Integrated liquid cooling machine box based on two-phase heat transfer and two-phase heat transfer method thereof

A liquid cooler and chassis technology, which is applied in the direction of using liquid cooling for modification, cooling/ventilation/heating transformation, etc., can solve the problem of poor temperature uniformity of the cold plate, achieve good temperature uniformity, avoid performance degradation, and reduce volume and the effect of weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The principles and features of the present invention are described below, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

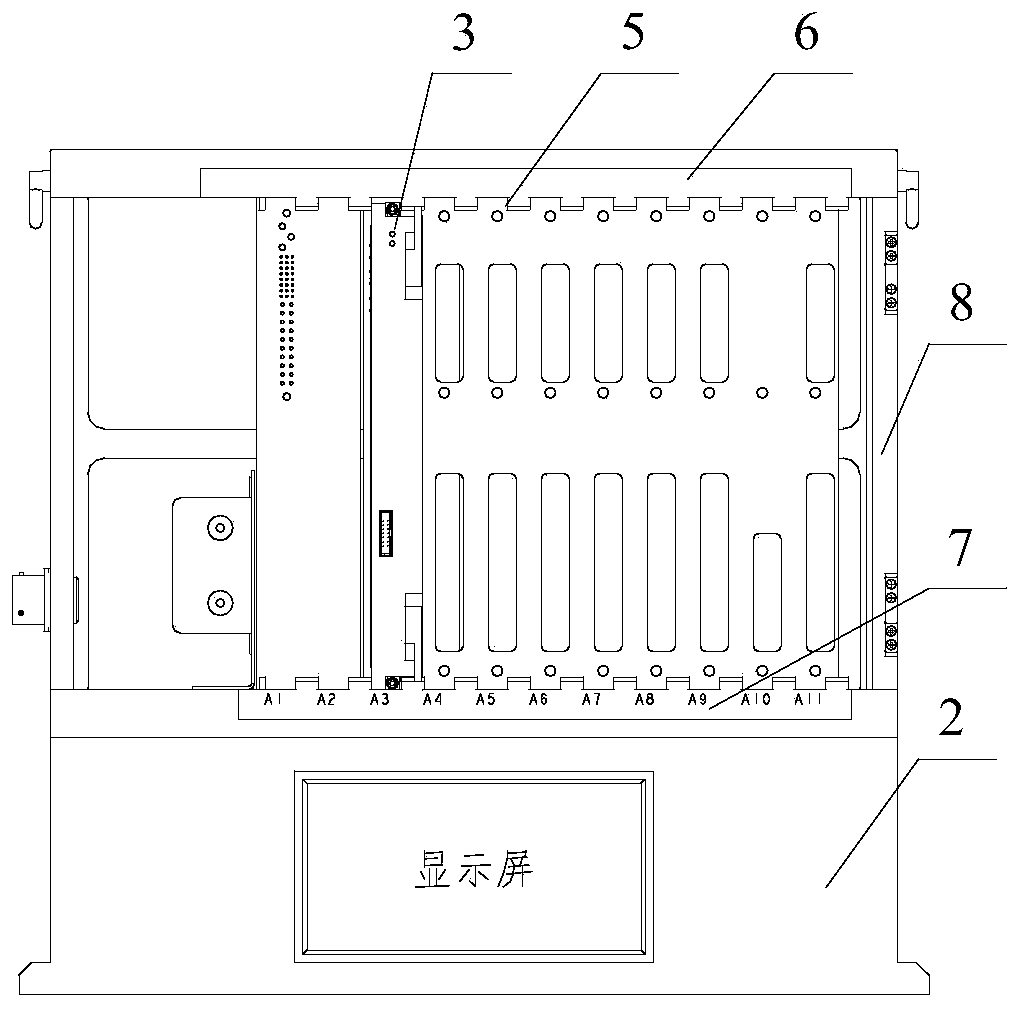

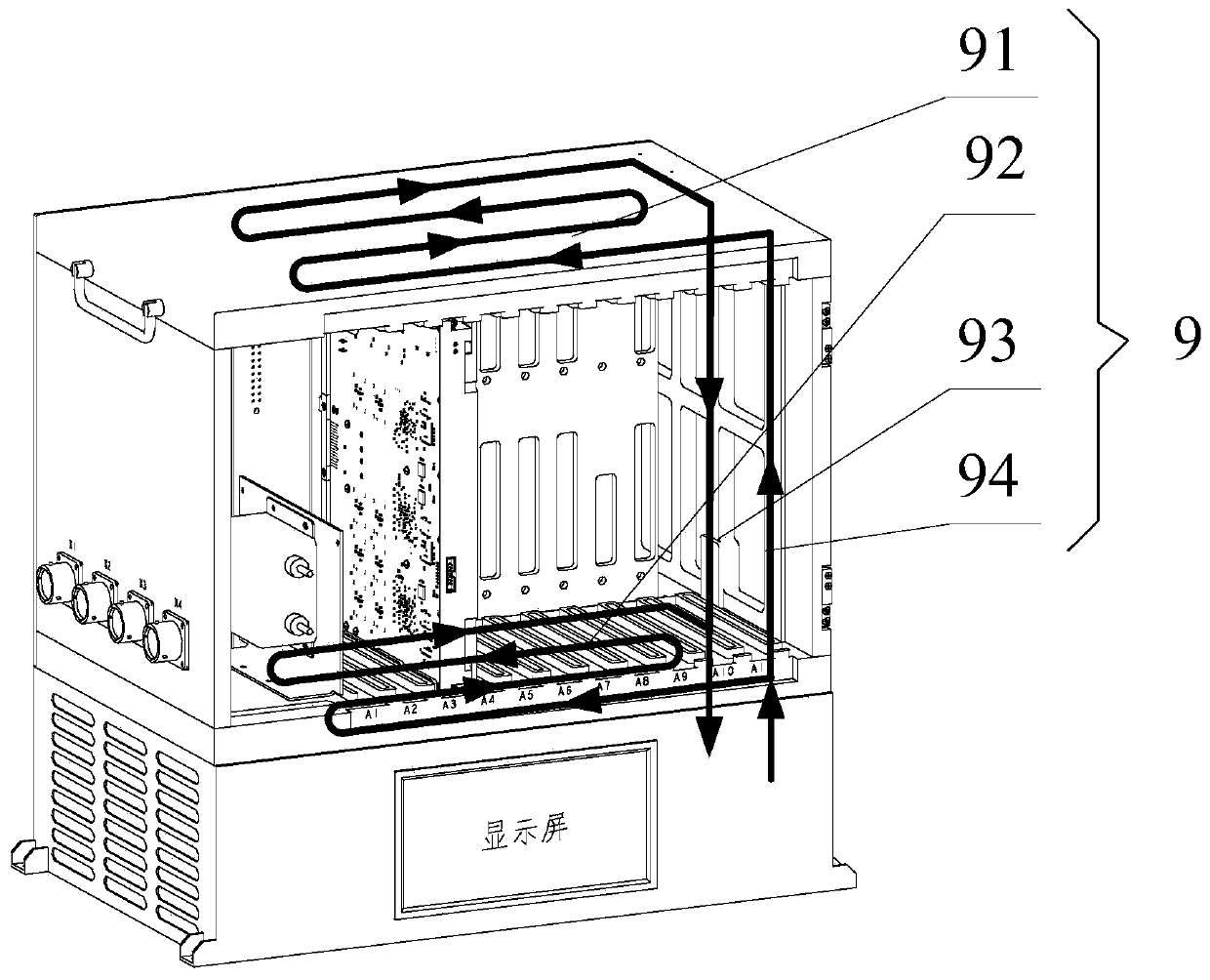

[0036] Such as Figure 1-Figure 7 As shown, an integrated liquid-cooled chassis based on two-phase heat transfer includes a chassis shell 1, a two-phase liquid cooling source 2, and a plug-in cold guide plate 4. Both the top wall and the bottom wall of the chassis shell 1 have The interconnected flow channels 9, the upper and lower ends of the plug-in cold guide plate 4 are respectively fixedly connected with the top wall and the bottom wall of the chassis shell 1, and are used to fix the electronic plug-in 3, and the two-phase liquid cooling source 2 and the The chassis shell 1 is fixedly connected, and the flow channel 9 has a flow channel inlet and a flow channel outlet that communicate with the two-phase liquid cooling source 2 through pipes.

[0037] Such...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com