Vacuum low-temperature grain drying machine

A vacuum low temperature, drying machine technology, applied in the direction of drying machine, drying, non-progressive drying machine, etc., can solve the problems of uneven drying moisture, long drying time, low heat conduction and heat dissipation efficiency, etc., to improve grain drying Efficiency, improved total heat transfer, optimized grain drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

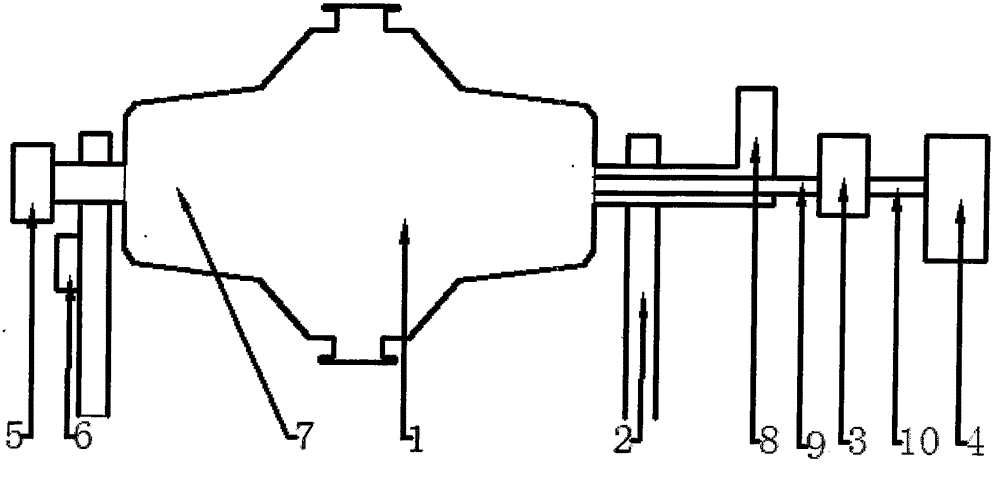

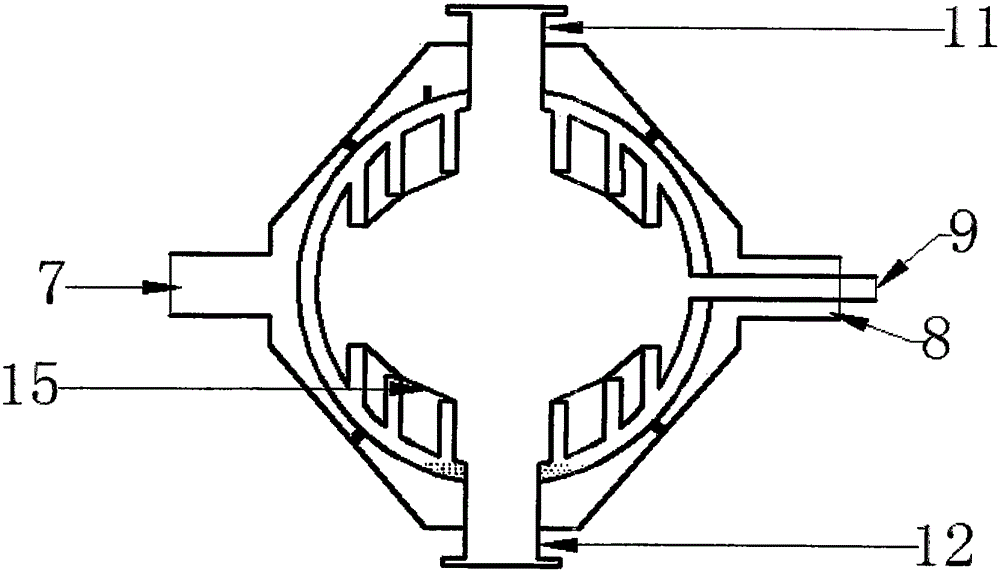

[0021] Such as figure 1 The shown vacuum low-temperature dryer for grain consists of a heat pipe type drying chamber (1), a bracket (2), a condenser (3), a vacuum pump (4), a heating device (5), a driving device (6), an air duct (10) Composition.

[0022] The thermal energy inlet (7) and thermal energy outlet (8) at both ends of the heat pipe type drying chamber (1) are installed on the support (2).

[0023] The driving device (6) is installed on the bracket (2), and the driving device (6) is used to drive the heat pipe type drying chamber (1) to rotate.

[0024] The thermal energy inlet (7) of the heat pipe type drying warehouse (1) is connected to the heating device (5) through the air duct (10); the heat energy outlet (8) of the heat pipe type drying warehouse (1) is connected through the air duct (10) to the heating unit (5).

[0025] The heating device (5) is a boiler.

[0026] The exhaust port (9) of the heat pipe type drying chamber (1) is connected to the condenser...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com