Heat pipe type double-cone vacuum drier

A vacuum dryer and vacuum drying technology, applied in the direction of non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of double cone vacuum dryer paralysis, scrapping, easily exposed welding quality problems, heat transfer medium leakage, etc. problem, to achieve the effect of optimizing the drying effect, improving the drying efficiency, and increasing the heat dissipation area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

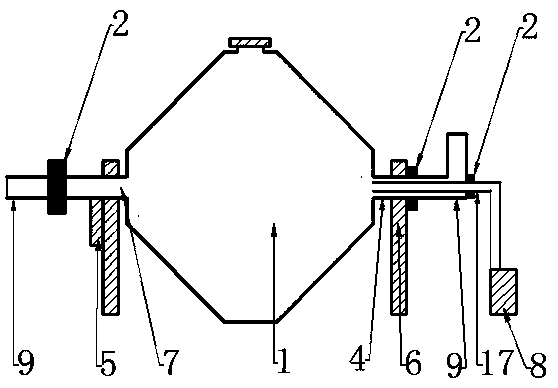

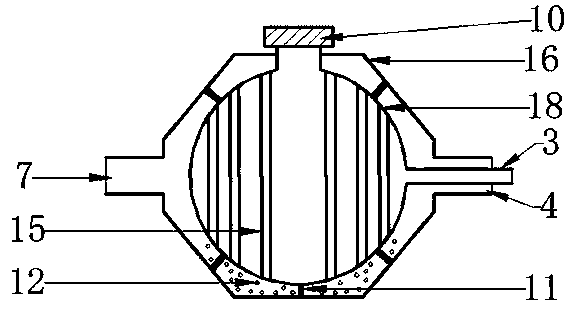

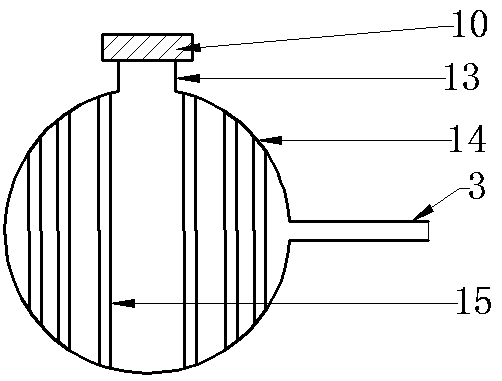

[0063] Such as figure 1 A heat pipe type double-cone vacuum dryer shown includes a double-cone vacuum drying chamber 1, a support wheel bracket 6, a rotary joint 2, a vacuum unit 8, a driving device 5, an air guide pipe 17, a heat conduction pipe 9, and a discharge valve 10.

[0064] The double-cone vacuum drying chamber 1 includes a heating chamber 16, a drying chamber 18, and a support 11.

[0065] The heating chamber 16 of the double-cone vacuum drying chamber 1 has a heat energy inlet 7 and a heat energy outlet 4 .

[0066] Described support roller support 6 comprises support roller, support.

[0067] 1. The supporting wheel is fixed on the bracket.

[0068] The heat energy inlet 7 and the heat energy outlet 4 of the heating chamber 16 of the double-cone vacuum drying chamber 1 are supported by the supporting rollers of the supporting roller bracket 6 .

[0069] The driving device 5 is installed on the bracket of the supporting wheel bracket 6, and the driving device 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com