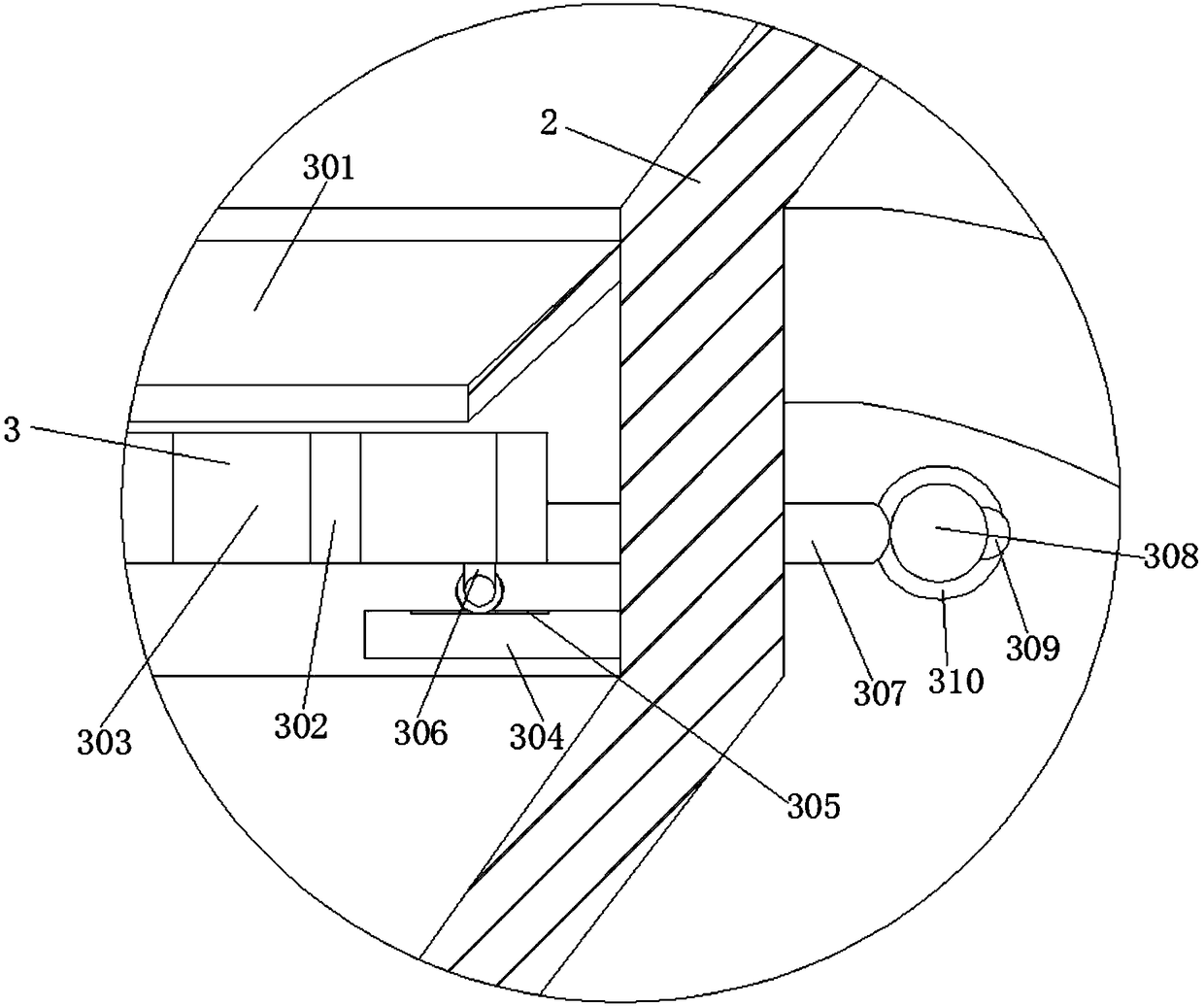

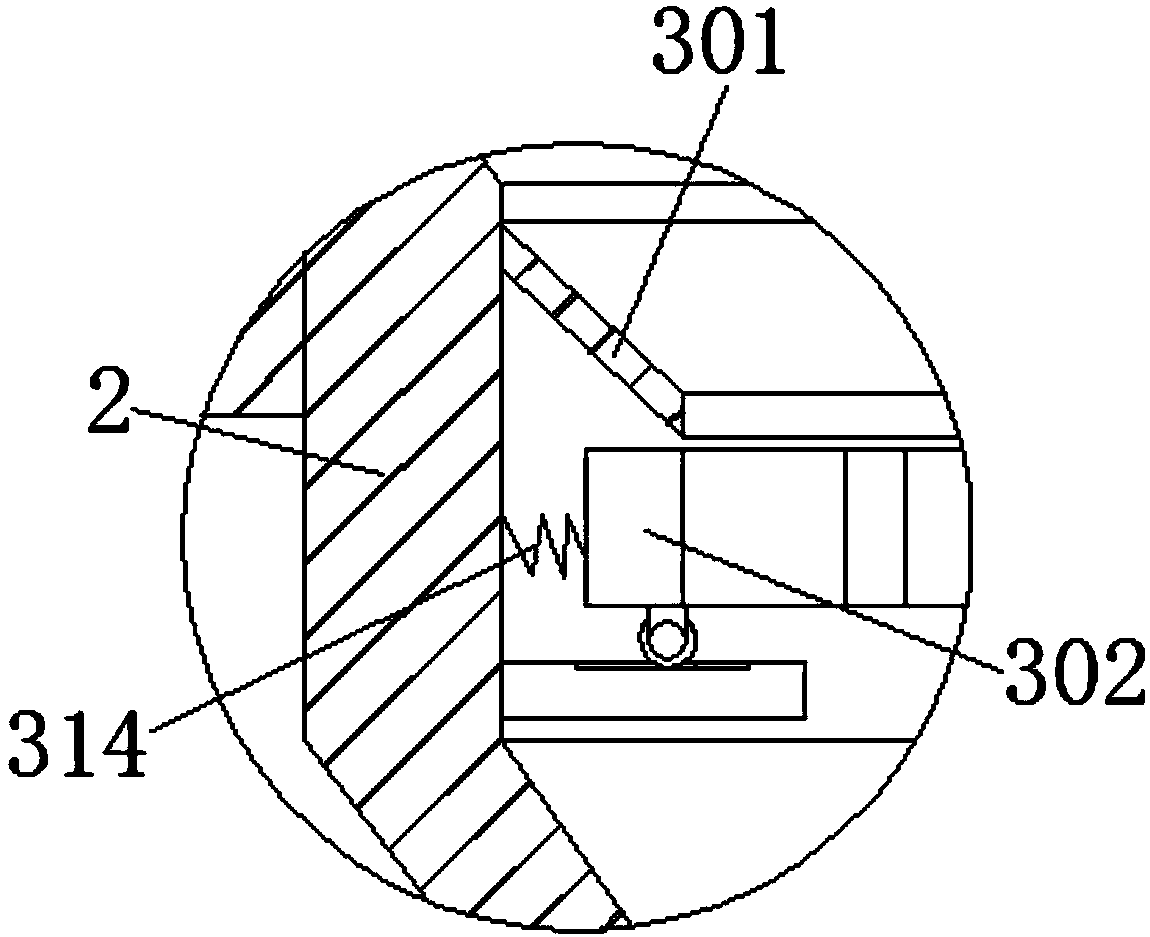

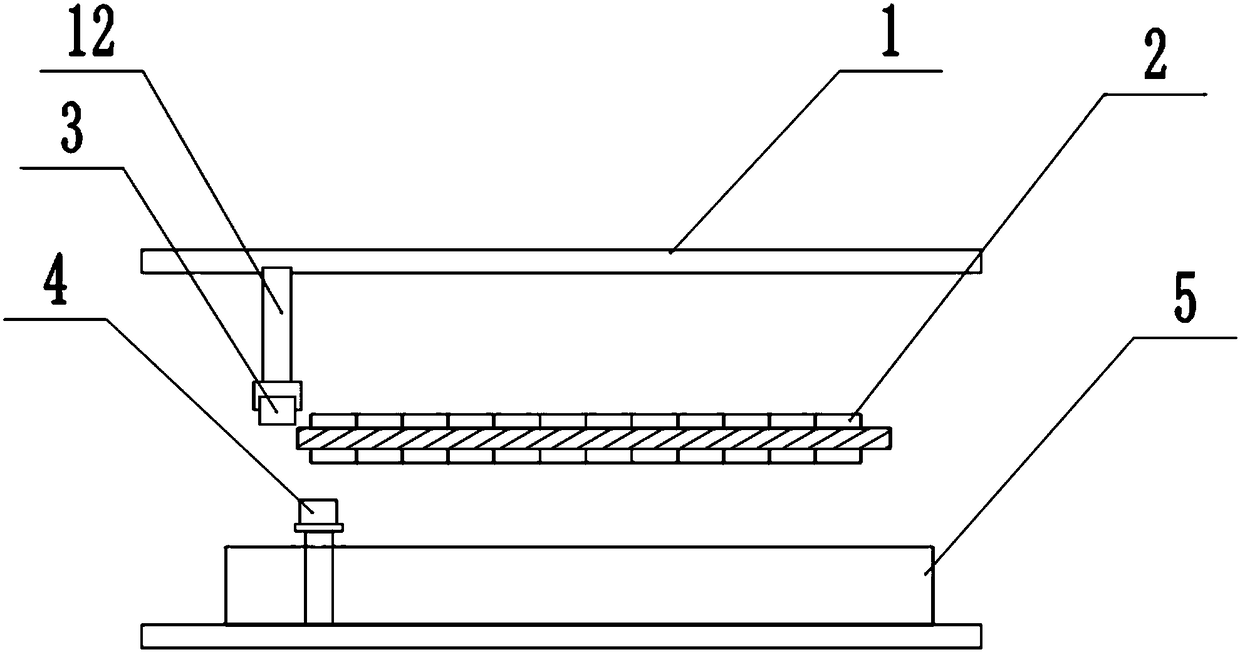

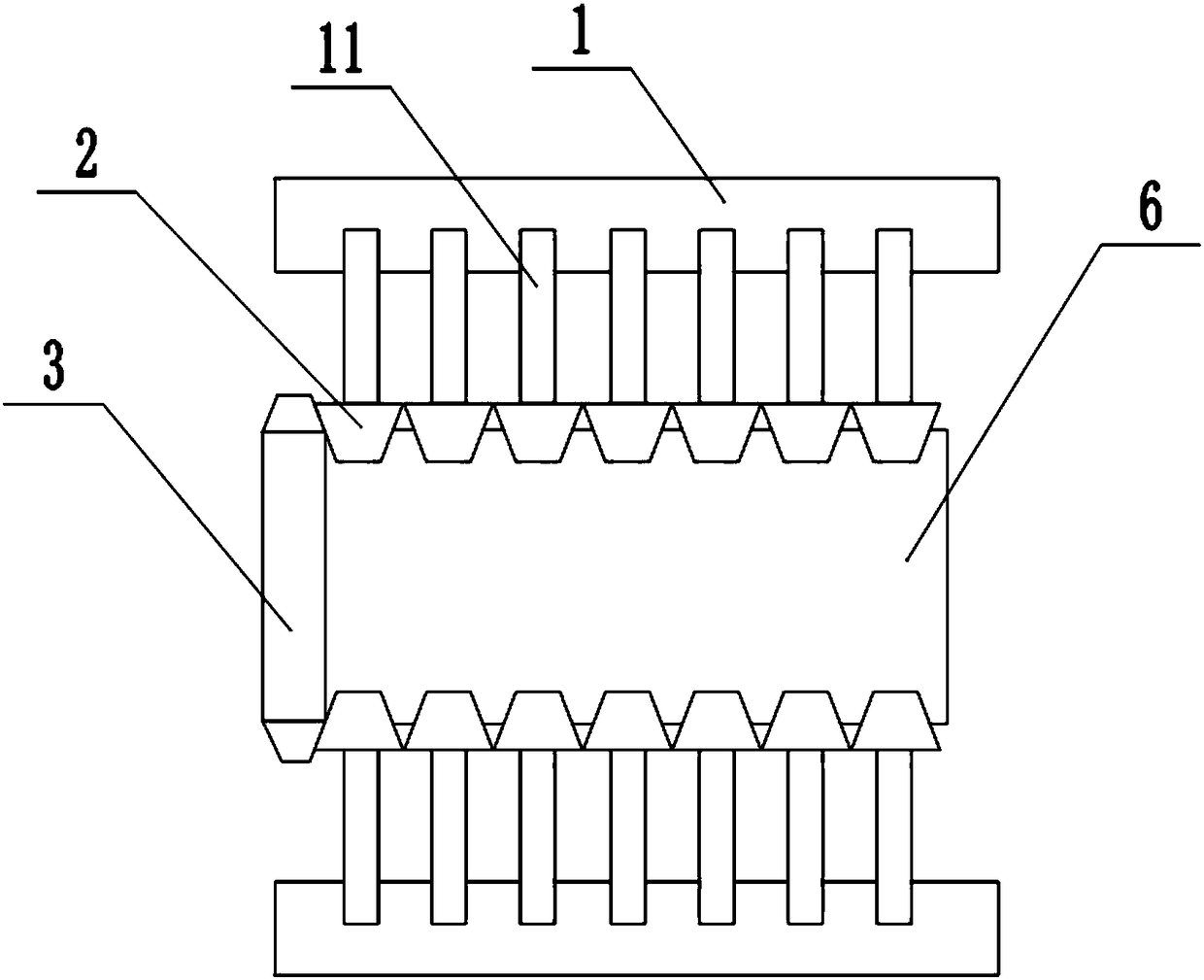

Coat-removing device for coat-removing oil-fried peanut kernels based on bionic kneading

InactiveCN108433120AReduce wasteReduce manufacturing costGas current separationHuskingEngineeringPeanut kernel

The present invention provides a coat-removing device for coat-removing oil-fried peanut kernels based on bionic kneading, and relates to the field. The coat-removing device for coat-removing the oil-fried peanut kernels based on the bionic kneading comprises a machine shell. The top part of the machine shell communicates with a material feeding funnel; the inside of the material feeding funnel isprovided with a stable material conveying device; a coat-removing device is arranged in the machine shell and connected with the material feeding funnel; two transmission devices are connected with the coat-removing device; a material discharging funnel is arranged inside the machine shell and fixedly connected with the lower sides of the transmission devices; and two peanut coat separation devices are arranged on the both sides of the machine shell. In the coat-removing device for coat-removing the oil-fried peanut kernels based on the bionic kneading, the operations of the transmission devices can drive two kneading plates to move up and down repeatedly; besides, the movement directions of the two kneading plates are opposite; and the opposite movement direction of the two kneading plates is similar to that of hand kneading, can ensure that the peanuts are not damaged and improves the integrity of the peanut kernels.

Owner:赵从琴

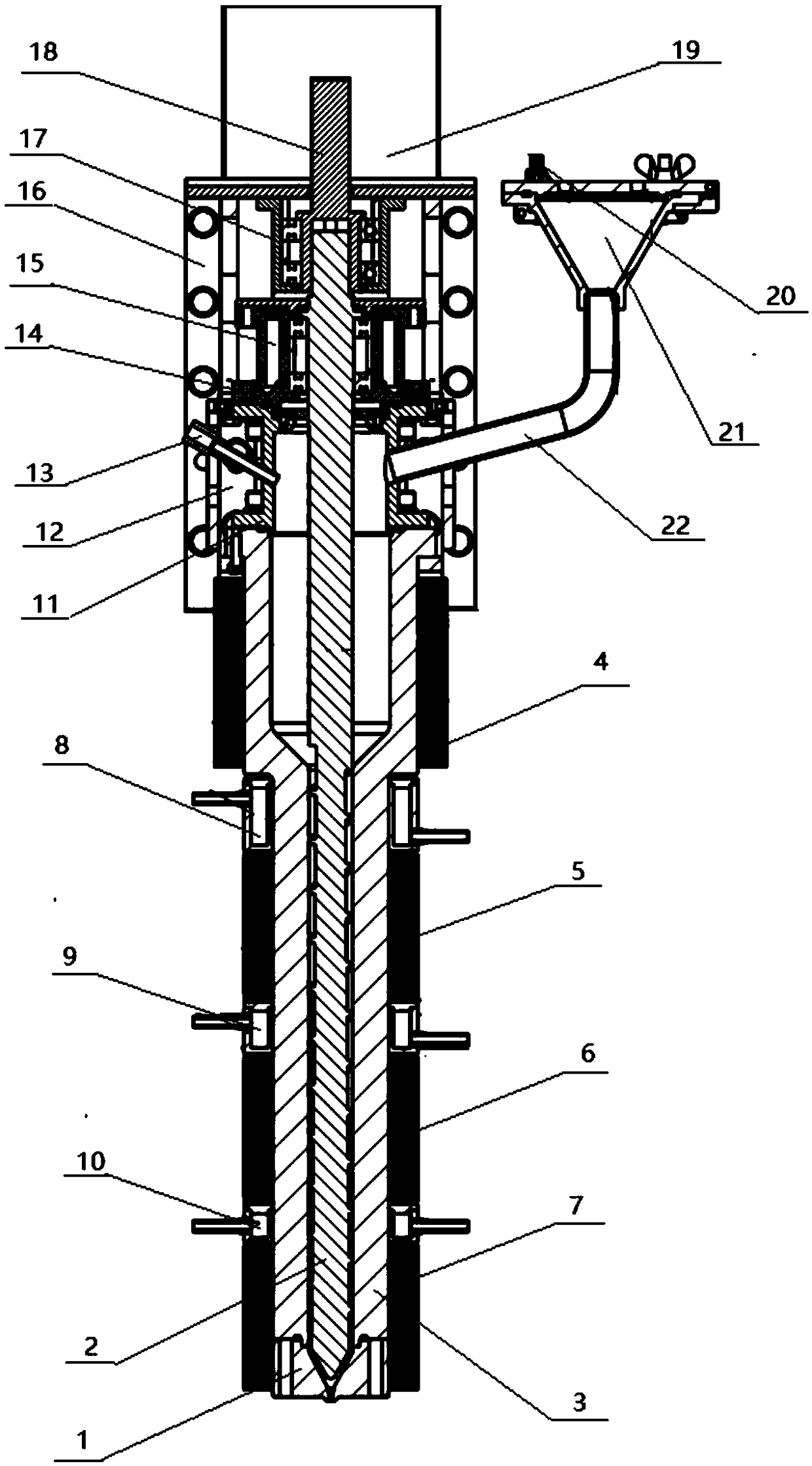

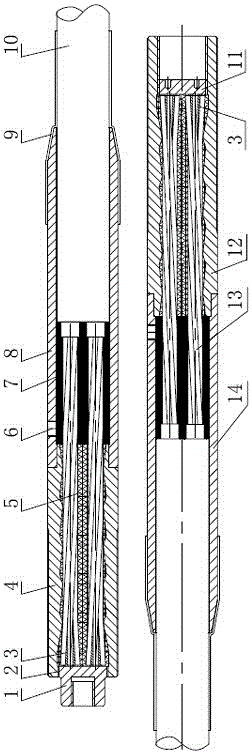

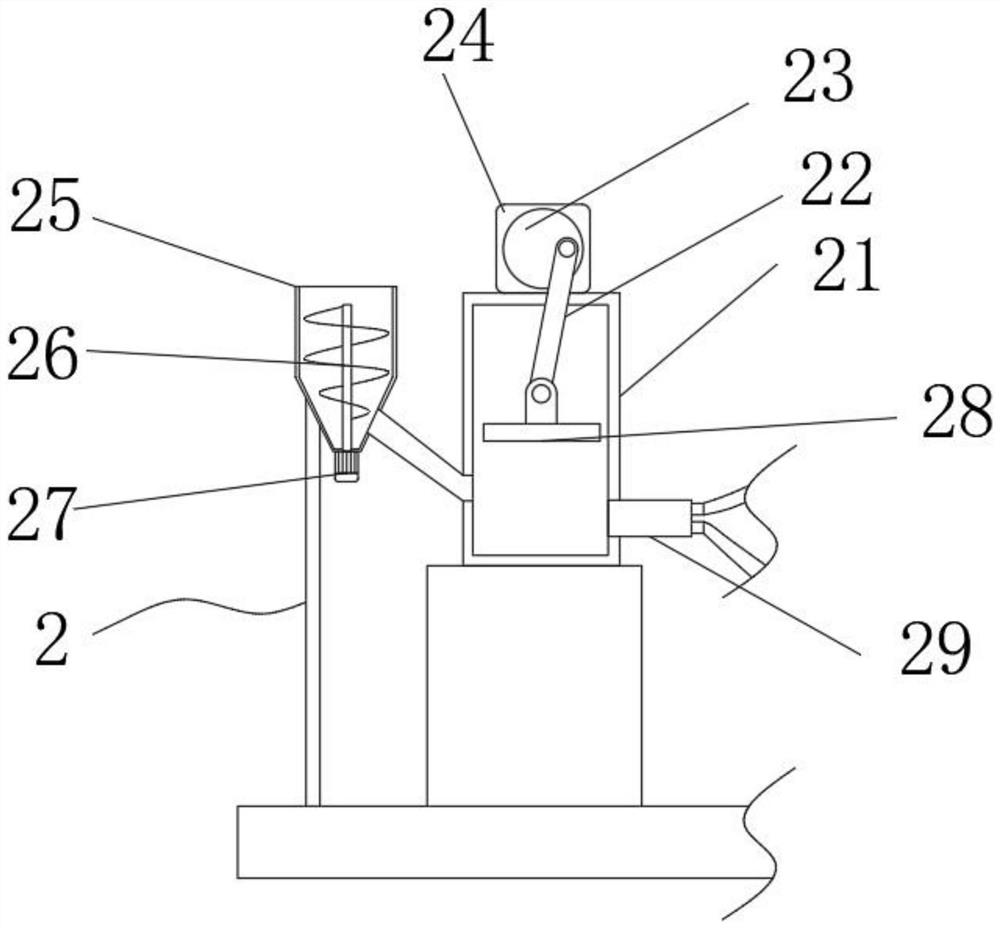

Metal semi-solid state melt extrusion additive manufacturing spraying nozzle

ActiveCN108941568AReduce thermal stressImproved rheological propertiesAdditive manufacturing apparatusTemperature controlSemi solid

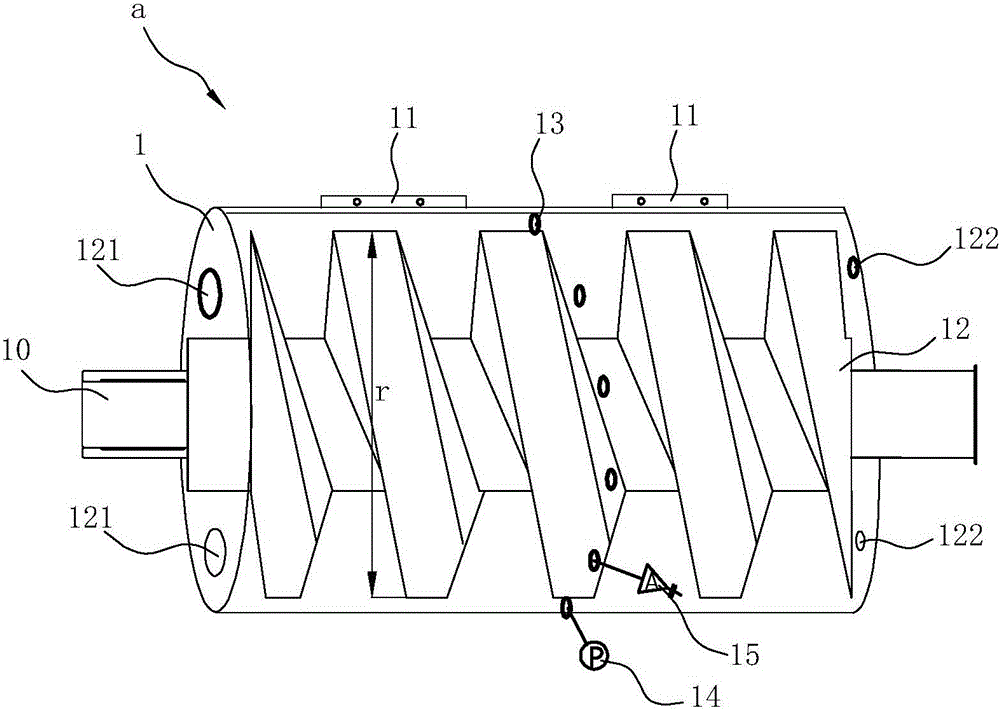

The invention provides a metal semi-solid state melt extrusion additive manufacturing spraying nozzle. The metal semi-solid state melt extrusion additive manufacturing spraying nozzle comprises a containing cavity and a stirring screw rod, wherein the stirring screw rod is coaxially arranged in the containing cavity in a clearance mode; the containing cavity is in a cylindrical shape with a variable cross section, and the diameter of the upper cylinder is larger than that of the lower cylinder; the upper cylinder and the equal-height part of the stirring screw rod form a material melting storage cavity; a plurality of semi-solid state material forming cavities which are gradually reduced by degrees are formed by the lower cylinder and the equal-height part of the stirring screw rod; a supporting frame which is provided with a feeding bin is fixedly arranged at the upper end of the containing cavity, an extrusion spraying nozzle is arranged at the lower end of the containing cavity, anda multi-section type resistance heating assembly, a multi-section water cooling ring assembly and a temperature control system are arranged on the outer side of the containing cavity correspondingly;the supporting frame is provided with a bearing system used for assembling the stirring screw rod, and a feeding assembly communicating with the feeding bin; a driving end of the stirring screw rod is connected with an output end of a speed reducer and the output end of a driving motor, and a free end of the stirring screw rod is in clearance fit with the extrusion spraying nozzle to be used forsqueezing the semi-solid state metal out. According to the metal semi-solid state melt extrusion additive manufacturing spraying nozzle, melt extrusion and forming of a light metal structural materialof aluminum / magnesium alloy with a relatively low melting point are realized.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

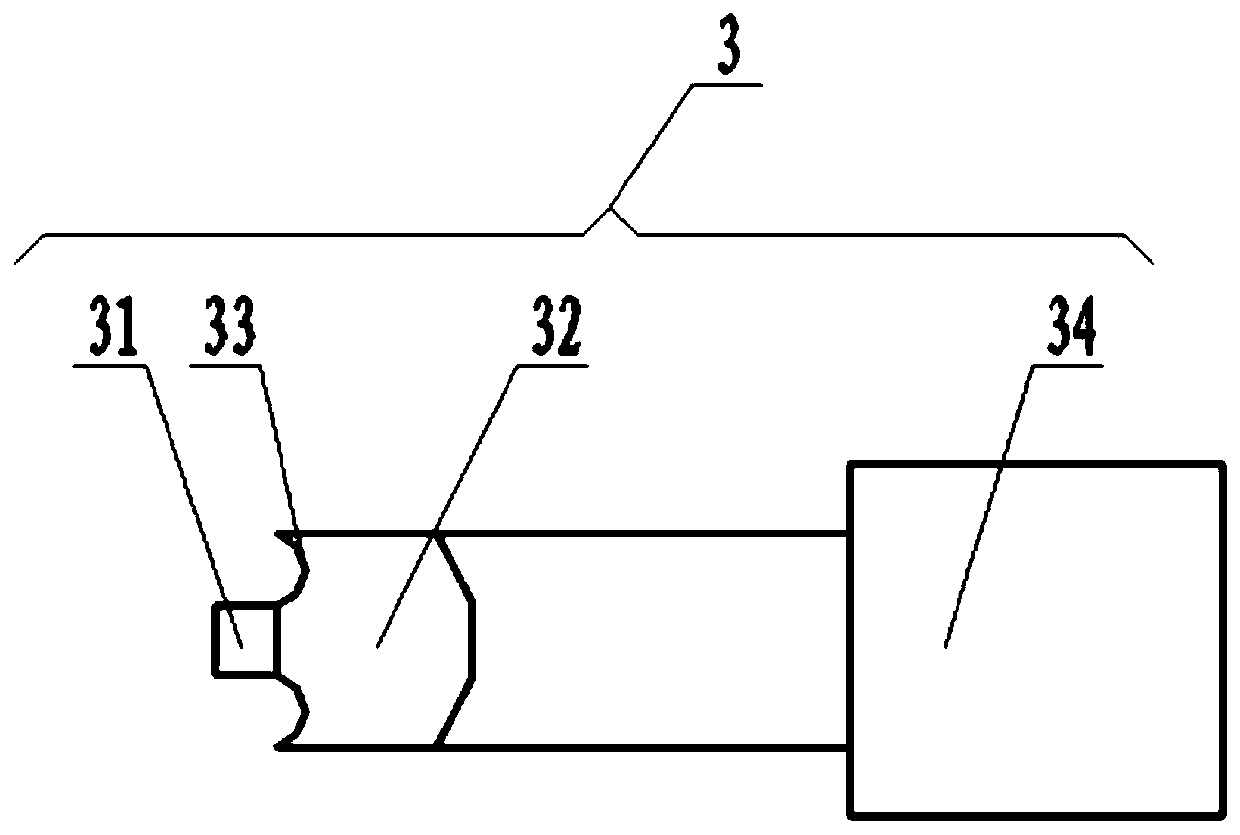

Steel strand stayed cable and manufacturing method thereof

ActiveCN106320609AUniform extrusion forcePrevent slippingBuilding reinforcementsEngineeringExtrusion

The invention relates to a steel strand stayed cable and a manufacturing method thereof. The problem that an existing stayed cable is assembly by extrusion and needs special extrusion equipment, and each steel strand needs to be equipped with an extrusion die of the corresponding specification, so that operation is troublesome, and the cost is high are solved. An anchoring end and a stretching end each comprises a taper sleeve arranged at the center steel wire end of the corresponding steel strand in a sleeving mode, an anchoring sleeve arranged at the end of a cable body in a sleeving mode and a sealing tube. The anchoring sleeves are filled with epoxy cold casting material, and the sealing tubes are filled with anti-corrosive polyurethane. The ends of the steel strands are expanded by the taper sleeves, during stretching, the steel strands are made to for a self-extrusion clamping structure through the taper sleeves, the steel strands do no needs to be subjected to extrusion sleeve assembly additionally, no special extrusion equipment is needed, and operation is easier. The anchoring sleeves are of a whole inner hole structure, the phenomenon that a plurality of long holes are formed is avoided, and machining is convenient.

Owner:浙锚科技股份有限公司

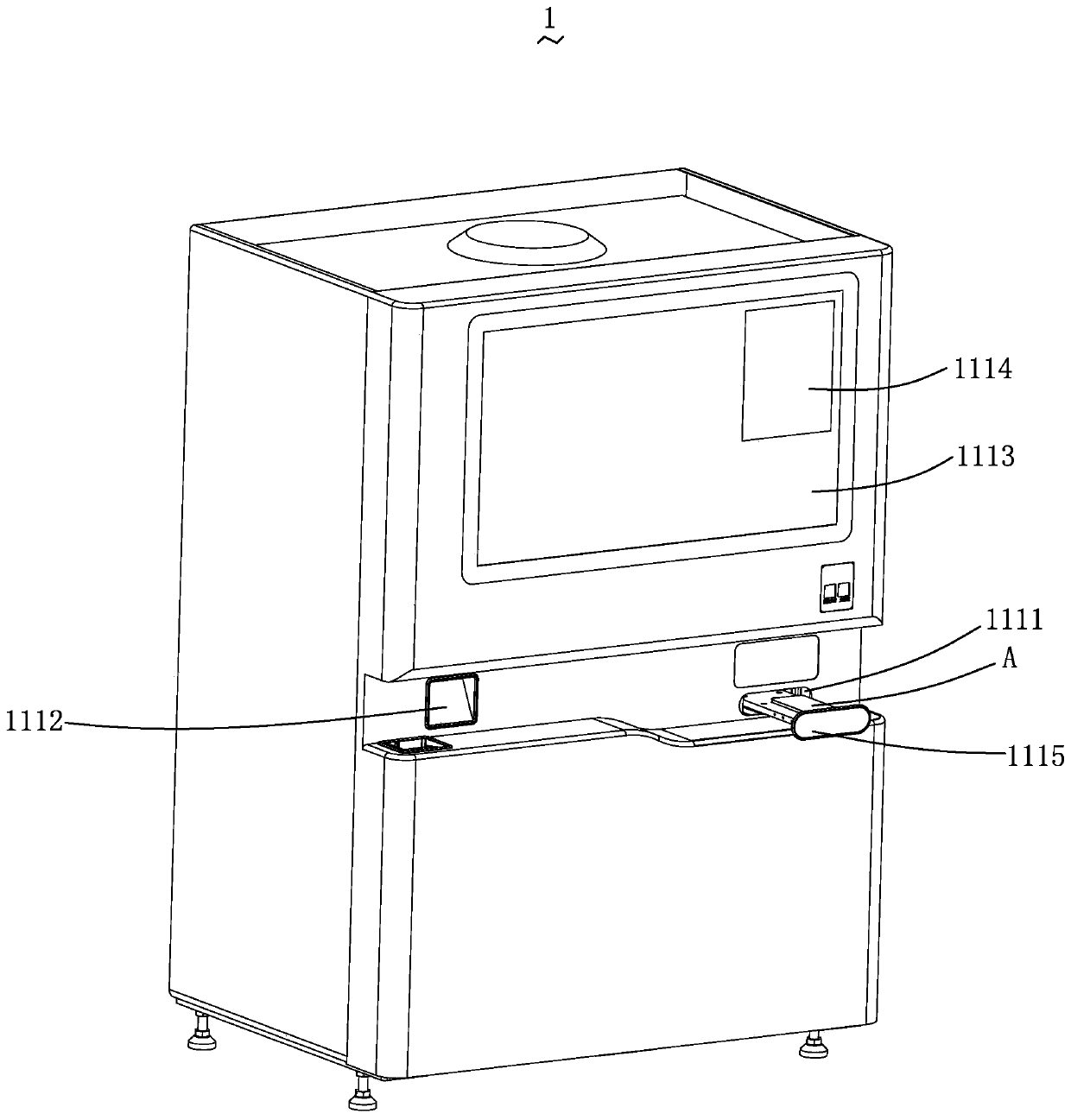

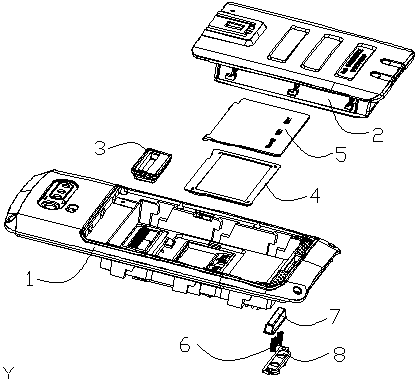

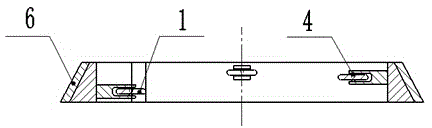

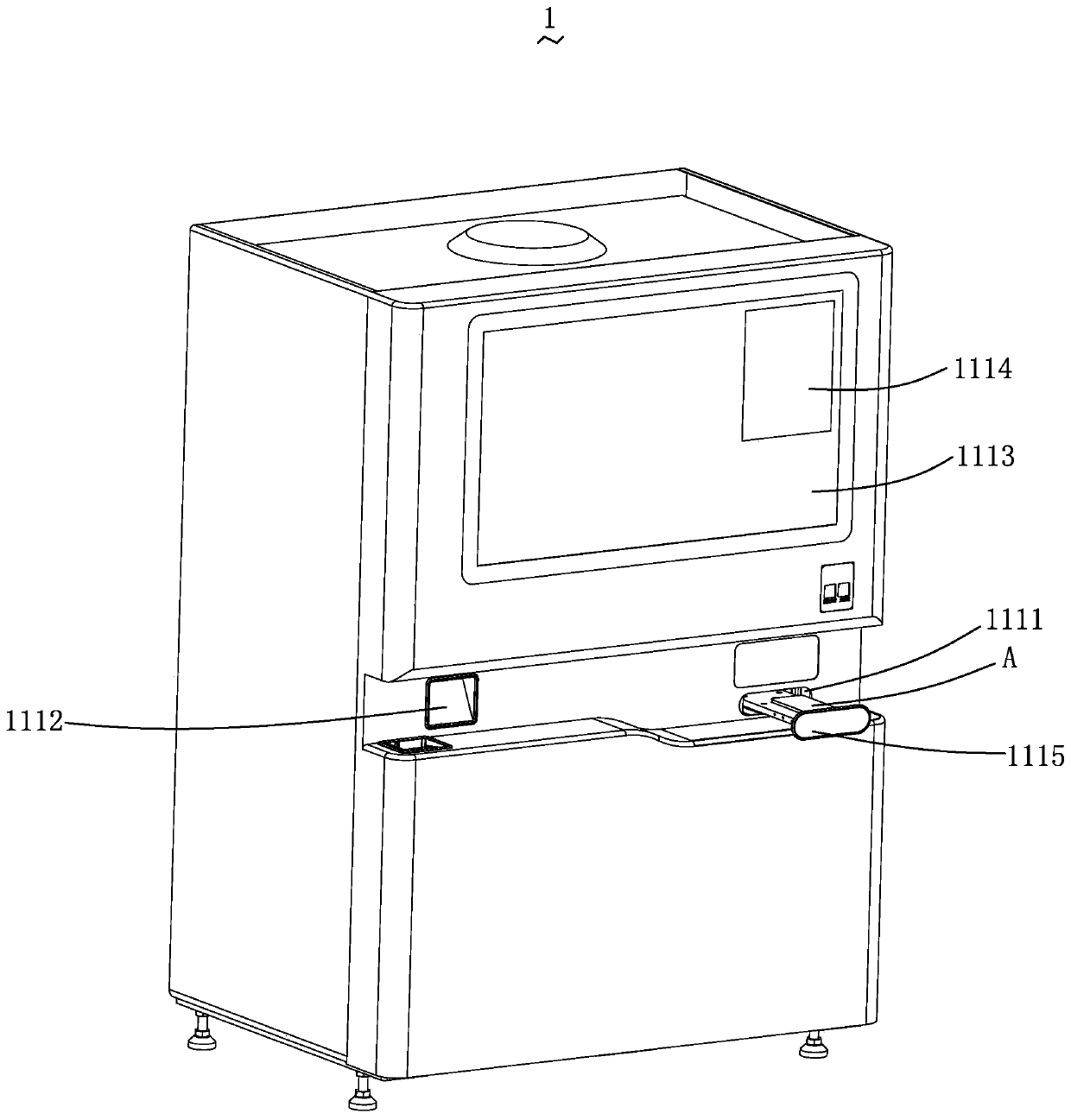

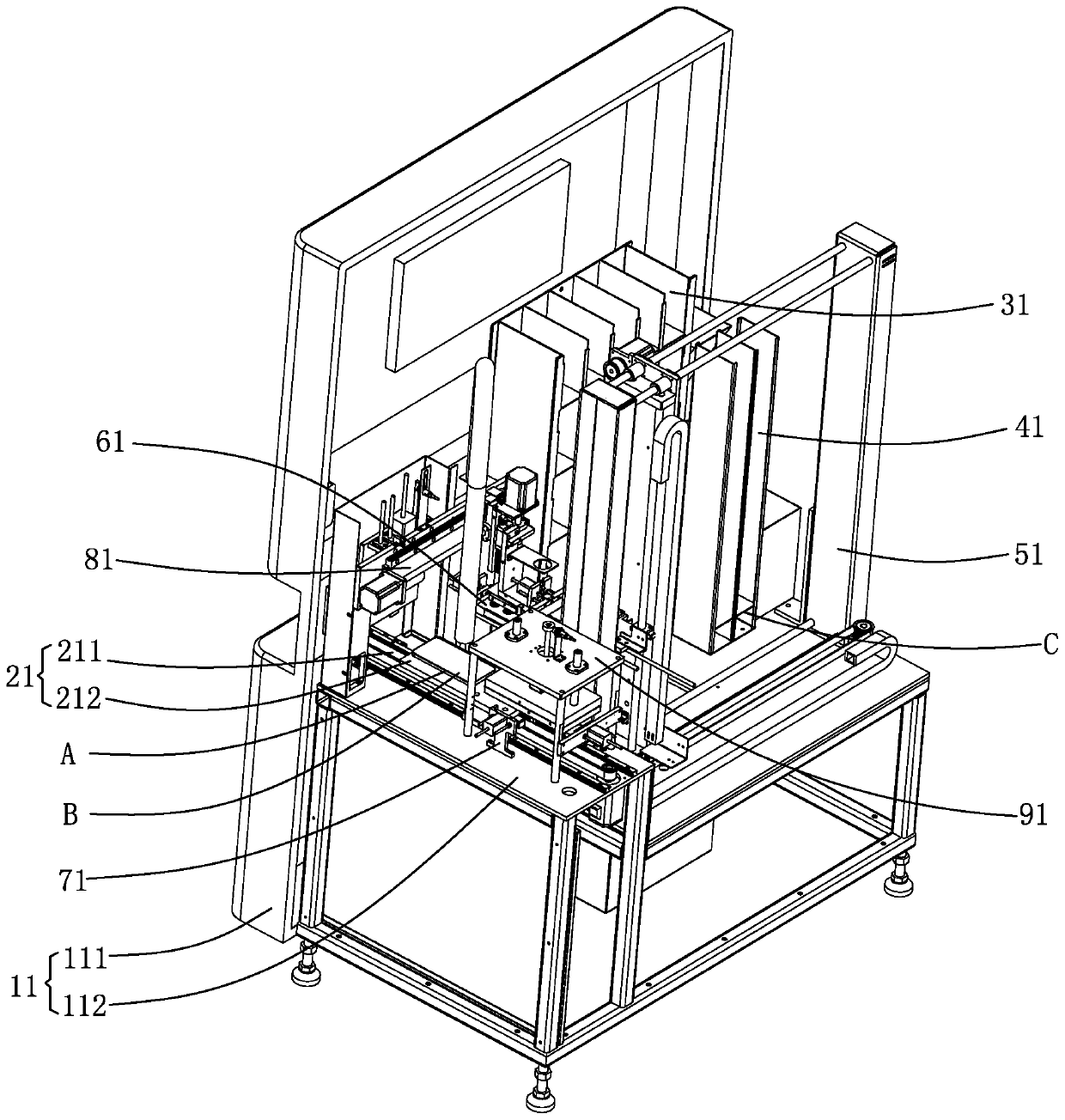

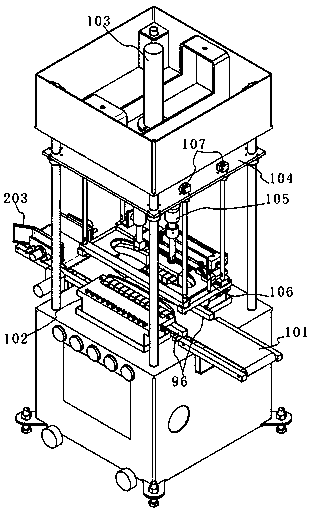

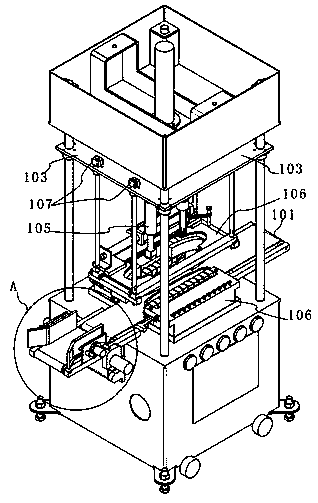

Self-service laminating machine and laminating method thereof

ActiveCN111231296AImprove general performanceMaximize economyFinal product manufactureEngineeringMechanical engineering

The invention relates to a self-service laminating machine which comprises a storing device, a stripping device, a moving device, a positioning device and a laminating device. The storing device comprises a film supply mechanism. Protection films are stored in the film supply mechanism. The stripping device is used for tearing off packaging layers on the protection films. The moving device comprises a conveying mechanism and a moving mechanism for moving electronic equipment and the protection films. The positioning device comprises a first positioning mechanism and a second positioning mechanism for positioning the protection layers and the electronic equipment correspondingly. The laminating device comprises a first laminating mechanism for primarily laminating the positioned protectionlayers on the positioned electronic equipment, and a second laminating mechanism for completing secondary laminating of the protection layers and the electronic equipment. At least one part of each protection layer is laminated through the first laminating mechanism, and at least one part of each protection layer is laminated through the first laminating mechanism and the second laminating mechanism. The invention further provides a laminating method of the self-service laminating machine. The self-service laminating machine and the laminating method therefore can be suitable for laminating different protection films on different types of electronic equipment and are high in universality.

Owner:广州一小时科技有限公司

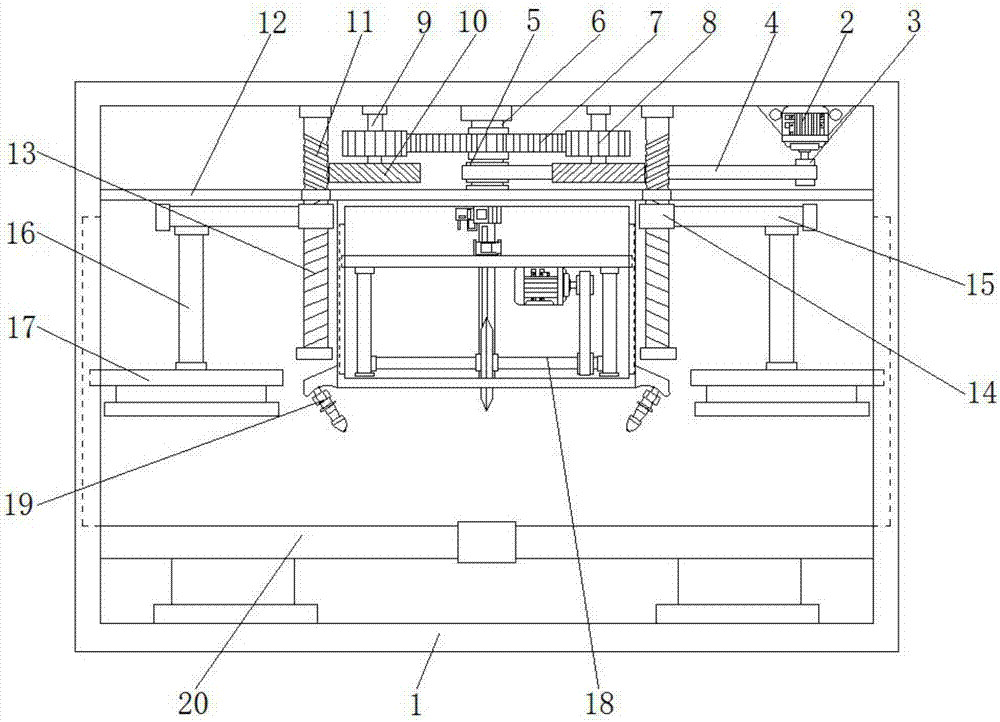

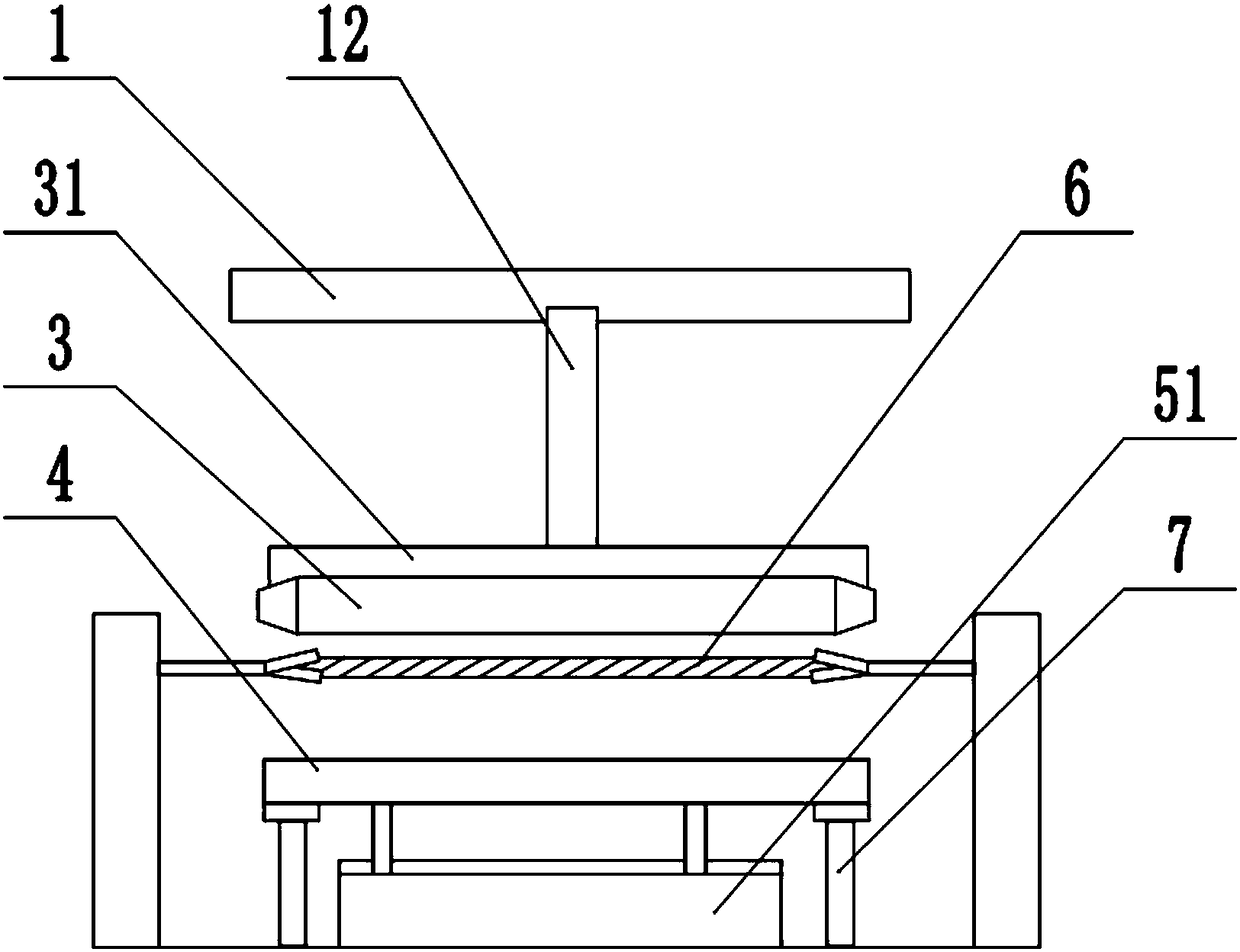

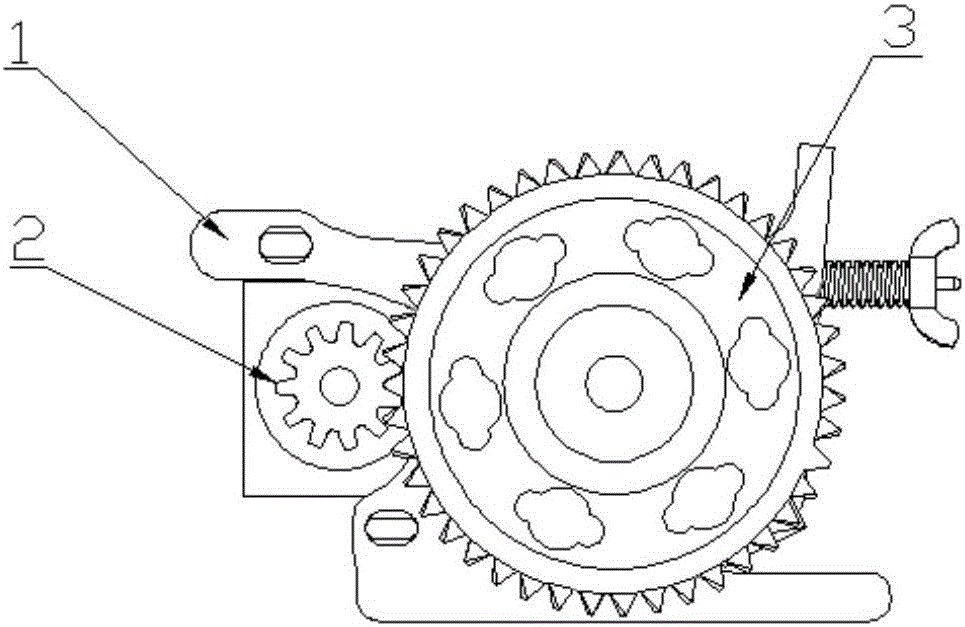

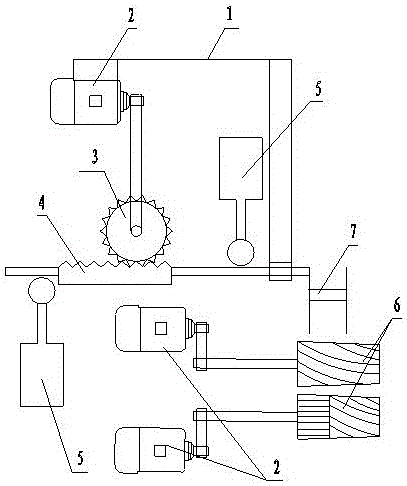

Cutting device having uniform extrusion function

ActiveCN107962249AUniform Squeeze FunctionUniform extrusion forceLarge fixed membersPositioning apparatusGear wheelElectric machinery

The invention discloses a cutting device having a uniform extrusion function. The cutting device comprises a box body; a top plate is fixedly connected between the two sides of the inner wall of the box body; the right side of the top of the inner wall of the box body is fixedly connected with a first motor through a motor base; an output shaft of the first motor is fixedly connected with a firstbelt wheel; the surface of the first belt wheel has transmission connection with a belt; one side, far away from the first belt wheel, of the belt has transmission connection with a second belt wheel;the axis of the second belt wheel is fixedly connected with a supporting shaft; the surface of the supporting shaft has transmission connection with a first gear; and the cutting device disclosed bythe invention relates to the technical field of mechanical cutting equipment. The cutting device having the uniform extrusion function can be used for effectively extruding a material in a cutting process, can also guarantee that the falling speed and the extruding force at the two sides are the same, guarantees that the material is subjected to a uniform extrusion force in the cutting process, guarantees normal proceeding of cutting, reduces unnecessary waste and improves the cutting efficiency.

Owner:广东库迪二机激光装备有限公司

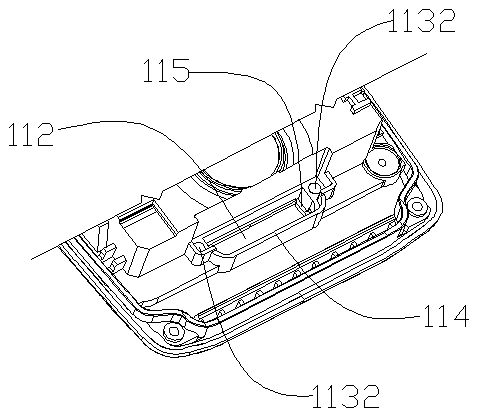

Waterproof structure of card slot position of electronic product

ActiveCN107624014AAchieve waterproofReduce manufacturing precisionHermetically-sealed casingsEngineeringMechanical engineering

The present invention relates to a waterproof structure of a card slot position of an electronic product. The waterproof structure comprises a shell, a cover plate and a second waterproof part. The shell is provided with a second concave surface. The second concave surface is at least provided with a card slot position. The second waterproof part is positioned in the cover plate and surrounds theperiphery of the card slot position. When the card slot position is covered by the cover plate, the cover plate and the second concave surface together extrude the second waterproof part to generate the deformation interference to be connected with the shell as a whole. The cover plate can also be opened from the shell to be separated from the shell. Therefore, a local waterproof structure for thecard slot position is provided. The structure is smaller in waterproof region, so that the waterproof effect is relatively easily guaranteed. Accordingly, the local waterproof structure of the card slot position can achieve the better waterproof effect.

Owner:POWER IDEA TECH (SHENZHEN) CO LTD

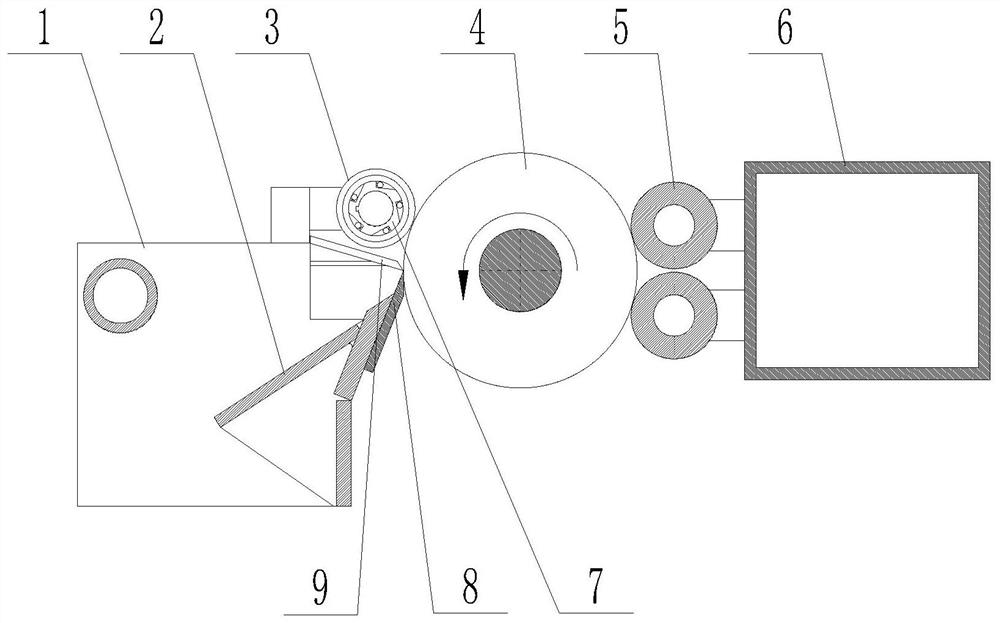

Upper paper guider of printer

ActiveCN102616005AExtended service lifeCompact and reasonable structureOther printing apparatusRubber ringPulp and paper industry

The invention discloses an upper paper guider of a printer, which comprises a mainboard and a star wheel. The star wheel consists of a toothed wheel and a smooth wheel arranged on the toothed wheel by means of injection molding, an elastic shaft penetrates through the star wheel, the star wheel is placed in a mounting groove on the mainboard via the elastic shaft, a press cake is connected onto the smooth wheel of the star wheel in an abutted manner, a groove for holding the toothed wheel is arranged on an end surface of the press cake, which contacts with the star wheel, a compression spring is connected to the top end of the press cake, one end of a compression spring is connected to the top end of the press cake, the other end of the compression spring is connected to the lower side of a pressure plate in an abutted manner, and the pressure plate is fixedly mounted onto the mainboard. The star wheel is elastically fixed onto the mainboard of the upper paper guider, accordingly, the star wheel can be automatically lifted up according to the thickness of a printed medium under the wheel, squeezing force and friction force of a lower paper guiding roller pressing on the printed medium are uniform, abrasion of a rubber ring on the surface of the lower paper guiding roller is reduced, and the upper paper guider is simple in structure, convenient in installation and applicable to equipment such as a laser or ink-jet printer, a copier, a scanner and the like required in printing.

Owner:KONG YUE ELECTRONICS & INFORMATION IND XIN HUI

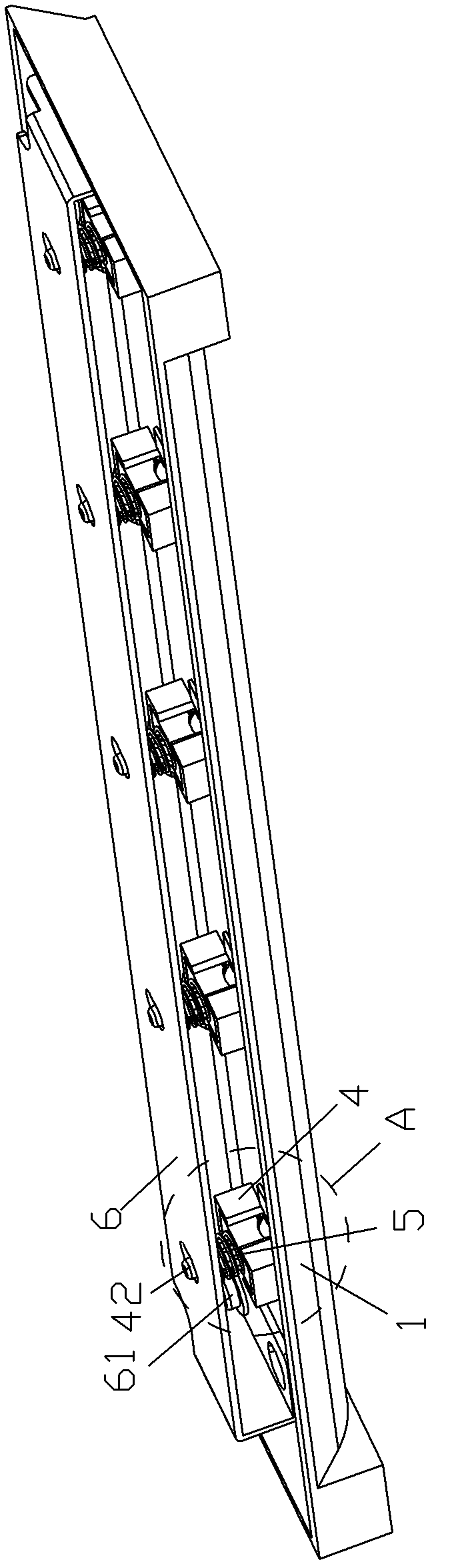

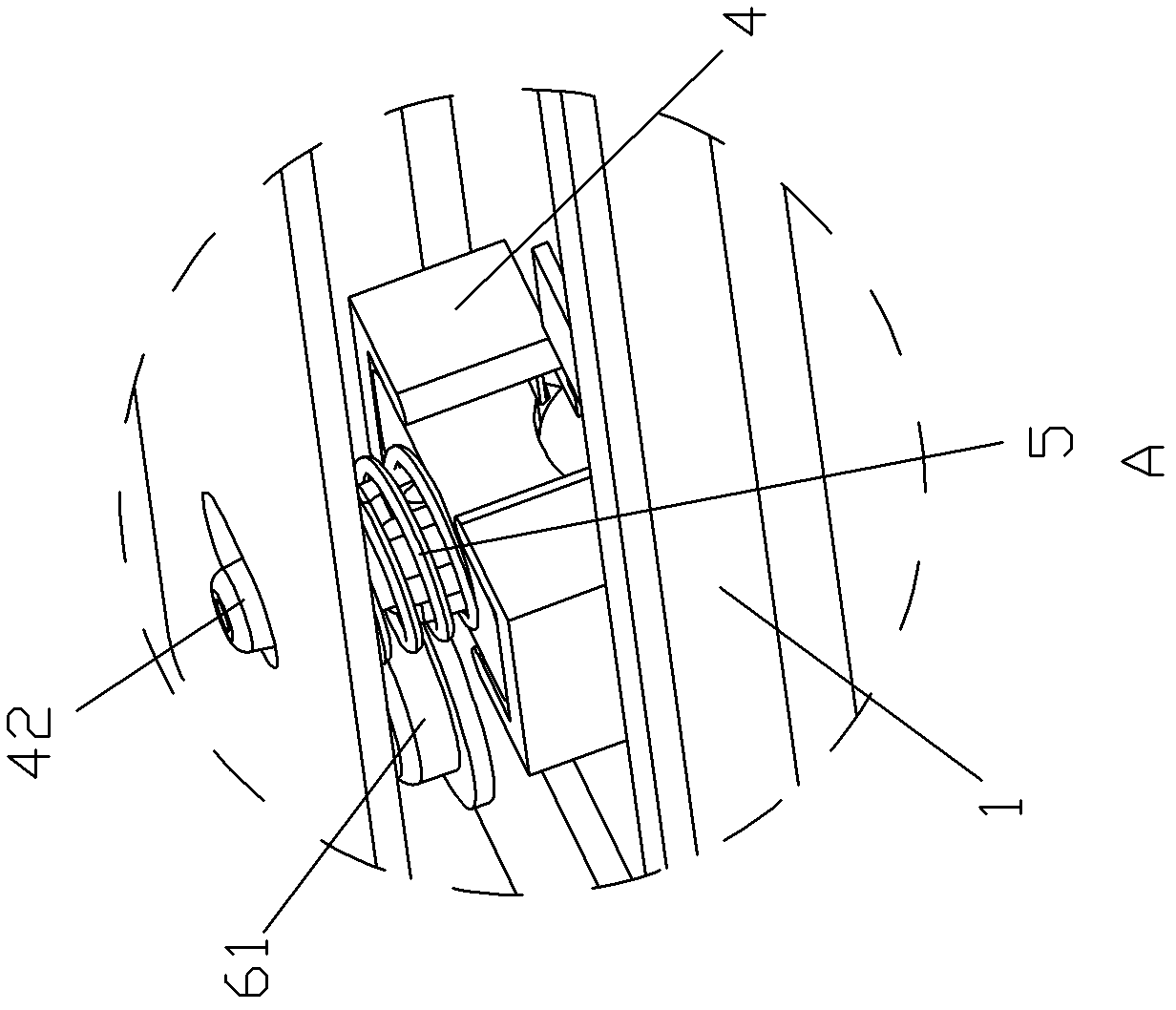

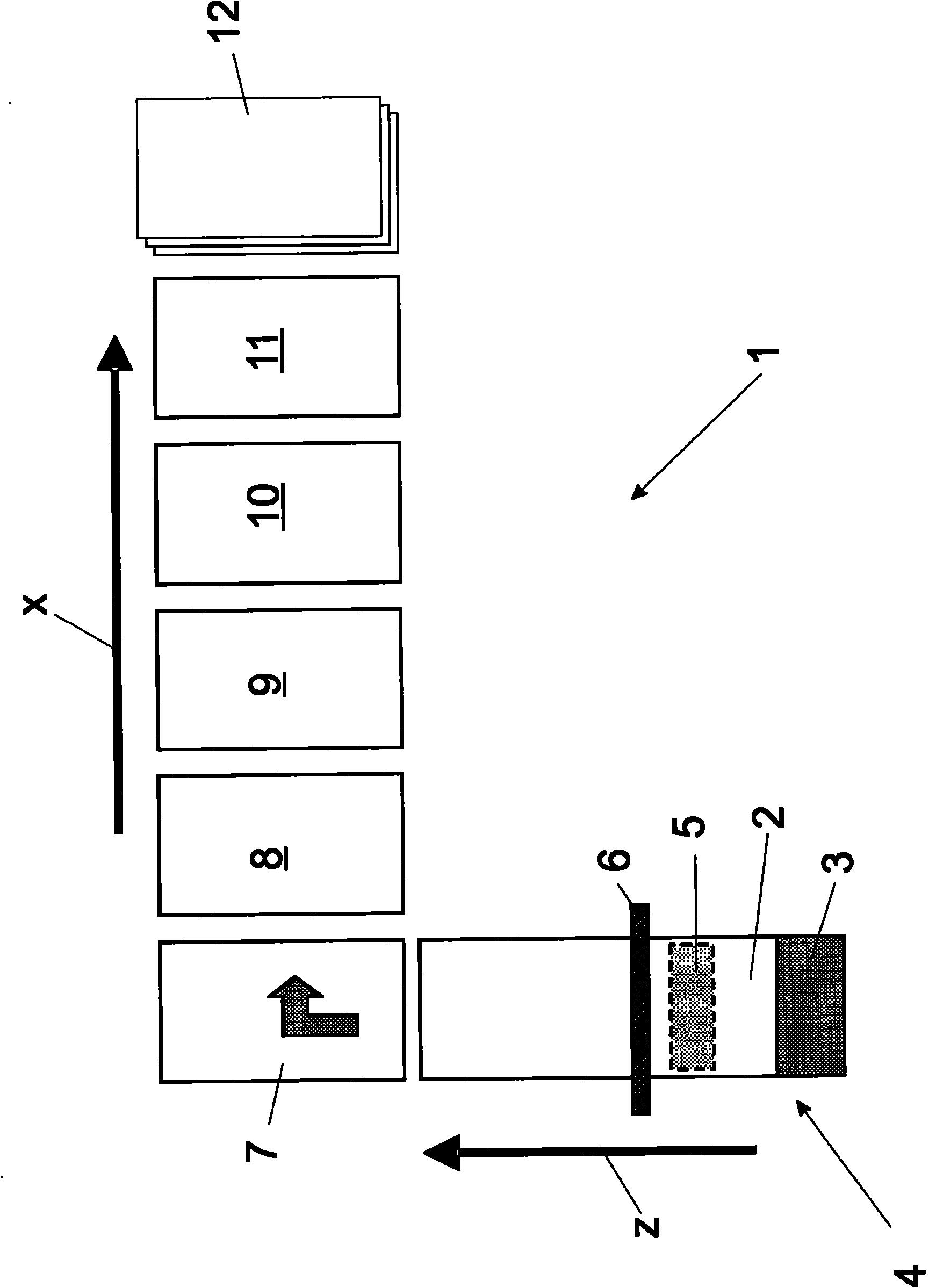

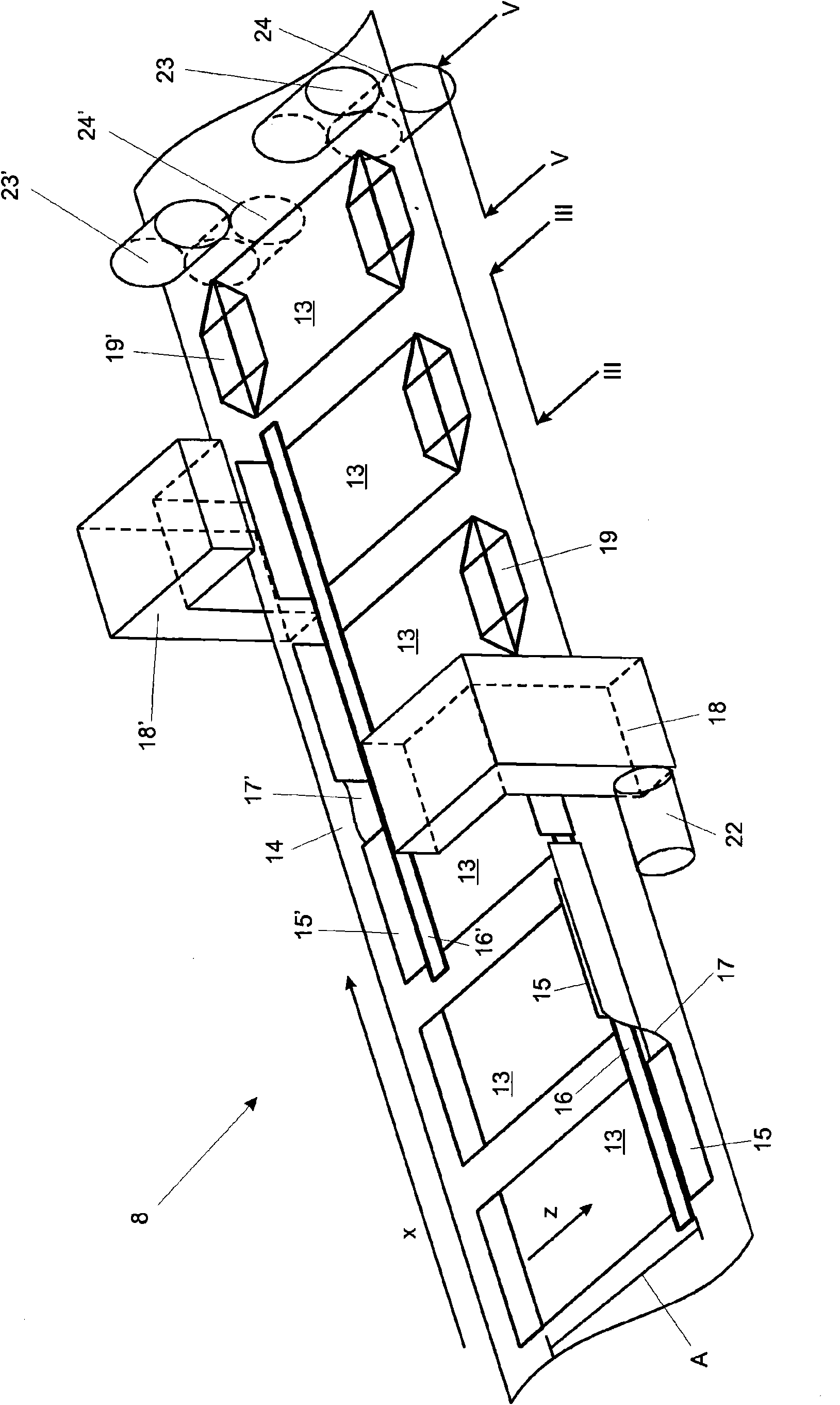

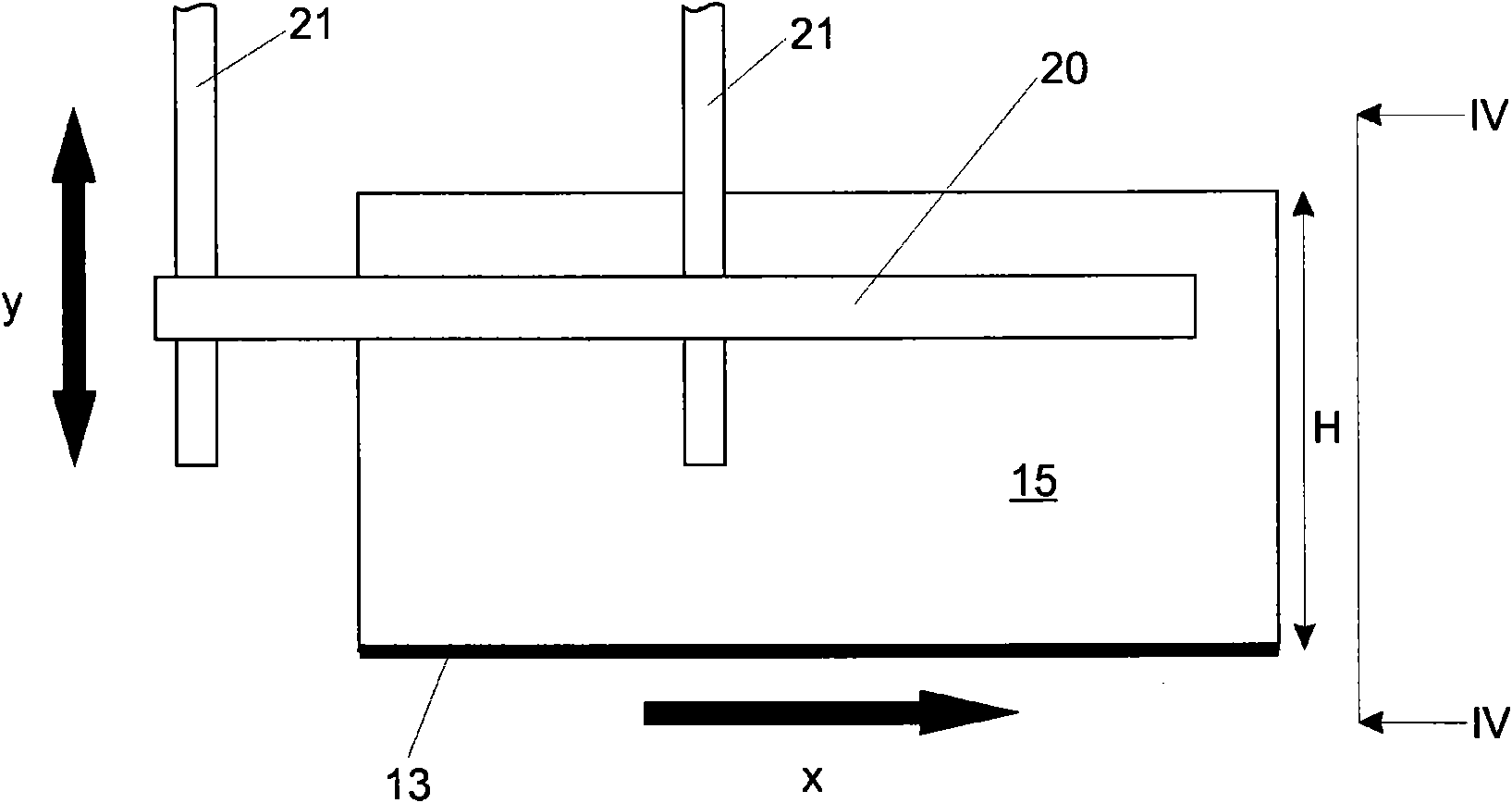

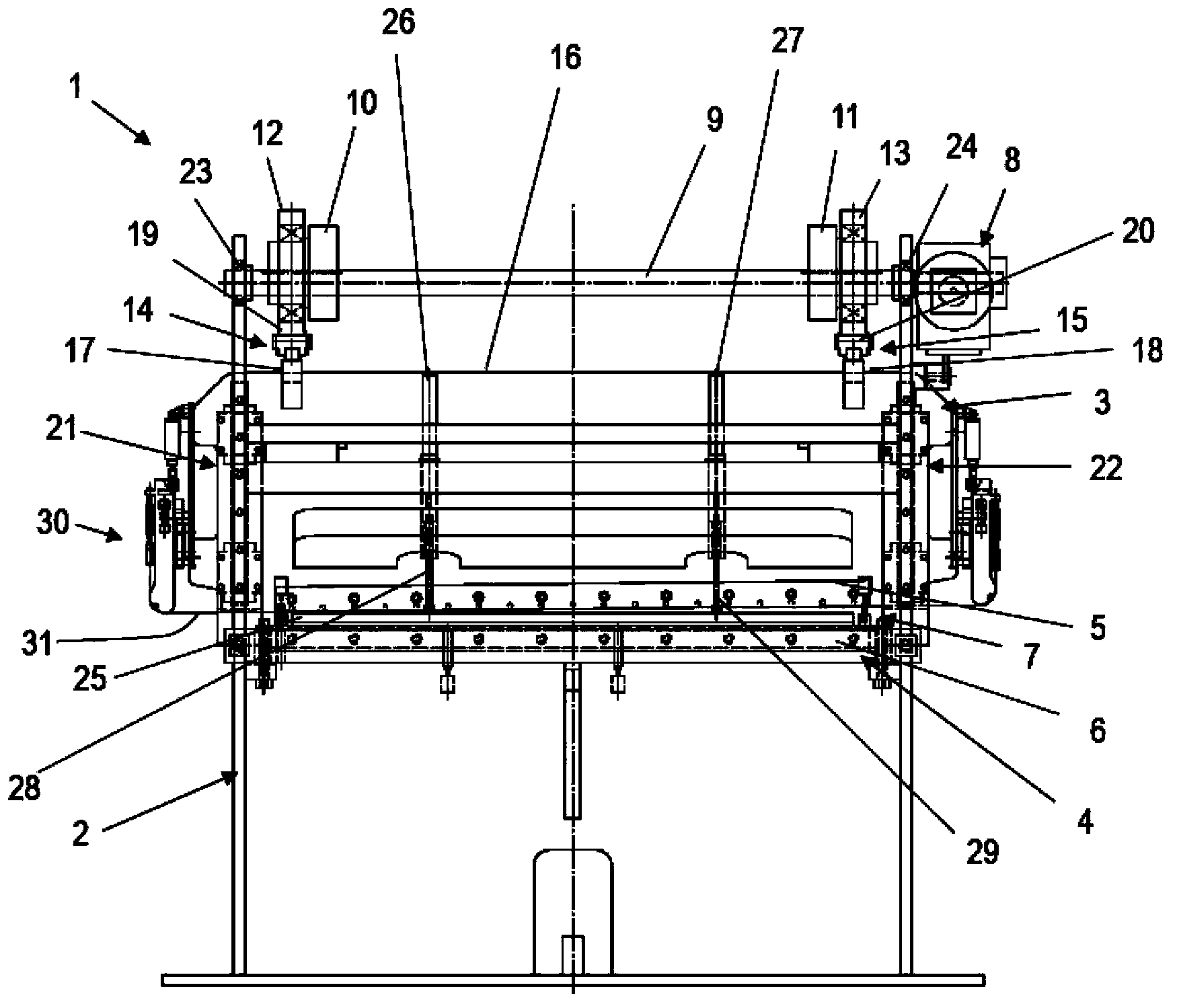

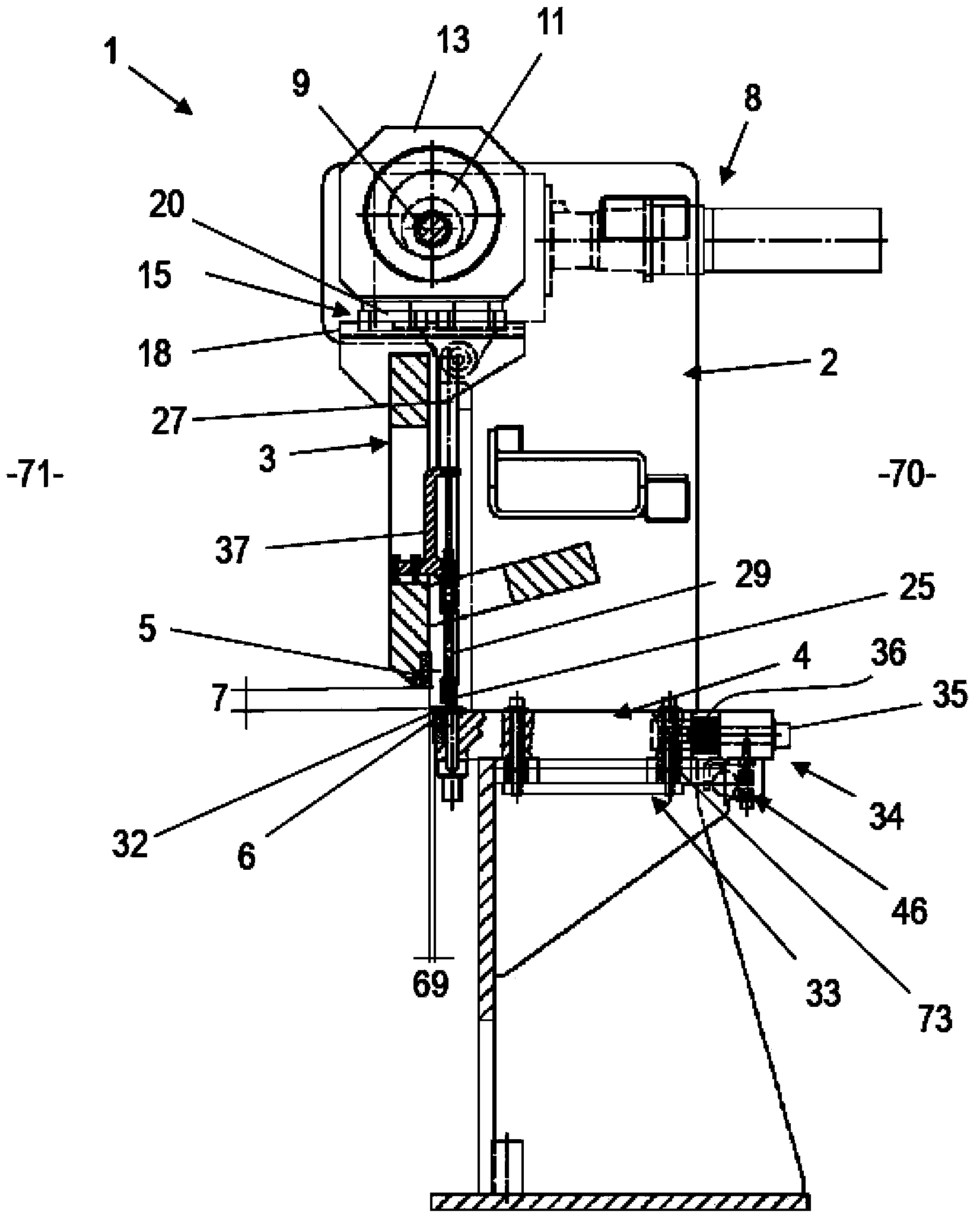

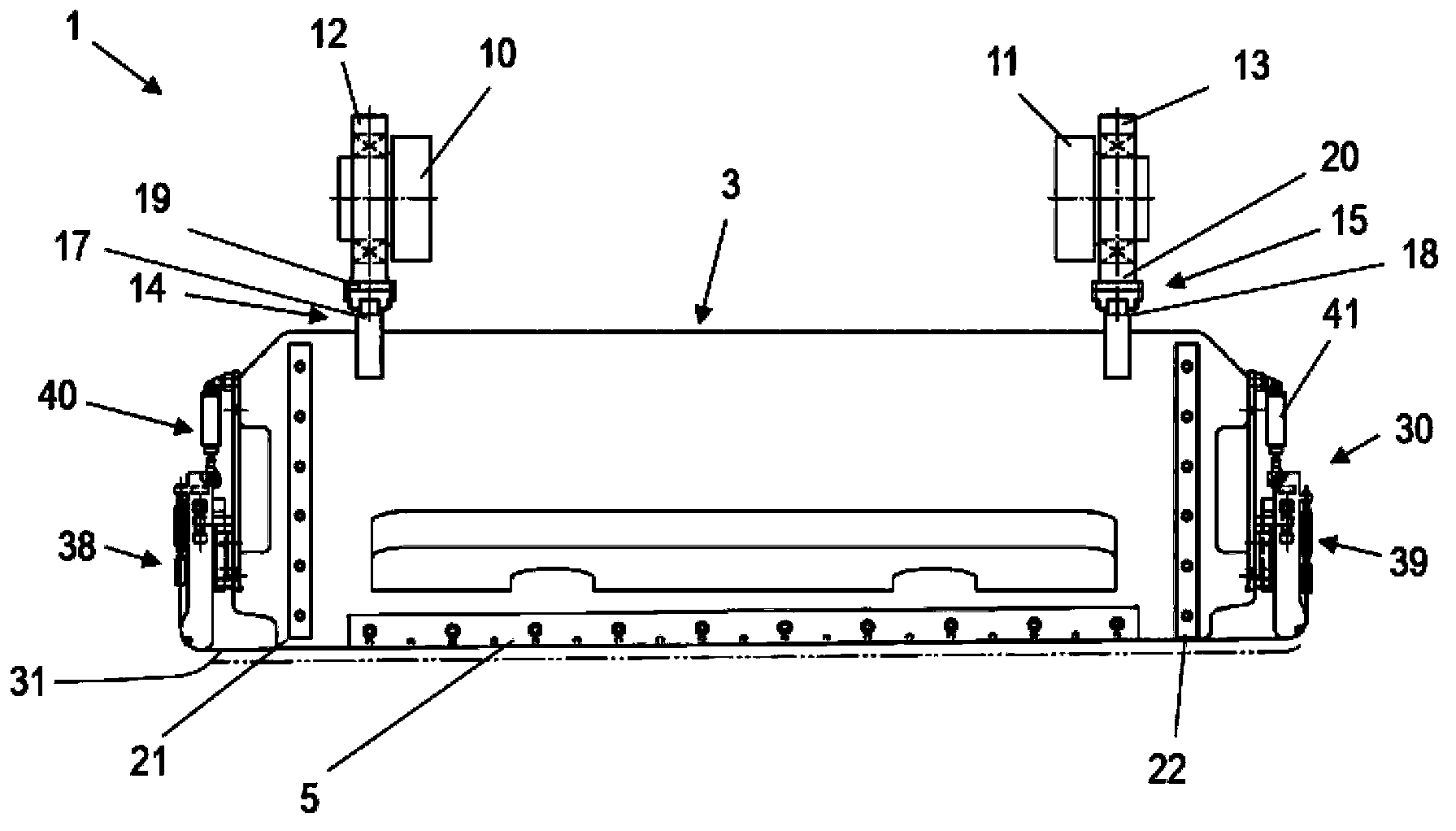

Device and method for producing bags

ActiveCN101983124ADie lowering and raisingGuaranteed to workEnvelopes/bags making machineryBag making operationsMechanical engineeringEngineering

The invention relates to a device for producing bags (1) from pieces (13) of tubing which can be transported in a transport direction (x) transversally to the longitudinal direction of the pieces of tubing by means of the device (1). The pieces (13) of tubing preferably comprise a fabric consisting of stretched plastic strips (2) and consist of two layers of material arranged one above the other. The device comprises the following components: at least one element (8) for opening an end (13) of a piece of tubing, by which means part of the end of the piece of tubing can be folded back onto a wall of the piece of tubing in order to open the end, such that said opened end can be attached to a bottom; and at least one pressure means for pressing at least parts of the opened end against a counter-layer in order to form fold edges. At least one transport means (30) is used to transport the piece of tubing in the direction of transport (x) once an end of said piece of tubing has been opened and before the action of the pressure means.

Owner:WINDMOELLER & HOELSCHER GMBH

Cloth tentering and sizing device

InactiveCN108517643AEven by forceRealize the effect of stenter settingHeating/cooling textile fabricsStretchingEngineeringSizing

The invention relates to the technical field of textile machinery, and discloses a cloth tentering and sizing device which comprises a rack. A plurality of push rod are slidably arranged on the rack;clamping devices are connected to the end parts of the push rods; a slide rod is slidably arranged above the rack; an elongated magnet is arranged on the end part of the slide rod; an elongated iron block corresponding to the elongated magnet is also arranged in the rack. A cloth is clamped through the clamping devices, the slide rod above the rack is pushed to move, the elongated magnet moves synchronously, the elongated iron block and the elongated magnet are attracted with each other under the action of a magnetic force, the cloth is clamped between the elongated magnet and the elongated iron block, the elongated magnet and the elongated iron block produce a uniform extrusion force on the cloth, two ends of the elongated magnet extrude the clamping device during a continuous elongated magnet moving process, and the clamping devices are used for tentering and sizing the clamped cloth parts, so that each part of the cloth is stressed by a longitudinal uniform extrusion force and is subjected to the horizontal tentering and sizing action, and the cloth cover is kept flat.

Owner:宁波希奇服饰有限公司

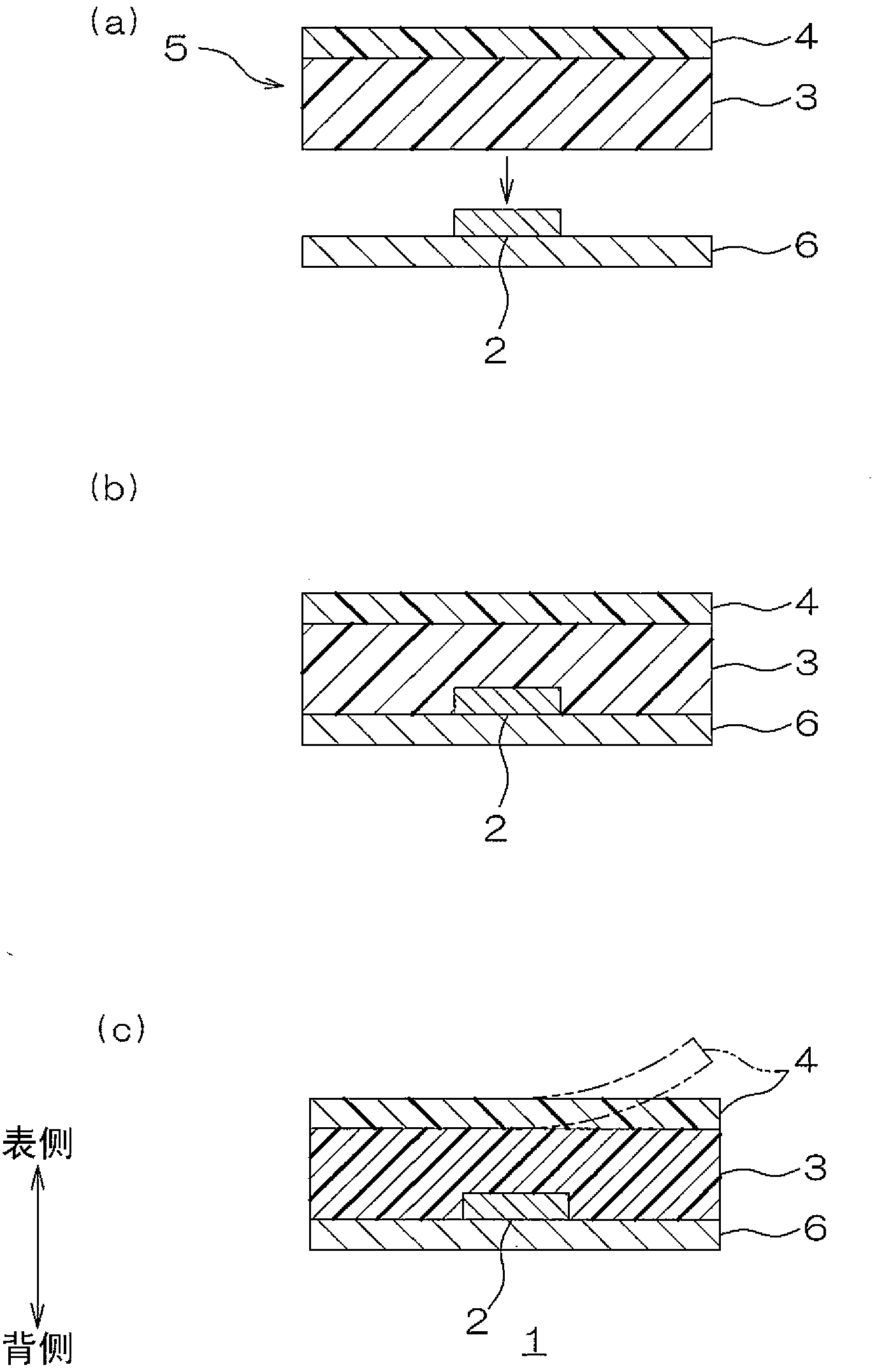

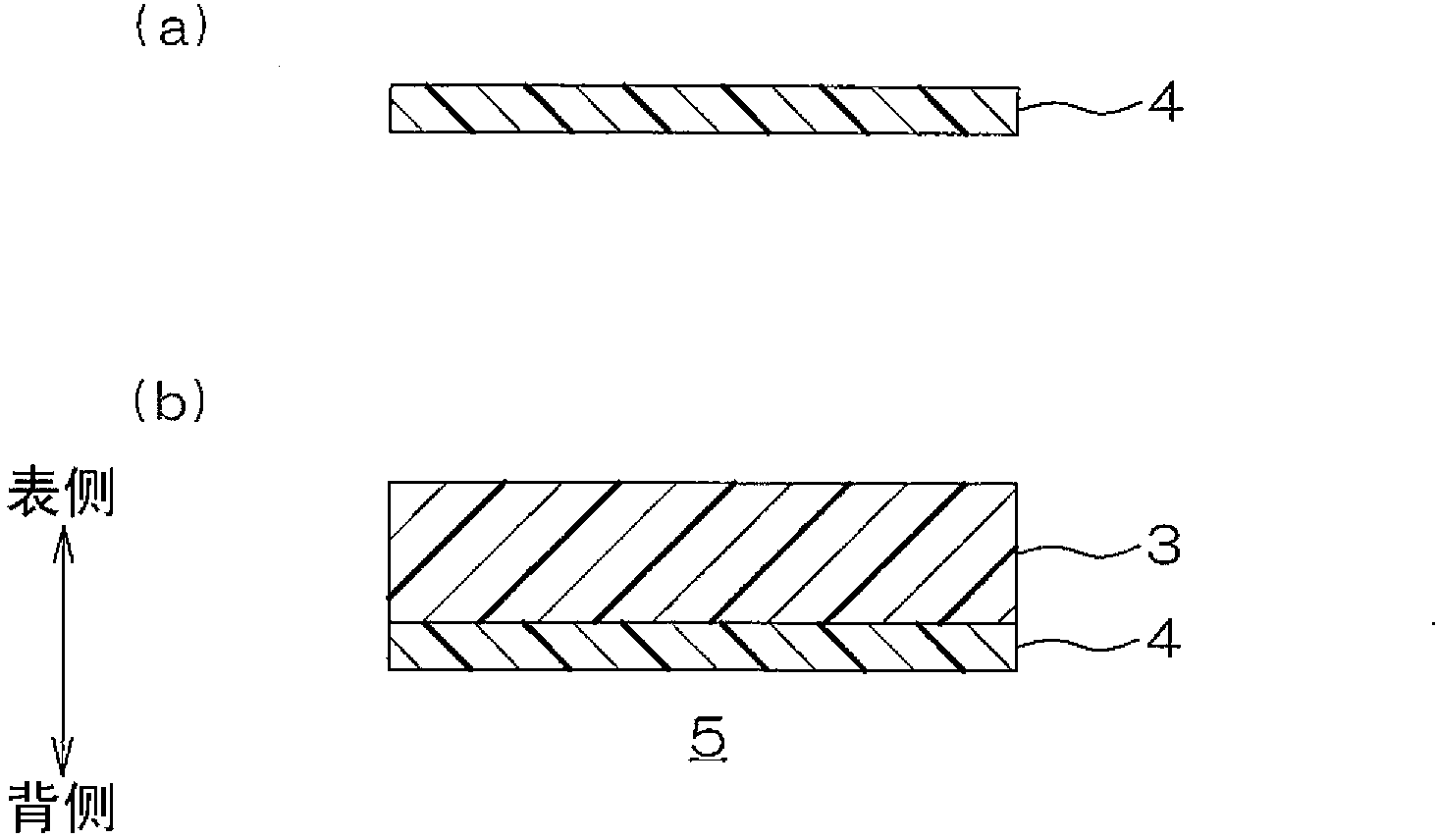

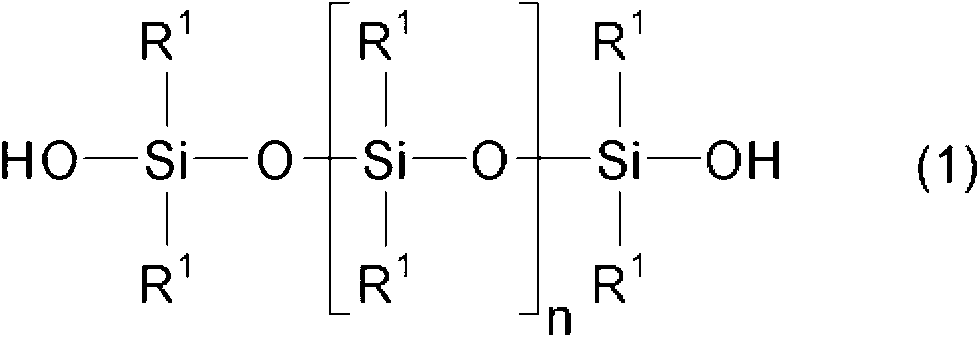

Light emitting diode device and method of producing the same

A method of producing a light emitting diode device (1) includes preparing an encapsulating resin layer; embedding a light emitting diode element in the encapsulating resin layer; and heating while pressing with gas the encapsulating resin layer having the light emitting diode element being embedded therein.

Owner:NITTO DENKO CORP

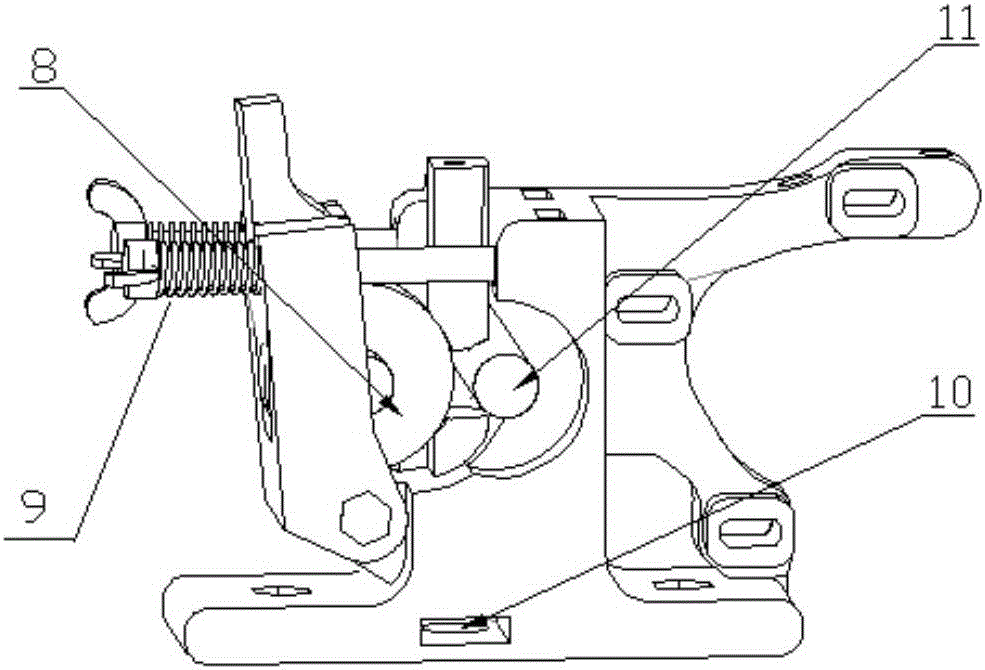

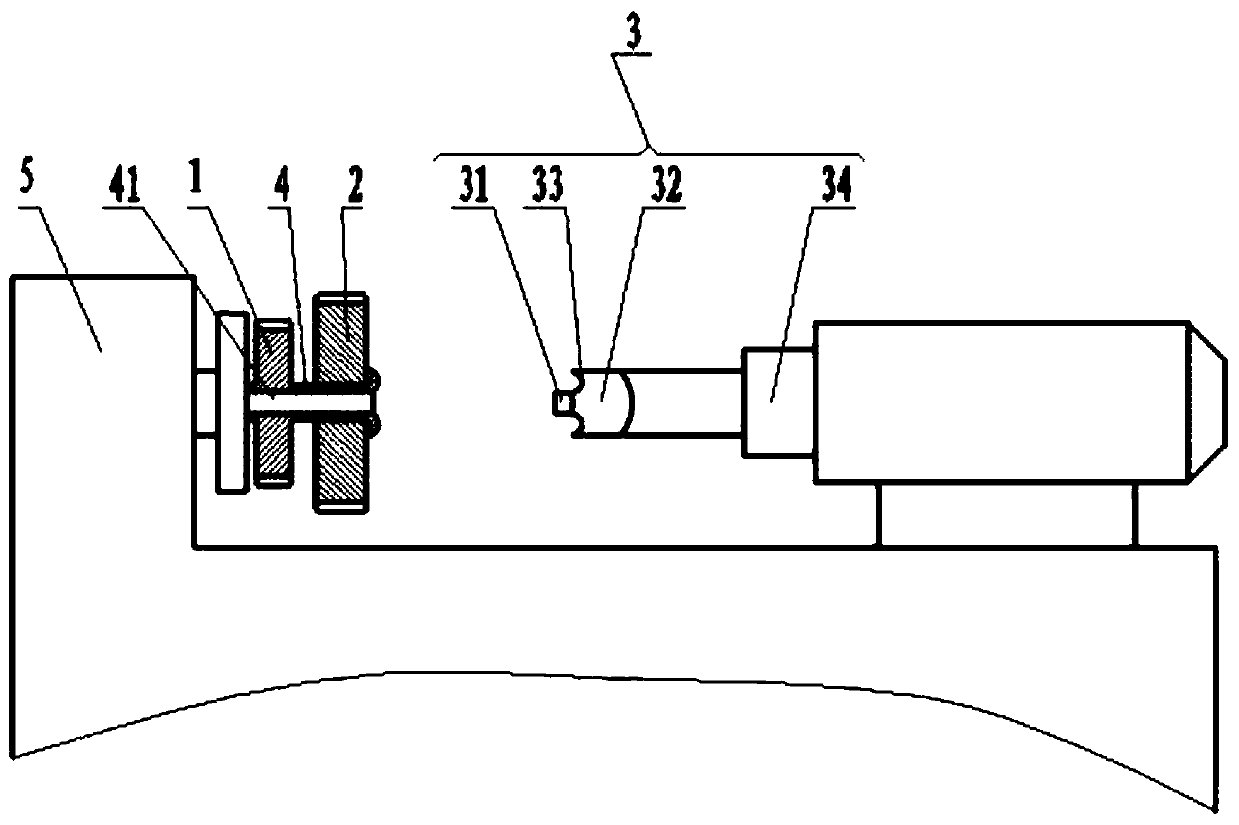

Wade extruder device capable of adjusting extruding force

InactiveCN106426930AEasy to adjustUniform extrusion forceManufacturing driving meansManufacturing data aquisition/processingDrive wheelEngineering

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

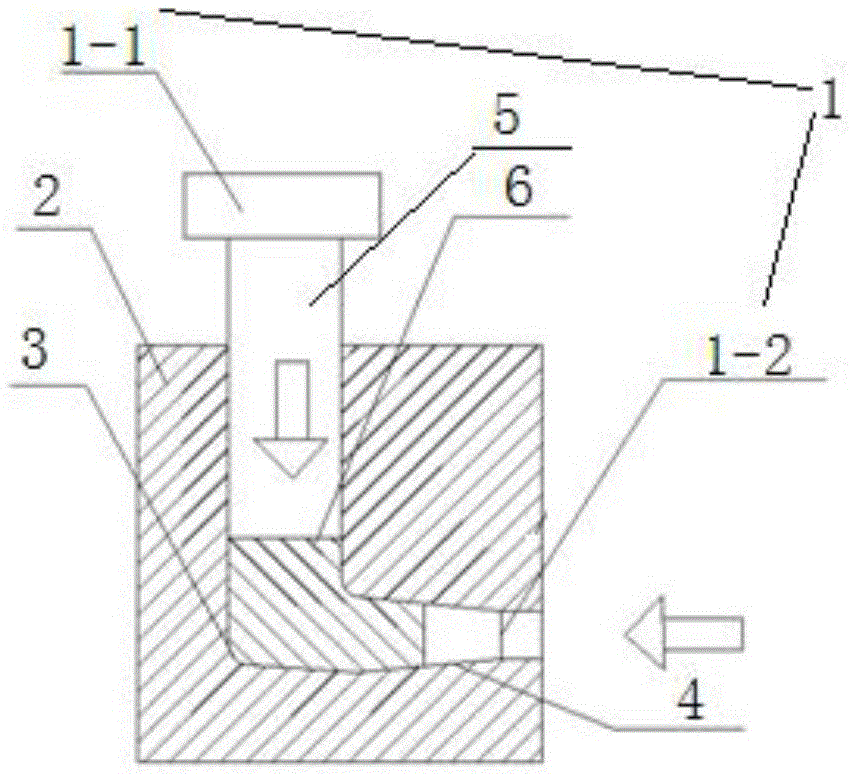

Device for preparing fine grains through variable section angular pressing and method thereof

The invention discloses a device for preparing fine grains through variable section angular pressing and a method thereof. The device comprises a die and a pressing rod. A cylindrical die cavity and a circular truncated cone die cavity are formed in the die. The taper of the circular truncated cone die cavity is alpha. The cylindrical die cavity and the circular truncated cone die cavity communicate mutually. A turn angle is formed in the connection position of the cylindrical die cavity and the circular truncated cone die cavity. Under the action of the pressing rod, a pressed workpiece reciprocates in the cylindrical die cavity and the circular truncated cone die cavity. According to the device disclosed by the invention, the cylindrical die cavity and the circular truncated cone die cavity are combined; the turn angle is formed, so that the pressed workpiece is subjected to continuous integral pressure in the turn angle position, pressing deformation force exerted on the pressed workpiece is more uniform under shear stress, and the grains are improved in fineness and more uniform. Through the pressing method disclosed by the invention, the conditions of nonuniform deformation and even non-deformation of the middle of the workpiece in the cyclic variable section pressing process are eliminated.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

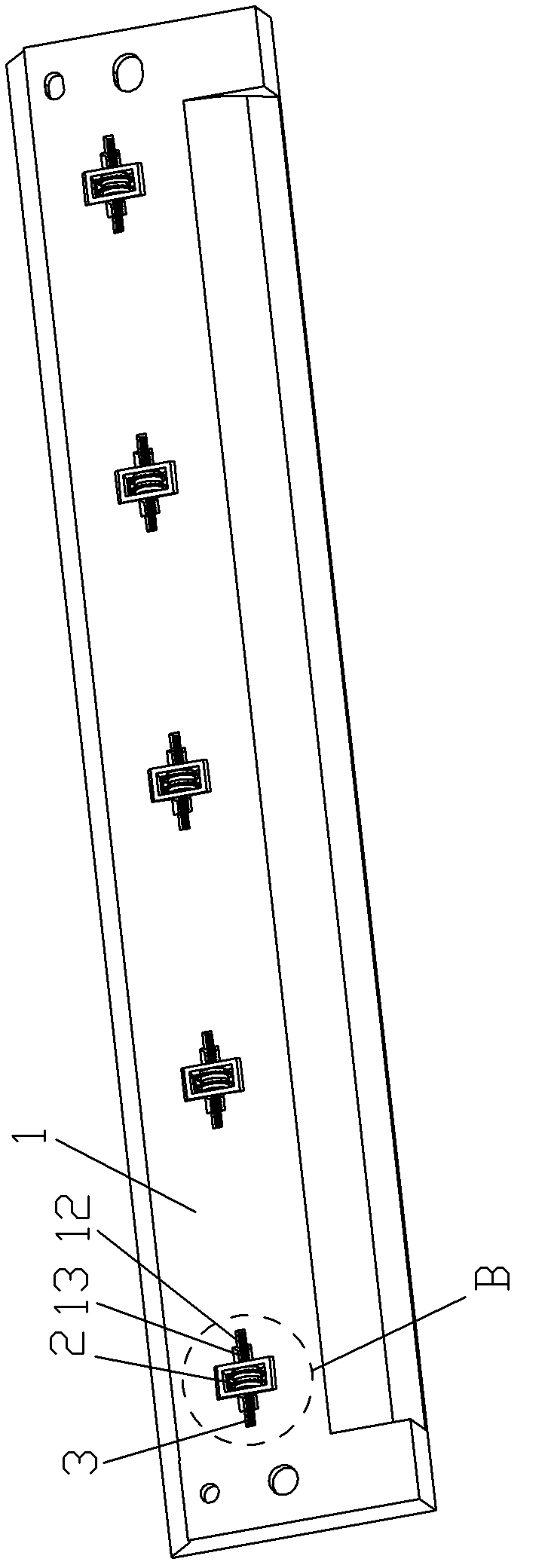

Cutting machine

The invention relates to a cutting machine for cutting sticky ribbons, particularly the ribbon comprises sticky thin cord fabric material comprising spinning silk and / or steel wire. The cutting machine comprises a main frame (2), a knife rest (3), a platen (4) with a lower blade (6), and a driving device (8) with a driving shaft (9), wherein the knife rest (3) with an upper blade (5) can vertically move and support on the main frame (2), a knife edge (7) is arranged between the upper blade (5) and the lower blade (6), the driving device (8) is used for driving the knife rest (3) with the upper blade (5) to vertically move relative to the main frame (2). In order to realize high hardness, the driving shaft (9) eccentrically supports in at least one bearing shell (12 or 13), and the bearing shell only can horizontally move and support on the knife rest (3) through linear guide parts (14 and 15).

Owner:KARL EUGEN FISCHER GMBH

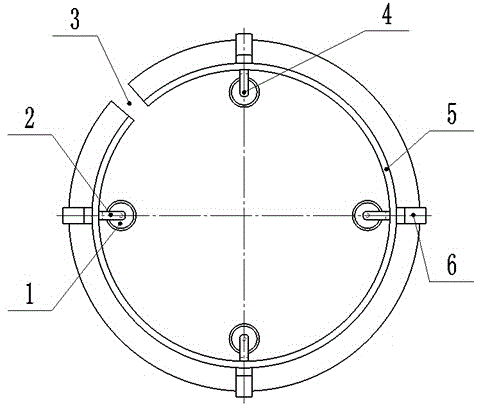

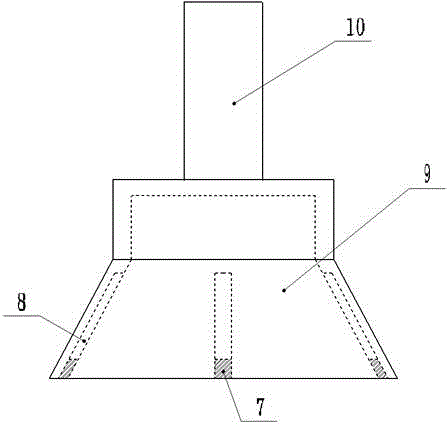

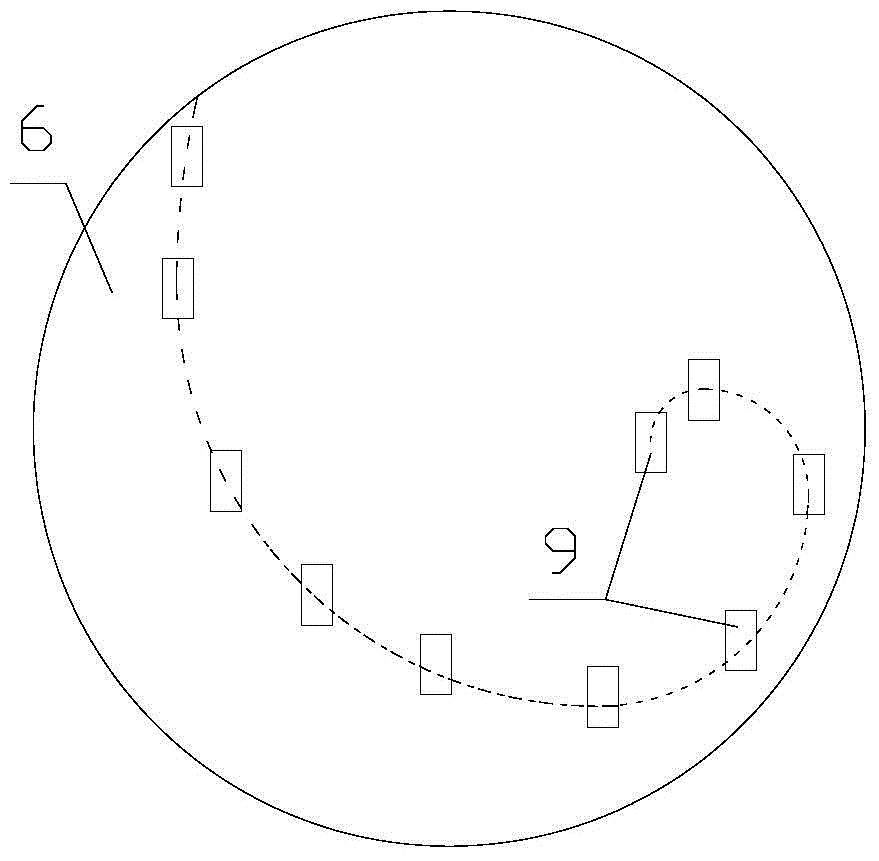

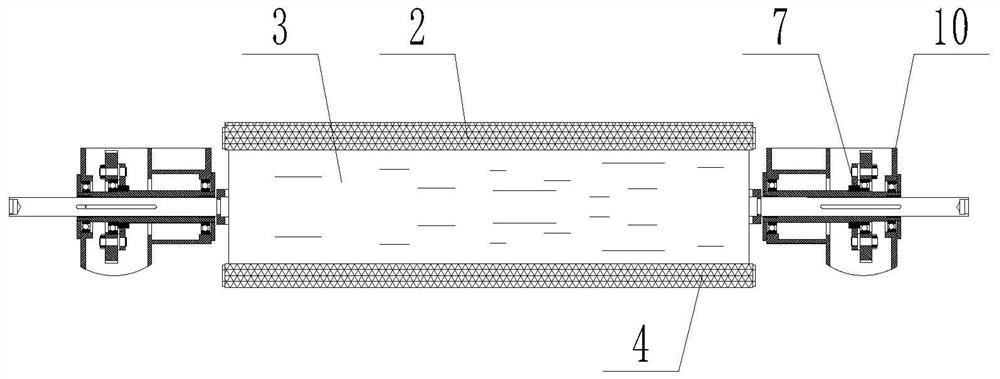

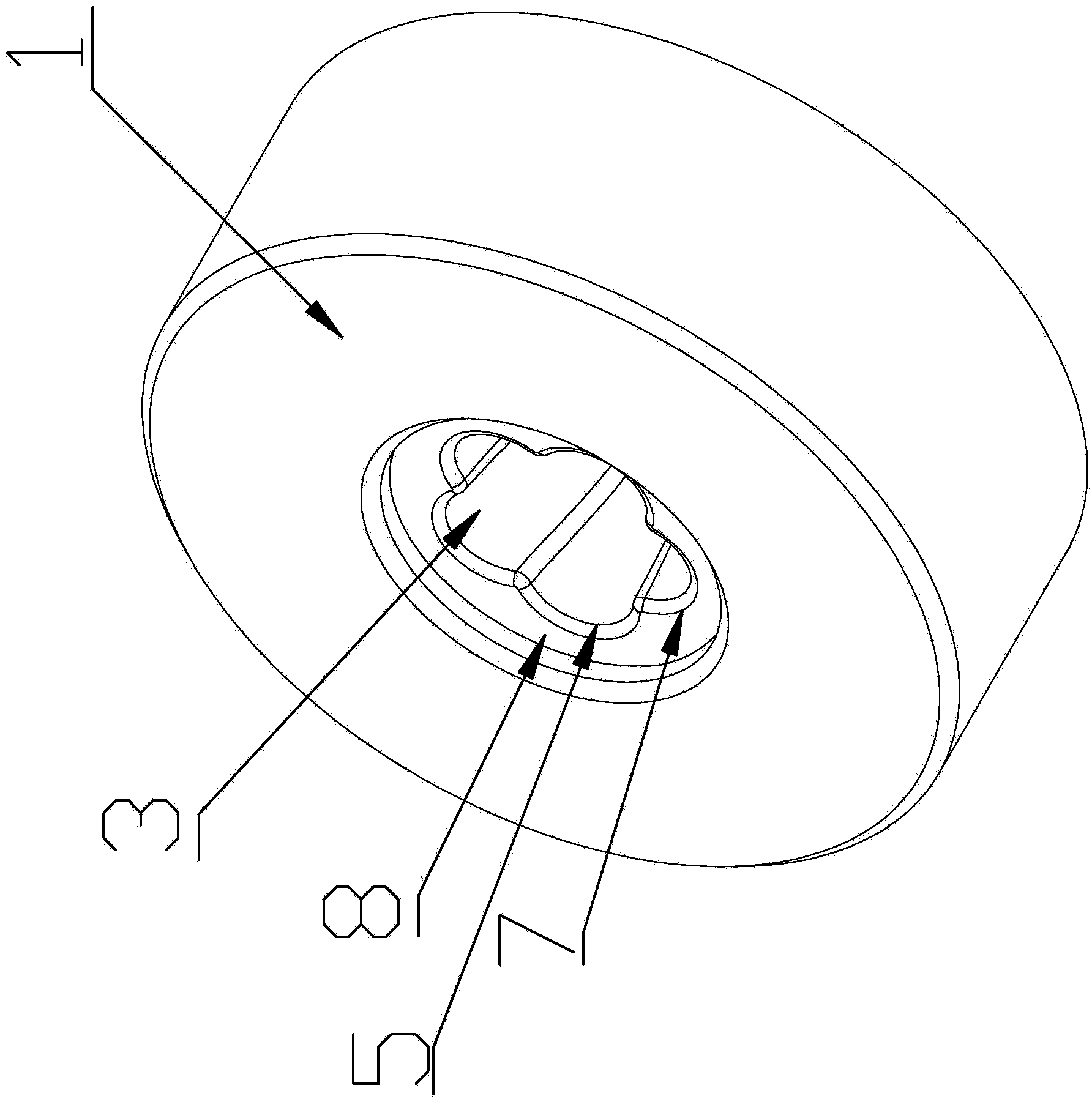

Rolling reinforcement device for large outer thread

ActiveCN104907469AIncrease squeezeUniform extrusion forceScrew-threads articlesProcess equipmentScrew thread

The invention belongs to the technical field of thread reinforcement, and relates to process equipment for machining, in particular to a rolling reinforcement device for a large outer thread. The rolling reinforcement device for the large outer thread is characterized by being provided with an annular rolling body and a rotating body; the annular rolling body is arranged in a rotating body cavity; the rotating body is composed of an upper portion cylinder and a lower portion frustum, the cylinder inner cavity is communicated with the frustum inner cavity, a clamp is arranged at the upper portion of the rotating body, and sliding channels are formed in the wall of the frustum inner cavity; the annular rolling body is provided with rolling wheels, supporting arms, pin shafts, an open ring and sliding bases, the outer wall of the open ring has the taper the same as that of the wall of the frustum inner cavity, the rolling wheels are evenly distributed on the inner side of the open ring through the supporting arms and the pin shafts, the sliding bases are evenly arranged on the outer wall of the open ring, the sliding bases are arranged in the sliding channels and matched with the sliding channels in a sliding mode. The rolling reinforcement device for the large outer thread is reasonable and simple in structure, and a method is advanced and scientific. By means of the rolling reinforcement device for the large outer thread, the extrusion force is larger and more uniform, and the rolling reinforcing effect on the large outer thread is better.

Owner:YANGZHOU UNIV

Oil press

The invention discloses an oil press. The oil press comprises a frying part and an oil pressing part. The frying part comprises a frying box, a first motor and a transmission shaft, wherein a material port used for adding materials and discharging materials is formed in the frying box, a sealing cover is arranged at the material port, and a cover plate is arranged one side face of the frying box; the first motor is in transmission connection with the transmission shaft, one end of the transmission shaft is arranged in the frying box, a main spiral stirring shaft is arranged at the end, located in the frying box, of the transmission shaft in the axial direction of the transmission shaft, the included angle theta between the lower surface of the main stirring blade and the plane perpendicular to the axial direction of transmission shaft ranges from 5 degrees to 10 degrees, the length, in the radial direction of the transmission shaft, of the main stirring blade is 1.5D-2D, and D is the diameter of the transmission shaft; a plurality of auxiliary stirring blades are arranged on the inner wall of the frying box, and the auxiliary stirring blades are spirally distributed with the axial direction of the transmission shaft as the center; a plurality of material blocking plates are arranged on the cover plate, and the line connecting the centers of the material blocking plates form an Achimedean spiral; the material blocking plates extend in the axial direction of the transmission shaft. The oil press is good in oil pressing effect.

Owner:BENGBU QIONGHUAI GRAIN & OIL

Isostatic pressing forming method and forming mold for ceramic roller bars

The invention discloses an isostatic pressing forming method and forming mold for ceramic roller bars, and relates to the field of isostatic pressing forming. The isostatic pressing forming mold comprises a bottom plate, a feeding assembly, an outer mold, an inner mold, a pressurizing assembly, a movable block, a pushing assembly, a fixed block, a first hydraulic bag, a second hydraulic bag, an exhaust pipe and feeding pipes, wherein the feeding assembly is mounted at one end of the top side of the bottom plate, the fixed block is installed on the top side of the bottom plate, the movable block is installed on the pushing assembly, and the inner mold is fixedly connected to the movable block. Through the arrangement of the feeding assembly, materials in a material hopper enter a feeding cylinder through a material guiding pipe, when a piston disc descends, the materials are discharged through discharging pipes, under the cooperation of six feeding pipes, filling of the materials can beachieved; the gap between the outer mold and an inner mold can be filled, through one-way injection material filling, gas mixing is reduced, the gas content is reduced, the compactness of blanks is improved, and through guide-in and synchronous filling of the six discharging pipes arranged in a surrounding mode, uneven material filling is avoided, and filling is more balanced.

Owner:合肥陶陶新材料科技有限公司

Tire port ring automatic rubber removing machine for preparing high-performance steel shots

InactiveCN106363834ASmooth rotationUniform extrusion forcePlastic recyclingEngineeringMechanical engineering

The invention provides a tire port ring automatic rubber removing machine for preparing high-performance steel shots. The machine consists of a frame, a speed adjusting motor, a gear, a rack, a proximity switch, an extruding roller, a push feeder and a controller; the extruding roller takes the shape of a conical table, one part is cylindrical, and the other part takes the shape of a conical table; a linear groove is convenient for extrusion; an inclined groove is convenient for a tire to enter and retreat from the extruding roller; the proximity switch controls the travel of the push feeder; one of a pressure or contact photoelectric sensor is arranged on the extruding roller; when the tire is contacted with the extruding roller, the extruding roller rotates; when the tire totally retreats from the extruding roller, the extruding roller stops operating; the rack and the push feeder are arranged on a movable rod; the push feeder is deviated from the extruding roller; the tire is positioned on the push feeder; then, the push feeder drives the tire to move; and when the extruding roller is contacted, the extruding roller rotates, the tire enters the extruding position of the extruding roller, the push feeder is stopped, and the extruding roller extrudes a tire port ring to deviate from the tire.

Owner:于海双

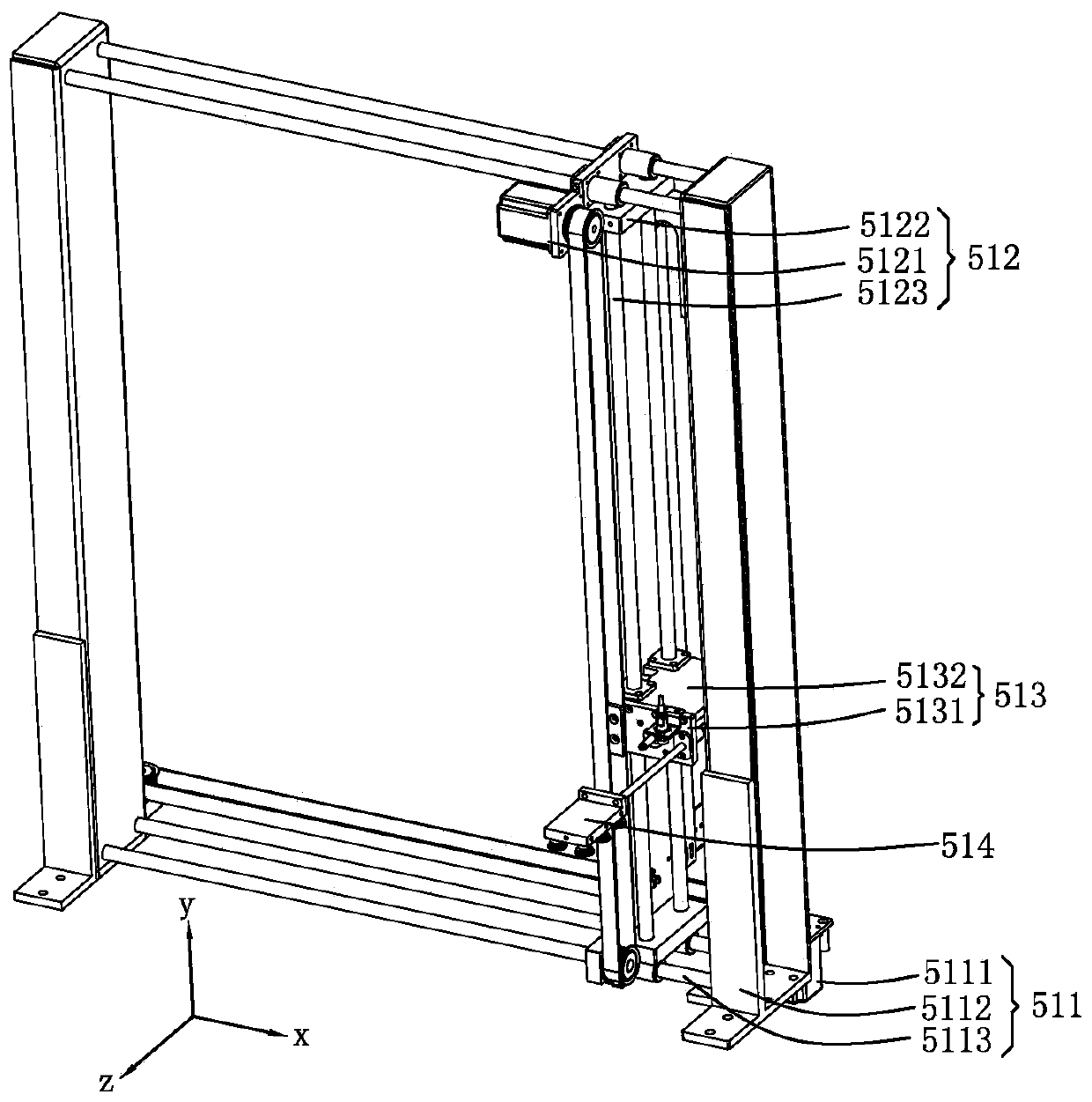

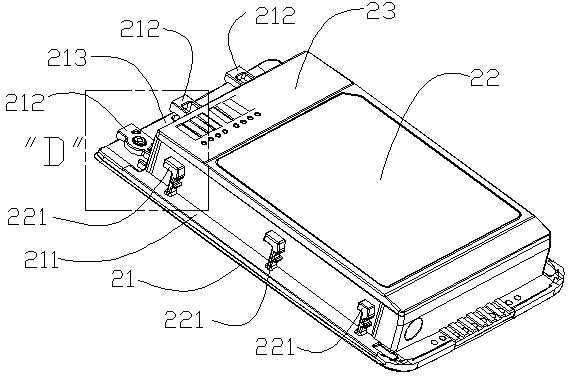

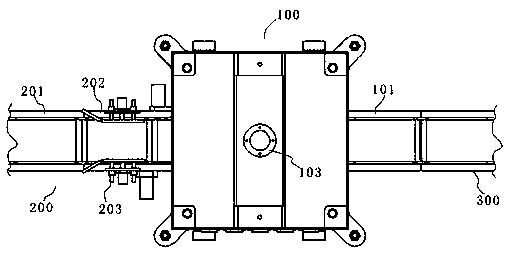

Self-service film pasting machine and film pasting method thereof

ActiveCN111113881AUniform extrusion forceImprove fit tightnessFinal product manufactureEngineeringService mode

The invention relates to a self-service film pasting machine which is used for pasting protective layers to different electronic equipment in a self-service mode. The self-service film pasting machinecomprises a first positioning device, a second positioning device, a first film pasting device and a second film pasting device, wherein the first positioning device and the second positioning deviceare mutually independent, and the first film pasting device and the second film pasting device are mutually independent; the first positioning device is used for positioning the protective layer, andthe second positioning device is used for positioning the electronic equipment; the first film pasting device obtains the protective layer from the first positioning device and pastes the protectivefilm to the positioned electronic equipment to complete primary pasting of the protective layer and the electronic equipment; and the second film pasting mechanism comprises a cavity cover, a cavity capable of containing different electronic equipment is formed in the cavity cover, and an air bag is arranged in the cavity to extrude the protective layer on the electronic equipment contained in thecavity so as to carry out secondary pasting. The invention further provides a film pasting method of the self-service film pasting machine, and the self-service film pasting machine and the film pasting method thereof have the advantages of being tight in pasting, free of bubbles and the like.

Owner:SHENZHEN BNT INTELLIGENT TECH CO LTD

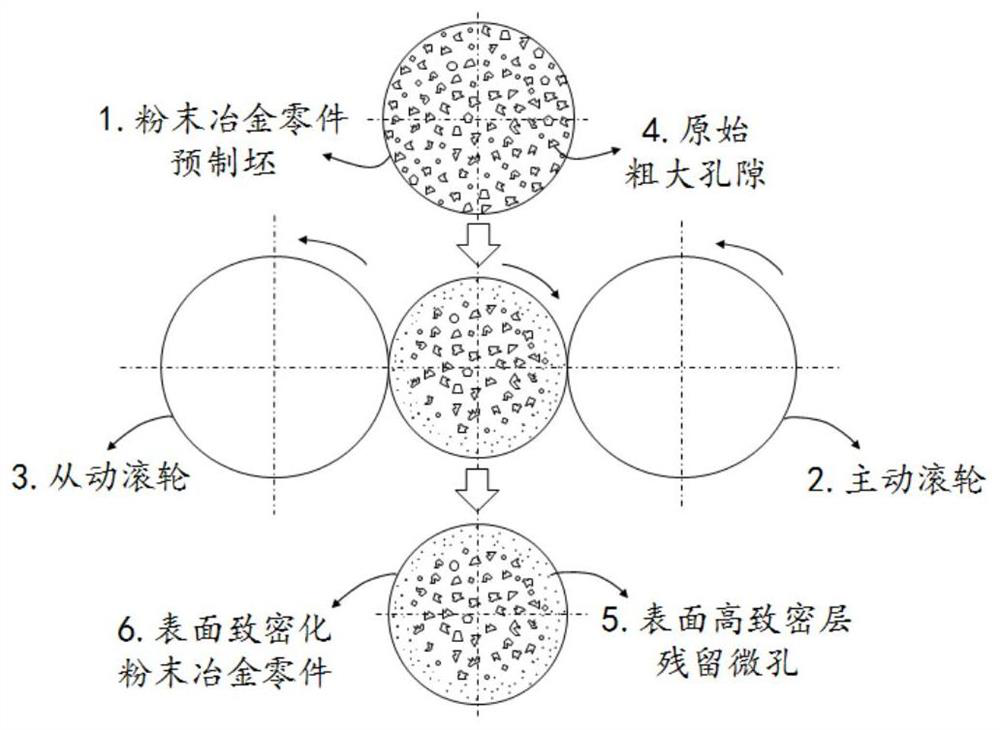

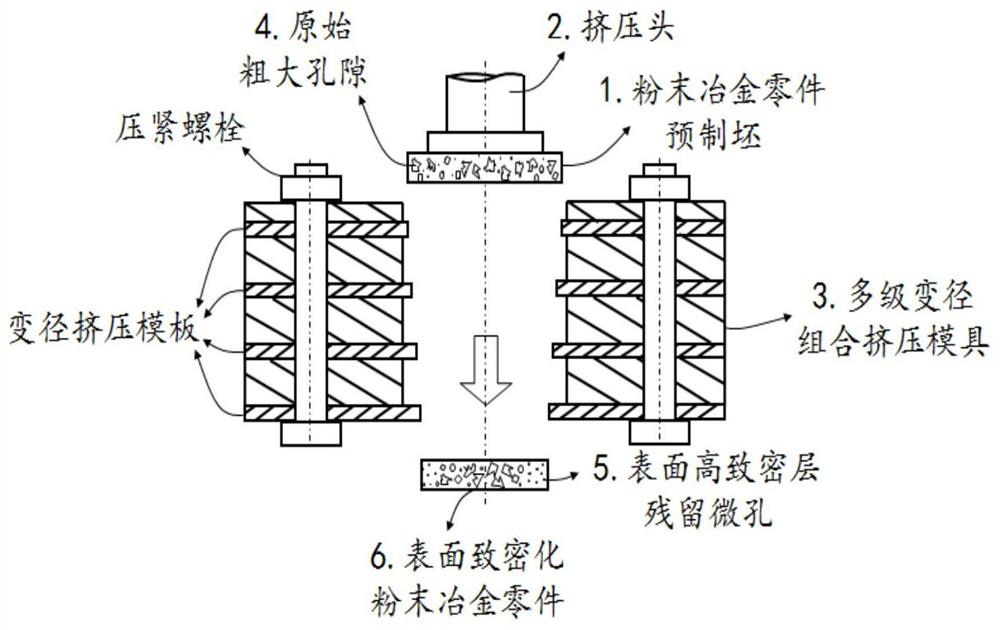

Powder metallurgy part and preparation method thereof

The invention discloses a powder metallurgy part and a preparation method thereof and belongs to the technical field of powder metallurgy. The preparation method of the powder metallurgy part comprises the following step of vibrating and extruding the surface of a prefabricated blank of the powder metallurgy part. The method can provide a uniform extruding force, so that surface metal plastic flowing and surface layer densifying of the prefabricated blank of the powder metallurgy part are more uniform and furthermore, the method can process the powder metallurgy part easily, can ensure the shape and the dimensional precision of the powder metallurgy part better, and further can reduce the extruding load, reduce the wear of an extruding die, prolong the service life of the extruding die andimprove the processing quality and the mechanical property of the powder metallurgy part. The prepared powder metallurgy part is low in extruding load, good in surface quality after being extruded, small in recurrent magnitude, more uniform in densifying of the densifying layer, high in hardness and good in wear resistance.

Owner:XIHUA UNIV

Ham rolling machine

PendingCN109662129AReduce salt contentGuaranteed qualityMassaging-based meat tenderisingSalt contentEngineering

The invention discloses a ham rolling machine. The ham rolling machine comprises a rack, a feeding port is formed in one end of the rack, a discharging port is formed in the other end of the rack, anannular belt conveying device is arranged on the rack, and the feeding port and the discharging port are formed in the two ends of the annular belt conveying device respectively. A plurality of rolling mechanisms and extruding mechanisms are arranged on the inner side face and the outer side face of the annular belt conveying device respectively, ham on a conveying belt is conveyed between the rolling mechanisms and the extruding mechanisms, and the rolling mechanisms and the extruding mechanisms exert rolling and extruding acting force on the ham in sequence in the ham conveying direction. According to the ham rolling machine, the rolling mechanisms and the extruding mechanisms are arranged on the upper side face and the lower side face of the annular conveying belt, under the extruding action of the rolling mechanisms and the extruding mechanisms, the human hands are simulated to knead the ham, the pickling procedure time is shortened, the salt content of the ham is reduced, the quality of the ham is guaranteed, and mechanical treatment equipment is provided; labor force is saved, and the production efficiency is improved.

Owner:CHINA NAT PACKAGING & FOOD MACHINERY

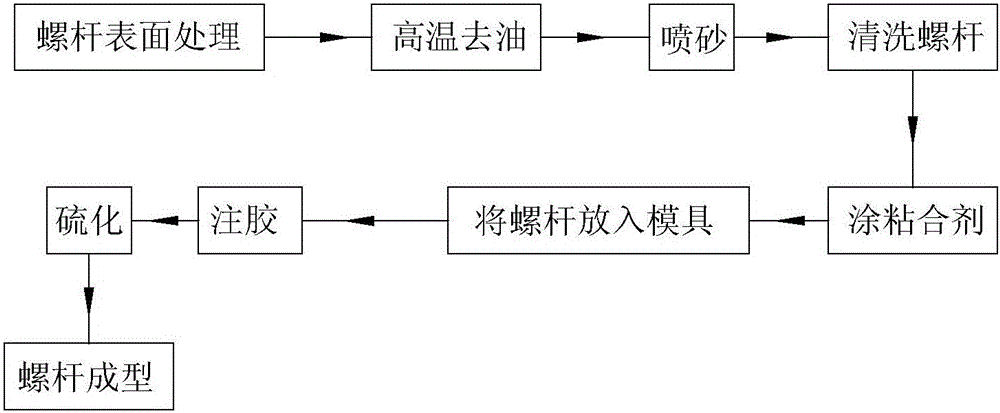

Preparation method of rubber lining screw rod

ActiveCN105922502ADifficulty of glue injection is reducedAvoid colloid wasteCoatingsEngineeringWear resistance

The invention relates to a preparation method of a rubber lining screw rod. The method adopts a rubber lining method of injecting rubber at the end part and exhausting in middle, so that the rubber injecting difficulty is reduced; a filter device is arranged in an exhaust port for allowing passing and exhausting of gas; a compact filter film can prevent outward flowing of rubber, so that the rubber waste caused by outward flowing of the rubber can be prevented, the pressure in a screw rod mold can be increased or stabilized, the bonding capacity of the rubber to the screw rod is enhanced, and the rubber lining quality is improved; and meanwhile, the screw rod is not stationary in the rubber lining process, but keeps rotating at low speed, so that a pressure forward surface and a pressure back surface of the screw rod can be continuously alternated to guarantee continuous balance and uniformity of pressure suffered by each part of the screw rod, and a fluid in a channel generates uniform extruding force on the screw rod to uniformly coat the rubber on the surface of the screw rod so as to enhance the wear resistance of the rubber lining screw rod.

Owner:ZHEJIANG OCEAN UNIV

Floating inner support positioning clamping device

InactiveCN107617755AImprove clamping effectSolve the clamping problemExpansion mandrelsArchitectural engineeringSteel ball

The invention relates to the technical field of clamping devices, in particular to a floating inner support positioning clamping device. The device comprises a base, a driving rod, a first expansion block, a second expansion block, a third expansion block, a linkage block, a steel ball and a connecting rod; the base is of a cavity structure, the driving rod is fixedly connected with the first expansion block, the outer wall of the first expansion block is in sliding connection with the inner wall of the base, the inner wall of the first expansion block is in sliding fit with the steel ball, the steel ball abuts against the second expansion block and the wedge face of the linkage block at the same time, the linkage block is fixedly connected to the lower end of the connecting rod, a cavityallowing the connecting rod to move downwards is formed in the first expansion block, the middle and the upper portion of the connecting rod are sleeved with the second expansion block and the third expansion block correspondingly, and the second expansion block and the third expansion block are in sliding fit with the connecting rod. The floating inner support positioning clamping device in the technical scheme has the beneficial effects of being good in fixing clamping effect and capable of effectively ensuring workpiece machining quality.

Owner:成都中源红科技有限公司

Duplicate gear riveting method

The invention provides a duplicate gear riveting method. The method comprises the following steps that a gear A, a gear B and a flanged rivet head are provided, wherein the gear A is fixedly connectedon a central shaft, the left end and the right end of the central shaft extend out of the left side and the right side of the gear A, a middle through hole is formed in the center shaft, and the flanged rivet head comprises a guiding column of a cylinder shape; one end of the central shaft is clamped on a lathe spindle, and then the gear B fixedly sleeves the other end of the central shaft; a lathe is started, the lathe spindle is rotated, the guiding column is sleeved with the middle through hole in the rotating process of the lathe spindle, and the guiding column extrudes the middle throughhole to enable the gear B to be integrally connected with the central shaft so as to obtain a duplicate gear. According to the technical scheme of the method, the influence of the vibration of a machine tool in the riveting process is reduced, the periphery of a flanged rivet rib generated by the deformation of the extruded edge of the central shaft is uniform, so that the firm and reliable effect is achieved, the peripheral rotating inertia is kept balanced, the using effect is improved, and the transmission precision of a transmission mechanism is guaranteed.

Owner:贵州华烽汽车零部件有限公司

Sole pressing assembly line for shoemaking and sole pressing method

PendingCN110786594AUniform extrusion forceQuality improvementSolesShoemaking devicesAssembly lineStructural engineering

The invention relates to a sole pressing assembly line for shoemaking. The sole pressing assembly line comprises an electric control system, a sole pressing unit and a feeding unit, wherein the feeding unit is provided with a correcting mechanism for correcting the attitude and position of a processed object; and the sole pressing unit comprises a sole pressing conveyer for conveying the processedobject to a working position, side pressing mechanisms arranged on the left and right sides of the sole pressing conveyer, a mounting frame arranged above the sole pressing conveyer, a lifting oil cylinder mounted at the top of the mounting frame, a mounting plate driven by the lifting oil cylinder to slide up and down along the mounting frame, top pressing mechanisms mounted at the bottom of themounting plate and a front-back tightening mechanism mounted below the mounting plate in a sliding manner through a guide inner frame. According to the sole pressing assembly line, the processed object can be safely conveyed to the working position according to the standard attitude through a feeding conveyer, a correcting conveyer, the sole pressing conveyer and the correcting mechanism, the left side and the right side are uniformly pressed through the side pressing mechanisms, the front side and the back side are uniformly pressed through the front-back tightening mechanism, and the wholeglued surface is uniformly pressed through the top pressing mechanisms.

Owner:泉州骏龙机械有限公司

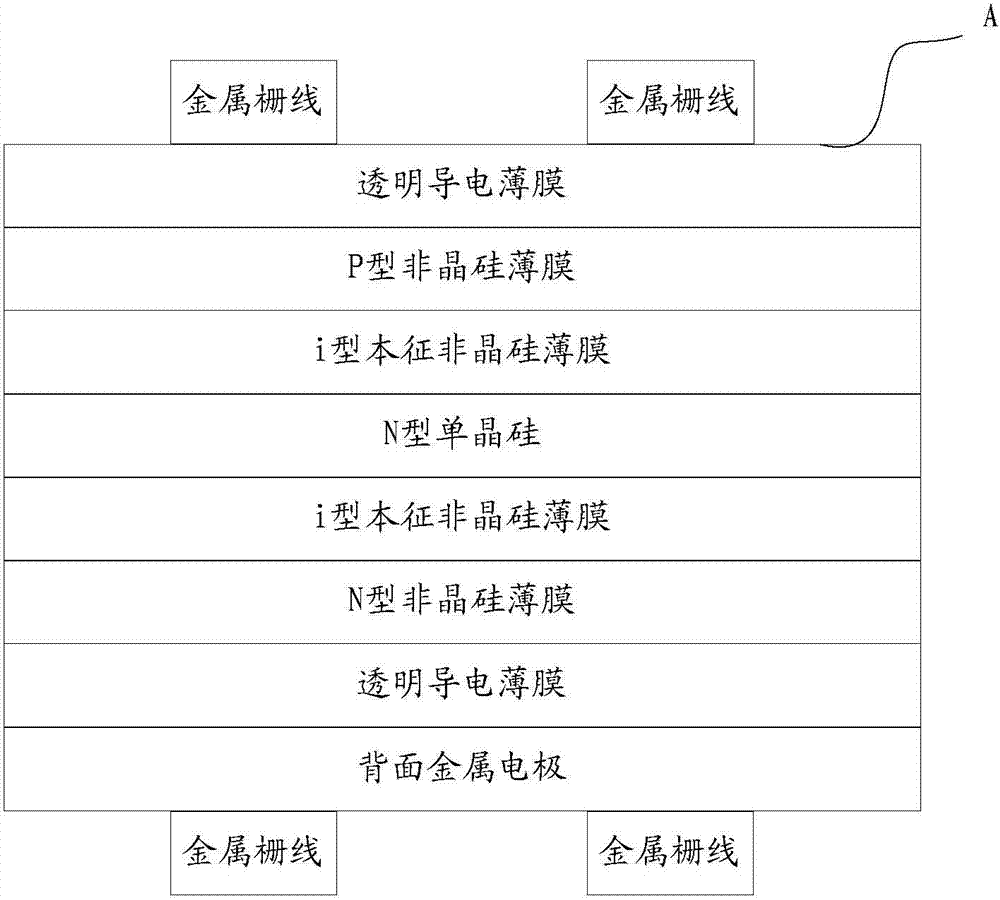

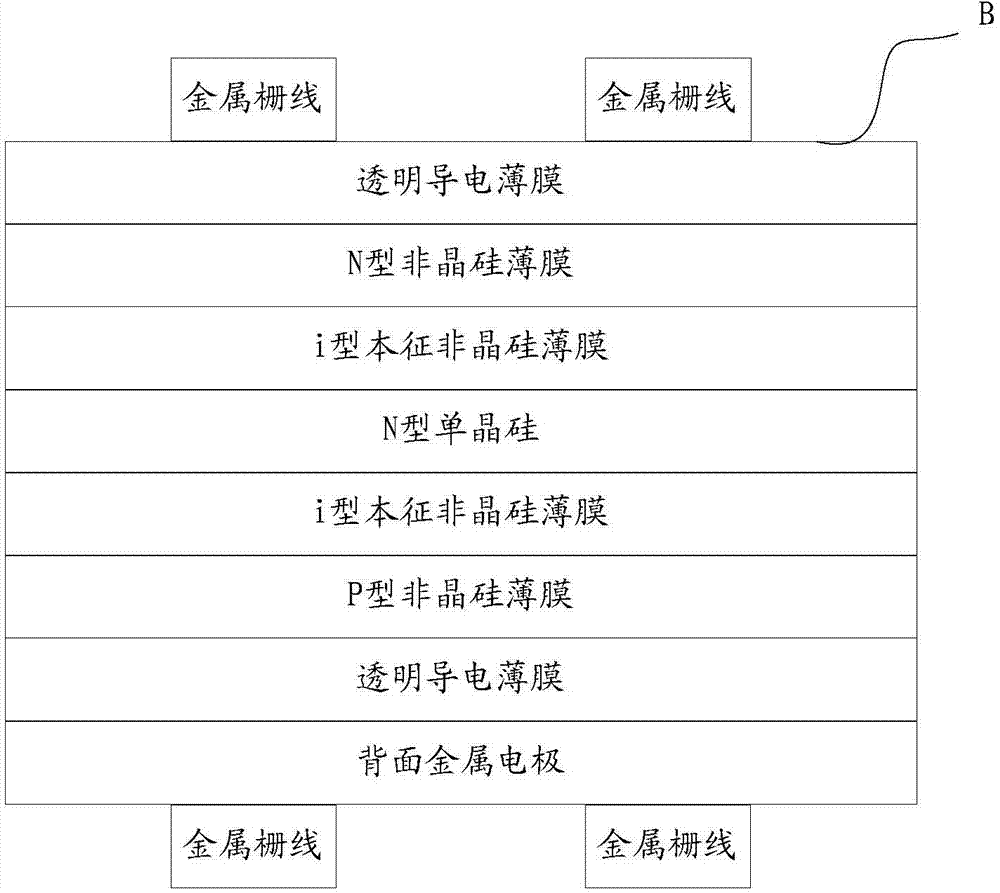

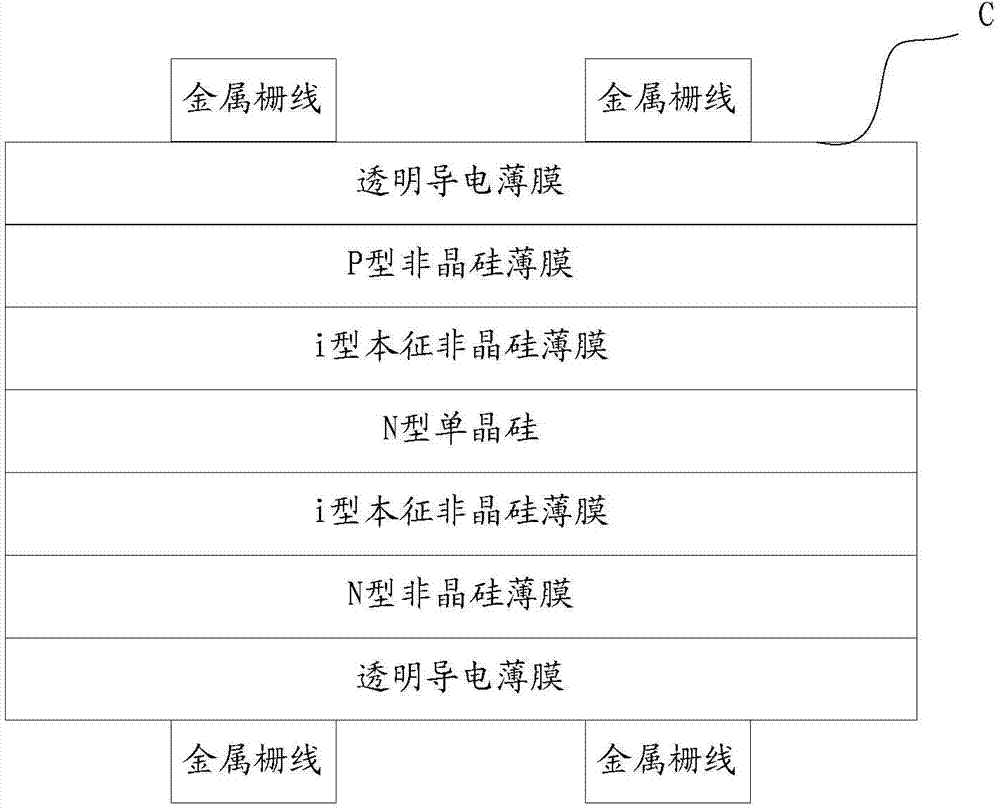

Solar cell assembly

ActiveCN104505414ASave the bending processSimplify the welding processPhotovoltaic energy generationSemiconductor devicesEngineeringSolar cell

The invention discloses a solar cell assembly, which comprises N lines and M rows of solar cells, wherein the solar cells in each line are serially connected, and at least K lines of N lines of solar cells have the following structure that every two adjacent solar cells in one line of solar cells form one group, each group of solar cells comprises a first solar cell and a second solar cell, the polarities of the front sides of the first solar cell and the second solar cell in at least one group are opposite, bus bars are arranged at the front sides or the back sides of the first solar cell and the second solar cell in the corresponding group, the first solar cell and the second solar cell in the corresponding group are serially connected by the bus bars, and the bus bars only need to be arranged at the front sides or the back sides of the adjacent first solar cell and the second solar cell in the corresponding group. The solar cell assembly has the advantages that the bending of the bus bars is avoided, the loss of the bus bars is reduced, and the fragment rate of the solar cell assembly is reduced.

Owner:ENN SOLAR ENERGY

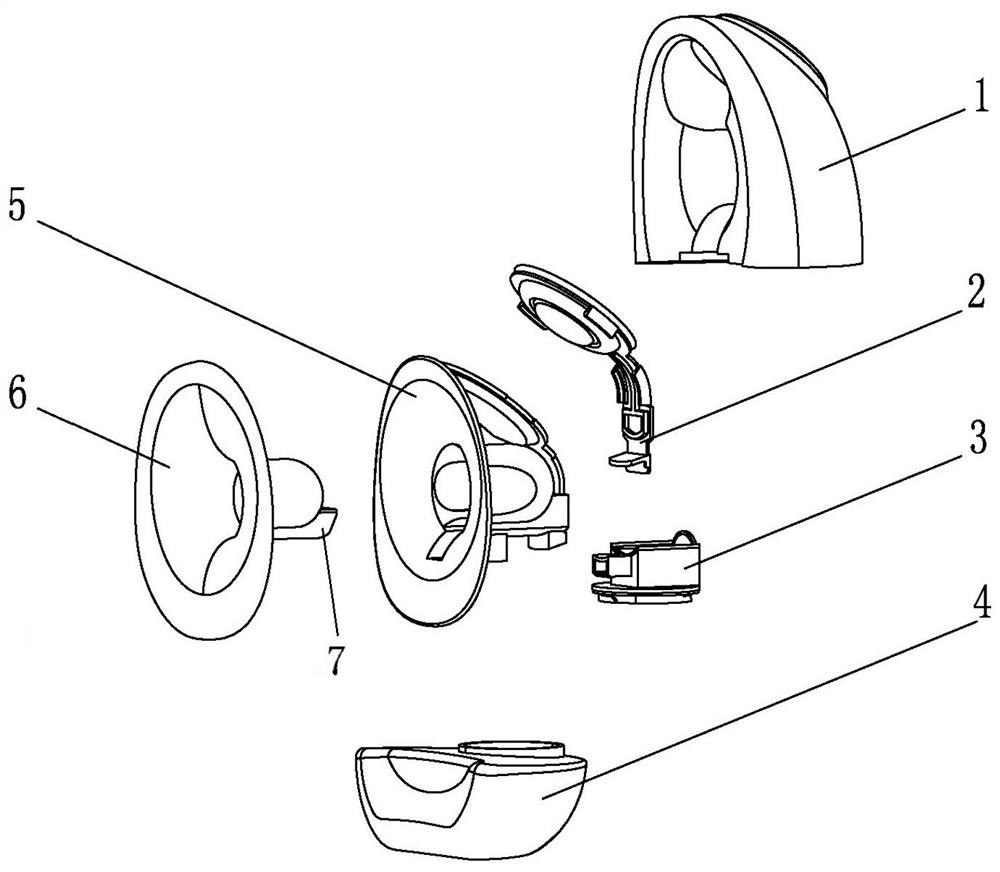

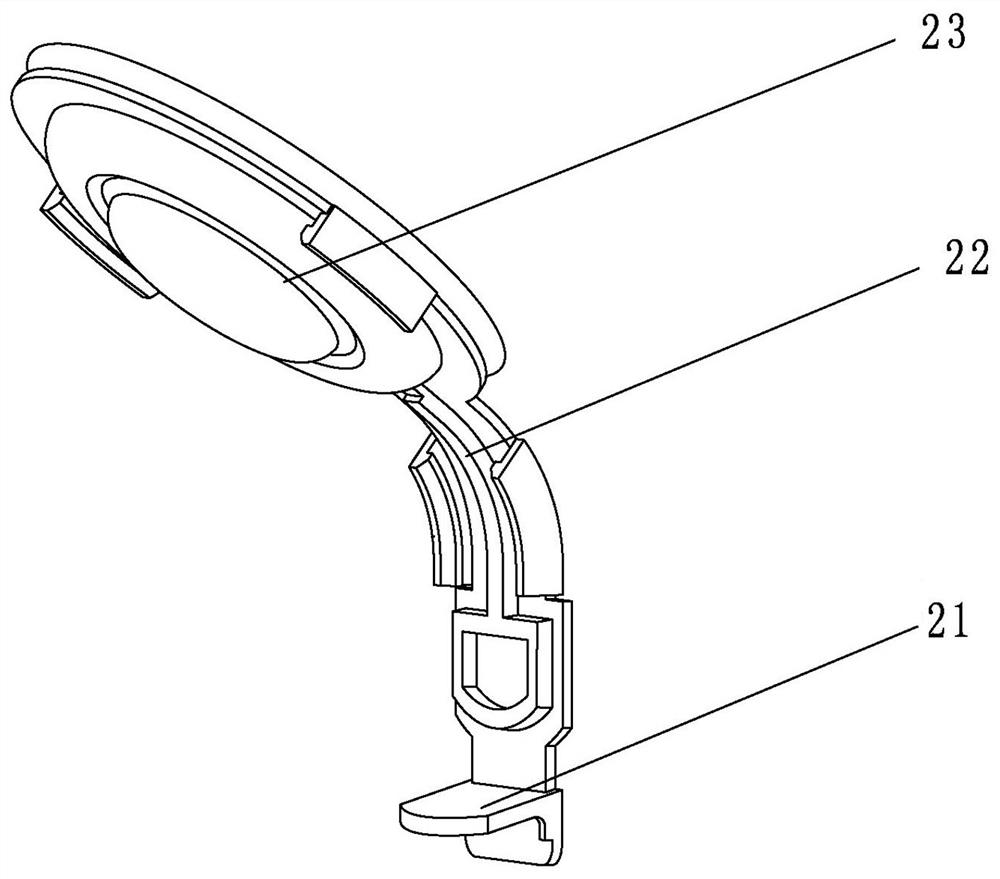

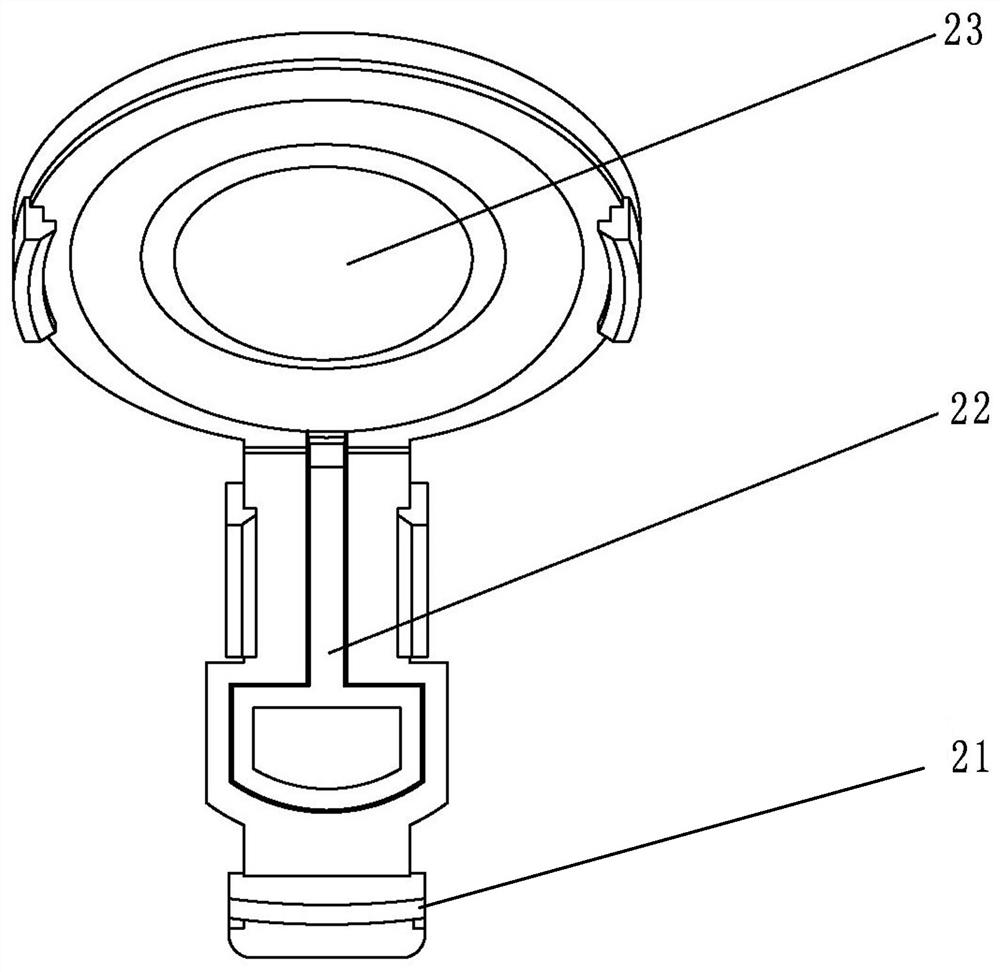

Wearable breast pump

PendingCN114767972AIncrease the lengthExtrusion pressure equalizationAcceleration measurement using interia forcesMilking pumpAreolaBreast pump (device)

The invention relates to a wearable breast pump, and belongs to the technical field of mother and baby products. The breast pump is formed by connecting a main machine assembly and an integrated machine core assembly. Different from the prior art, an integrated functional assembly comprising a butterfly-shaped air bag, a one-way valve plate and a negative pressure channel groove is arranged, a negative pressure buffering air path is formed, negative pressure air flow in the breast suction cover flows horizontally, the extrusion pressure of negative pressure on breasts is relatively balanced, and the comfort of a breast-feeding person is improved when the breast-feeding device is used by the breast-feeding person. The negative pressure cavity is connected with the milk outlet through the long-strip flat negative pressure channel groove, the negative pressure acts on the breasts of the human body from the breast protection pad to the milk outlet, the thickness of the breast protection pad is gradually reduced from the two ends to the middle, and under the negative pressure effect, the thin area in the middle of the breast protection pad can deform more easily, so that the breast protection effect is better. And the human mammary areola part is squeezed and massaged to be consistent with the condition reflex arc of natural lactation of the human body, so that the electric milk suction can be closer to natural lactation.

Owner:GUANGDONG HORIGEN MOTHER & BABY PROD CO LTD

Integrated veneer lathe with and without spindle

The invention discloses an integrated veneer lathe with and without a spindle, and belongs to the field of wood processing equipment. The integrated veneer lathe with and without the spindle comprises a machine frame, wherein the machine frame is provided with a tool apron, a tool rest, a pressure bar roller, double rollers, a double-roller base, a rotary cutter and a spindle mechanism; the tool rest is arranged on the tool apron; the rotary cutter is arranged on the tool rest; the double rollers are installed on the double-roller base; and a clutch is installed on the pressure bar roller or the double rollers or the spindle mechanism. According to the integrated veneer lathe with and without the spindle provided by the invention, the clutch is installed on the pressure bar roller or the double rollers or the spindle mechanism, so that damage to a machine or a log caused by different rotating speeds output by two power sources can be prevented.

Owner:SHANDONG JINLUN MASCH CO LTD

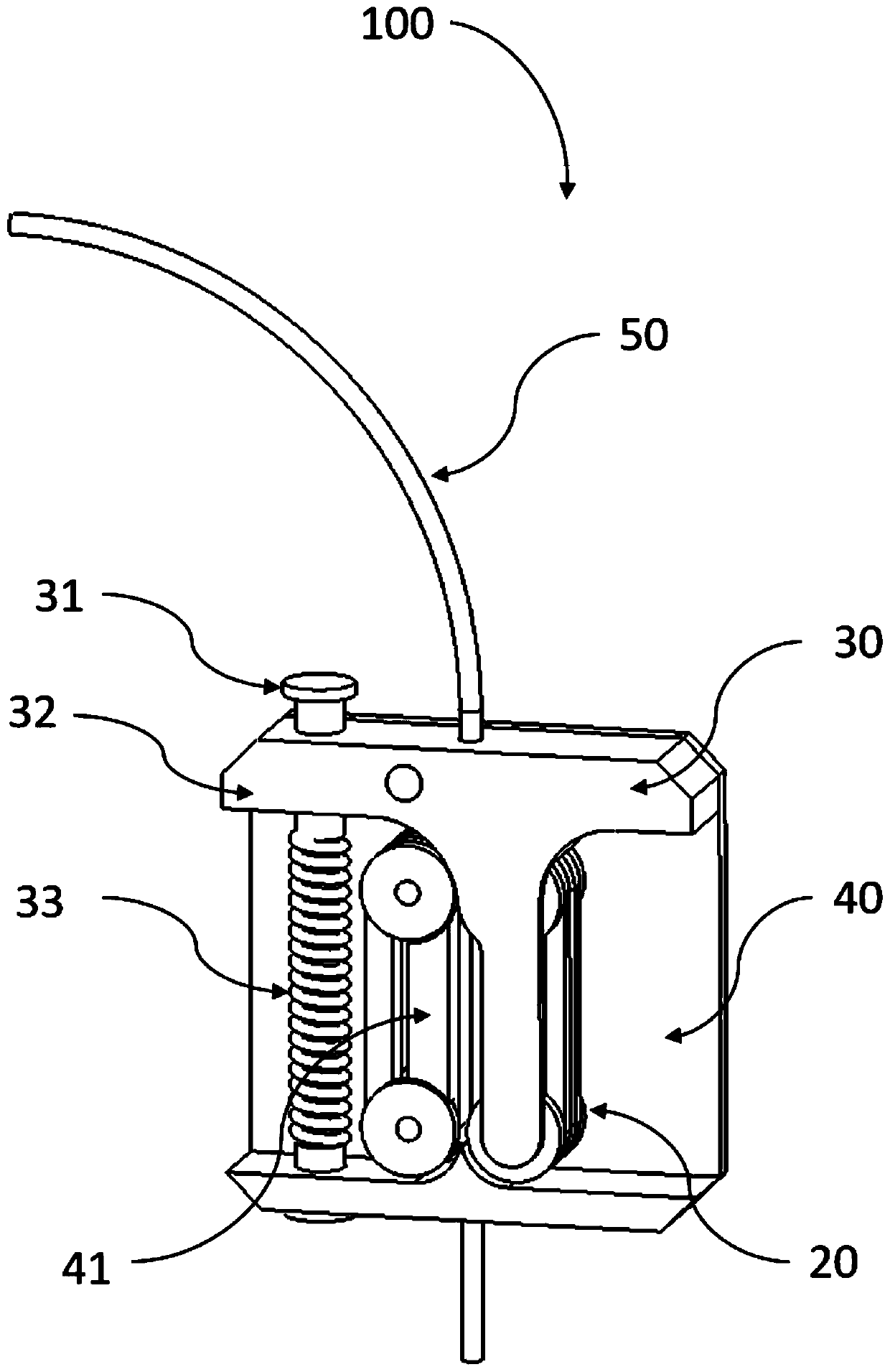

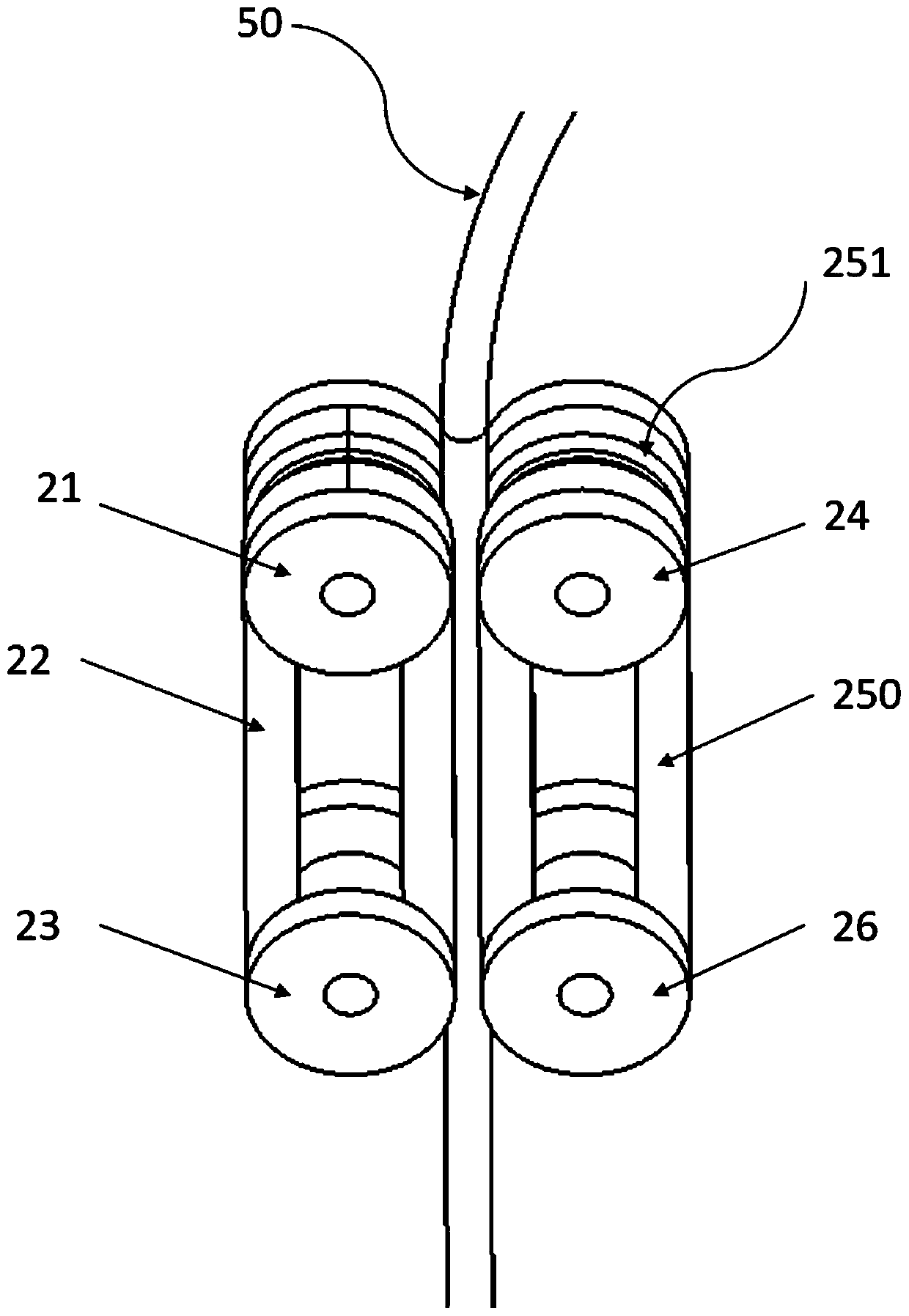

Conveying mechanism for 3D printer

InactiveCN110614771AStable deliveryEasy to installAdditive manufacturing apparatus3D object support structuresEngineeringExtrusion

The invention discloses a conveying mechanism for a 3D printer. The conveying mechanism comprises a first mounting part and a second mounting part, a conveying structure is arranged between the firstmounting part and the second mounting part, a driving part of the conveying structure is mounted on the first mounting part, a driven part of the conveying structure is mounted on the second mountingpart, the second mounting part can rotate relative to the first mounting part, and wire materials are arranged between the driving part and the driven part and conveyed through friction force. According to the conveying mechanism, the wire materials are clamped through a driving belt and a driven belt, the materials are conveyed through the friction force, and destroy and damage to the wire materials are reduced while stable conveying of the wire materials is ensured; guiding is conducted through a guiding groove, and the magnitude and direction of extrusion force are stable; and the guiding groove can achieve the effect of straightening the materials, and the problem of a conveying obstacle caused by wire material folds is reduced.

Owner:XI AN JIAOTONG UNIV

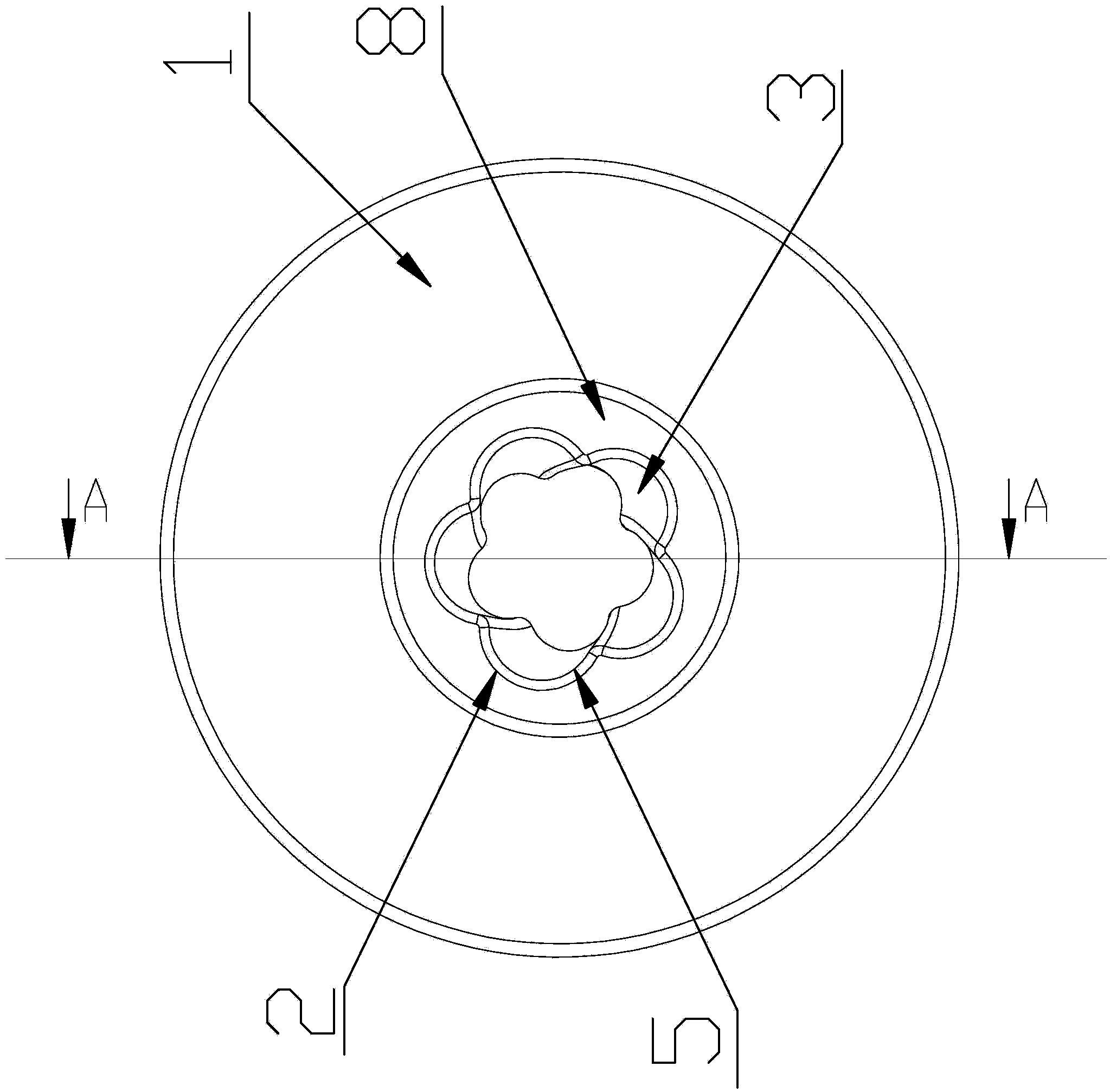

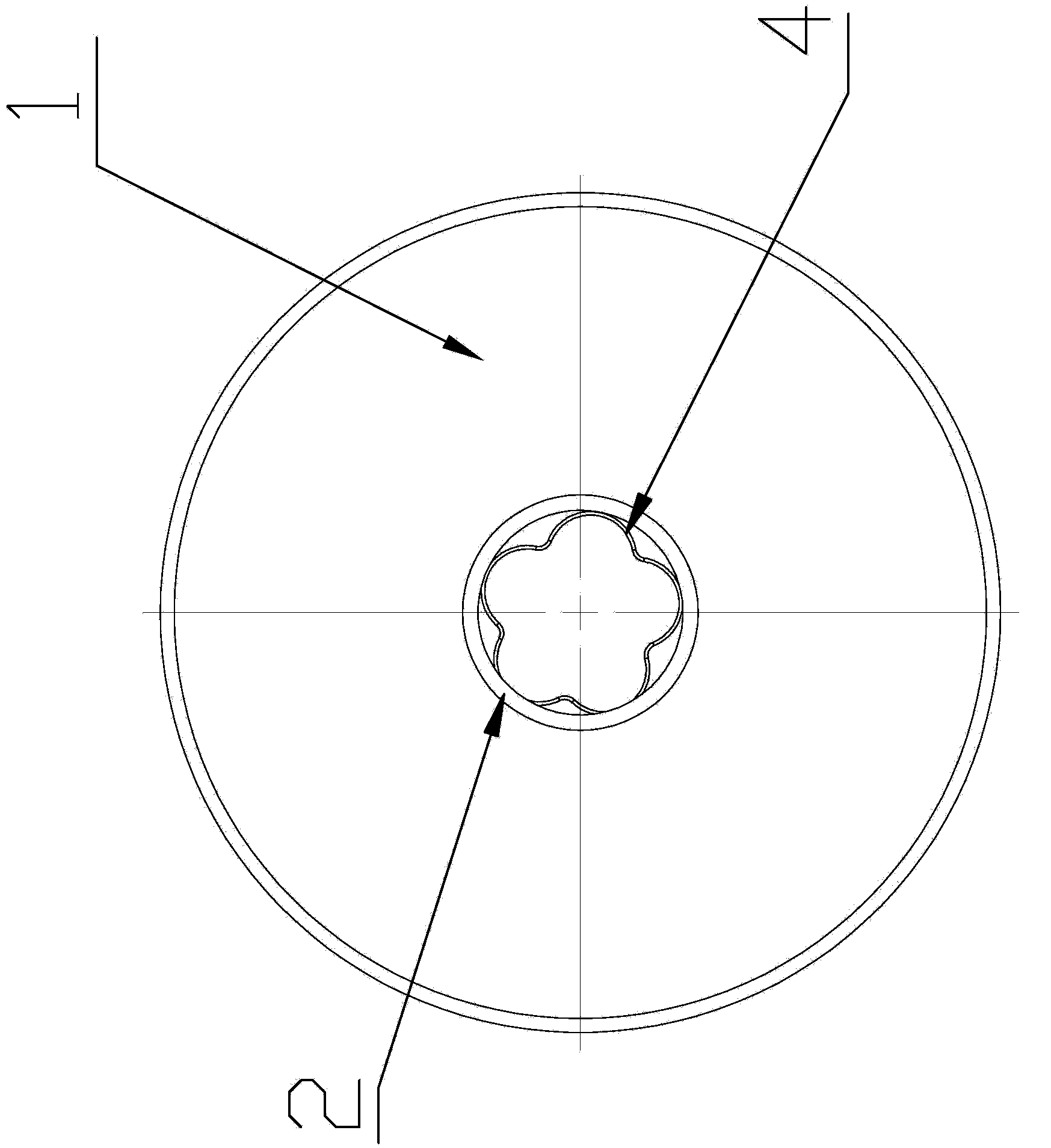

Die for manufacturing seamless five-petal plum-blossom-shaped steel pipe

InactiveCN103894434AImprove performanceHigh tensile strengthDrawing diesEngineeringMechanical engineering

The invention discloses a die for manufacturing a seamless five-petal plum-blossom-shaped steel pipe. The die comprises a die body (1) arranged on cold-drawing equipment, wherein a forming channel (3) is formed in the die body (1), and is provided with an inlet (5) and an outlet (4); a feed opening (7) in which a round pipe can be inserted is formed in one end, close to the inlet (5), of the forming channel (3), and a discharge opening (3) is formed in one end, close to the outlet (4), of the forming channel (3); each of the inlet (5) and the outlet (4) of the forming channel (3) has a five-petal plum-blossom-shaped cross section; the forming channel (3) is a spiral channel. According to the die for manufacturing the seamless five-petal plum-blossom-shaped steel pipe, the performance of the produced seamless five-petal plum-blossom-shaped steel pipe is higher than that of a conventional cold-drawn seamless five-petal plum-blossom-shaped steel pipe, the filling of concrete is avoided, and the die is low in cost and convenient to use.

Owner:NINGBO DEYI STEEL PIPE MFG

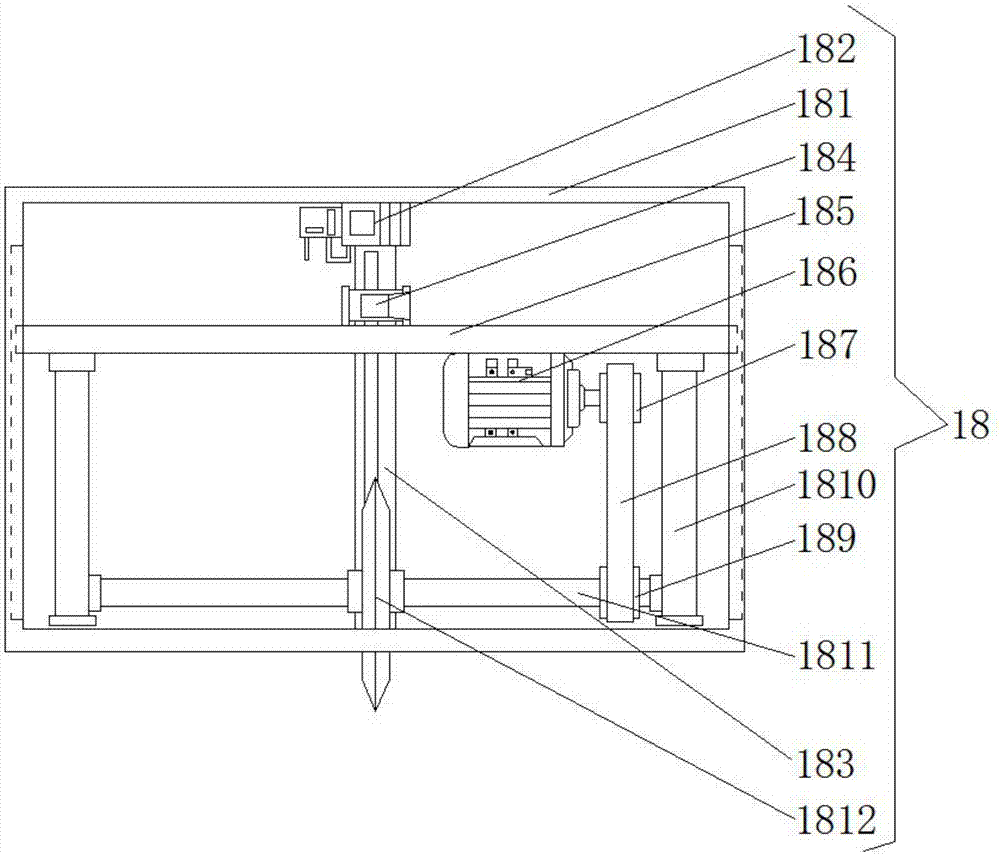

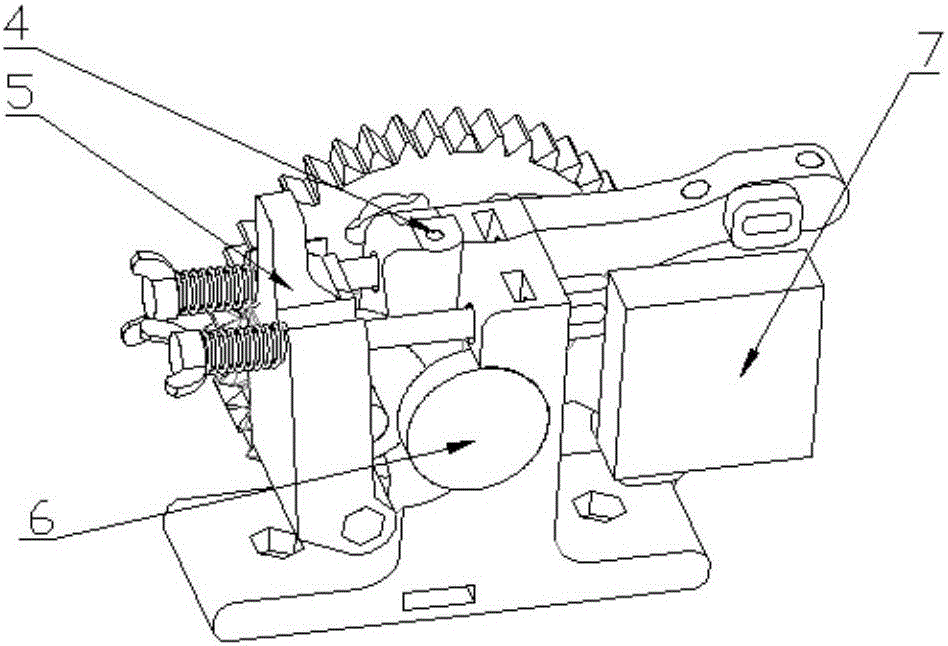

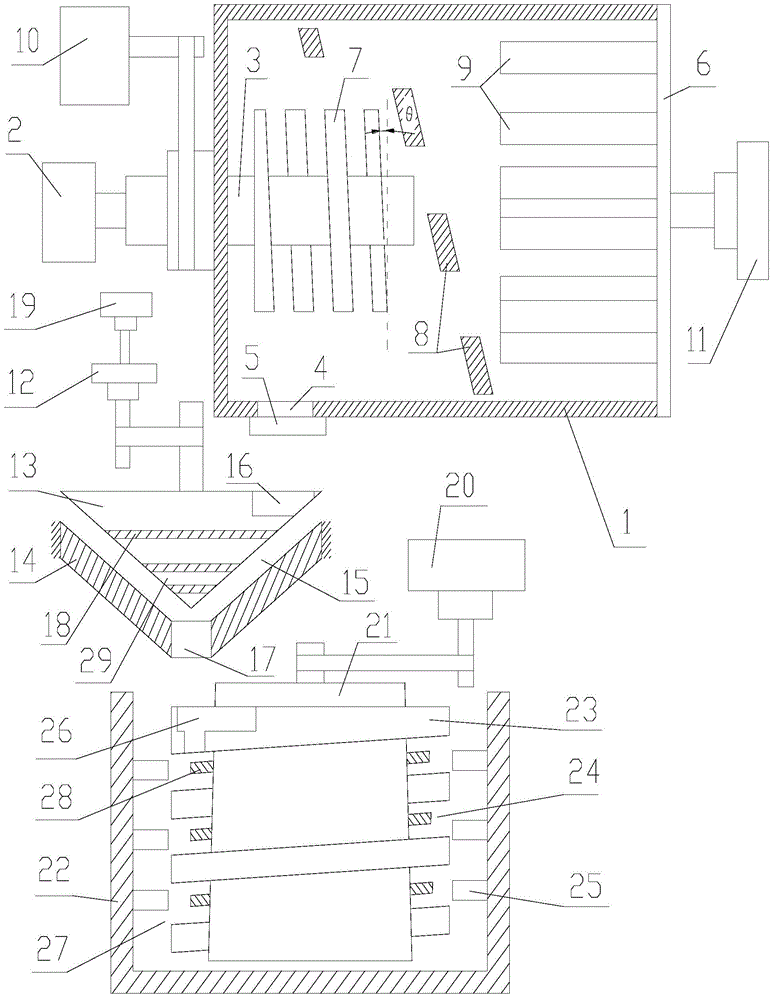

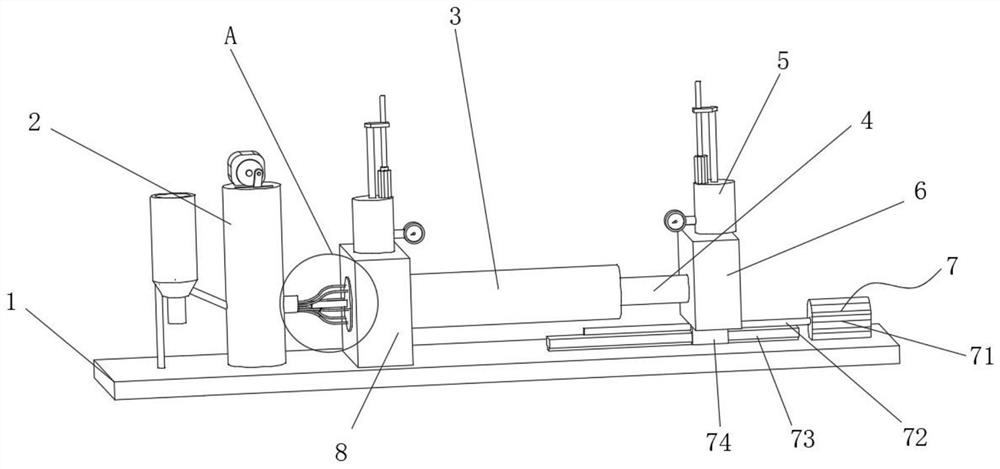

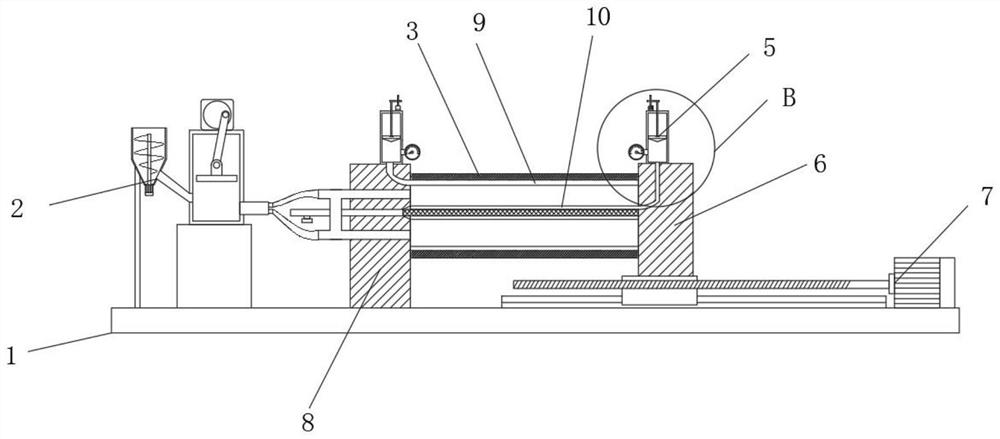

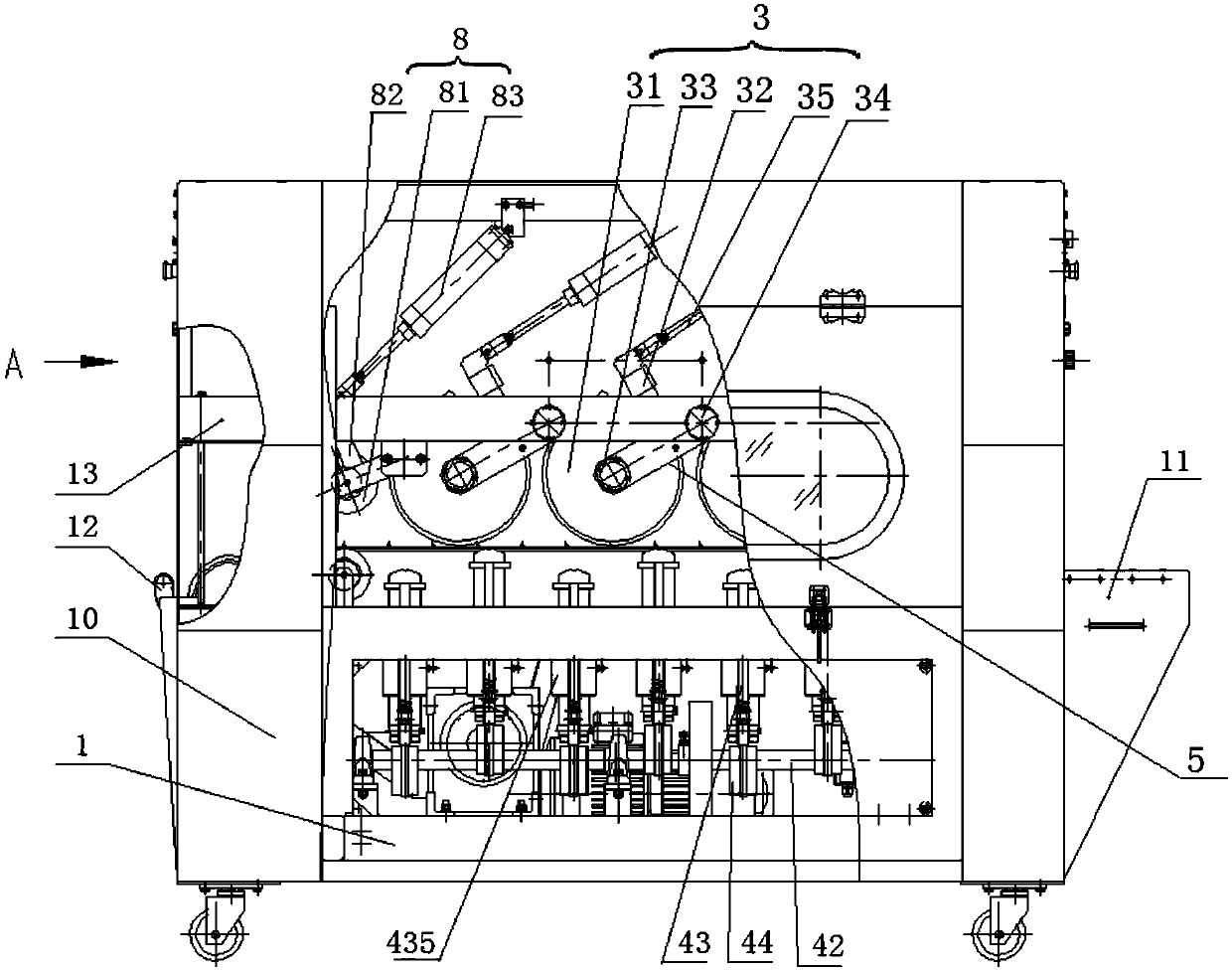

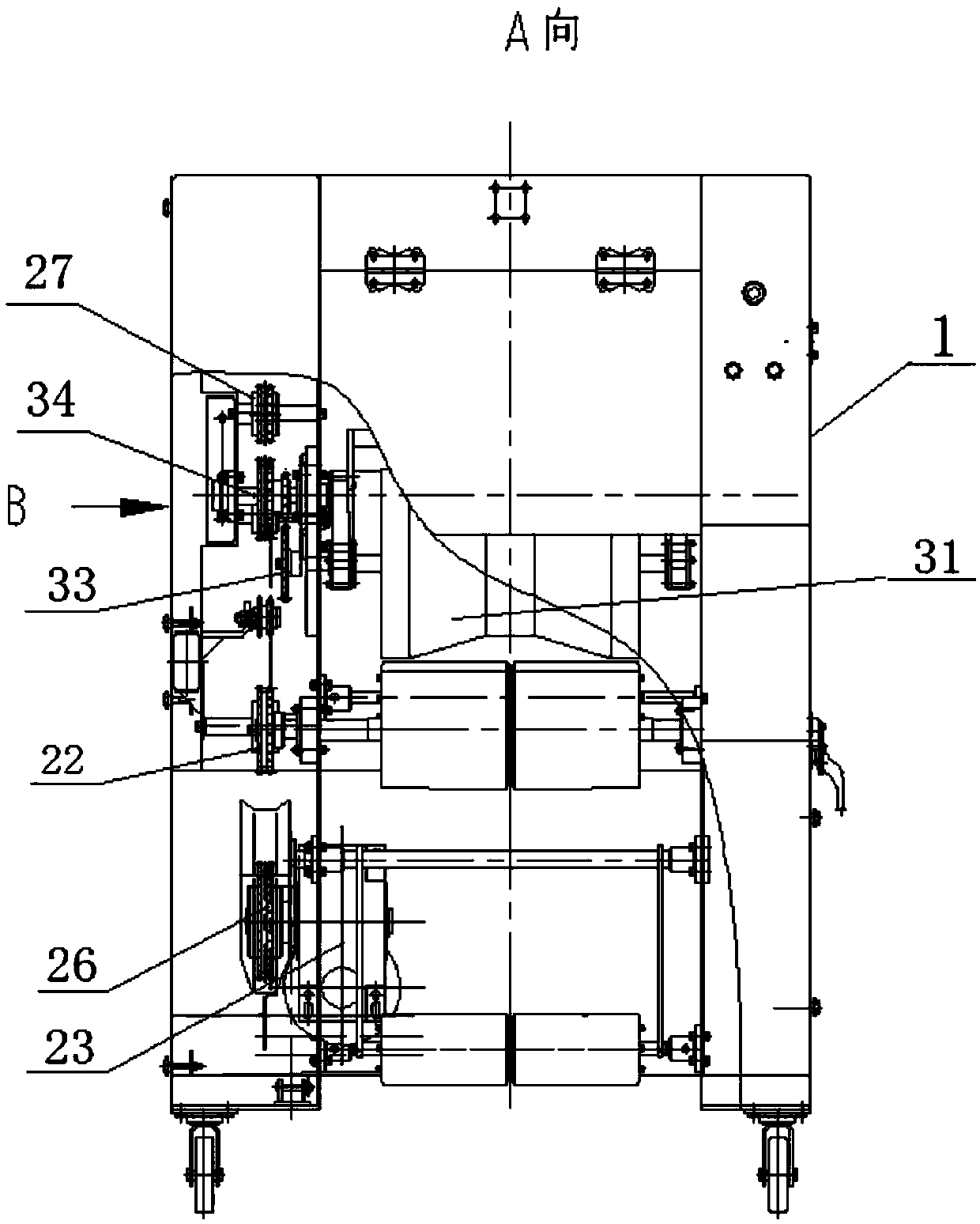

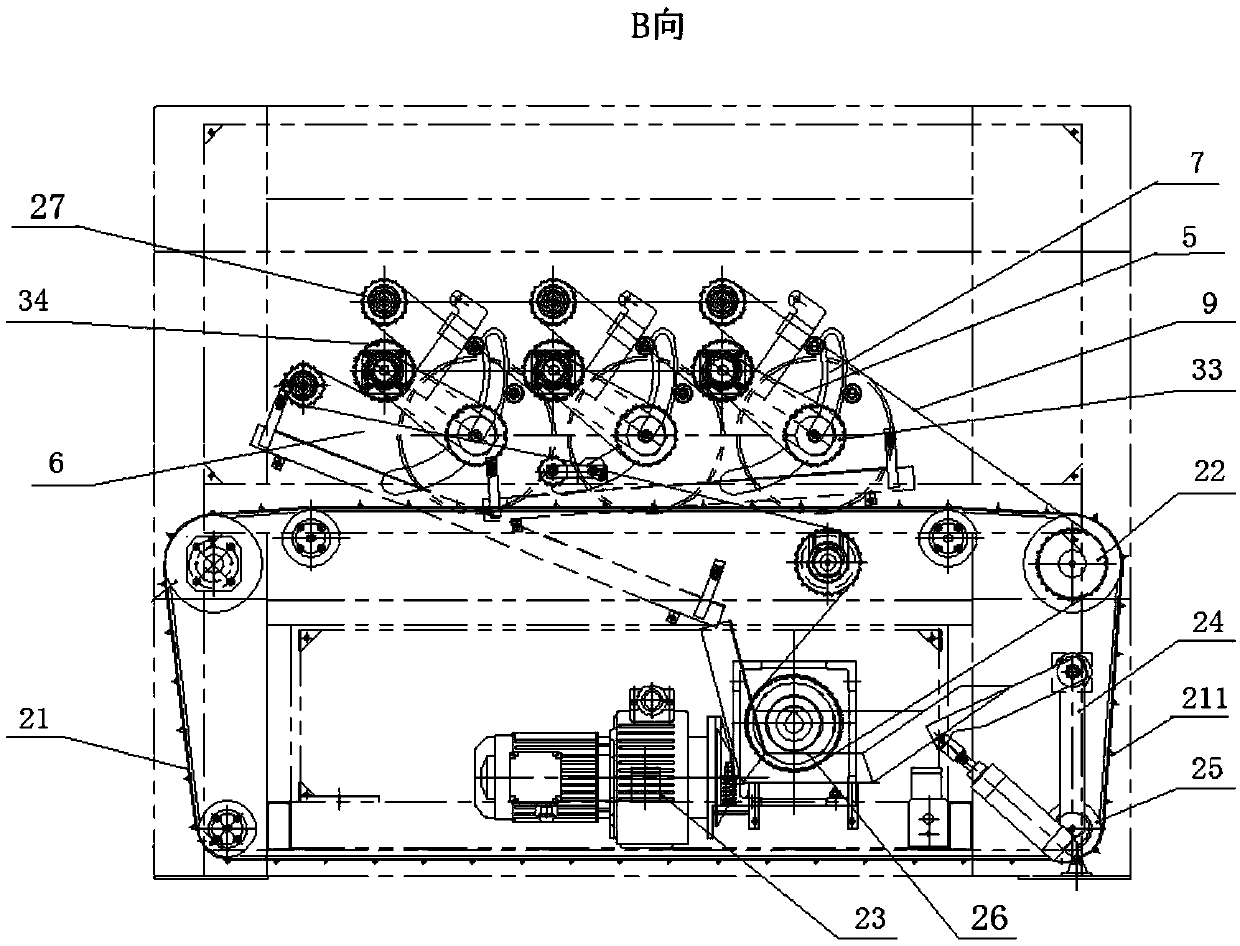

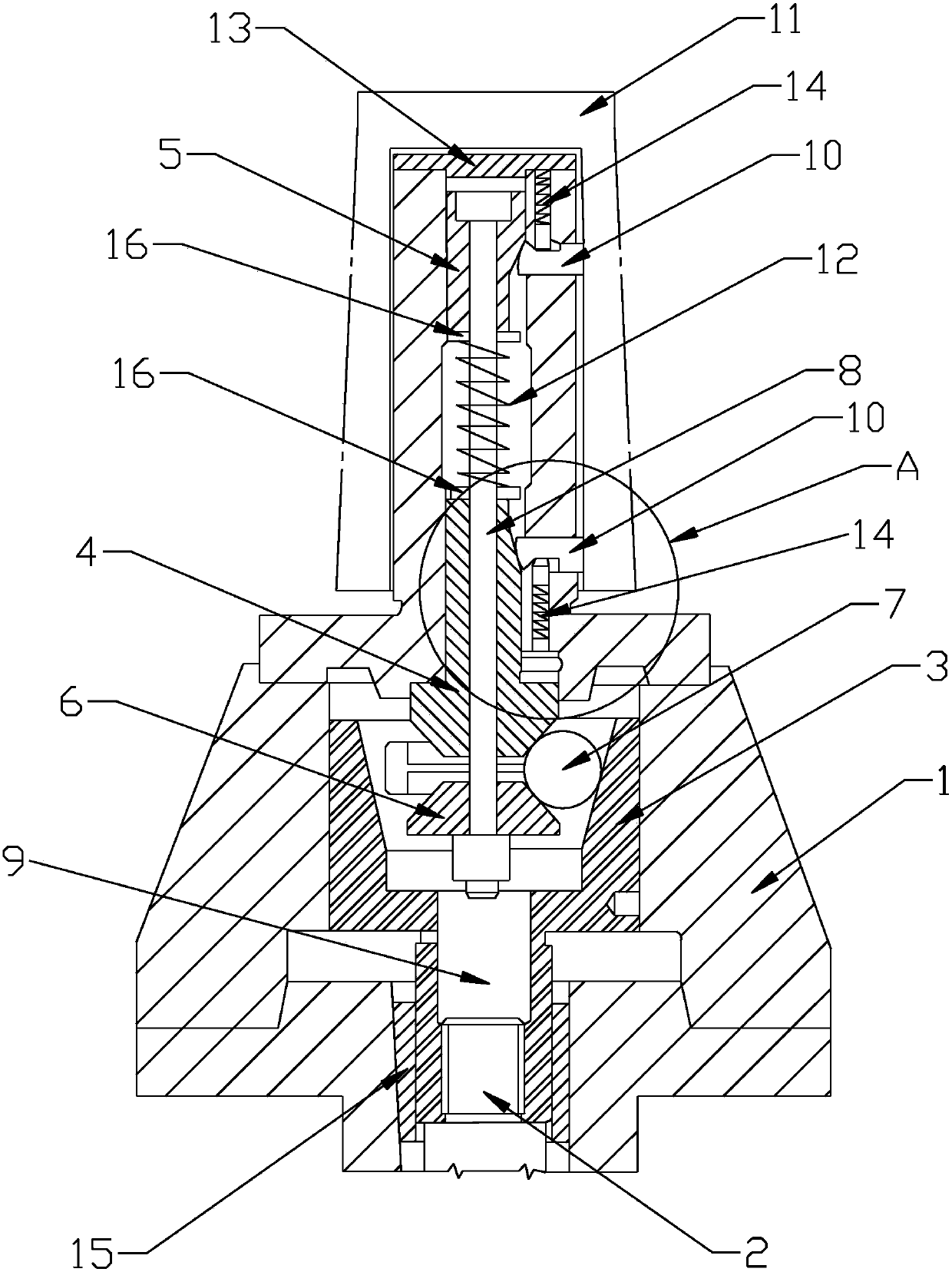

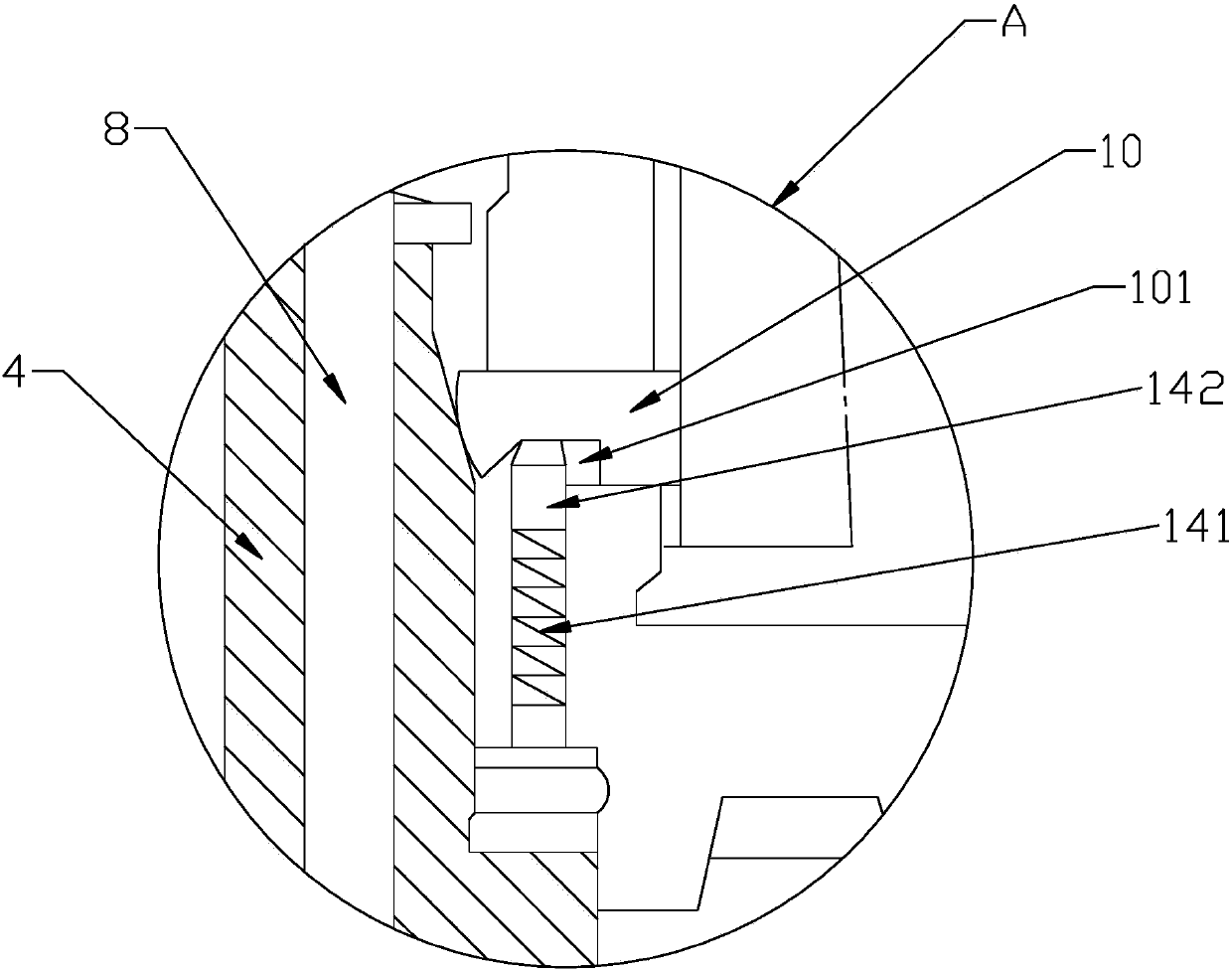

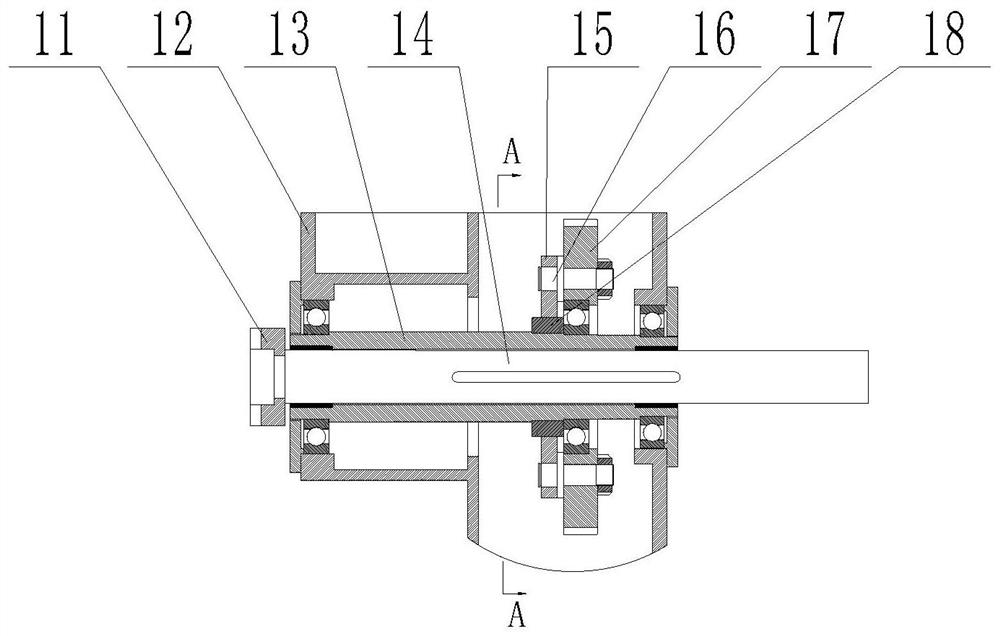

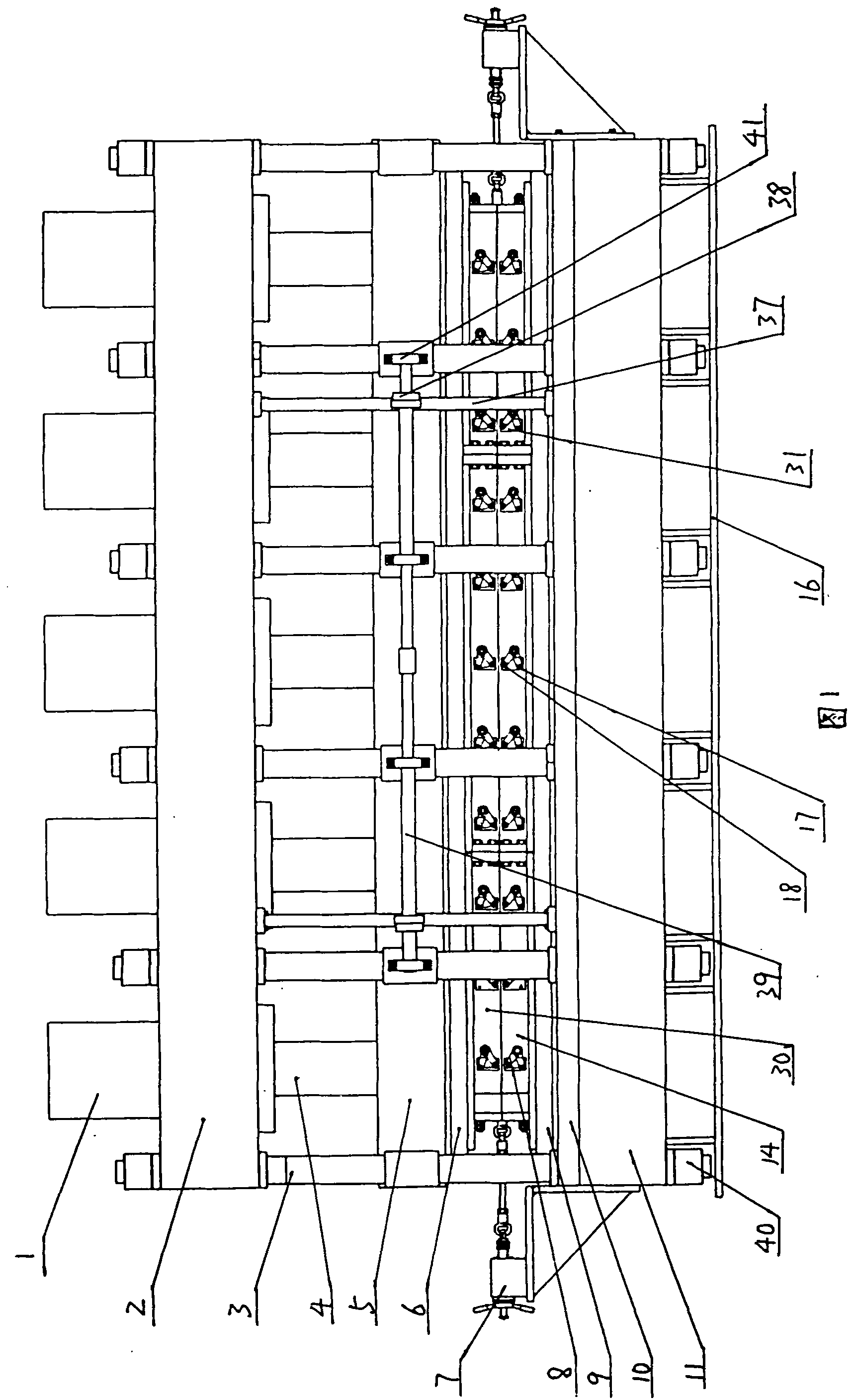

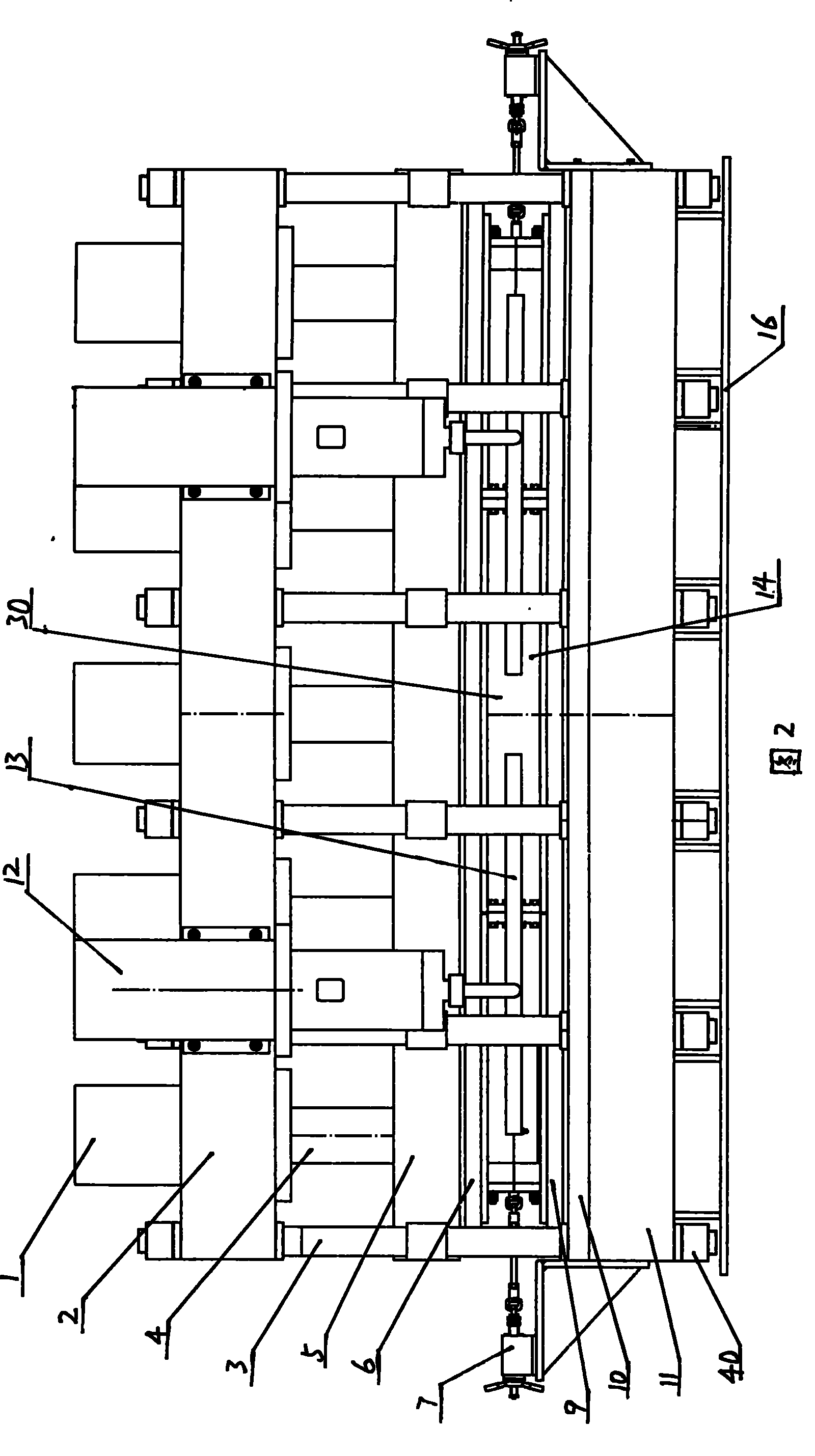

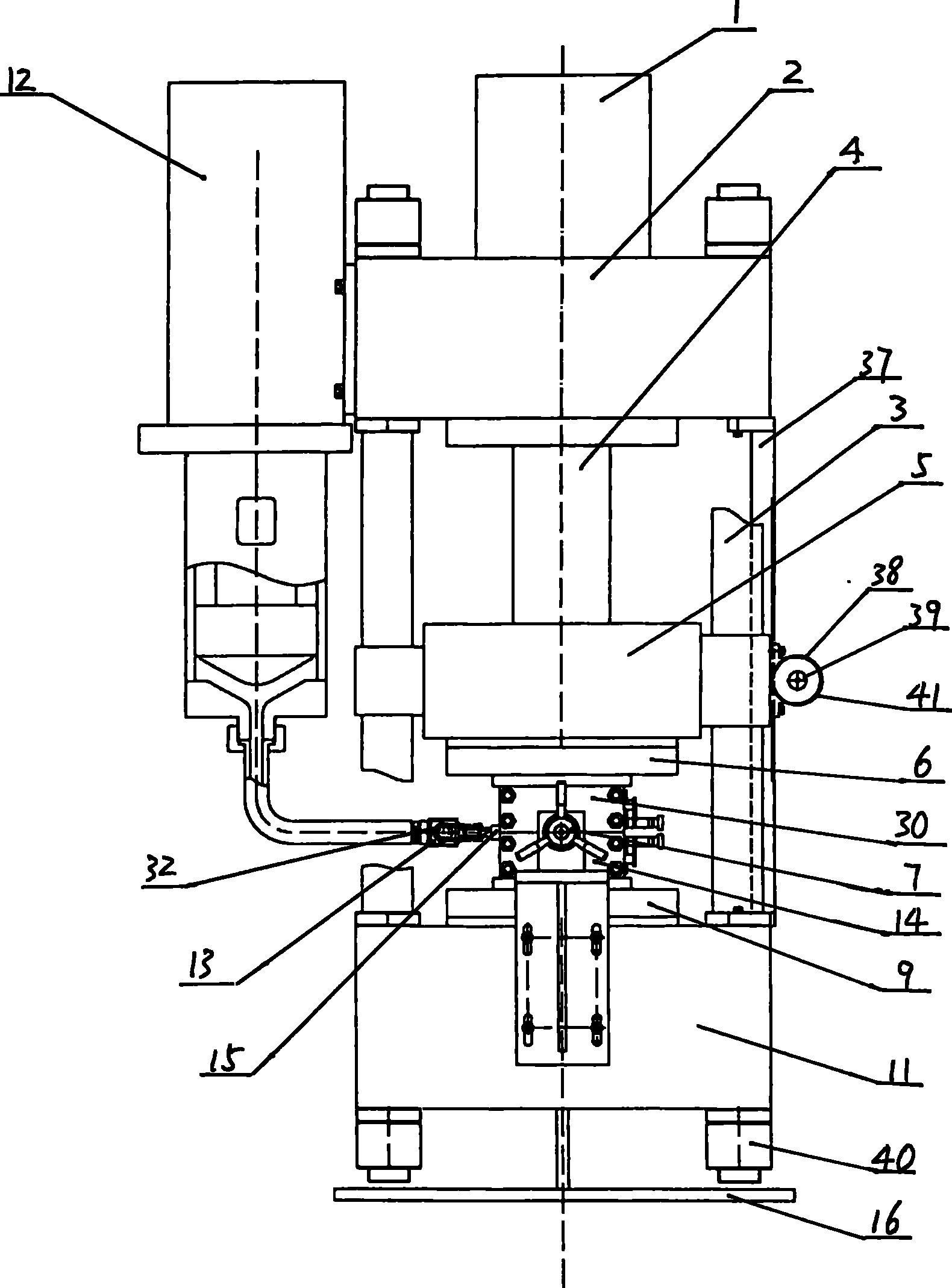

Composite long rod insulator injection molding machine

InactiveCN101284414BUniform extrusion forceMeet quality requirementsDomestic articlesTemperature controlAutomatic control

The invention discloses a composite long rod insulator injection molding machine and includes a hydraulic molding machine, a hydraulic system, more than two vertical or horizontal rubber injection molding machines arranged on one side of the hydraulic molding machine, an upper die and a lower die which can be matched into an integral mold, a plurality of mandrel locating devices, a mandrel tension apparatus and a mold of an injection nozzle, a temperature controlling apparatus, an automatic control system and a device which controls the synchronized movement of piston rods. The hydraulic system is provided with a plurality of oil cylinders, the lower ends of the piston rods are fixed on the same slide block, the mandrel locating devices are uniformly distributed in the cavities of the upper die and the lower die, and includes locating mandrels with racks, gears meshed with the racks of the locating mandrels and regulating crank wrenches fixed with the gear shafts. The extrusion of themandrels has uniform press, the quality and the service life of the composite long rod insulator are greatly improved, the defective index in production process is lowered, the tailings are reduced, the raw material is saved, the work efficiency is greatly improved, the production cost is reduced and the cleaning is easy.

Owner:白玉成

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com