Continuous heat pipe type hot air drying machine

A hot air dryer and heat pipe type technology, which is applied in the direction of dryer, drying gas arrangement, drying, etc., can solve the problems of uneven drying moisture, lack of cooling of materials, and easy agglomeration of materials, so as to optimize materials Drying effect, uniform quality, and the effect of improving material drying efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

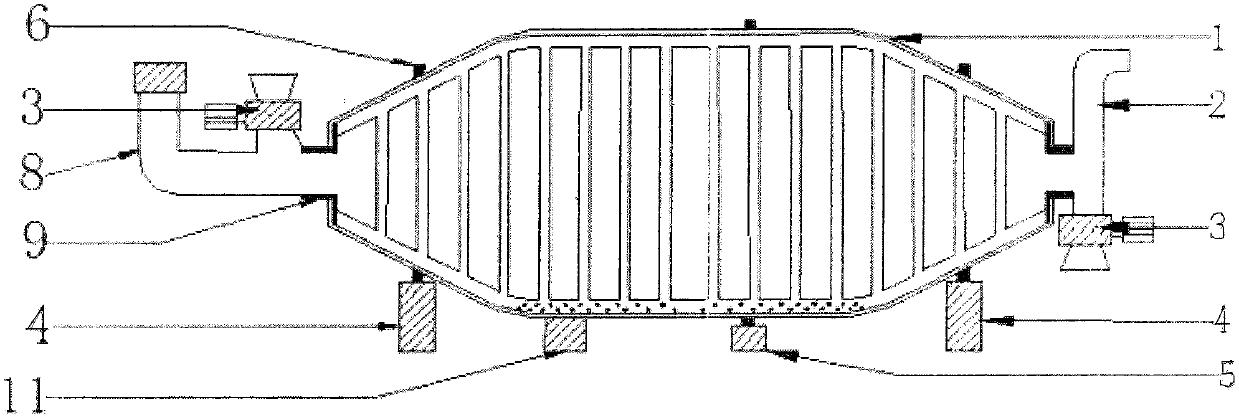

[0035] like figure 1 A continuous heat pipe type hot air dryer shown is composed of heat pipe vacuum drying chamber (1), air intake device (2), support (4), unloading device (3), heating device (11), driving device (5 ), track (6) and exhaust device (8).

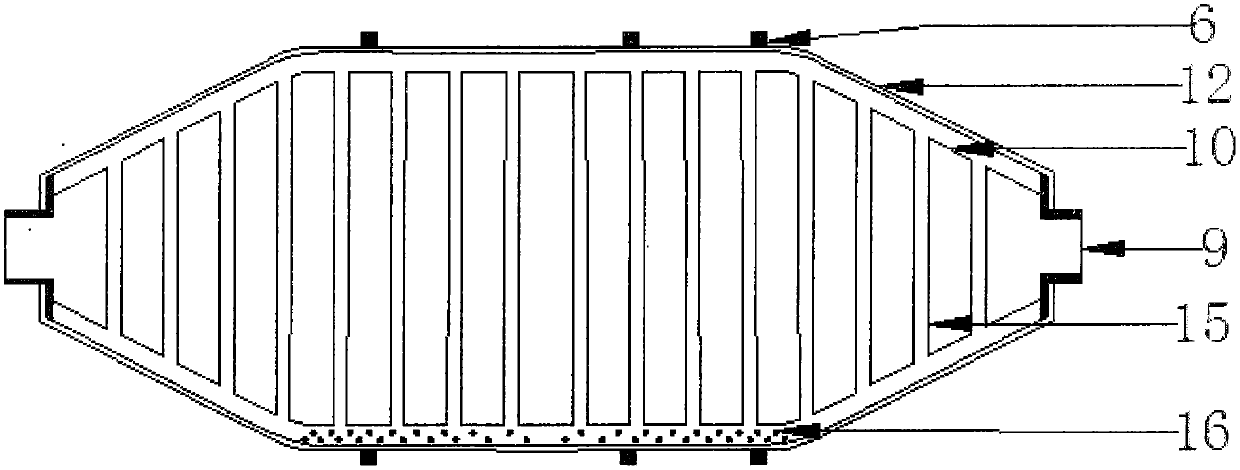

[0036] like figure 2 The shown heat pipe vacuum drying chamber (1) is composed of an outer shell (12) and an inner chamber (10).

[0037] 1. The shell (12) is outside the inner compartment (10), and the inner cavity between the shell (12) and the inner compartment (10) is filled with a heat-conducting working medium (16).

[0038] 2. Radiating pipes (15) and helical blades are arranged in the inner shell (12).

[0039] like figure 1 , figure 2 3 rails (6) are fixedly installed on the shown casing (12).

[0040] The outer cover of the shell (12) has an insulating layer, and the shell (12) and the insulating layer are not connected.

[0041] The discharge device (3) and air intake device (2) are installed on the inlet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com