Heat pipe type roller dryer

A tumble dryer and heat pipe type technology, applied in dryers, drying, non-progressive dryers, etc., can solve the problem of limited heating area of thermally conductive working medium, insufficient total thermal energy of thermally conductive working medium, and unavailability of materials. thermal energy etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

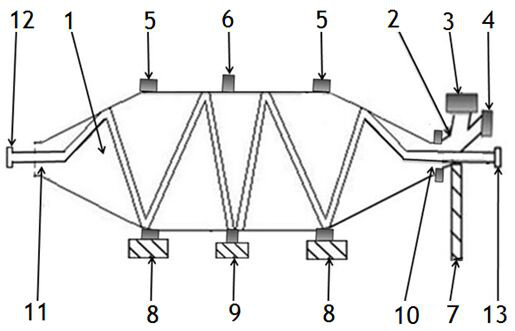

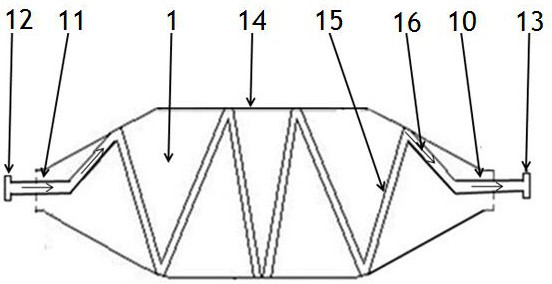

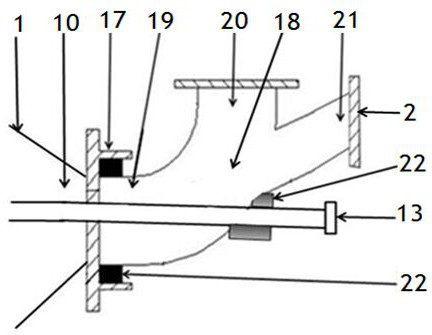

[0086] Such as figure 1 The heat pipe type tumble dryer shown includes a tumble drying chamber 1 , a raceway 5 , a gear ring 6 , a three-way joint device 2 , a discharge device 3 , an exhaust device 4 , supporting wheels 8 , and a driving device 9 .

[0087] The drum drying bin 1 has an inlet port 10 and an outlet port 11 .

[0088] The outer diameter of the drum drying bin 1 is 1800 mm; the length of the drum drying bin 1 is 8000 mm.

[0089] The gear ring 6 and the raceway 5 are installed on the cylinder body 33 of the drum drying chamber 1, and the gear ring 6, the raceway 5 and the cylinder body 33 of the drum drying chamber 1 are connected and fixed as a whole.

[0090] The support roller 8 supports the raceway 5 of the drum drying bin 1 .

[0091] The driving device 9 is a hydraulic motor.

[0092] The driving wheel of the driving device 9 occludes and drives the teeth of the gear ring 6 on the fixed drum drying bin 1, and the gear ring 6 drives the drum drying bin 1;...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com