Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Uniform drying quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Oolong tea indoor sun-drying processing technique

ActiveCN106035777AAccelerates and promotes dehydrationReduce exposure to lightPre-extraction tea treatmentClimate change adaptationReduction rateComputer science

The invention belongs to the technical field of tea processing, particularly relates to an oolong tea indoor sun-drying processing technique and aims to provide an oolong tea processing technique adopting indoor sun-drying. The technique includes steps: picking fresh leaves; indoors sun-drying; shaking and airing; frying; removing red edges and spreading to retain moisture; rolling and fermenting for the second time; drying. The technique is characterized in that according to the indoor sun-drying processing technique, a bamboo mat needs to be set up at a position of 0.5-1 m higher than the ground according to daily yield, a sunshade net of 75-80% in sunshade rate needs to be set up at a position of 2 m above the bamboo mat, the tea leaves are spread on the bamboo mat according to leaf spreading quantity, the tea leaves need to be slightly turned and stirred by hands every other 12-15 min in the process of sun-drying, and the tea leaves are moved into a room for spreading and airing for 40-50 min when weight reduction rate of the lea leaves is 4-5% through sun-drying. The processing technique is clean, sanitary, simple, convenient and efficient, and tea leaves obtained by the technique are uniform in tea color.

Owner:黄山职业技术学院

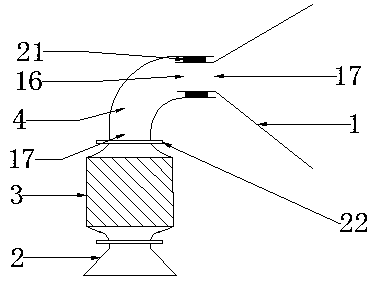

Drying device for tea processing

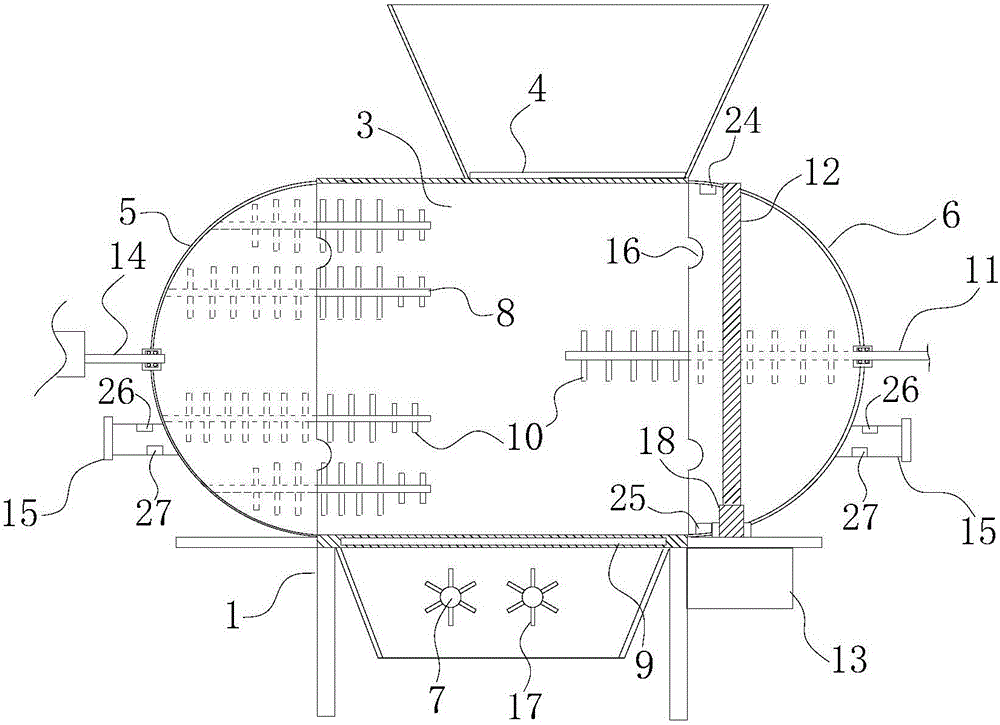

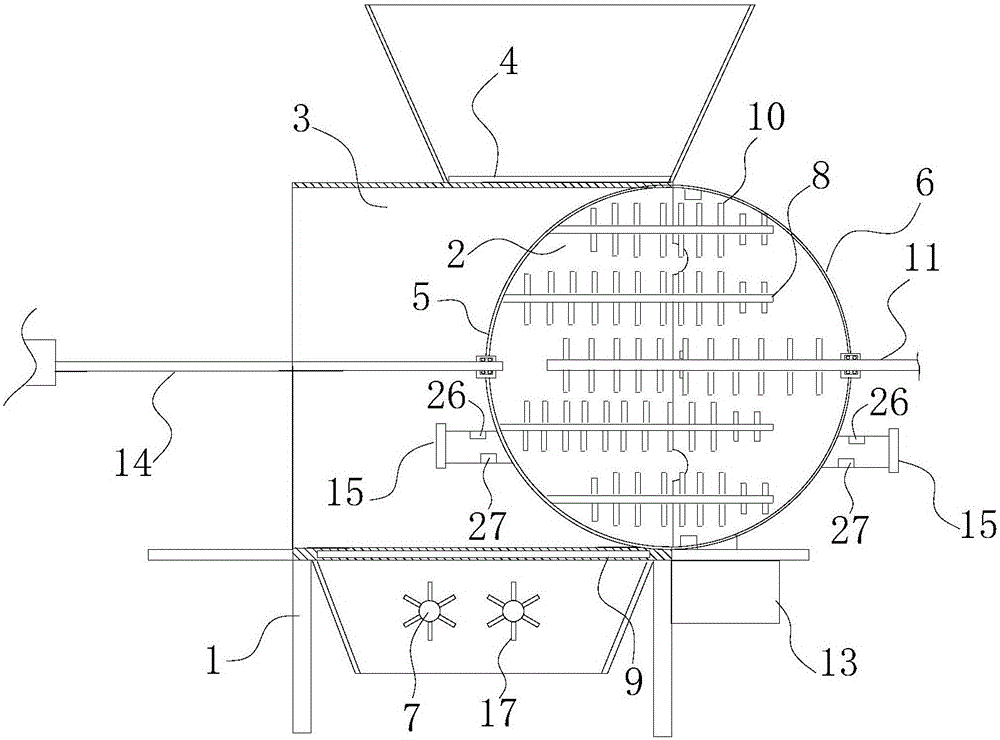

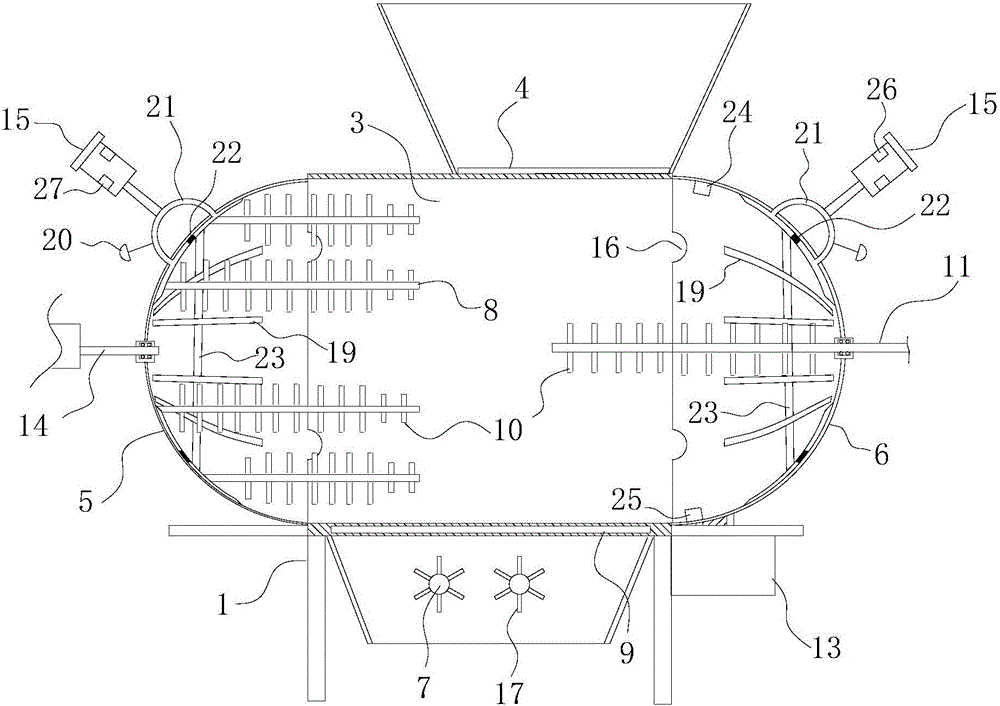

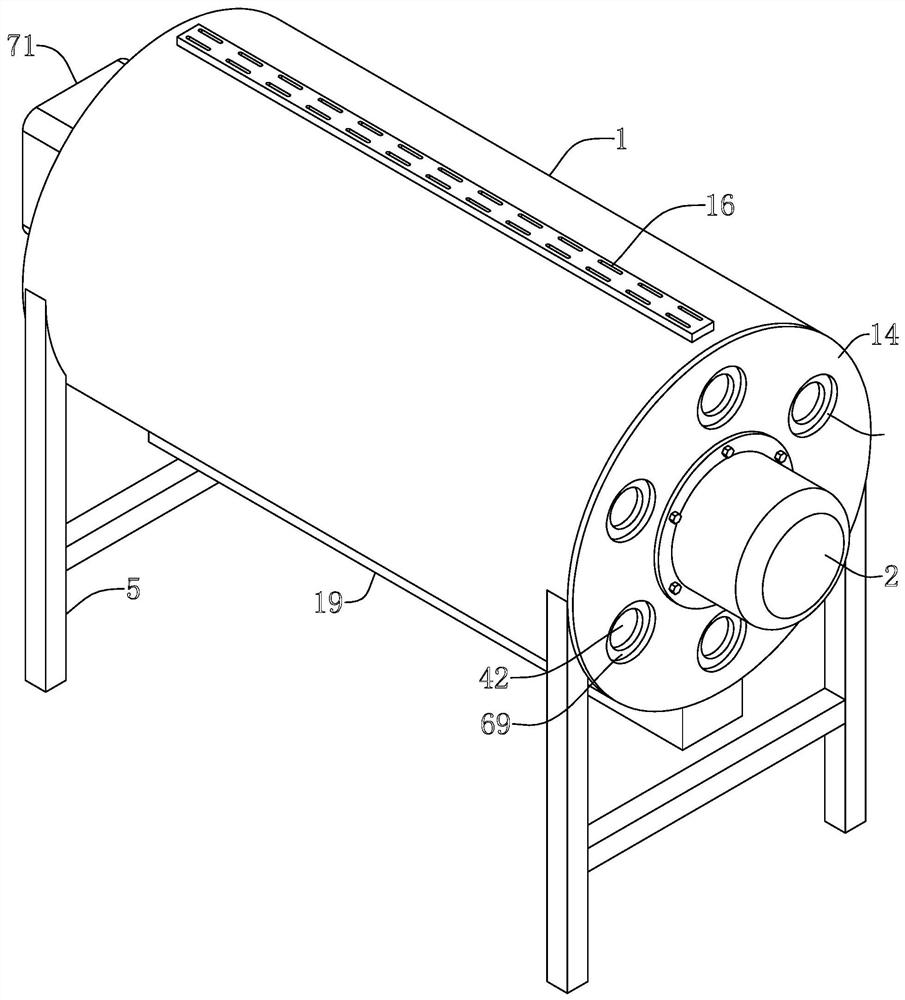

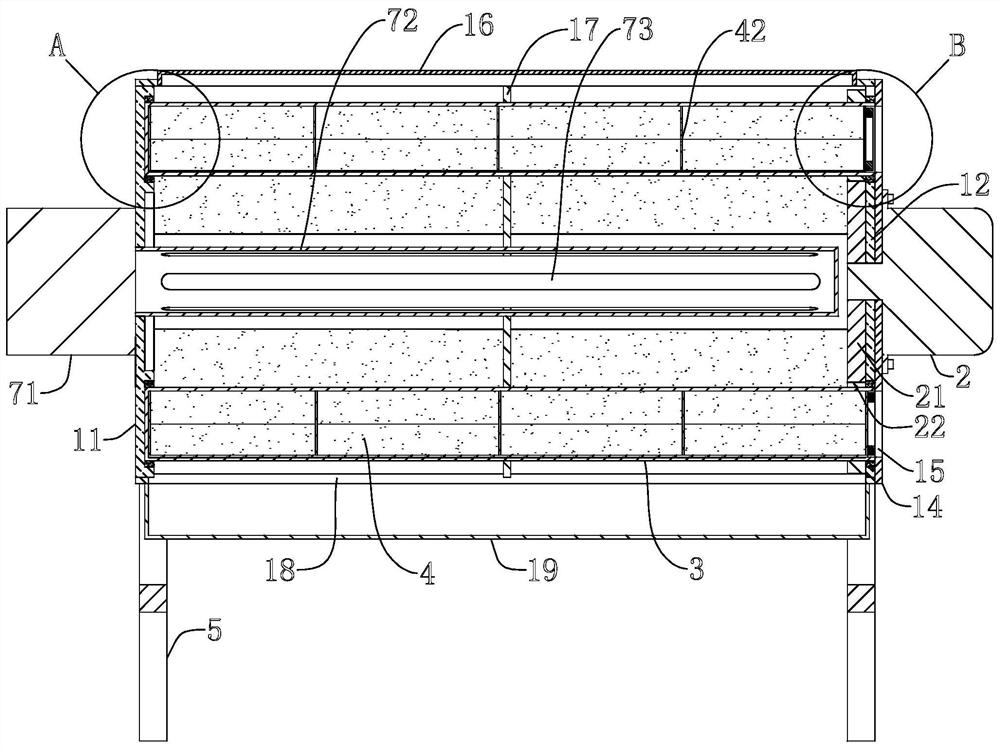

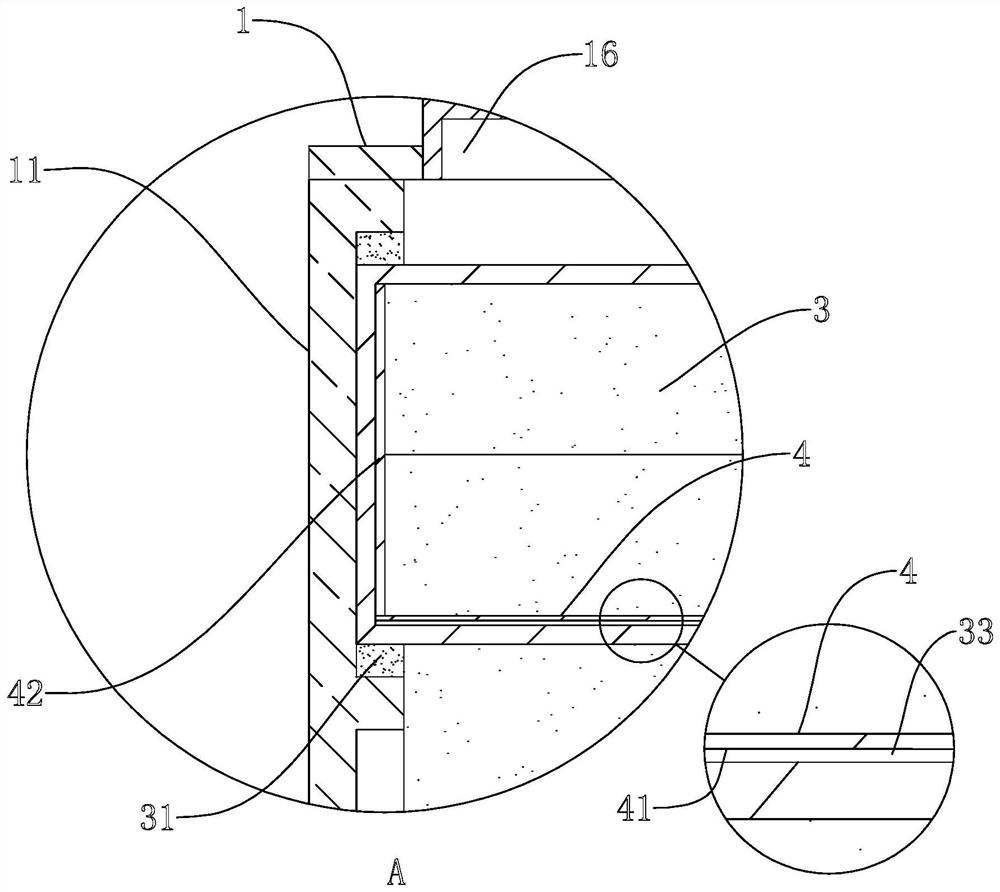

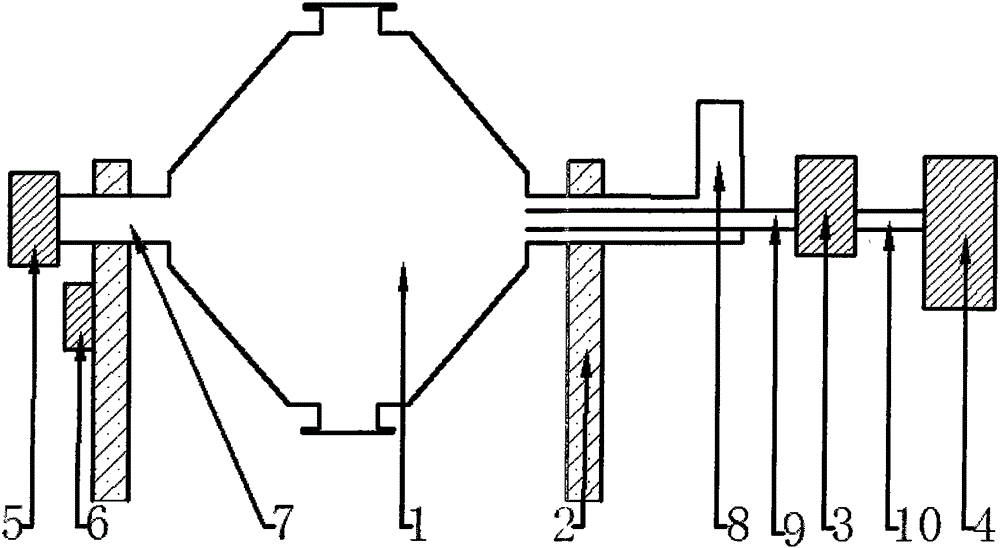

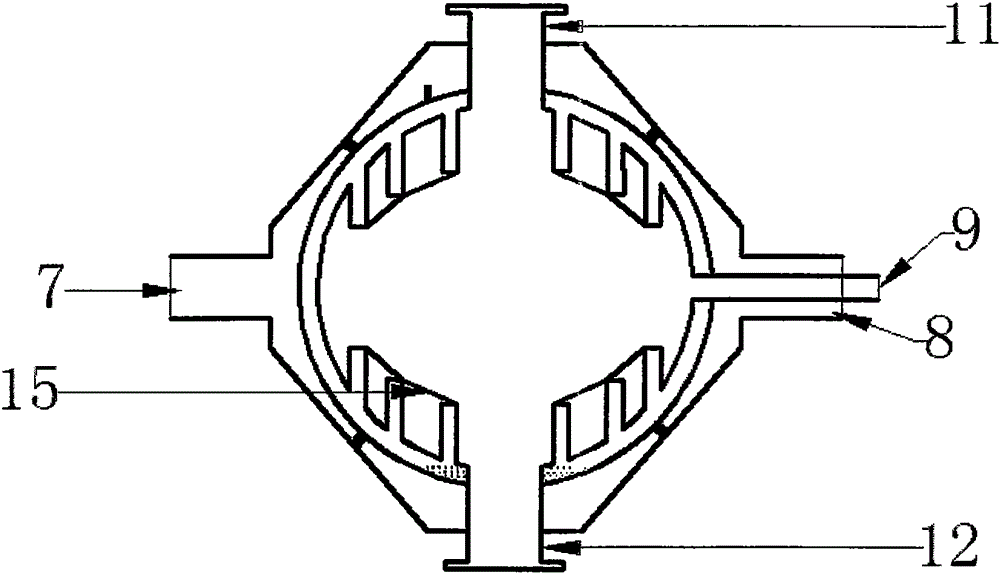

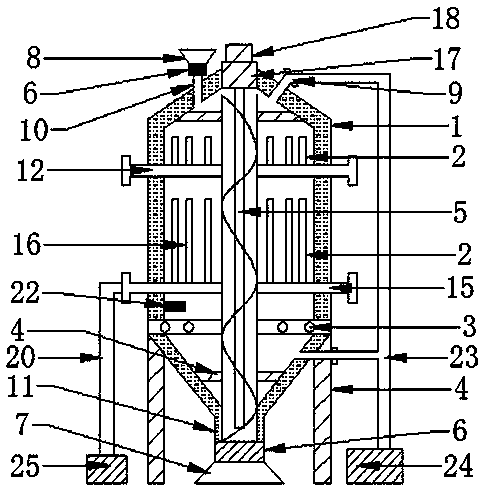

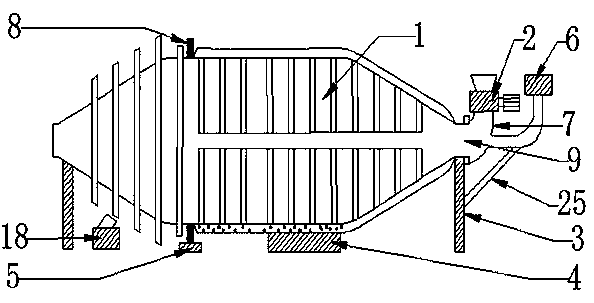

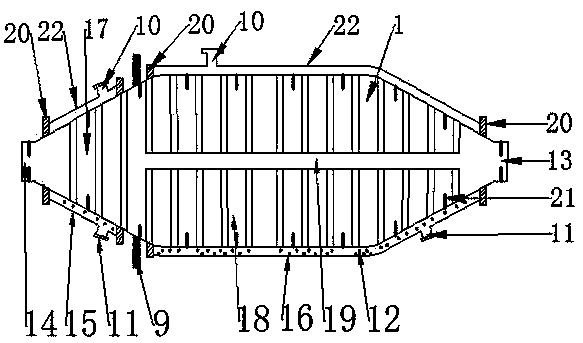

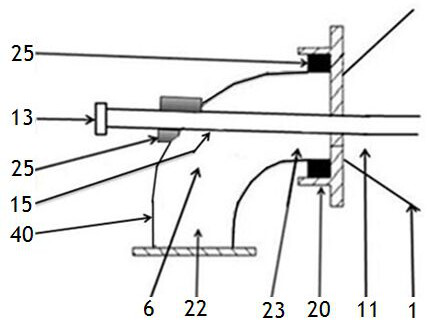

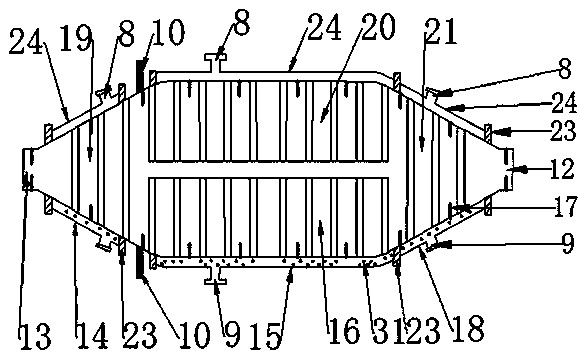

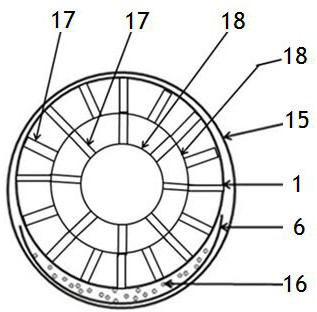

PendingCN113587579AUniform drying qualityEasy to take outDrying gas arrangementsDrying chambers/containersElectric machineEngineering

The invention discloses a drying device for tea processing. The drying device comprises a main body, a left end plate and a right end plate are arranged on the main body, a rotating motor is arranged on the right end plate, a first gear and second gears are arranged on the right end plate, the rotating motor drives the first gear to rotate, the second gears are meshed with the first gear, and a rotary drum is inserted into each second gear; the rotary drums are rotatably connected to the left end plate and the right end plate, a storage groove is formed in each rotary drum, the outer walls of the storage grooves are attached to the inner walls of the rotary drums, a limiting groove is formed in the lower end of each storage groove, a limiting strip is arranged in each rotary drum, a feeding port is formed in the right end plate, a cover plate is rotatably connected to the right side of the right end plate, and a plurality of inlets are formed in the cover plate; and heating elements are arranged in the main body. According to the drying device, tea leaves are placed in the storage grooves, then the storage grooves are formed in the rotary drums, the motor drives the rotary drums to rotate through the first gear and the second gears, the heating elements evenly heat the tea leaves in the rotary drums, the tea leaves are dispersed in all the rotary drums to be rotationally stirred, and the effect that the drying quality of the tea leaves is uniform is guaranteed.

Owner:云南五季生物科技有限公司

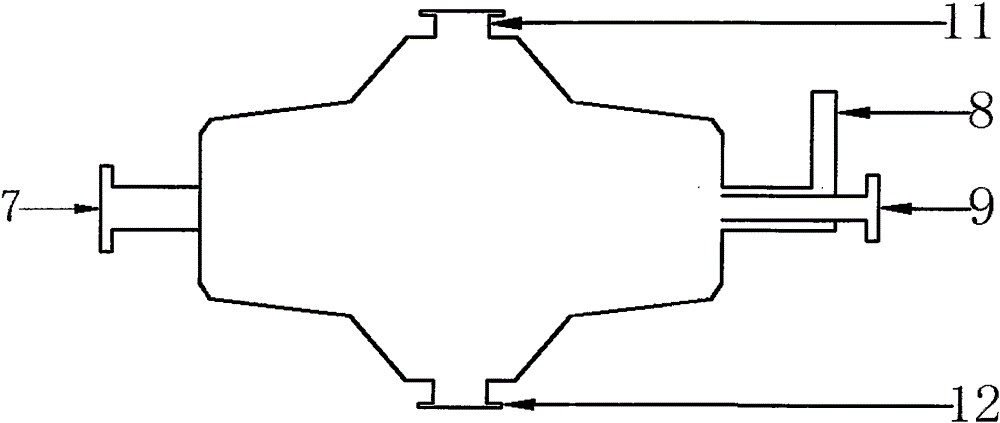

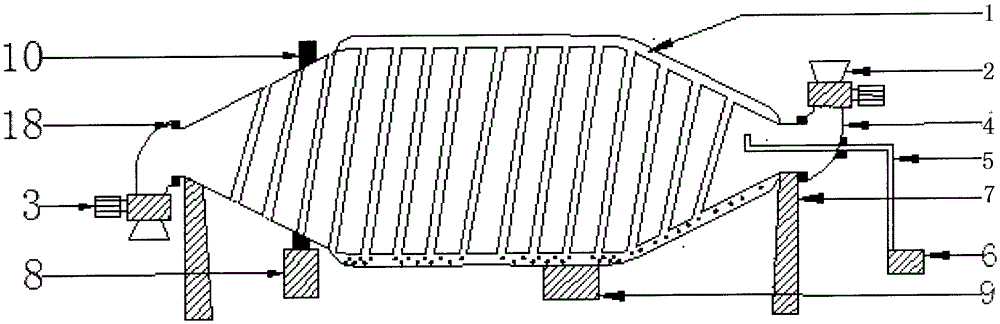

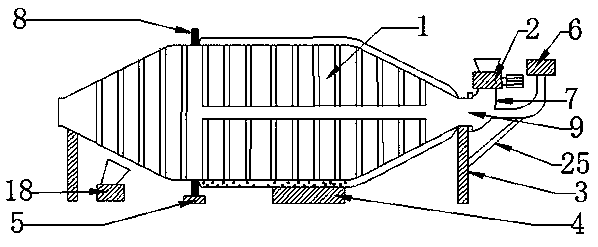

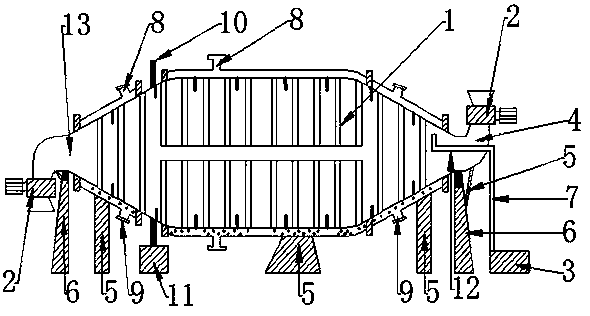

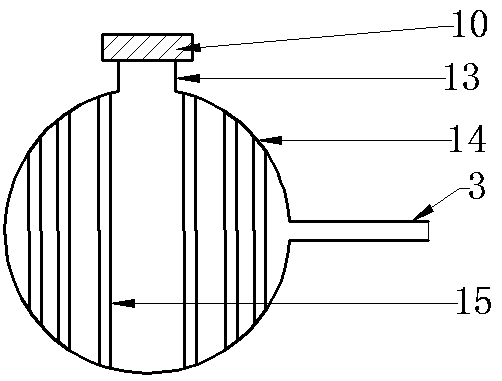

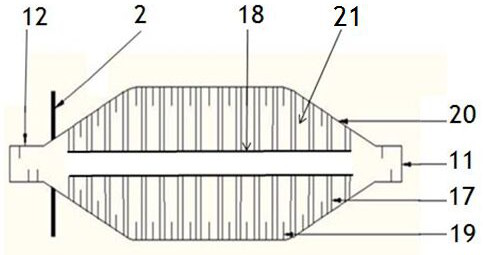

Heat pipe type vacuum dryer

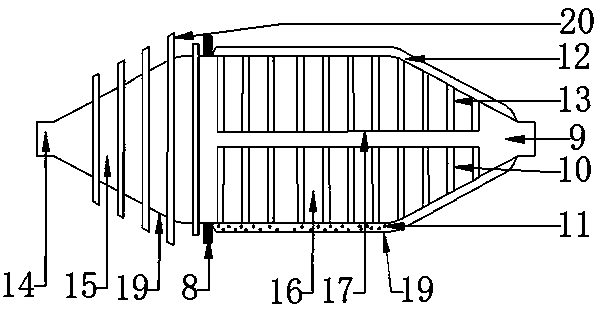

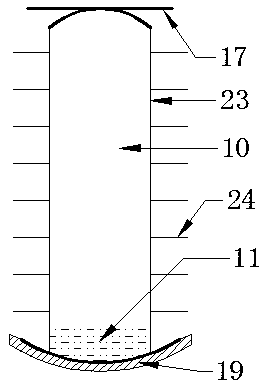

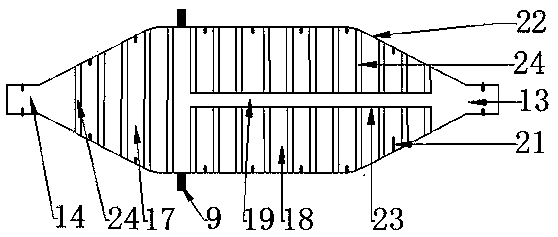

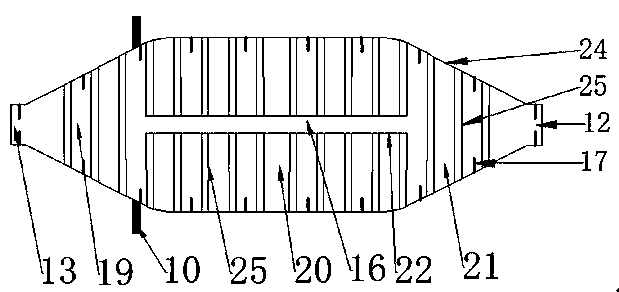

InactiveCN106369963ALow powerTo achieve the effect of energy saving and emission reductionDrying chambers/containersDrying machines with non-progressive movementsProcess engineeringAtmospheric pressure

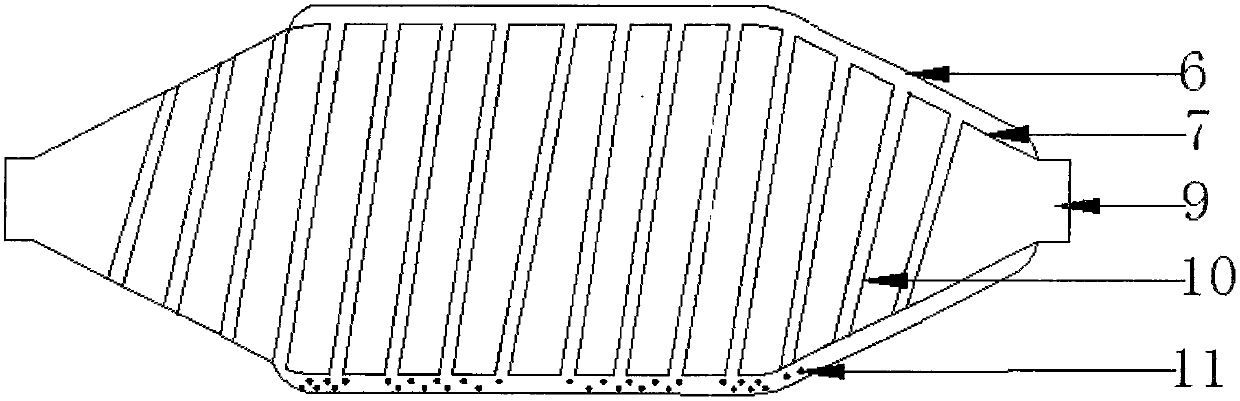

The invention discloses a heat pipe type vacuum dryer composed of a heat pipe type drying bin, a support, a condenser, a vacuum pump, a heating device, a driving device and a gas guiding pipe. The two ends of the heat pipe type drying bin are installed on the support, and according to the appearance shape, the heat pipe type drying bin is in the shape of double cones, a sphere or a cylinder. A heat energy inlet and a heat energy outlet of the heat pipe type drying bin are connected to the heating device through the gas guiding pipe. A gas exhausting port of the heat pipe type drying bin is connected to the condenser and the vacuum pump through the gas guiding pipe, and the atmospheric pressure in the heat pipe type drying bin reaches the vacuum degree of -0.094 Mpa to -0.098 Mpa. According to the heat pipe type vacuum dryer, the inner wall single layer plane cooling of the drying bin is changed into the inner wall stereoscopic cooling of the drying bin, the cooling area is increased by 5-30 times, the heat guiding and dissipating speed is increased, the drying time is shortened, continuous stirring and crushing can be achieved, the drying efficiency is improved, and the drying effect is optimized; and the effects of using waste heat, saving energy and reducing emission are achieved.

Owner:张国利

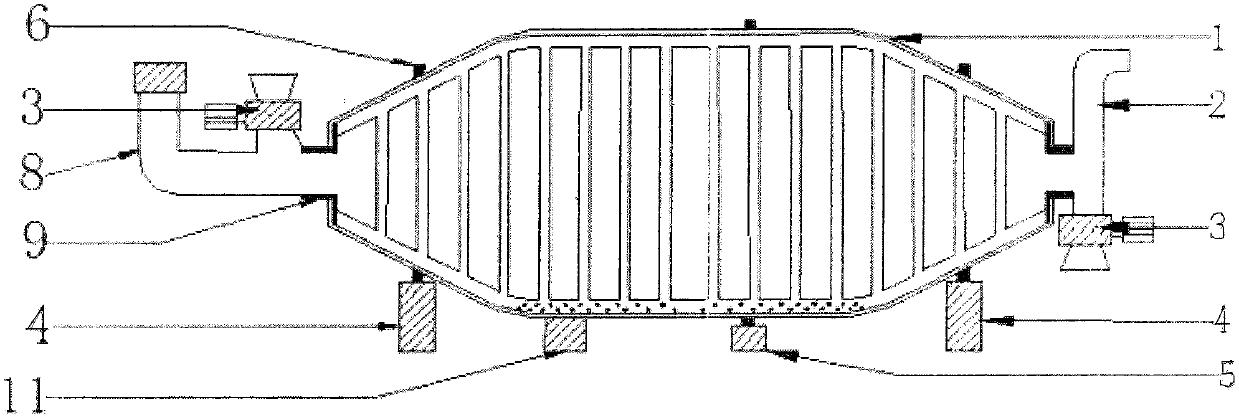

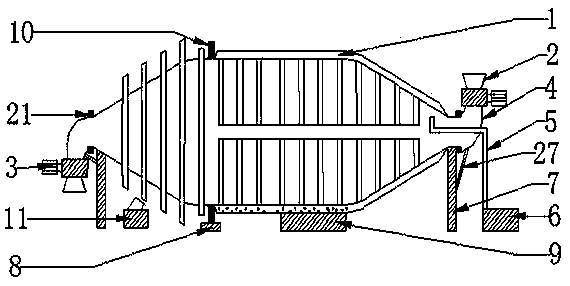

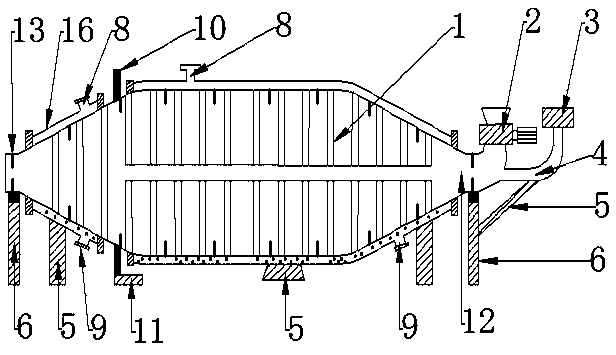

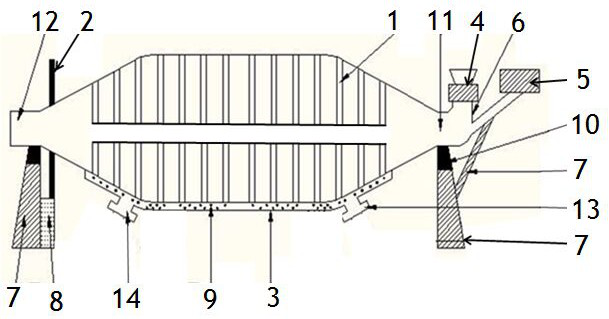

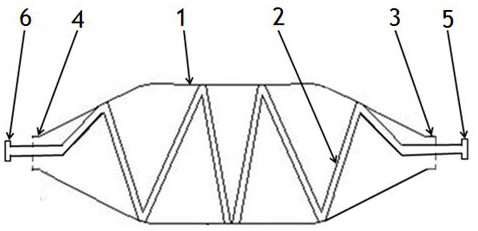

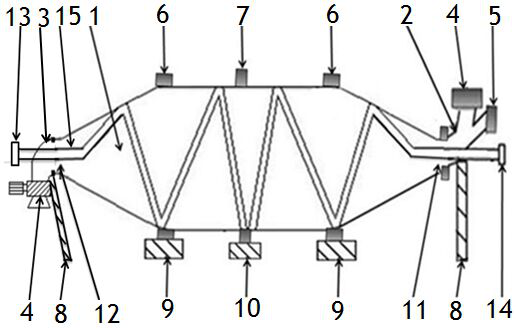

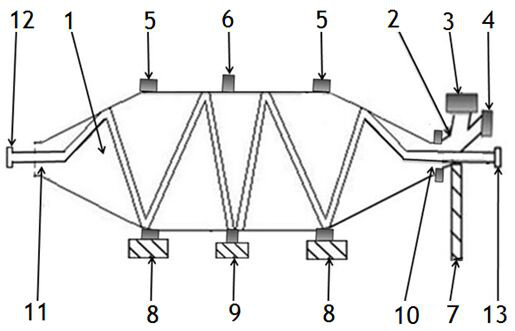

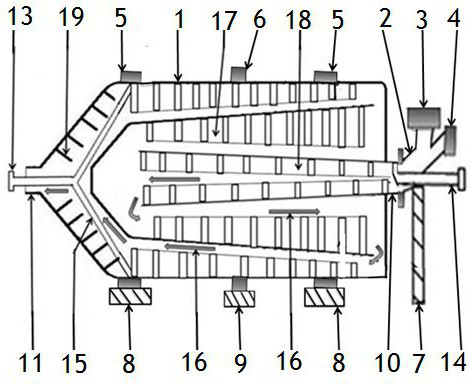

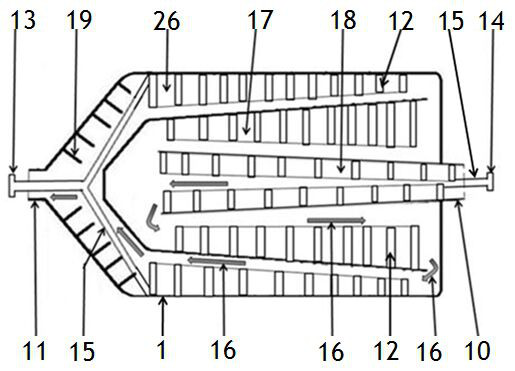

Hot air drying machine with cooling section

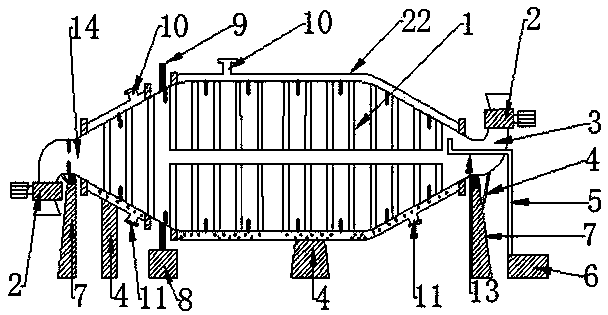

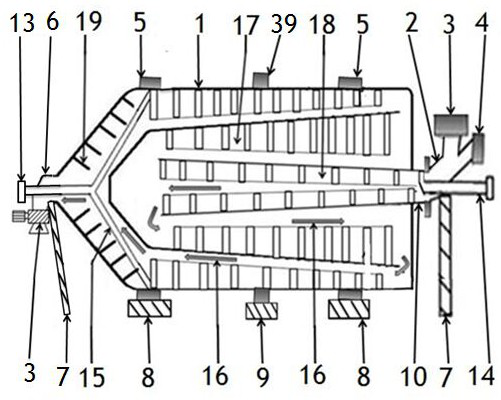

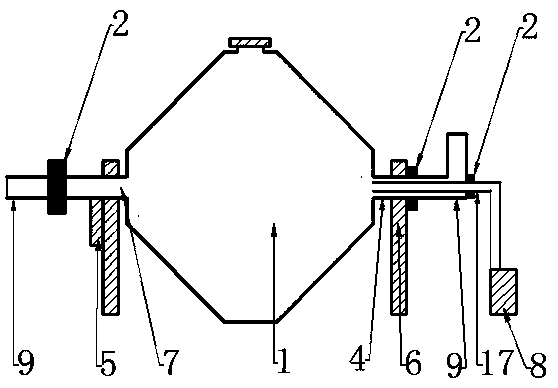

InactiveCN105509435AImprove cleanlinessGuarantee material qualityDrying gas arrangementsDrying machines with non-progressive movementsEngineeringGreening

The invention relates to a hot air drying machine with a cooling section. The hot air drying machine consists of a drying bin, a vacuum material inlet and outlet device, brackets, a heating device, a driving device, an air ventilation pipeline, a fan and a rail, wherein the drying bin is provided with the cooling section; the brackets are used for supporting a material inlet and a material outlet at the two ends of an inner bin; the vacuum material inlet and outlet device is arranged at the material inlet and the material outlet at the two ends of the inner bin; a conveying pipeline is fixedly connected with the air ventilation pipeline; the driving device is used for driving the trail on the drying bin with the cooling section; the heating device is used for directly heating an outer casing of the drying bin with the cooling section. The hot air drying machine has the advantages that in the material drying process, the drying bin with the cooling section is driven by the driving device to rotate, spiral heat radiating vertical pipes are used for stirring and pushing, the drying of a material has no dead space, the easiness in caking of the material in the drying section of the inner bin in the drying process is avoided, the drying time of the material is shortened, the drying quality of the material is uniform, the dried material can be cooled in the cooling section, the drying efficiency of the material is improved, the drying effect of the material is optimized, and the greening, drying, energy-saving and environment-friendly effects are realized.

Owner:张海娟

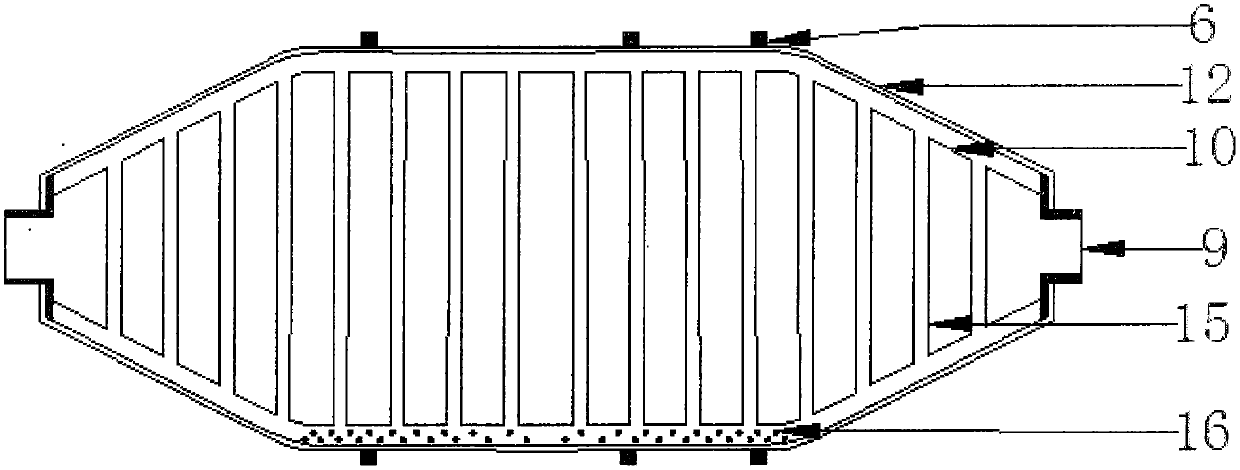

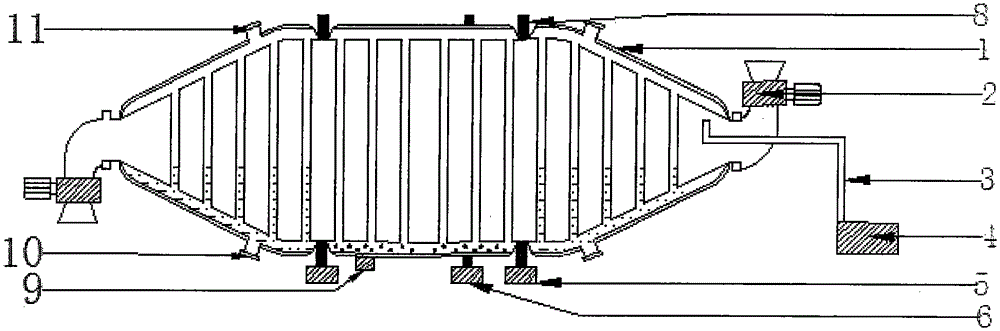

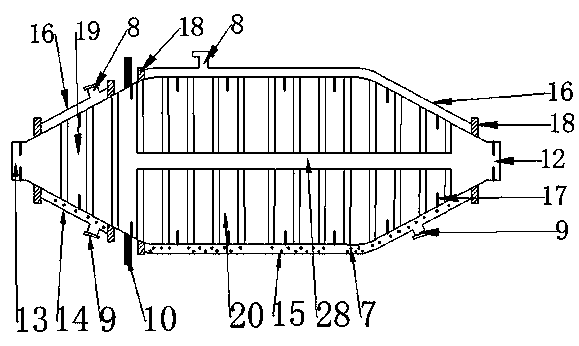

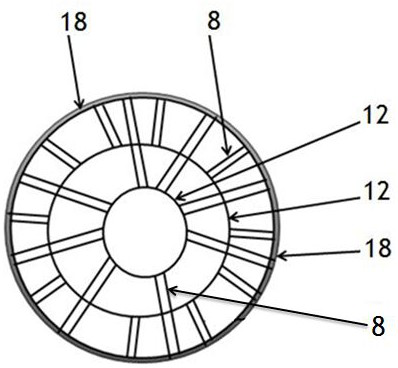

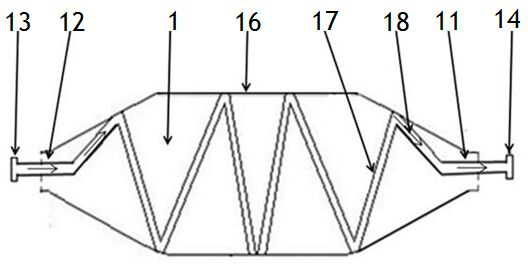

Vacuum drying machine with cooling section

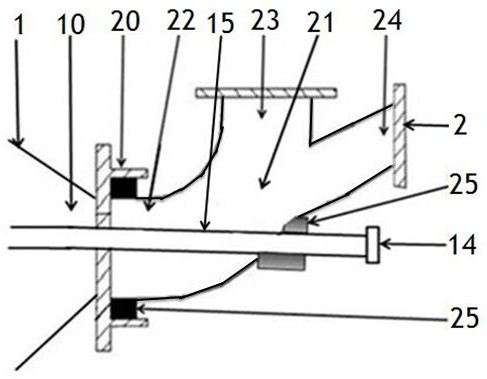

ActiveCN105371621ANot easy to agglomerateShorten drying timeDrying solid materialsDrying machines with non-progressive movementsEngineeringDrying time

The invention discloses a vacuum drying machine with a cooling section. The vacuum drying machine is composed of a drying bin with the cooling section, a hopper, a discharge device, an elbow, a gas guide pipe, a support, a vacuum unit, a heating device, a driving device and rails. The drying bin with the cooling section is composed of a shell, an inner bin, a heat conduction medium and a safety valve. The support supports a feed port and a discharge port of the two ends of the inner bin. The vacuum unit sucks gas in a bin body of the inner bin through a gas guide pipe. In the material drying process, the drying bin with the cooling section can be rotated on the support through the driving device, cooling vertical pipes arrayed spirally have functions of stirring and propelling materials, no dead corners exist during material drying, materials are not prone to caking when dried in the drying section of the inner bin, material drying time is shortened, material drying quality is uniform, dried materials are cooled in the cooling section, material drying efficiency is improved, the material drying effect is optimized, and green, energy-saving and environment-friendly drying is achieved.

Owner:温州市金榜轻工机械有限公司

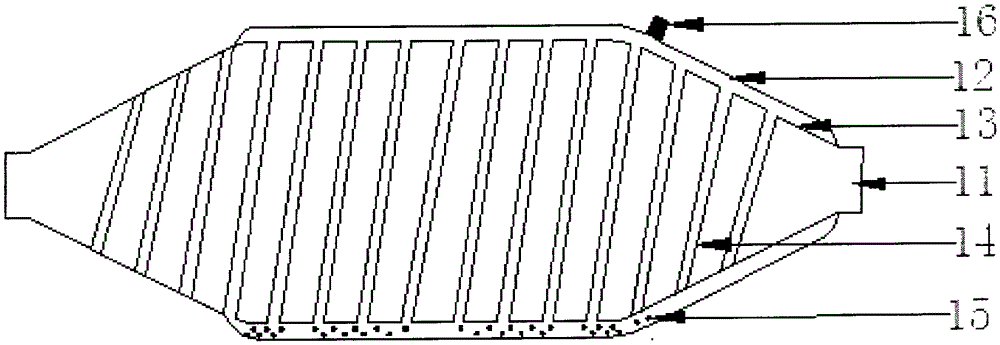

Single-box drying equipment with uniform heating function

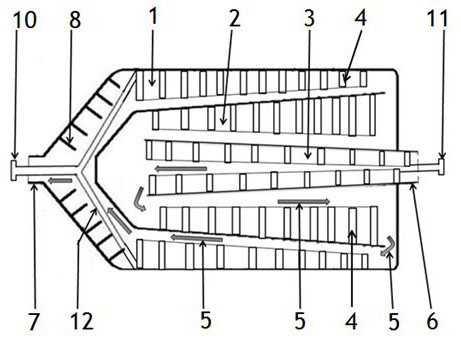

InactiveCN105783441AHeating and drying evenlyComprehensive and uniform heating and dryingDrying gas arrangementsDrying chambers/containersInfraredInsulation layer

The invention relates to single-box drying equipment with the uniform heating function. The single-box drying equipment comprises a box body, a cavity is formed inside the box body, a heat insulation layer is arranged on the inner wall of the box body, an exhaust fan extracting air from the cavity is fixedly arranged at the upper end of the box body, and a plurality of infrared heating devices are arranged on the inner side of the heat insulation layer and are attached to the inner wall of the heat insulation layer in a surrounding mode; a PLC control cabinet is arranged on one side of the box body and is connected to the infrared heating devices through circuits; a plurality of material trays capable of being extracted are arranged inside the cavity, the material trays of the odd layers are detachably connected to the inner wall of one side of the box body, the material trays of the even layers are detachably connected to the inner wall of the other side of the box body, a roundabout airflow channel is formed among the material trays, and the material trays are gauze trays with wooden frameworks; an air inlet is formed in the lower part of the box body. Compared with the prior art, the single-box drying equipment has the advantages that heating is uniform, the drying quality of materials is uniform, the drying efficiency is high, and the cost is low.

Owner:张冬梅

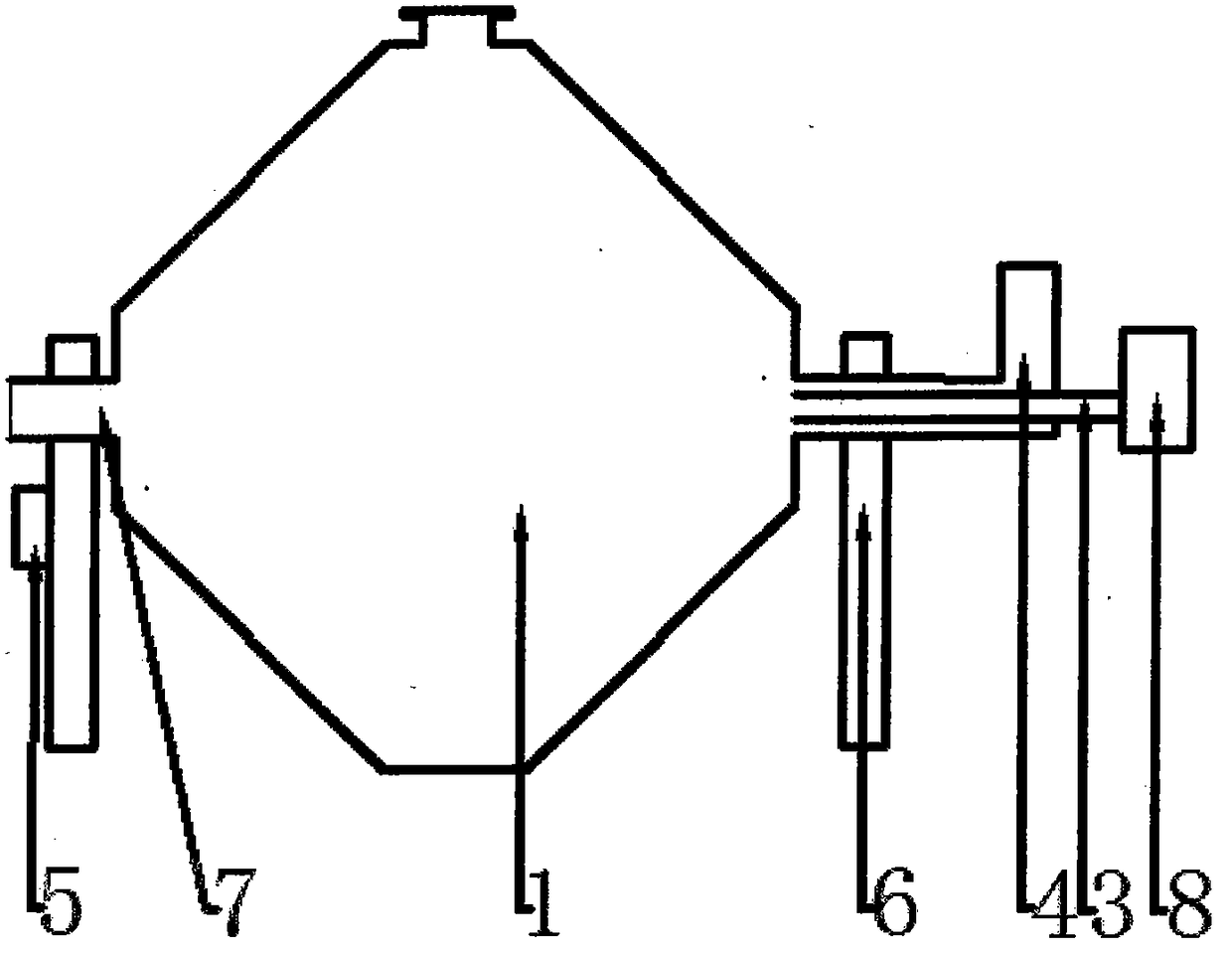

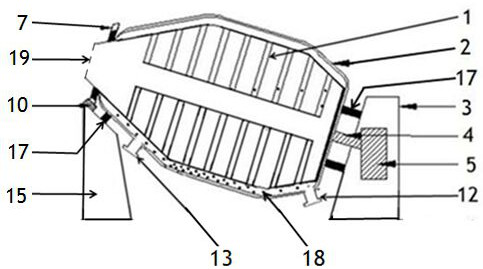

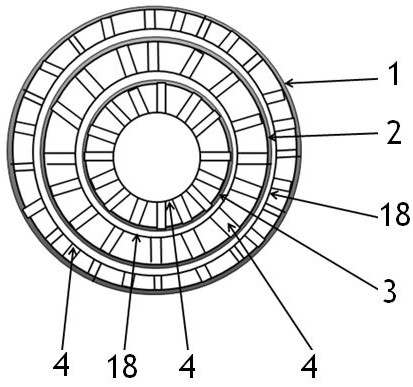

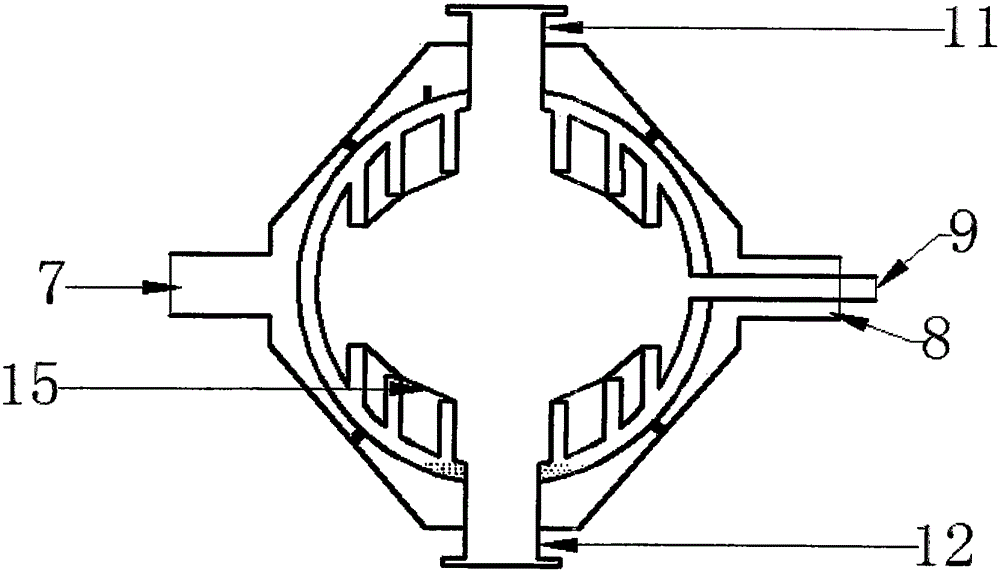

Three-dimensional heating type two-cone vacuum drier

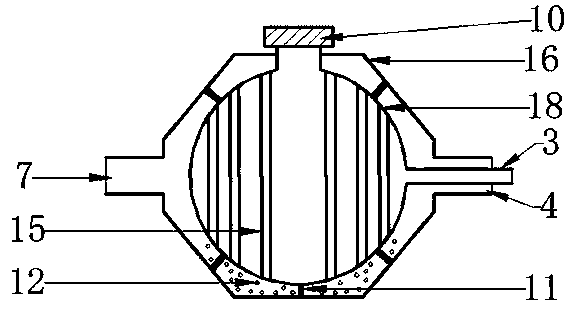

ActiveCN105318680AWith stirring functionNot easy to agglomerateDrying using combination processesDrying machines with non-progressive movementsPulp and paper industryVacuum drying

The invention discloses a three-dimensional heating type two-cone vacuum drier. The three-dimensional heating type two-cone vacuum drier is composed of a three-dimensional heating type vacuum drying chamber, a support, a vacuum unit and a driving device. The two ends of the three-dimensional heating type vacuum drying chamber are disposed on the support, and the driving device is disposed on the support and used for driving the three-dimensional heating type vacuum drying chamber to rotate. An exhaust port of the three-dimensional heating type vacuum drying chamber is connected to the vacuum unit. According to the three-dimensional heating type two-cone vacuum drier, under the condition of spaces with the same size, three-dimensional heat dissipation and heating of the inner wall of the drying chamber are adopted; the heat dissipation area is 8-60 times larger; heat conduction and dissipation speed is increased; total heat energy transmission amount for drying is increased; a heat dissipation pipe can achieve a stirring function, so that wet materials are not prone to being agglomerated; the product drying quality is uniform; the drying efficiency is improved and the drying effect is optimized.

Owner:无锡施洛华机械有限公司

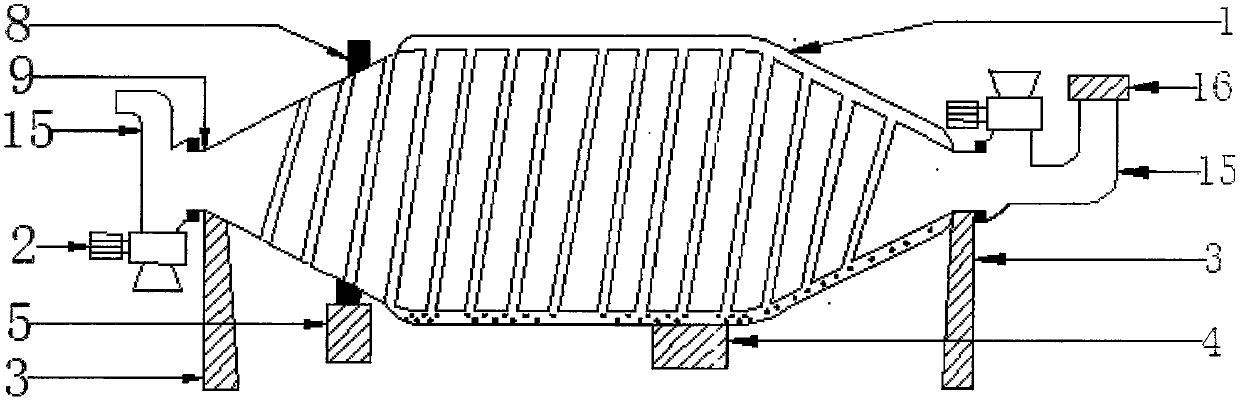

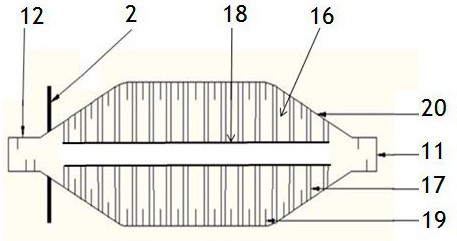

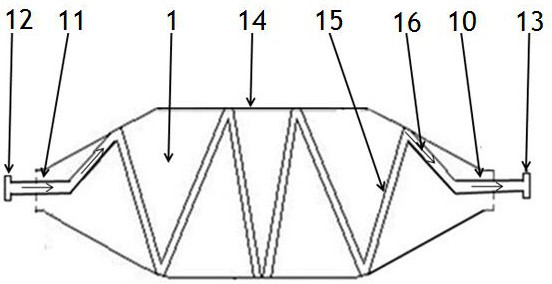

Continuous heat pipe type hot air drying machine

InactiveCN105509453AImprove heat conduction and heat exchange speedShorten drying timeDrying gas arrangementsHeating arrangementSpiral bladePulp and paper industry

The invention provides a continuous heat pipe type hot air drying machine, which consists of a heat pipe vacuum drying cabin, an air inlet device, a support frame, a discharging device, a heating device, a driving device, rails and an exhaust device, wherein the discharging device, the air inlet device and the exhaust device are arranged on material inlet and outlet openings of an inner cabin; the rails arranged on a case of the heat pipe vacuum drying cabin is arranged on the support frame; the driving device is used for driving the rails arranged on the case; the heating device is used for directly heating the case of the heat pipe vacuum drying cabin. The heat exchange is directly performed in the drying cabin; the heat exchange area is increased by 12 to 60 times; the heat conduction and heat exchange speed of material drying is accelerated. The materials are fed into or discharged from the vacuum drying cabin through the discharging device, and the materials can be subjected to continuous hot air drying. A heat radiation pipe and a spiral blade have the stirring function; no dead corner exists during the material drying; the material drying time is shortened, so that the material drying quality is uniform; the material drying efficiency is improved; the material drying effect is optimized; the dried materials are cooled; the effects of green drying, energy saving and environment protection are achieved.

Owner:张海娟

Stereo Heating Double Cone Vacuum Dryer

ActiveCN105318680BWith stirring functionNot easy to agglomerateDrying using combination processesDrying machines with non-progressive movementsThermal energyProcess engineering

A three-dimensional heating type double-cone vacuum dryer of the present invention is composed of a three-dimensional heating type vacuum drying chamber, a support, a vacuum unit, and a driving device. The two ends of the three-dimensional heating vacuum drying chamber are installed on the support, and the driving device is installed on the support. The driving device is used to drive the rotation of the three-dimensional heating vacuum drying chamber. The exhaust port of the three-dimensional heating vacuum drying chamber is connected to the vacuum unit. In the case of the same size space, the three-dimensional heating type double-cone vacuum dryer can dissipate heat for the three-dimensional heat dissipation and heating of the inner wall of the drying chamber. The heat dissipation area is increased by 8‑60 times, and the heat conduction and heat dissipation speed is improved. Improvement; the cooling pipe has a stirring function, and the wet material is not easy to agglomerate, so that the drying quality of the product is uniform, the drying efficiency is improved and the drying effect is optimized.

Owner:无锡施洛华机械有限公司

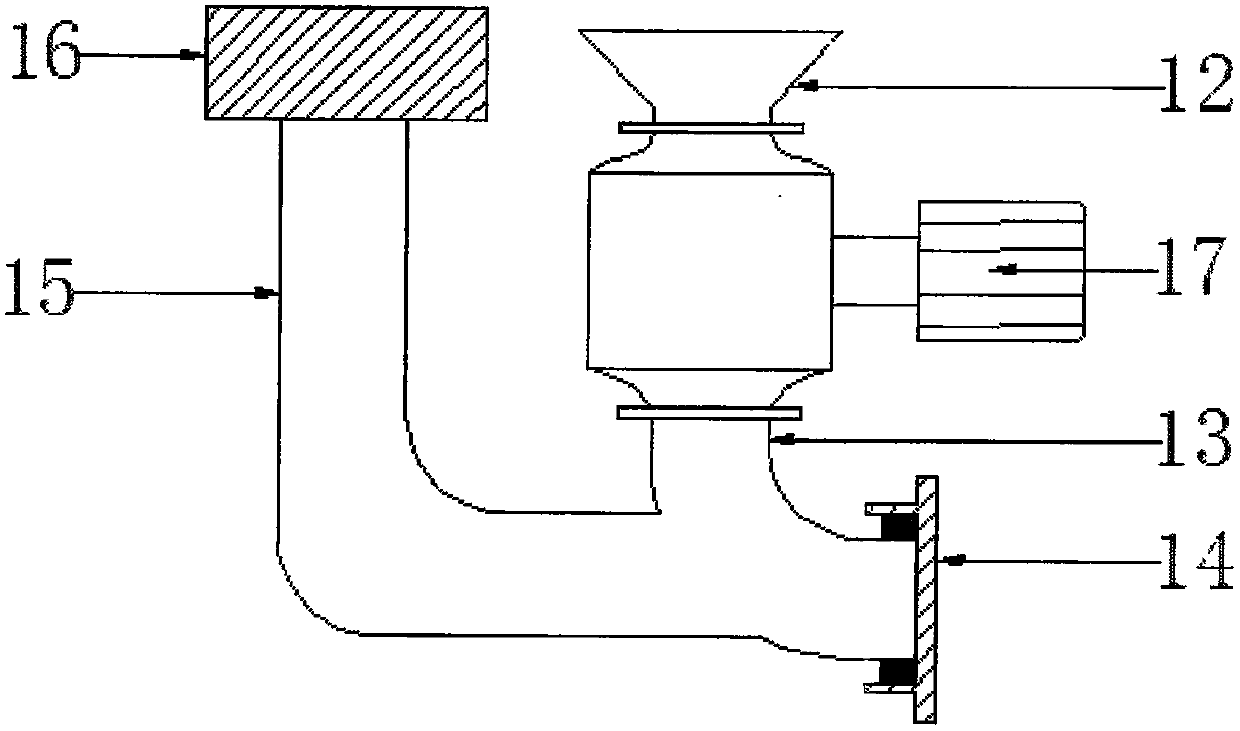

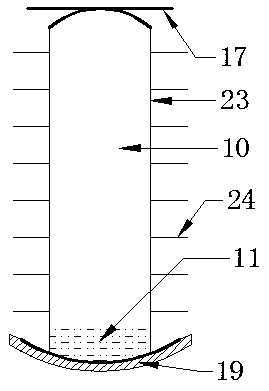

Vacuum dryer

InactiveCN108571875AImprove qualityImprove efficiencyGranular material dryingDrying solid materials without heatThermal energyCondensation process

The invention discloses a vacuum dryer. The vacuum dryer comprises a drying storehouse, a heat transfer device, grain discharge devices, a bracket, a lifting device, a valve, a feed hopper, an outlethopper, a sealing device, an online moisture test device, a vacuum set, a heating device, a gas guide tube, a heat conduction tube, a heat conduction medium and a thermal insulation layer, wherein thevacuum set is connected with an air exhaust port in the drying storehouse through the heat conduction tube; the valve is used for controlling the entry and exit of materials in the drying storehouse;the heat transfer device is connected with the heating device through the heat conduction tube; the drying storehouse is internally provided with 1-5 sets of grain discharge devices, the online moisture test device is arranged in the drying storehouse; the heat conduction medium carrying thermal energy directly performs heating and heat conducting on the materials through a heat pipe of the heattransfer device, the thermal conversion efficiency is high, loss is small, and the heat conduction and heat transfer speed is improved; waste-heat utilization can be carried out on the heat energy released by the condensable gas in the moisture in the condensation process of a condenser; the lifting device dries the materials circularly and drily; each grain discharge device has a stirring function, so that the drying quality of the materials is even, thereby improving the drying efficiency of the materials and optimizing the drying effect of the materials.

Owner:程相杰

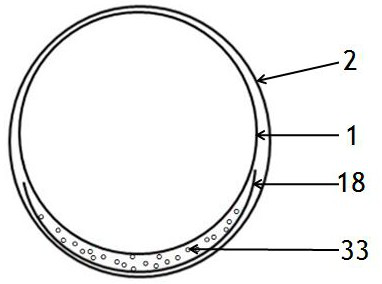

Drum vacuum dryer

InactiveCN109387039AReduce entryReduce air intakeDrying solid materials without heatDrying gas arrangementsHeat conductingEngineering

The invention relates to a drum vacuum dryer. The drum vacuum dryer comprises a vacuum drying chamber, a hopper, a discharging device, an elbow, an air duct, a vacuum unit, a riding wheel bracket, a driving device, a heating device, a gear ring, a fan, a sealing device and a bracket. The vacuum drying chamber comprises a heating chamber, a drying chamber and a heat conducting working medium; the riding wheel bracket fixedly supports the vacuum drying chamber and is provided with a feed opening and a discharge opening. A flange-free end of the elbow and the feed opening and the discharge opening of the vacuum drying chamber are hermetically connected into a whole by the sealing device, and an end with a flange of the elbow is fixedly connected into a whole with the discharging device. Whenthe vacuum drying chamber is driven to rotate by the driving device, the air duct and the elbow are stationary, and the joint of the air duct and the elbow is sealed and airtight. The heat energy of the heating device heats a material, conducts heat to the material and radiates heat from the material through the heat conducting working medium, so that the heat conversion efficiency is high and theloss is small; the dried material is cooled in a cooling section, so that the material drying efficiency is improved, and the material drying effect is optimized. When one heat pipe is damaged and leaks, the use of the whole drum vacuum dryer is not affected.

Owner:程长春

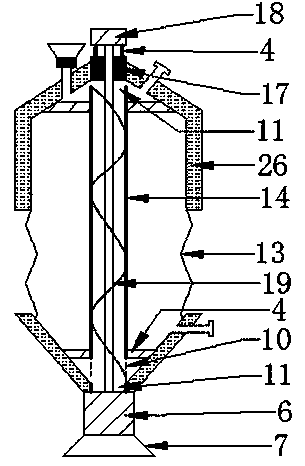

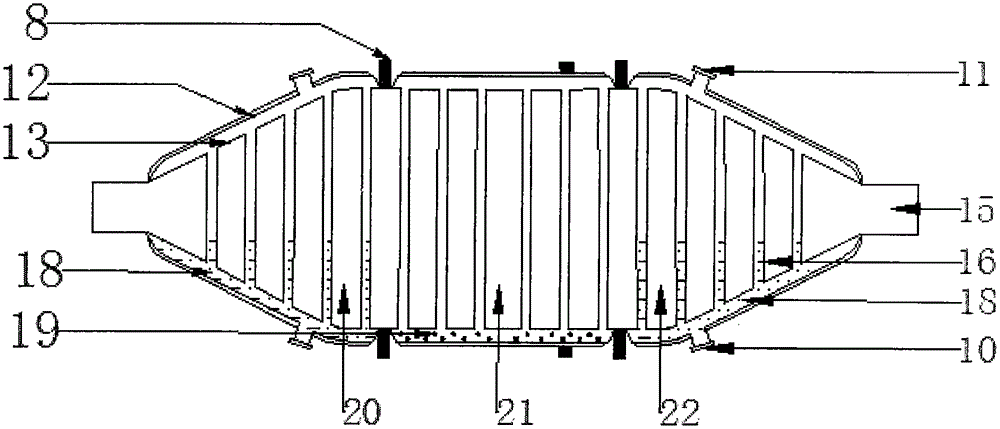

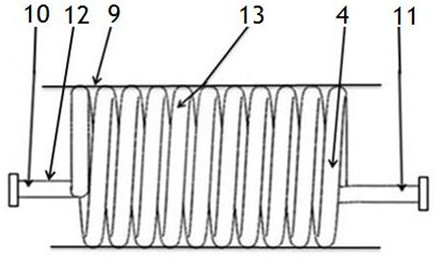

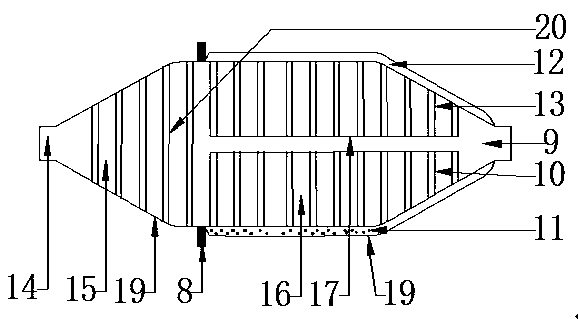

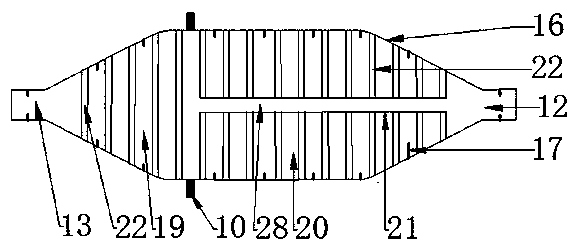

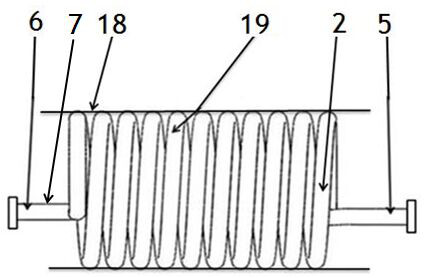

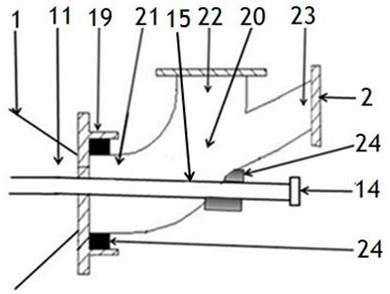

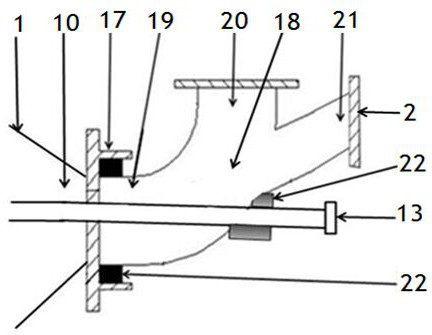

Thermal tube type vacuum drier capable of utilizing afterheat

ActiveCN105423721AShorten drying timeUniform drying qualityDrying using combination processesDrying machines with non-progressive movementsVertical tubeHelical blade

The invention discloses a thermal tube type vacuum drier capable of utilizing afterheat. The thermal tube type vacuum drier consists of a thermal tube drying cabin capable of utilizing afterheat, an air guide pipe, a bracket, a vacuum unit, a heating device, a driving device, rails and a vacuum charging and discharging device, wherein the rail on the thermal tube drying cabin capable of utilizing afterheat is mounted on the bracket; the driving device is used for driving the rail on an inner cabin; one end of the air guide pipe is connected to the vacuum unit after passing through the vacuum charging and discharging device; the other end of the air guide pipe is connected to the inside of the inner cabin; the inner cabin of the drying cabin adopts three-dimensional heat conduction by a cabin body and a cooling vertical tube, so the heat conduction speed and the heat exchange speed are increased; a cooling tube and a helical blade have a stirring function; no dead corner exists in material drying; the material drying time is shortened, so that the material can be dried uniformly; the material drying efficiency is improved; the material drying effect is optimized; the material can be cooled during a vacuum drying process; heat energy released in cooling of the material is also utilized, so continuous vacuum material drying can be realized.

Owner:常州奕诺梵节能科技有限公司

Conduction heating type cylinder dryer

InactiveCN111609681AReduce weightReduce manufacturing costDrying chambers/containersIndirect heat exchangersDrive shaftHelical blade

The invention provides a conduction heating type cylinder dryer. The conduction heating type cylinder dryer comprises a cylinder drying bin, a heating tank, a heat preservation cover, a rear support,a driving device, supporting wheels, a front support and an exhaust device. The cylinder drying bin comprises a cylinder, spiral blades, heating pipes, a supporting frame, a transmission shaft and a rolling path. Each heating pipe comprises a metal pipe, a heat conduction working medium and a heating device. Heat energy conducts heat conduction and heating on materials through a barrel in the cylinder of the cylinder drying bin and the heating pipes on the barrel, the heat dissipation area of a heater with heating strips is increased by 8-35 times, the heater conducts enough heat to the heat conduction working media, the heat conduction working media conduct heat conduction and heat exchange of liquid-vapor phase change in the cavities of the pipes, the heat energy is conducted to the materials in the cylinder through the heating pipes for heat conduction and heating, the material drying efficiency is improved, the material drying effect is optimized, the material drying moisture uniformity is improved, the material drying efficiency is improved, the material drying effect is optimized, and the conduction heating type cylinder dryer is environmentally friendly in drying, and is energy-saving.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

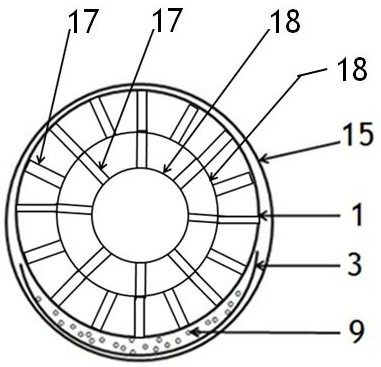

Heat pipe type three-cylinder drying bin

InactiveCN111692874AIncrease cooling areaImprove heat conduction and heating speedDrying solid materialsHeating arrangementThermodynamicsEngineering

The invention provides a heat pipe type three-cylinder drying bin. The heat pipe type three-cylinder drying bin comprises a heat pipe type heating device and a three-cylinder drying bin body. The heatpipe type heating device comprises a heating pipe and a heat conduction pipe; and the heating pipe comprises a metal pipe, a heat conduction working medium and a heating sealing head. The heat pipe type heating device is mounted in a bin of the three-cylinder drying bin body. Heat energy carried by the medium conducts heating conduction and heating on materials in the three-cylinder drying bin body by the heat conduction pipe and the heating pipe of the heat pipe type heating device; and the heat dissipation area of a heater with heating strips is increased by 8 times to 35 times, the heaterconducts the heat energy to the heat conduction working medium, and the heat conduction working medium carries out "liquid vapor phase change" heat conduction heat exchange in a pipe inner cavity. Theheat energy is conducted to the materials in a roller through the heating pipe for conducting heat conduction and heating; and the heating pipe in the three-cylinder drying bin body can conduct heatconduction and heating on the materials and also play the role in stirring the materials when the materials are dried, the drying quality of the materials in the three-cylinder drying bin body is uniform, the material drying efficiency is improved, and the material drying effect is optimized.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Vacuum low-temperature grain drying machine

InactiveCN106705605AWith stirring functionStir continuouslyFood processingClimate change adaptationThermal energyProcess engineering

The invention discloses a vacuum low-temperature grain drying machine. The vacuum low-temperature grain drying machine is composed of a heat-pipe drying bin, a support, a condenser, a vacuum pump, a heating device, a drive device and a gas guide pipe. The two ends of the heat-pipe drying bin are installed on the support, and the appearance shape of the heat-pipe drying bin is a cylinder. A heat energy inlet and a heat energy outlet of the heat-pipe drying bin are connected to the heating device through the gas guide pipe; and a gas exhaust port of the heat-pipe drying bin is connected to the condenser and the vacuum pump through the gas guide pipe, and a gas pressure in the heat-pipe drying bin achieves a vacuum degree of -0.094Mpa to -0.098Mpa. The inner wall of the drying bin is used for three-dimensional heat dissipation, and the heat dissipation area is increased by 5-30 times, so that a heat conduction and dissipation speed is increased, a grain drying time is shortened, continuous grain stirring can be realized, the grain drying efficiency is increased and the grain drying effect is optimized; and the effects of waste heat utilization, energy conservation and emission reduction are achieved.

Owner:张国利

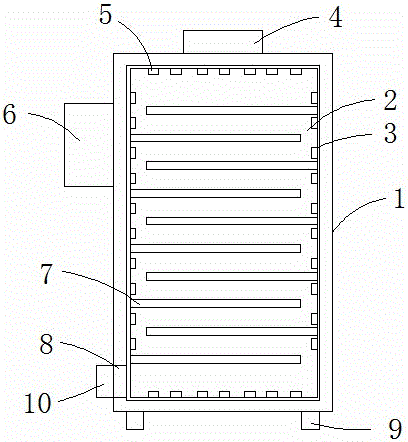

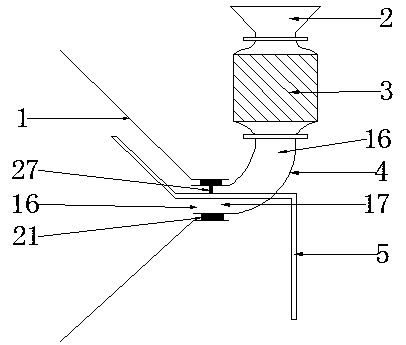

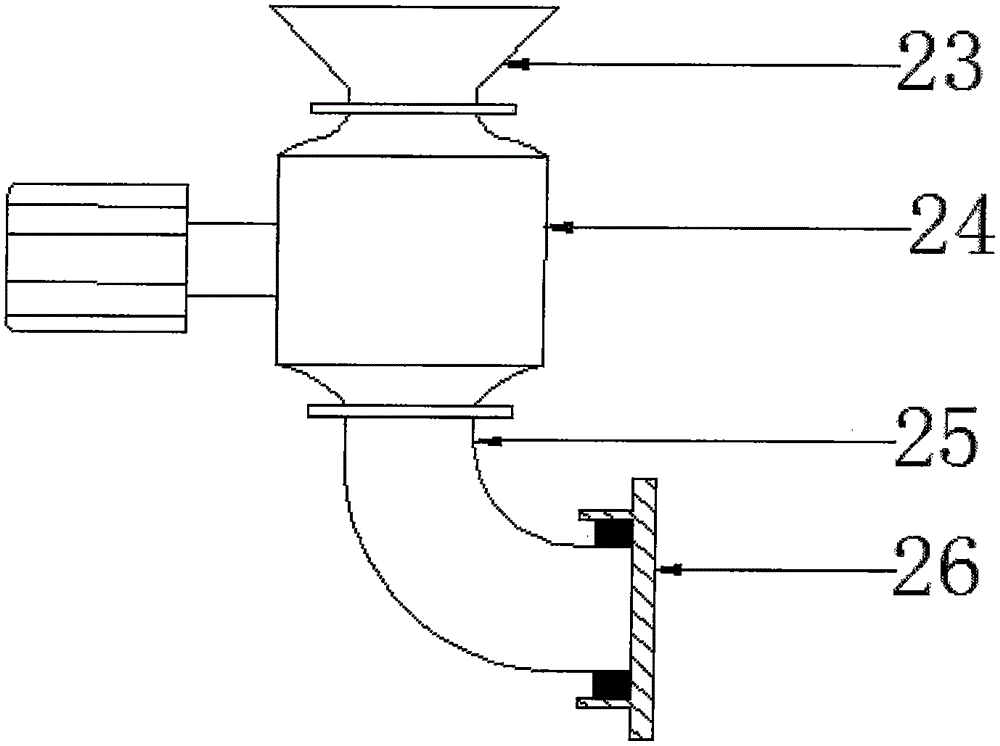

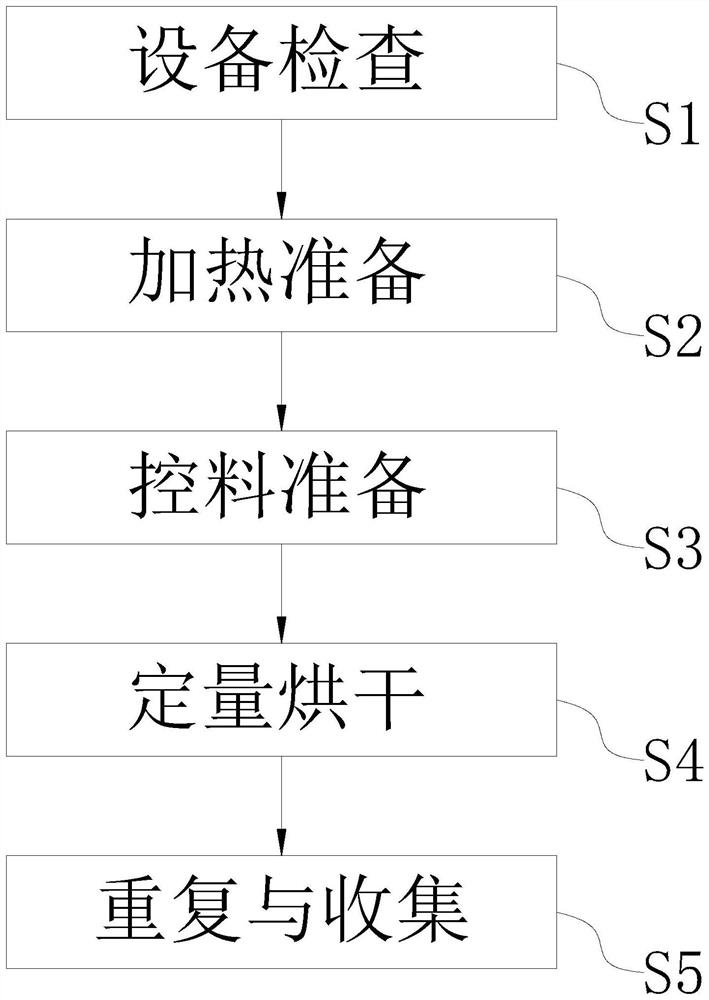

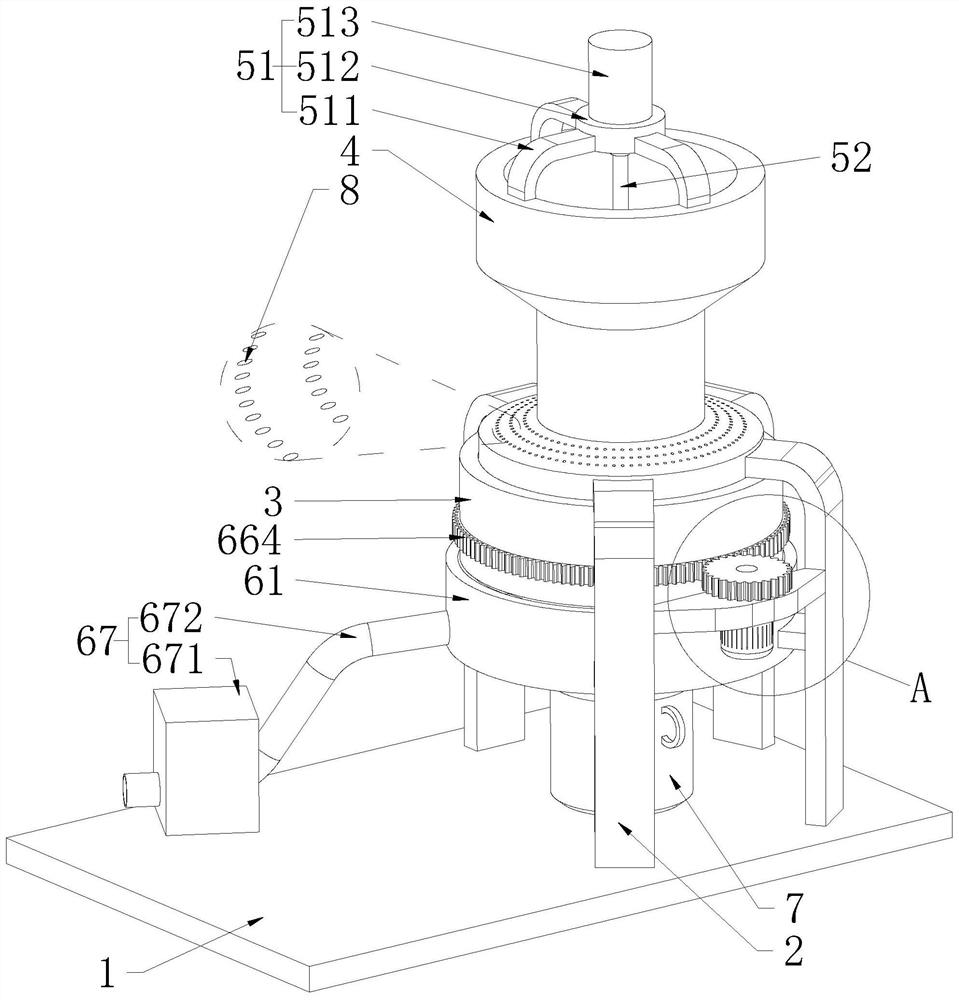

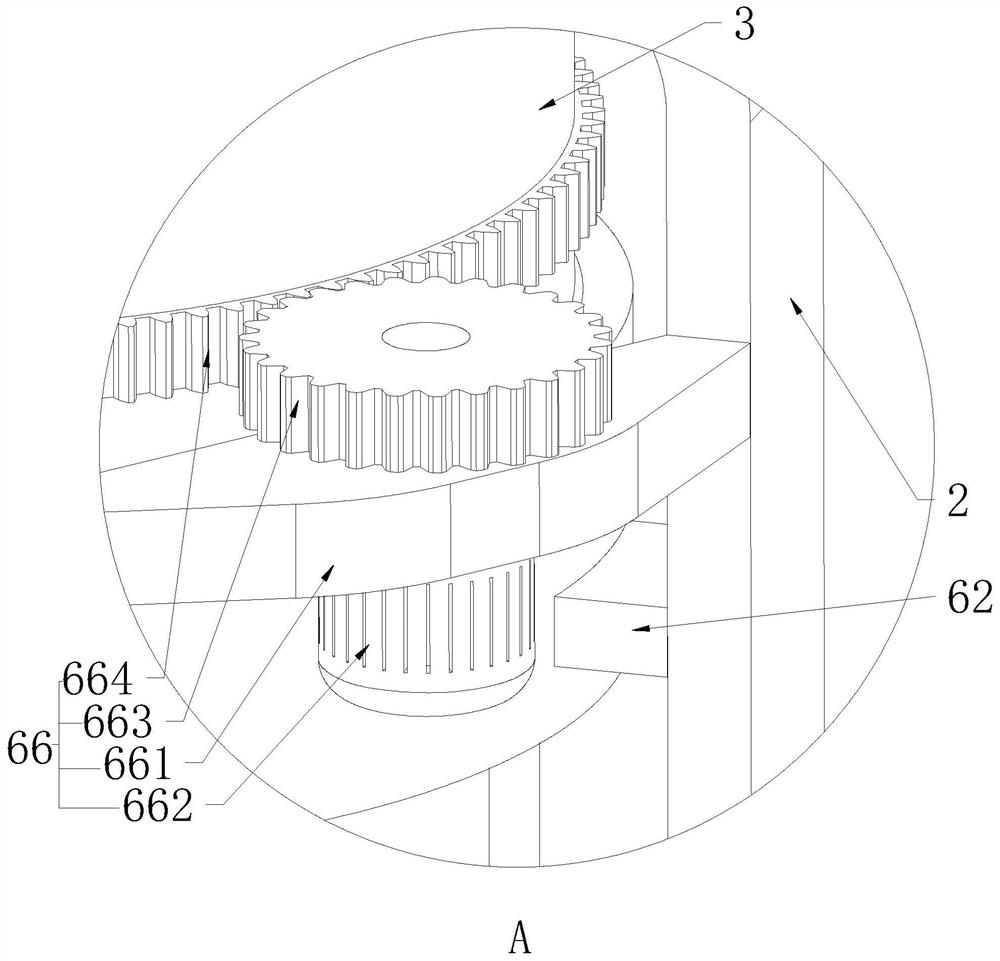

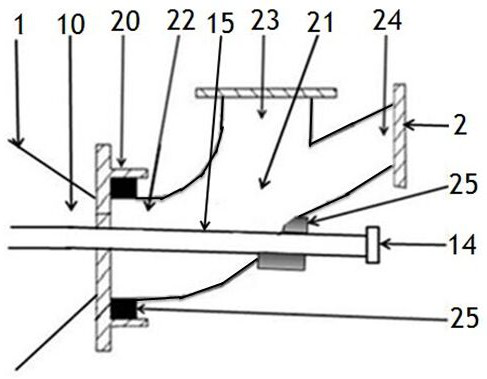

Preparation method of probiotic particles

InactiveCN112484434AFully dryUniform drying qualityDrying gas arrangementsDrying chambers/containersProcess engineeringProbiotic

The invention relates to a preparation method of probiotic particles and relates to the technical field of particle drying processes. Probiotic particle preparation equipment is applied. The equipmentcomprises a drying cylinder, a fixed cylinder, a quantity control device and a drying device. According to the preparation method of the probiotic particles, to-be-dried probiotic particles are turned over in the drying cylinder through the drying device, so that hot air flows from bottom to top and makes full contact with the probiotic particles, and the effect of fully drying the probiotic particles is achieved; and materials are quantitatively controlled through the quantity control device, so that the probiotics particles are kept at the set quantity every time the probiotics particles are dried, the drying process of each time is in the same control state, and therefore the effect that the overall drying quality is more uniform is achieved.

Owner:姜德涵

Roller type hot air dryer

InactiveCN109387051AReduce entryIncrease air intakeDrying chambers/containersDrying solid materialsSpiral bladePulp and paper industry

The invention provides a roller type hot air dryer. The roller type hot air dryer comprises a roller drying bin, a discharging device, a riding wheel support, a heating device, a driving device, an exhaust device, a three-way pipe, a gear ring, a fan, a sealing device and a support. The roller drying bin comprises a heating bin, a drying bin body and a heat conduction working medium. The riding wheel support supports the roller drying bin. The exhaust device is fixed to a flange of an exhaust port of the three-way pipe, one end of the discharging device is fixedly connected to a flange of a feed inlet of the three-way pipe, and the other end of the discharging device is fixedly connected to a hopper; a discharging port of the three-way pipe and a feed inlet of the roller drying bin are dynamically and hermetically connected and fixed through a sealing device. When a certain heat pipe is damaged and leakage is caused, only the heat pipe cannot work, but application of the whole drying bin is not affected. The roller drying bin rotates under the driving action of the driving device, a spiral blade has stirring and propelling functions, materials are not likely to agglomerate when thematerials are dried in the drying bin body, the dried materials are cooled in a cooling section, the drying efficiency of the materials is improved, and the drying effect of the materials is optimized.

Owner:程长春

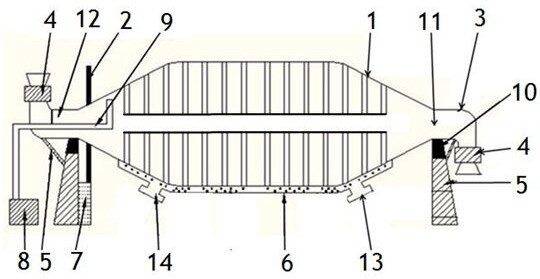

Roller vacuum drying machine with cooling section

InactiveCN109387040AReduce air intakeImprove sealingDrying solid materials without heatDrying machines with non-progressive movementsEngineeringMechanical engineering

The invention discloses a roller vacuum drying machine with a cooling section. The roller vacuum drying machine comprises a roller drying bin, an unloading device, an elbow, a support, an air guide pipe, a vacuum unit, a riding wheel support, a driving device, a gear ring, a sealing device and a material hopper. The roller drying bin comprises a heating bin, a cooling bin, a drying bin, a sealingunit and a heat conduction medium. The riding wheel support supports the drying bin of the roller drying bin. The gear ring drives the drying bin to do rotation movements under the effect of the driving device. The end, without a flange, of the elbow and a material inlet and outlet of the roller drying bin are in sealed connection into a whole through the sealing device. One end of the unloading device is fixedly connected with the flange on the elbow. The other end of the unloading device is provided with the material hopper. One end of the air guide pipe is connected to the vacuum unit. Theother end of the air guide pipe penetrates through the elbow and extends into the roller drying bin. Materials in the drying section are heated by the heat energy in the heating bin, the heat converting efficiency is high, loss is small, the dried materials are cooled in the cooling section, and the heat energy released during material cooling can also be used as waste heat; when a certain heat pipe is damaged and leakage happens, the use of the whole roller vacuum drying machine with the cooling section is not influenced.

Owner:程长青

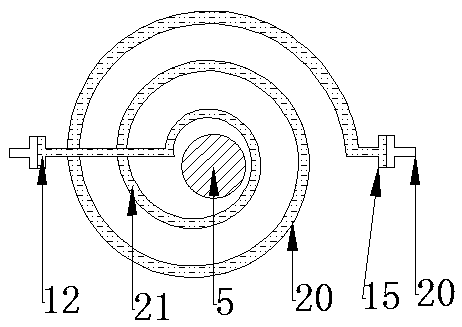

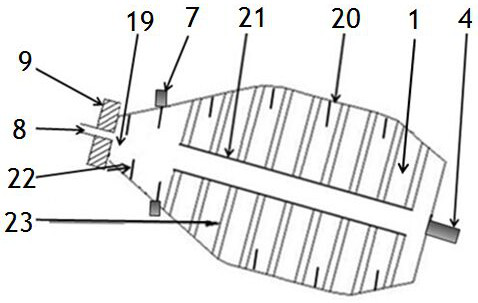

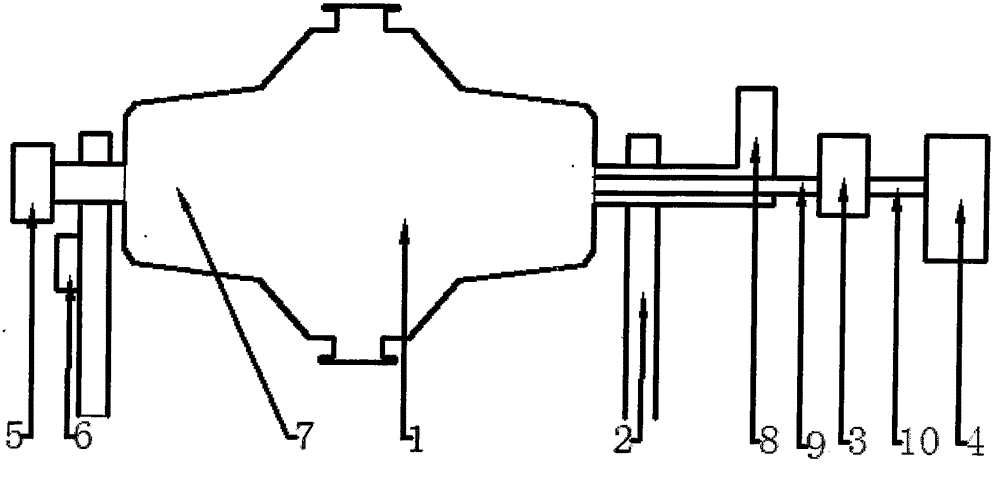

Heat pipe type three-cylinder vacuum dryer

InactiveCN111947413ADoes not affect normal useUniform drying qualityDrying solid materials without heatDrying chambers/containersProcess engineeringWheel drive

The invention discloses a heat pipe type three-cylinder vacuum dryer. The heat pipe type three-cylinder vacuum dryer comprises a vacuum drying bin, a roller path, a gear ring, a three-way joint device, a discharging device, a vacuum unit, an elbow device, a support, supporting wheels and a driving device, wherein the heat pipe three-cylinder drying bin comprises a heating device, a three-cylinderdrying bin and spiral blades; heat energy carried by a medium is conduct to heat materials in the three-cylinder drying bin through the heating device; the heat dissipation area of the heater with heating strips is increased by 8-35 times; the heater with the heating strips conducts heat energy to a heat conduction working medium; the heat conduction working medium performs heat conduction and heat exchange of liquid-vapor phase change in an inner cavity of a pipe; the heat energy is conducted to the materials in a roller through a heating pipe to heat the materials; the vacuum unit pumps anddischarges air in the three-cylinder drying bin and moisture generated during material drying; and the heating device in the three-cylinder drying bin stirs the materials during material drying work,the material drying quality in the three-cylinder drying bin is uniform, the material drying efficiency is improved, and the material drying effect is optimized.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Conduction type drum dryer

InactiveCN109387052AReduce entryIncrease air intakeIndirect heat exchangersDrying solid materialsHeat conductingDrum drying

The conductive type drum dryer comprises a drum drying silo, a discharge device, a supporting wheel bracket, a heating device, a drive device, an exhaust device, a tee pipe, a gear ring, a fan, a sealing device and a bracket. The drum drying silo includes a heating silo, a drying silo and a heat conducting medium. The supporting wheel bracket supports the drum drying silo. The exhaust device is fixed on a flange of an exhaust port of the tee pipe, one end of the discharge device is fixedly connected with a flange of a feed hole of the tee pipe, and the other end of the discharge device is fixedly connected with a hopper. A discharge hole of the tee pipe is sealingly, dynamically and fixedly connected with a feed hole of the drum drying silo through the sealing device. When one heat pipe is damaged and leaks, that is to say, only the one heat pipe can not work and the use of the whole drying silo is not affected. The drum drying silo rotates under driving of the drive device, a spiralblade has the function of agitation and propulsion, materials do not agglomerate easily in the drying silo, and the dried material is cooled in a cooling section, so that the drying efficiency of thematerials is improved and the drying effect of the materials is optimized.

Owner:程长春

Cylinder drying machine with cooling segment

InactiveCN109387049AReduce air intakeIncrease air intakeDrying solid materialsDrying machines with non-progressive movementsSpiral bladeEngineering

The invention discloses a cylinder drying machine with a cooling segment. The cylinder drying machine comprises a cylinder drying bin, a discharging device, an exhaust device, a three-way pipe, supports, riding wheel supports, a gear ring, a drive device and a sealing device. A discharging port of the three-way pipe and a feeding port of the cylinder drying bin are sealed by the sealing device andare integrally connected. The exhaust device is fixed to a flange at an exhaust port of the three-way pipe, one end of the discharging device is fixedly connected with a flange at the feeding port ofthe three-way pipe, and the discharging device and the feeding port of the three-way pipe are connected and integrally fixed. The cylinder drying bin is driven by the driving device to rotate on theriding wheel supports. Drying, heating and heat conduction are conducted on materials by heat energy through conductive mediums, the heat transformation efficiency is high, the consumption is low, andthe material drying speed is increased. Spiral blades and heat pipes have the functions of stirring and pushing forward the materials and make the drying mass of the materials even, and the heat energy released by the dried materials during cooling can also be subjected to waste heat utilization. When one heat pipe is damaged and leaks, the usage of the whole cylinder drying machine with the cooling segment is not influenced.

Owner:程长青

Drum vacuum dryer

InactiveCN109387065ASlow heatingLow boiling pointDrying solid materialsHeating arrangementHeat conductingDrum drying

The invention relates to a drum vacuum dryer, which comprises a drum drying container, a discharge device, a vacuum unit, an elbow, a bracket, a support wheel bracket, a guide pipe, a gear ring, a driving device, a sealing device and a hopper; the drum drying container includes a heating container, a cooling container, a preheating container, a drying container, a sealing device and a heat conducting medium. The material inlet and outlet of the elbow and the drying container are connected by the dynamic seal fixed by the sealing device. One end of the discharge device is fixedly connected to the flange of the elbow, and the other end of the discharge device is provided with the hopper. One end of the guide pipe is connected to the vacuum unit and the other end extends through the elbow tothe inside of the drying container. The gear ring drives the drying container to rotate on the bracket of the support wheel bracket. The heat energy heats and conducts the material through the heat conducting medium, the heat conversion has the advantages of high efficiency and small loss, thereby improving the material drying speed. After drying, the material is cooled in the cooling section, andthe heat energy released when the material is cooled is capable of being re-utilized. When a heat pipe is damaged and leakage occurs, the use of the whole drum vacuum dryer with cooling section wouldnot be affected.

Owner:张国利

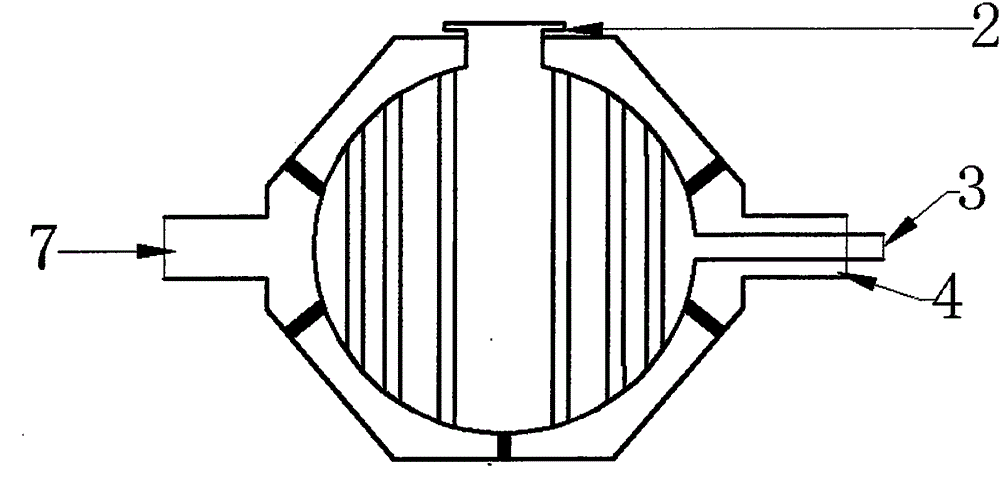

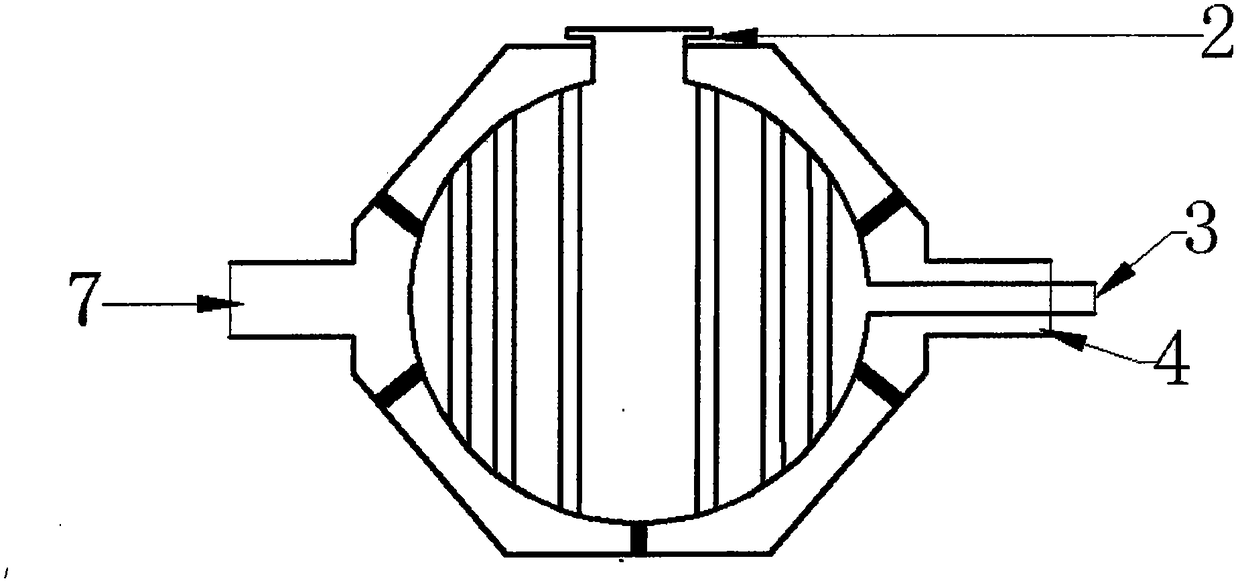

Heat pipe type double-cone vacuum drier

InactiveCN109724383AImprove negative pressure resistanceImprove firmnessDrying solid materialsDrying machines with non-progressive movementsProcess engineeringExhaust pipe

The invention discloses a heat pipe type double-cone vacuum drier. The drier comprises a double-cone vacuum drying bin, a supporting wheel support, a rotating joint, a vacuum unit, a driving device, an air guide pipe, a heat conduction pipe and a discharging valve. The double-cone vacuum drying bin comprises a heating bin, a drying bin and a support. A heat energy inlet and a heat energy outlet ofthe heating bin of the double-cone vacuum drying bin are supported and borne by supporting wheels of the supporting wheel support, the driving device drives the double-cone vacuum drying bin to rotate. The drying bin is arranged inside the heating bin, connecting of the heating bin and the drying bin is supported and fixed by the support, the drying bin comprises a bin body, a heat pipe type radiating pipe, an exhaust pipe and a material feeding and discharging port. The discharging valve is fixedly installed on the material feeding and discharging port of the drying bin. According to the drier, the heat dissipation area of the bin body of the drying bin and the heat pipe type radiating pipe is increased by 10-60 times when the drying bin is same in volume, the heating and heat conductionspeed of heat energy is increased, the drying efficiency of materials is improved, and the purpose of rapidly drying the materials is achieved; and when one certain heat pipe type radiating pipe is damaged, leakage is generated, the use of the whole heat pipe type double-cone vacuum drier is not influenced.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Internal heating type drum dryer

InactiveCN111637709ADry evenlyUniform drying qualityDrying solid materialsDrying machines with non-progressive movementsThermodynamicsInsulation layer

The invention discloses an internal heating type drum dryer which comprises a drum drying bin, a gear ring, a heating tank, a feeding device, an exhaust device, a three-way device, a support, a driving device, a medium, supporting wheels and a heat insulation layer. The drum drying bin is driven by the driving device, the drum drying bin is supported by the supporting wheels on the support to moverotationally, the drum drying bin comprises a drum, spiral blades, a heating pipe and fixing strips; and the heating pipe comprises a metal pipe, a heat conducting working medium and a heating device. The lower half part of the drum drying bin is immersed in a medium in the heating tank, the heat dissipation area of a heater with the heating strips is increased by 8-35 times, the heat conductingworking medium carries out heat conduction and exchange of liquid-vapor phase change in an inner cavity of the pipe, the heat energy in the heating tank carries out heat conduction heating on materials through a drum body in the drum of the drum drying bin and the heating pipe on the drum body, and the drying quality of the materials in the drum drying bin is uniform. The material drying efficiency is improved, the material drying effect is optimized, and environment-friendly drying and energy conservation; environmental protection are achieved.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Heat-pipe-type drum drying bin

InactiveCN111692873AIncrease cooling areaImprove heat conduction and heating speedDrying solid materialsHeating arrangementHeat conductingDrum drying

The invention discloses a heat-pipe-type drum drying bin. The heat-pipe-type drum drying bin comprises a heat pipe heating device and a drum drying bin; the heat pipe heating device is installed in abin of the drum drying bin; the heat pipe heating device comprises a heating pipe and a heat conducting pipe; the heating pipe comprises a metal pipe, a heat conducting work medium and a heating sealhead; the heat energy carried by the medium conducts heat conduction and heating for materials in the drum drying bin through the heat conducting pipe and the heating pipe of the heat pipe heating device; and the heat dissipation area of a heater with heating strips is increased by 8-35 times, the heater transmits heat energy to the heat conducting work medium, and the heat conducting work mediumconducts the heat conduction and heat transfer of 'liquid vapor phase change' in the inner cavity of the pipe. The heating pipe in the drum drying bin can conduct heat conduction and heating for the materials, and can stir the materials during the material drying working, the drying quality of the materials in the drum drying bin is uniform, the drying efficiency of the materials is improved, thedrying effect of the materials is optimized, and green drying, energy saving and environmental protection are achieved.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Vacuum dryer with cooling section

ActiveCN105371621BNot easy to agglomerateShorten drying timeDrying machines with non-progressive movementsDrying solid materialsEngineeringDrying time

The invention discloses a vacuum drying machine with a cooling section. The vacuum drying machine is composed of a drying bin with the cooling section, a hopper, a discharge device, an elbow, a gas guide pipe, a support, a vacuum unit, a heating device, a driving device and rails. The drying bin with the cooling section is composed of a shell, an inner bin, a heat conduction medium and a safety valve. The support supports a feed port and a discharge port of the two ends of the inner bin. The vacuum unit sucks gas in a bin body of the inner bin through a gas guide pipe. In the material drying process, the drying bin with the cooling section can be rotated on the support through the driving device, cooling vertical pipes arrayed spirally have functions of stirring and propelling materials, no dead corners exist during material drying, materials are not prone to caking when dried in the drying section of the inner bin, material drying time is shortened, material drying quality is uniform, dried materials are cooled in the cooling section, material drying efficiency is improved, the material drying effect is optimized, and green, energy-saving and environment-friendly drying is achieved.

Owner:温州市金榜轻工机械有限公司

Heat pipe type roller vacuum dryer

InactiveCN111998630ADoes not affect normal useIncrease the probability of collision contactDrying solid materials without heatDrying chambers/containersThermodynamicsGear wheel

The invention discloses a heat pipe type roller vacuum dryer. The heat pipe type roller vacuum dryer comprises a roller drying bin, roller paths, a gear ring, a three-way joint device, an elbow connector device, discharging devices, a vacuum unit, brackets, riding wheels and a driving device, wherein a heating device comprises heating pipes, a heat conduction pipe and fixing strips; the heating pipes comprise metal pipes, heat conduction working media and heating end sockets; the heating end sockets comprise heating plates, heat conduction working media and heaters; heat energy carried by themedia in the heat conduction pipes of the heating devices carries out heat conduction heating on the heating end sockets through pipe bodies of the heat conduction pipes; the heat dissipation areas ofheaters with heating strips of the heating end sockets are increased by 8-35 times; liquid heat conduction working media in the pipe inner cavities of the heating pipes are vaporized after being subjected to heat conduction heating by heat energy on the heaters of the heating end sockets; the heat conduction working media perform liquid-vapor phase change heat conduction heat exchange in the pipeinner cavities; and heat energy carried by the heat conduction working media is conducted to materials outside the metal pipes through the metal pipes for performing heat conduction heating, so thatthe heat conduction drying effect on the materials is improved.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Heat pipe type roller dryer

InactiveCN111854371AIncrease heat conduction areaDoes not affect normal useDrying chambers/containersDrying solid materialsVapor phaseWheel drive

The invention discloses a heat pipe type roller dryer which comprises a roller drying cabin, a raceway, a gear ring, a three-way connection device, a discharging device, an exhauster, a riding wheel and a driving device. Thermal energy carried by a medium is conducted to and heats material in the roller through a heat conduction pipe and heating pipes of a heating device; the radiating area of a heater provided with a heater strip of a heating sealing head is increased by 8-35 times; the heater of the heating sealing head conducts thermal energy to a heating conducting working medium; the heating conducting working medium carries out heat conduction and exchange of liquid-vapor phase change in a pipe cavity; the thermal energy is conducted to material in the roller through the heating pipes for heat conduction and heating; the heating pipes in the rotary roller drying cabin conduct heat to the material; the heating pipes rotatably crossed with each other and having high density increase the collision contact rate with the material and the heat conducting area and improve the heat conducting and drying effect to the material; the low-temperature air entering the roller drying cabinplays a role in cooling the dried high temperature material; and when one of the heating pipes is damaged and leaks, application of the entire roller is not affected.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Internal heating type roller vacuum drying machine

InactiveCN111649562ADry evenlyUniform drying qualityDrying machines with non-progressive movementsDrying solid materialsThermodynamicsInsulation layer

The invention discloses an internal heating type roller vacuum drying machine which comprises a drum drying bin, a gear ring, an elbow device, a discharging device, a bracket, a heating tank, a driving device, a vacuum unit, an air guide pipe, a heat insulation layer, a riding wheel and a hopper. The drum drying bin comprises a drum, a spiral blade, heating pipes and a fixing strip. Each heating pipe comprises a metal pipe, a heat conduction working medium and a heating device; and the lower ends of the heating pipes are fixed on a drum body in the drum. Heat energy carried by the medium in the heating tank carries out heat conduction heating on materials through the drum body in the drum of the drum drying bin and the heating pipes on the drum body, and the heat conduction heat exchange area of a heater with the heating strip is 8-35 times larger than that of a heating plate; and the vacuum unit exhausts air in the drum drying bin and moisture generated when materials are dried. Whenone heating pipe is damaged and generates leakage, the use of the whole drum drying bin is not influenced, the material drying efficiency is improved, the material drying effect is optimized, and environment-friendly drying, energy conservation and environmental protection are achieved.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Heat pipe type three-cylinder dryer

InactiveCN111947412ADoes not affect normal useUniform drying qualityDrying chambers/containersDrying machines with non-progressive movementsThermodynamicsGear wheel

A heat pipe type three-cylinder drying machine comprises a heat pipe three-cylinder drying bin, roller paths, a gear ring, a three-way connector device, a discharging device, an exhaust device, a support, riding wheels and a driving device. The heat pipe three-cylinder drying bin comprises heating devices, a three-cylinder drying bin body and spiral blades. Heat energy carried by a medium carriesout heat conduction and heating on materials in the three-cylinder drying bin body through heat conduction pipes and heating pipes of the heating devices; heaters with heating strips conduct heat energy to a heat conduction working medium, the heat conduction working medium carries out heat conduction and heat exchange of liquid-vapor phase change in inner cavities of the pipes, and the heat energy is conducted to materials in a roller through the heating pipes for heat conduction and heating; and when a certain heating pipe is damaged to cause leakage, use of the whole three-cylinder drying bin body is not influenced. When the heating devices in the three-cylinder drying bin body carry out heat conduction and heating on the materials, the effect of stirring the materials during material drying work is achieved, the drying quality of the materials in the three-cylinder drying bin body is uniform, the material drying efficiency is improved, and the material drying effect is optimized.

Owner:MENGZHOU YUANHONG DRYING EQUIP RES & DEV CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com