Solar cell assembly

A solar cell module and solar cell technology, applied in the field of solar cells, can solve the problems of large hidden danger of debris and high cost of solar cell modules, and achieve the effects of low debris rate, omitting bending process and reducing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

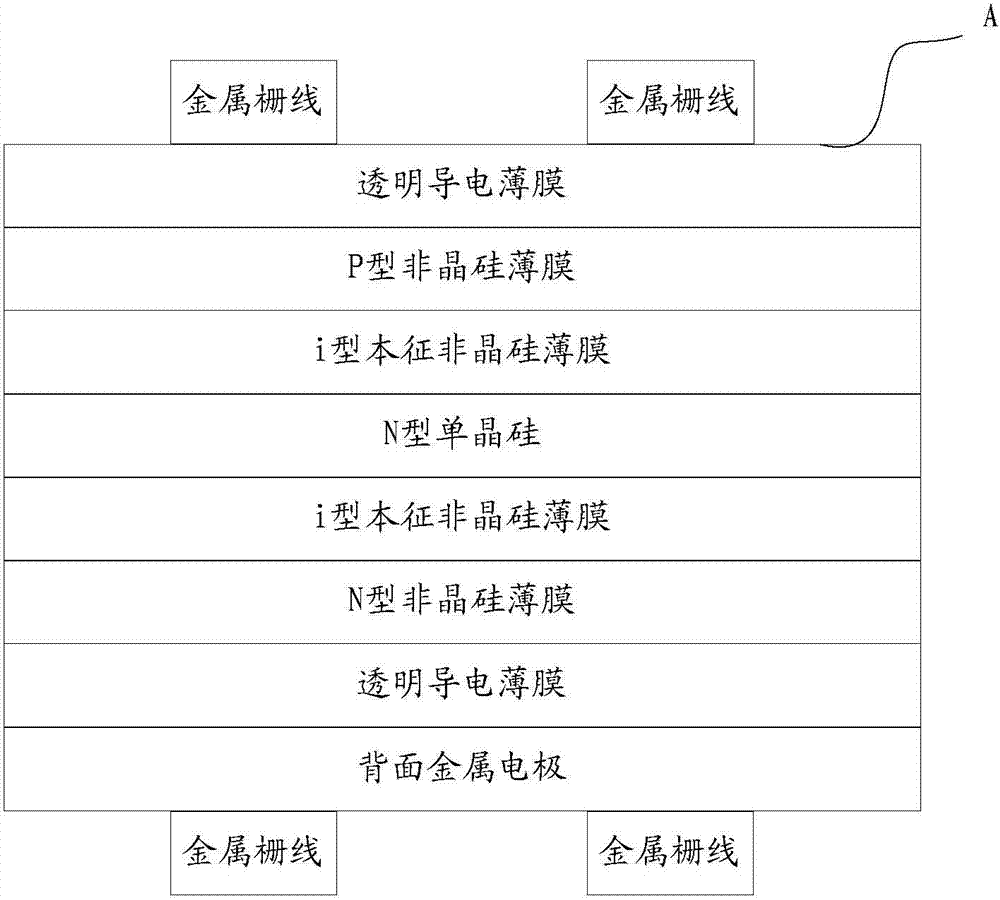

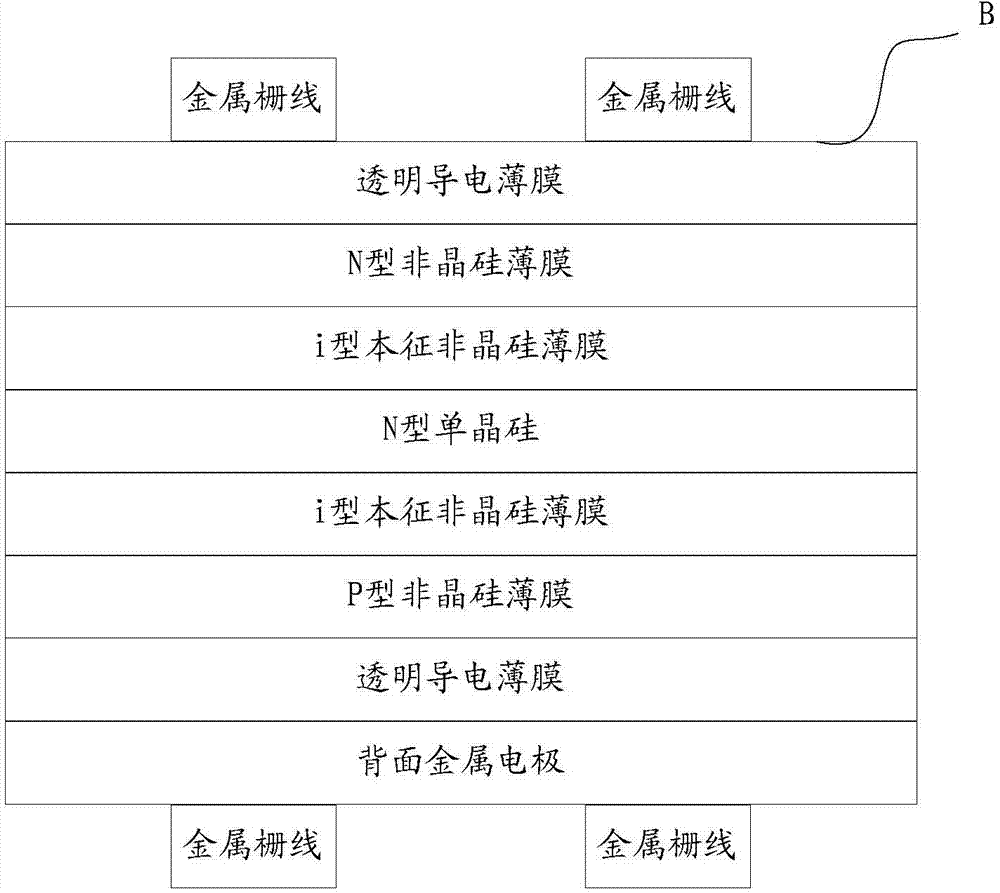

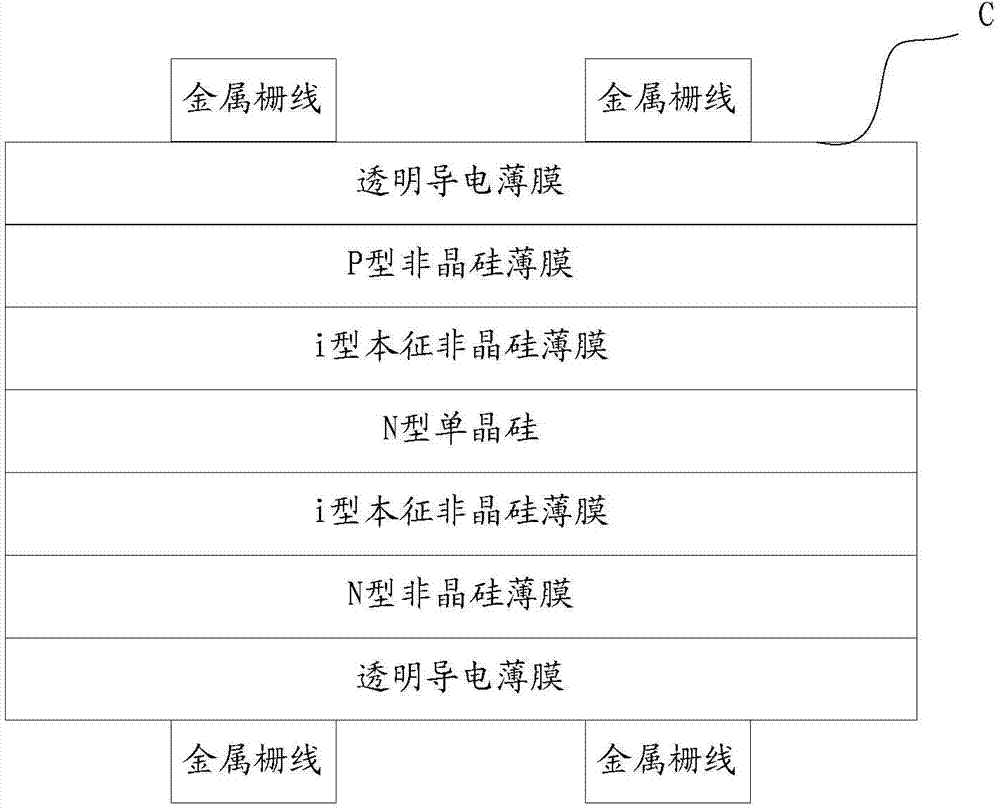

[0055] Such as Figure 5A The illustrated solar cell assembly provided by the embodiment of the present invention includes N rows and M columns of solar cells, and the solar cells in each row are connected in series; among the N rows of solar cells, at least K rows of solar cells have the following structure:

[0056] Two adjacent solar cells in a row of solar cells form a group, and each group of solar cells includes a first solar cell and a second solar cell, wherein at least one group of the first solar cells and the front electrodes of the second solar cells gender opposite (eg Figure 5A The front side of the first solar cell in the group is the positive pole, the front side of the second solar cell is the negative pole, and the front side or the back side of the first solar cell and the second solar cell in the group are provided with a converging strip (such as Figure 5A The front of the first solar cell and the second solar cell in the group is provided with a conflu...

Embodiment 2

[0087] Such as Figure 6 The first solar cell assembly shown includes solar cells in N rows and M columns, and the solar cells in each row are connected in series; the first solar cells adjacent to each other in columns 1 to c in each row of solar cells and the second solar cell constitute c-1 groups of solar cells, the polarities of the front sides of the first solar cell and the second solar cell in each group of solar cells are opposite, and the polarities of the first solar cell and the second solar cell in the group are A confluence strip is arranged on the front or the back, and the confluence strip connects the first solar cell and the second solar cell in the group in series, wherein, 12.

[0088] Wherein, the manner of connecting the first solar cell and the second solar cell in each group in series by the bus strip refers to Embodiment 1, and will not be repeated here.

[0089] The above-mentioned structure of the solar cell module allows the busbar to be arranged o...

Embodiment 3

[0091] Such as Figure 7 The second type of solar cell assembly shown includes solar cells in N rows and M columns, and the solar cells in each row are connected in series; in each row of solar cells, two adjacent first solar cells in the d-th column to the M-th column Constitute M-d group of solar cells with the second solar cell, the polarity of the front of the first solar cell and the second solar cell in each group of solar cells is opposite, and the front of the first solar cell and the second solar cell in this group or A confluence strip is arranged on the back, and the confluence strip connects the first solar cell and the second solar cell in the group in series, wherein, 12.

[0092] Wherein, the manner of connecting the first solar cell and the second solar cell in each group in series by the bus strip refers to Embodiment 1, which will not be repeated here.

[0093] The above-mentioned structure of the solar cell module makes the busbar only need to be arranged o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com