Method for manufacturing anti-negative pressure plastic-lined steel pipeline

A technology of plastic and steel matrix, applied in the direction of tubular articles, other household appliances, household appliances, etc., can solve the problems of cracking, deformation of the plastic lining layer, low bonding strength between the plastic lining layer and the steel matrix, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

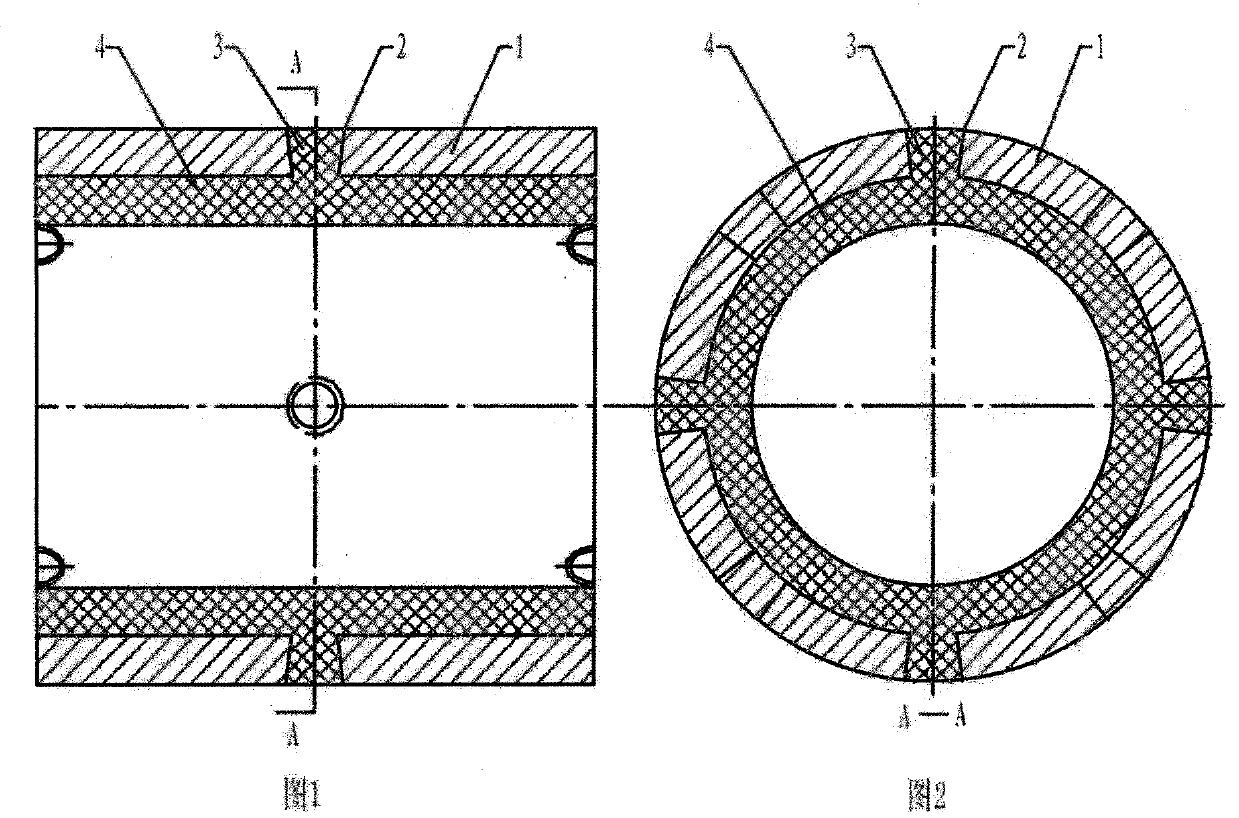

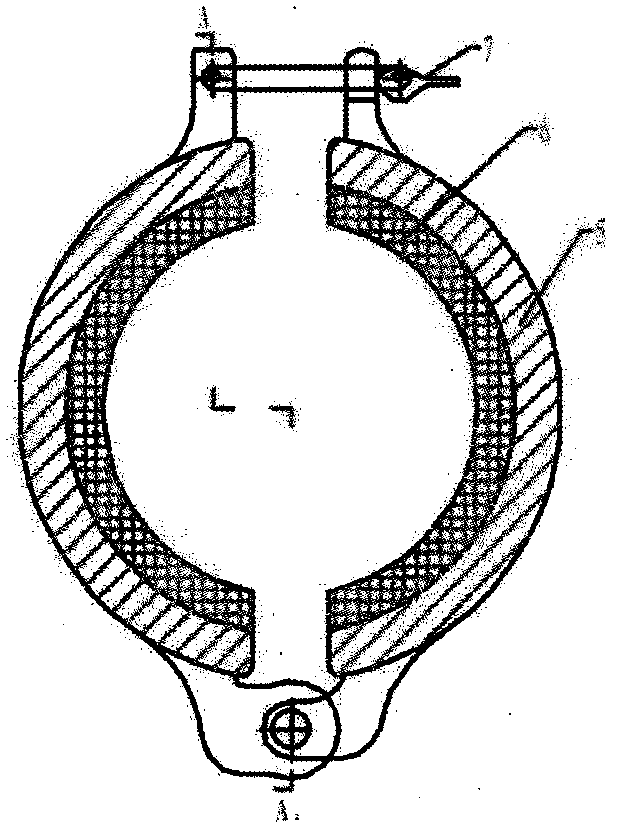

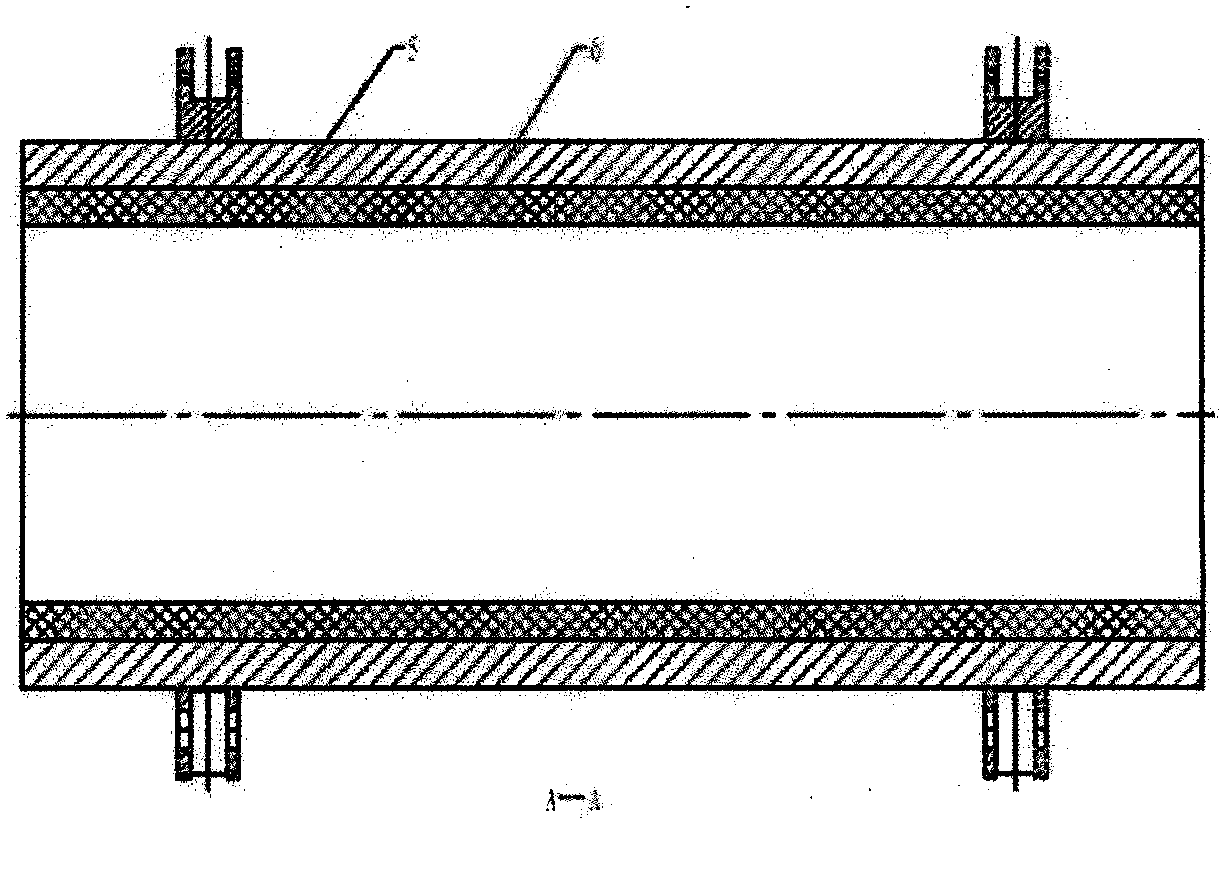

[0011] Such as figure 1 , figure 2 As shown, before the steel-lined plastic pipe is coated with plastic, the tapered anti-drop holes 2 are drilled on the steel substrate 1 using group drills, and then the steel substrate 1 after the prefabricated anti-drop holes 2 is sent to the electric furnace for heating, and the temperature reaches After request, take out the steel substrate 1, place it on the rotomolding machine, and quickly install it on the outside as image 3 , Figure 4 The shown steel jacket 5 is inlaid with the PTFE sealing sleeve 6, and then the cam quick lock device 7 is pulled to clamp the steel jacket 5, and the PTFE sealing sleeve 6 is used to carry out the anti-fall hole on the steel substrate 1. It is sealed to prevent the plastic powder from leaking out during rolling and forming a compact anti-dropping column 4. Turn on the rotomolding machine and spray a certain amount of plastic powder into the steel substrate 1. After the plastic powder is melted at high...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com