Horizontal extruder core rod supporting device

A technology of horizontal extruders and cores, which is applied in the direction of presses, material forming presses, manufacturing tools, etc., and can solve the problems of workpiece quality, mandrel bending deformation, and rigidity reduction that affect extrusion molding. Problems, achieve the effect of maintaining rigidity, avoiding bending deformation, and maintaining support strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In the present invention, the components without specific structures and connection methods are usually conventional components or connection methods.

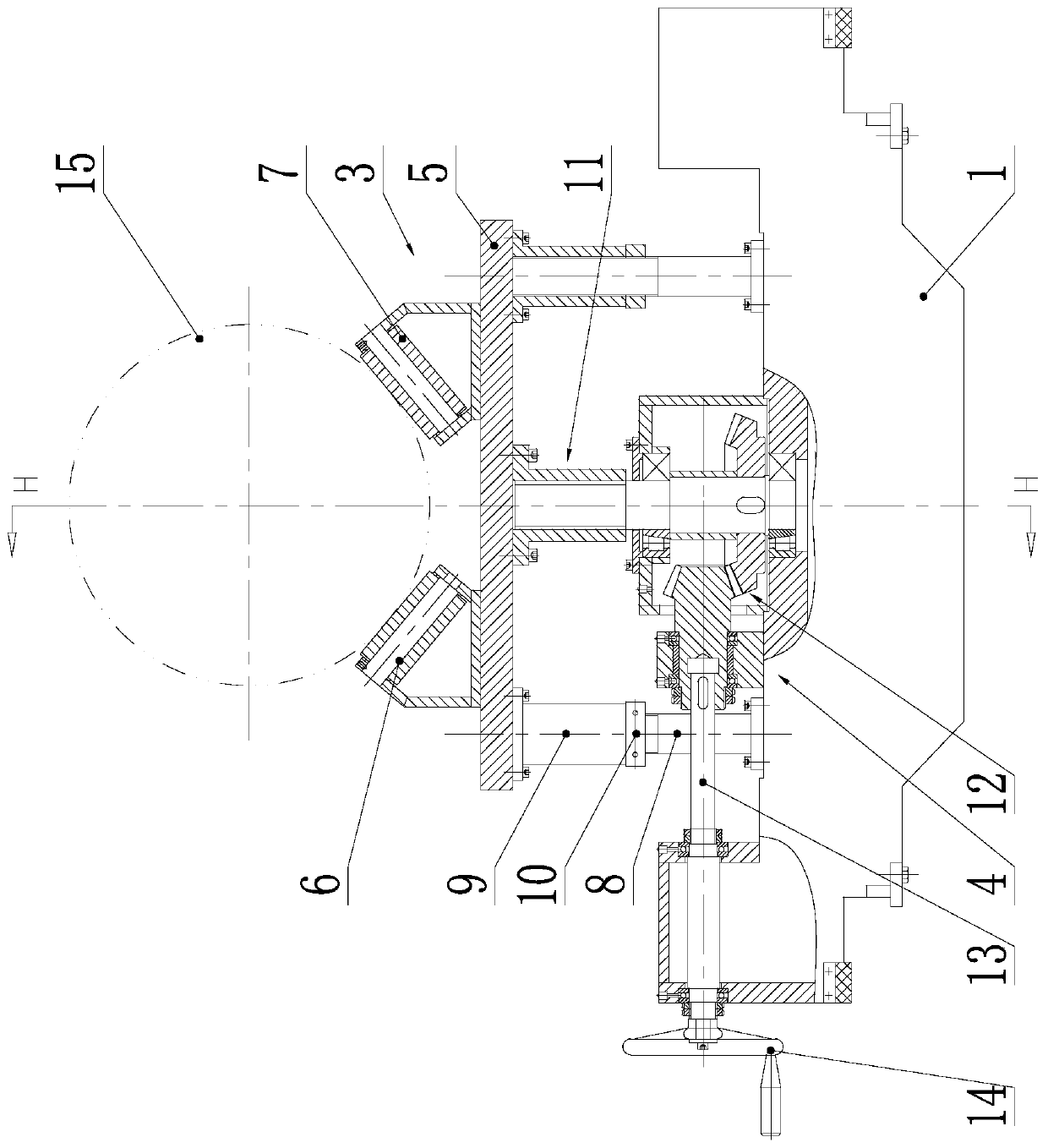

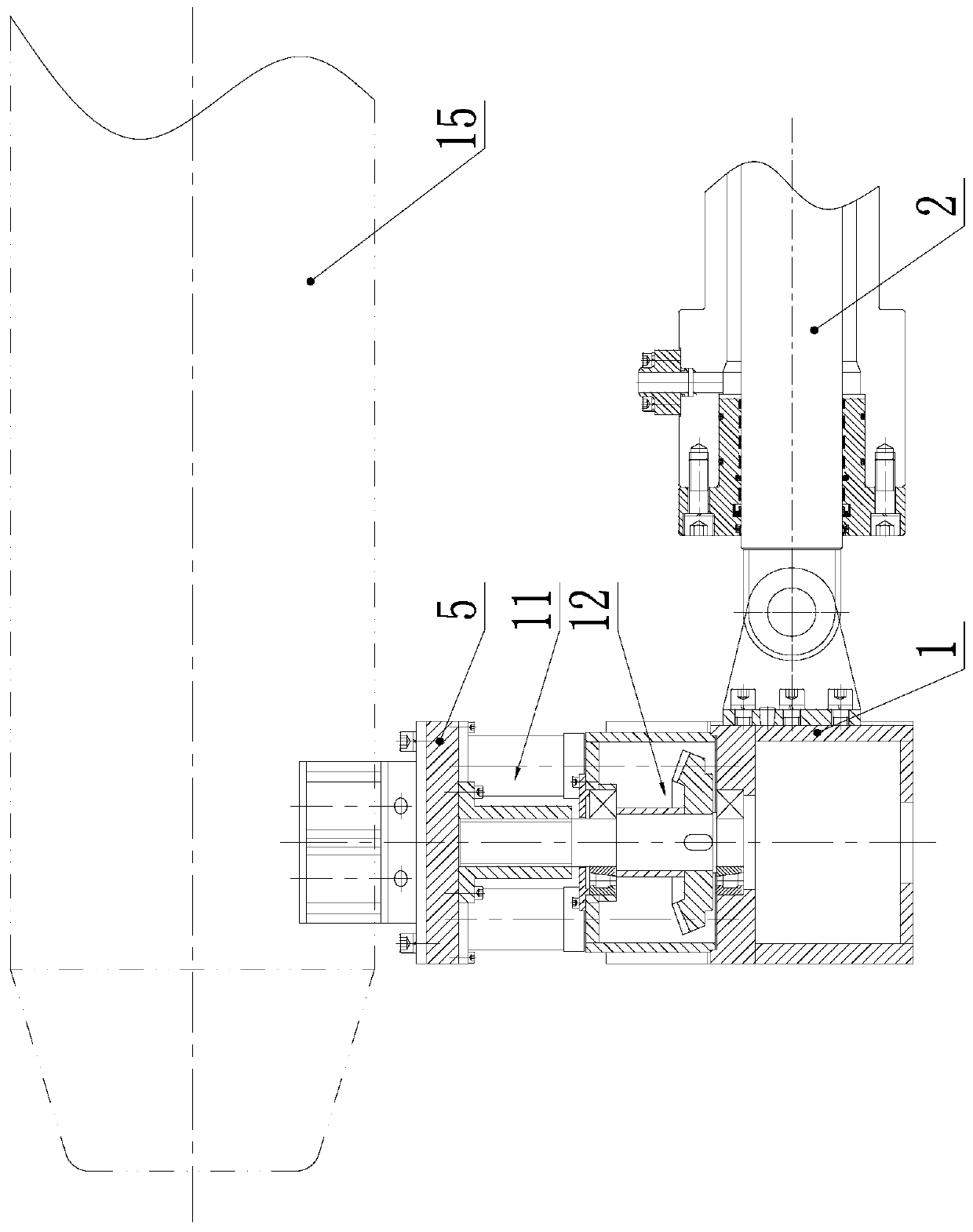

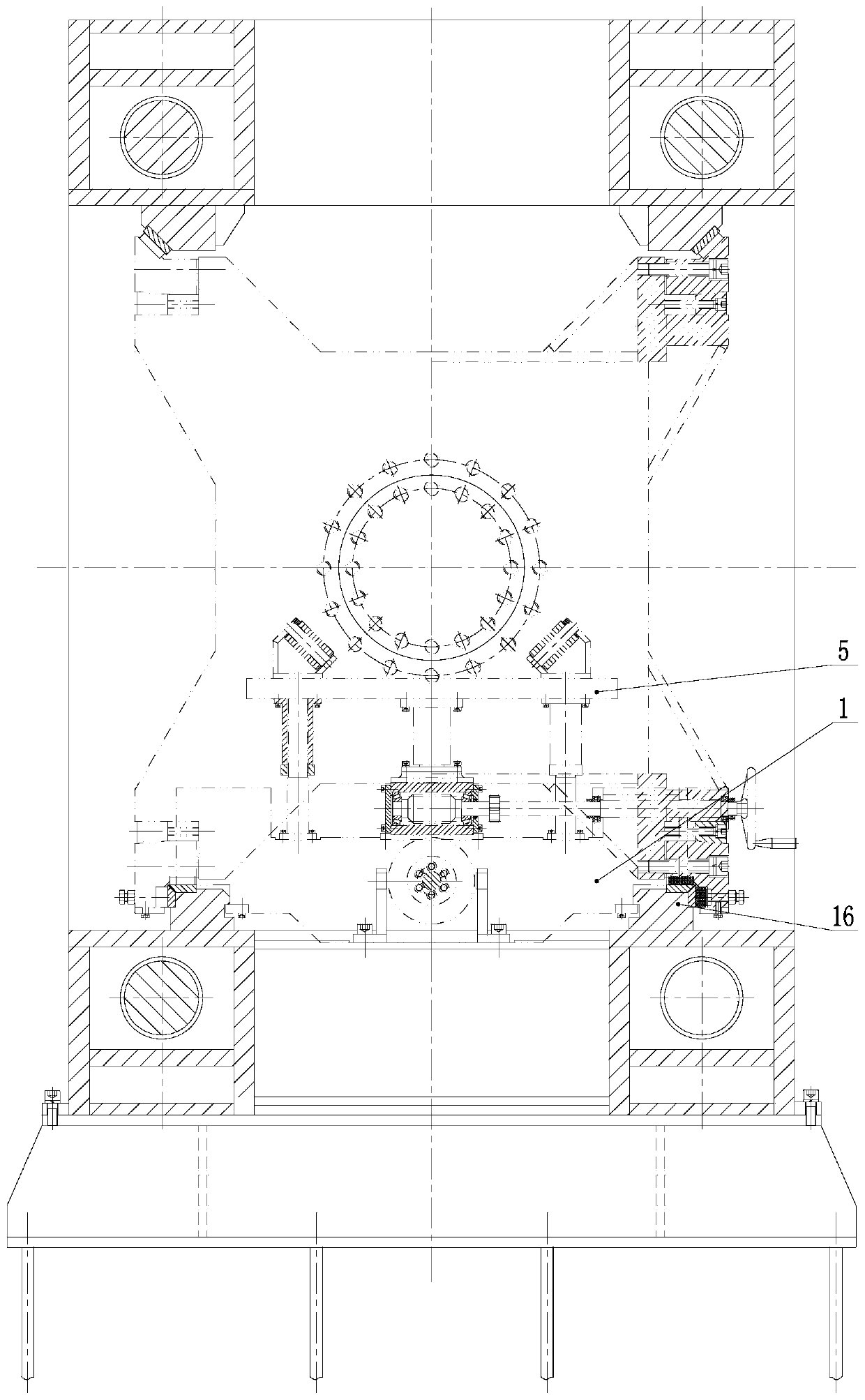

[0027] see Figure 1 to Figure 3, is a specific embodiment of a support device for a horizontal extruder mandrel. The support device for the rod of the horizontal extrusion mandrel includes an installation base 1 , a drive mechanism 2 and a support mechanism 3 . The installation base 1 is set on the base track 16 of the horizontal extruder, driven by the drive mechanism 2, and moves along the axial direction of the horizontal extruder mandrel, and the installation base 1 can slide or roll to fit on the horizontal extruder. On the base track of the extruder, in this embodiment, the mounting base is slidably fitted on the base track of the horizontal extruder, the driving mechanism 2 is a hydraulic cylinder, and the cylinder body of the hydraulic cylinder is fixed on the horizontal extruder. The piston rod of the hydrau...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com