Cloth tentering and sizing device

A stenter setting and cloth technology, which is applied in the direction of heating/cooling fabrics, textiles and papermaking, fabric surface trimming, etc., can solve the problems of uneven cloth surface, lifting page edge, uneven force on cloth, etc. Keep the effect of flatness and uniform force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described in detail below through specific implementations:

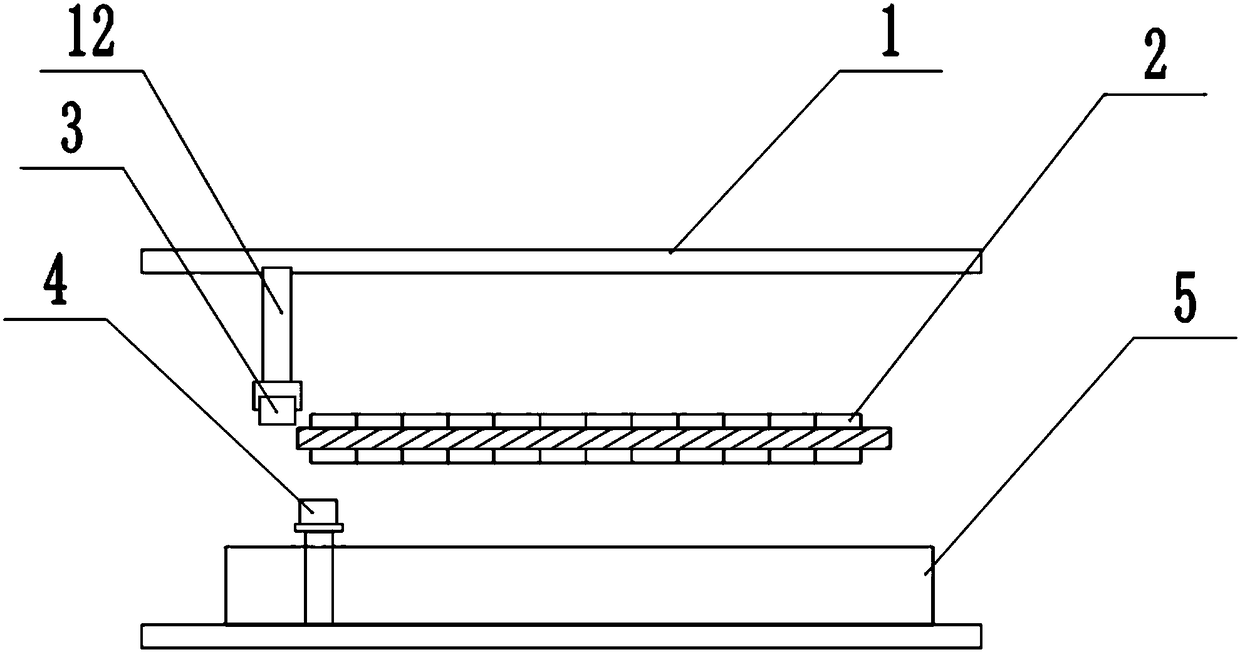

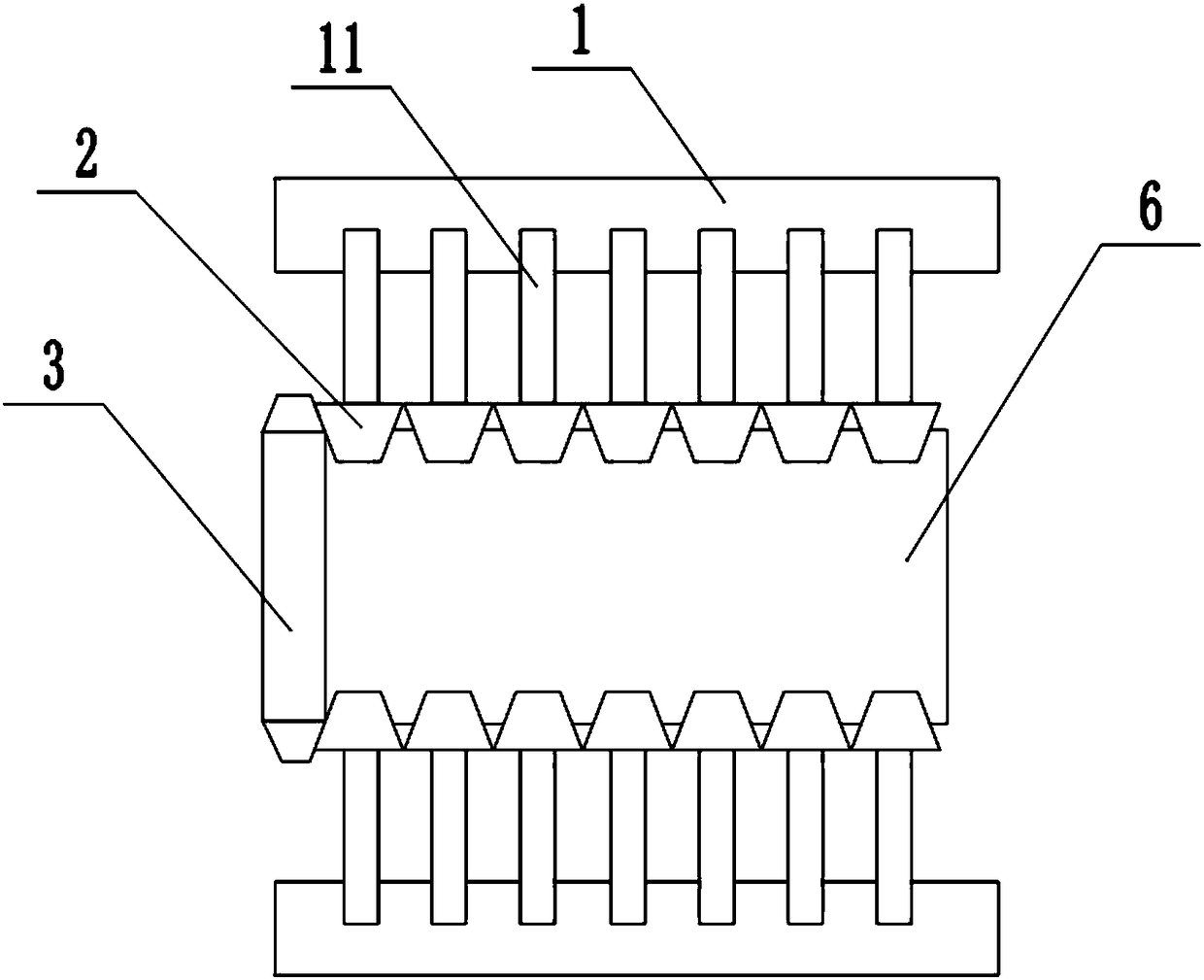

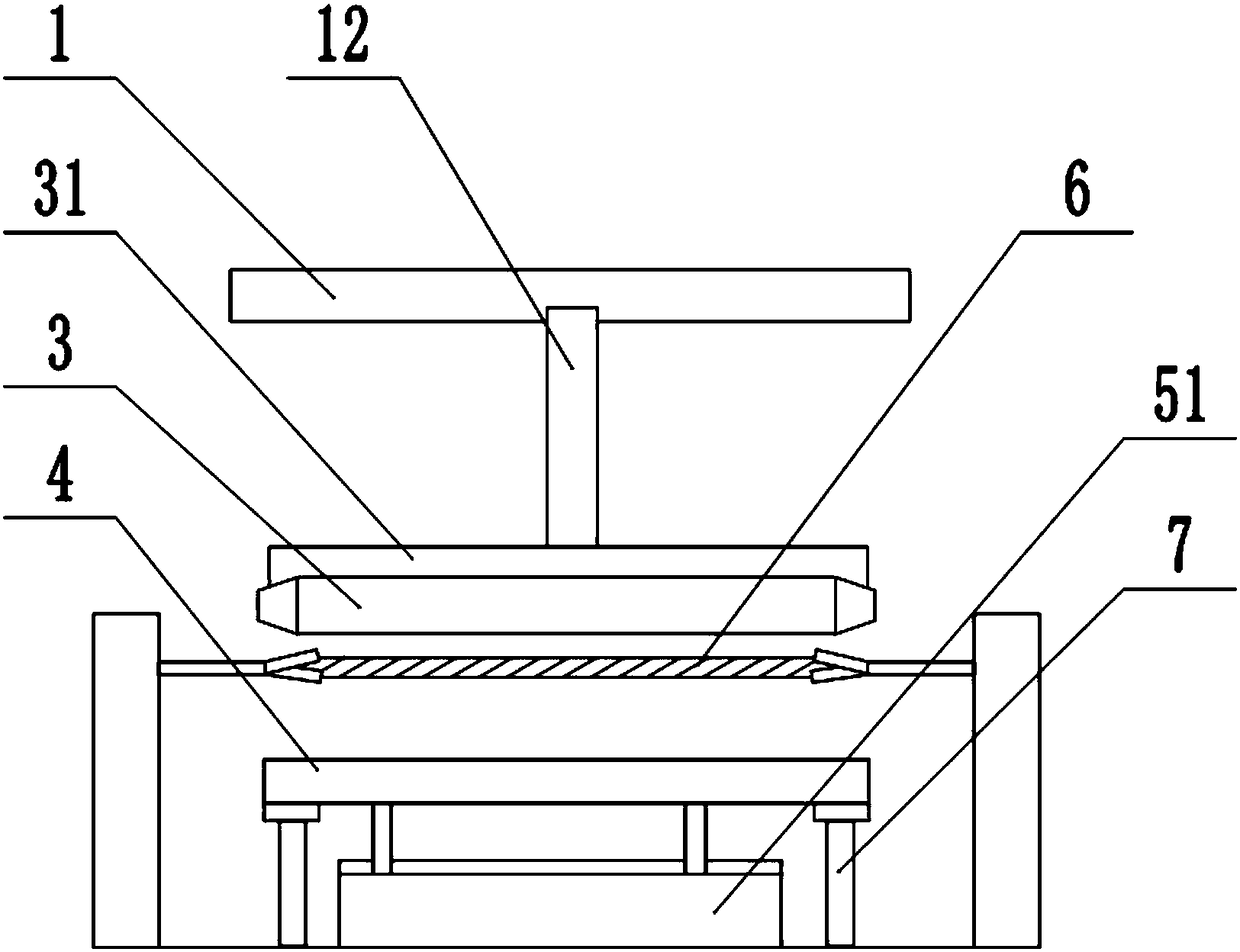

[0017] The reference signs in the drawings of the specification include: frame 1, push rod 11, sliding rod 12, clamping device 2, upper clamping piece 21, lower clamping piece 22, torsion spring 23, ejector 24, elongated magnet 3. Support 31, long iron block 4, open storage box 5, baffle 51, cloth 6, and telescopic frame 7.

[0018] The embodiment is basically as attached Figure 1 to 4 Shown: a fabric tentering setting device includes a frame 1, a plurality of push rods 11 are slidably installed on both sides of the frame 1, and the push rods 11 are connected with a clamping device 2 for clamping the fabric 6, so The frame 1 is slidably connected with a sliding rod 12, the sliding rod 12 is connected with a support, and the support is provided with an elongated magnet 3, and the elongated magnet 3 is located above the clamping device 2; An elongated iron block 4 is arranged...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com