Conduction heating type cylinder dryer

A tumble dryer and conduction heating technology, which is applied in dryers, non-progressive dryers, drying and other directions, can solve the problems of limited heating area, lack of heat energy for drum materials, and limited heat conduction area. The effect of cost reduction, power reduction, and compression resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

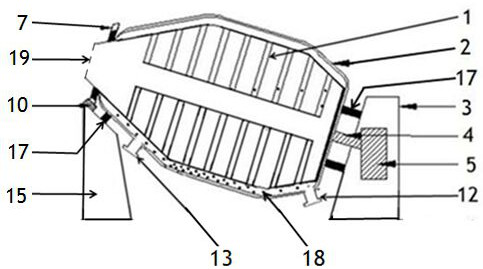

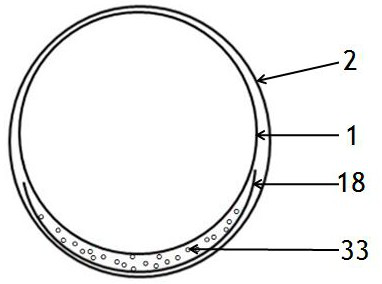

[0073] like figure 1 , figure 2 , image 3 , Figure 4 The shown conductive heating drum dryer includes a drum drying bin 1, a heating tank 18, a heat preservation cover 2, a rear support 3, a driving device 5, supporting wheels 10, a front support 15, and an exhaust device.

[0074]The conduction heating type tumble dryer is fixed on the ground.

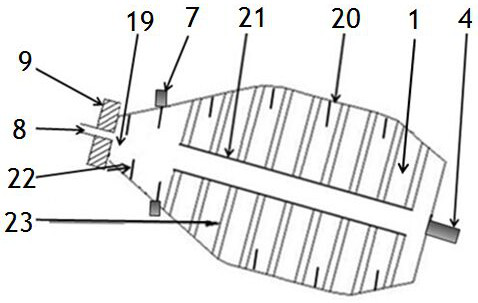

[0075] The drum drying chamber 1 includes a drum 20 , a spiral blade 22 , a heating pipe 23 , a support frame 21 , a transmission shaft 4 and a raceway 7 .

[0076] The cylinder body 28 of the drum 20 is made of an 8mm metal plate.

[0077] The diameter of described cylinder 20 is 2800mm, and length is 6800mm.

[0078] The transmission shaft 4 is installed on the cylinder body 28 at the big end of the drum 20 , the moving shaft 4 and the cylinder body 28 of the drum 20 are fixed as one, and the transmission shaft 4 of the drum drying chamber 1 is supported by the rear bracket 3 .

[0079] A raceway 7 is installed on the cylin...

Embodiment 2

[0123] like Figure 7 , figure 2 , image 3 , Figure 4 The conduction heating drum dryer shown includes a drum drying chamber 1, a heating tank 18, a heat preservation cover 2, a rear support 3, a driving device 5, supporting wheels 10, a front support 15, and an exhaust device.

[0124] like Figure 7 , figure 2 , image 3 , Figure 4 The structures of the conduction heating tumble dryer shown in Embodiment 2 and the conduction heating tumble dryer introduced in Embodiment 1 will not be repeated.

[0125] like Figure 7 The conductively heated tumble dryer is shown mounted on a chassis 6 on which wheels 14 are mounted. The chassis 6 has wheels 14 so that the conductive heating drum dryer can be moved to a suitable place to dry materials, and the conductive heating drum dryer can be used for drying work in different places.

[0126] The conduction heating drum dryer is a conduction heating drum vacuum dryer; the vacuum drying process is selected to improve the dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com