Drying device for tea processing

A drying device and technology for tea leaves, which are applied in the directions of drying, drying machine, drying gas arrangement, etc., can solve the problems of different drying quality of tea leaves, inability to ensure uniform heating of tea leaves, and inability to ensure uniform distribution of tea leaves, so as to achieve the goal of heating Uniform, uniform quality, easy-to-use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

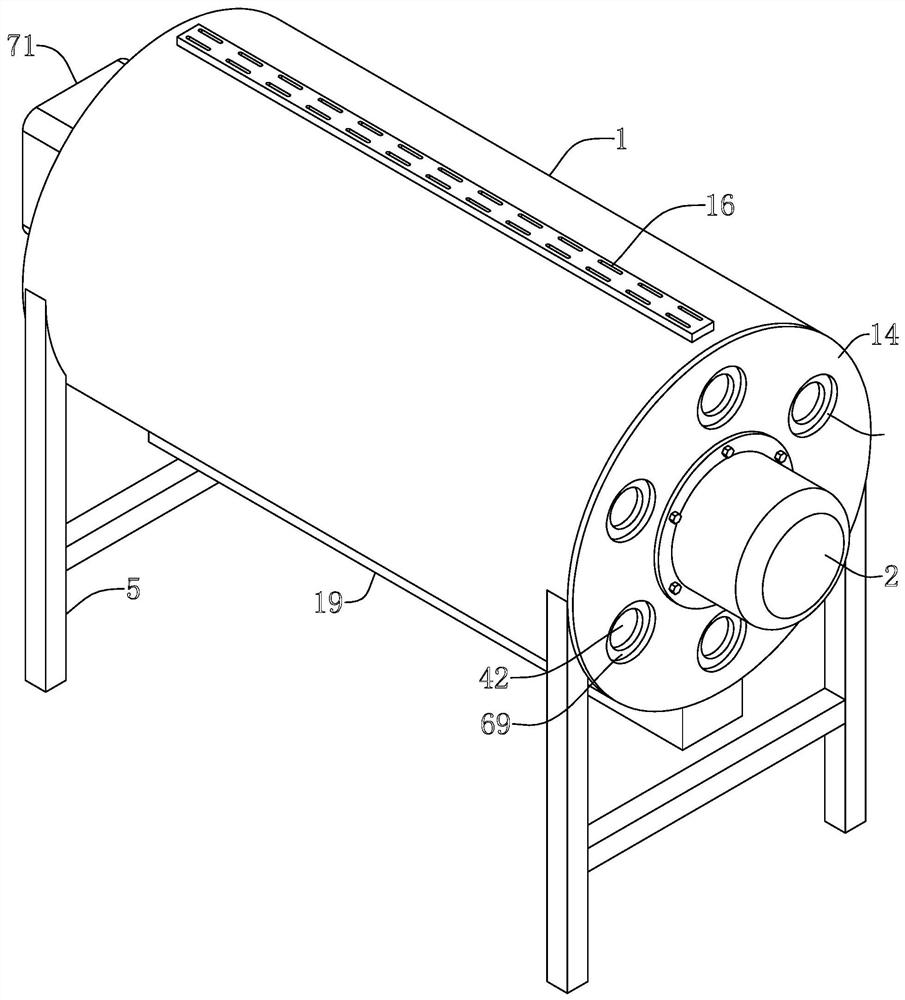

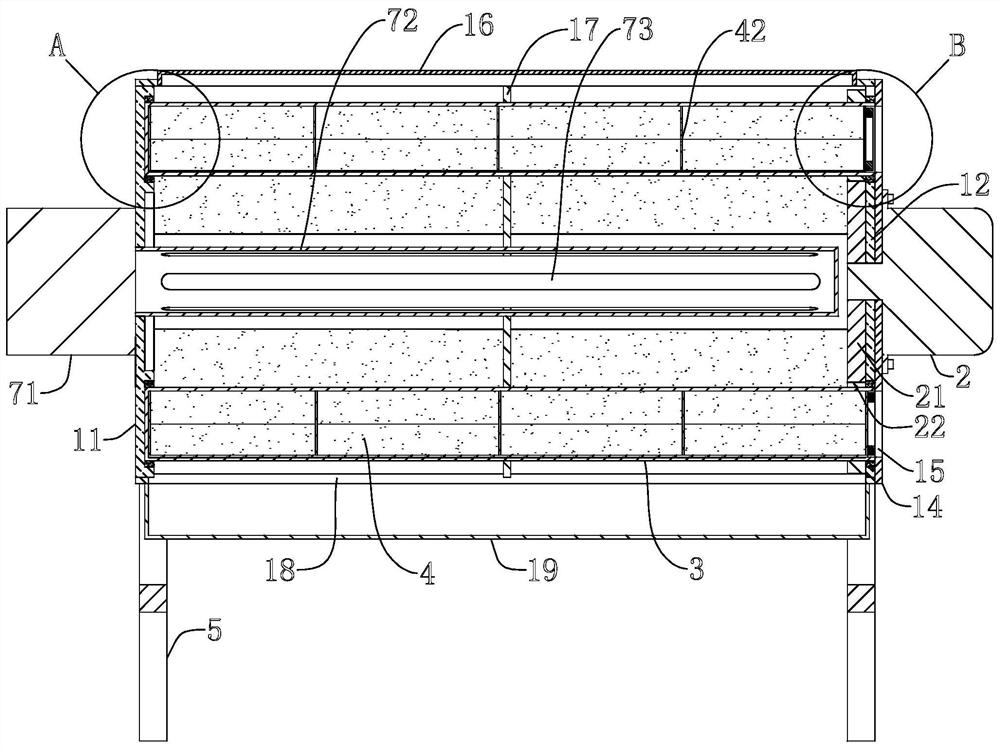

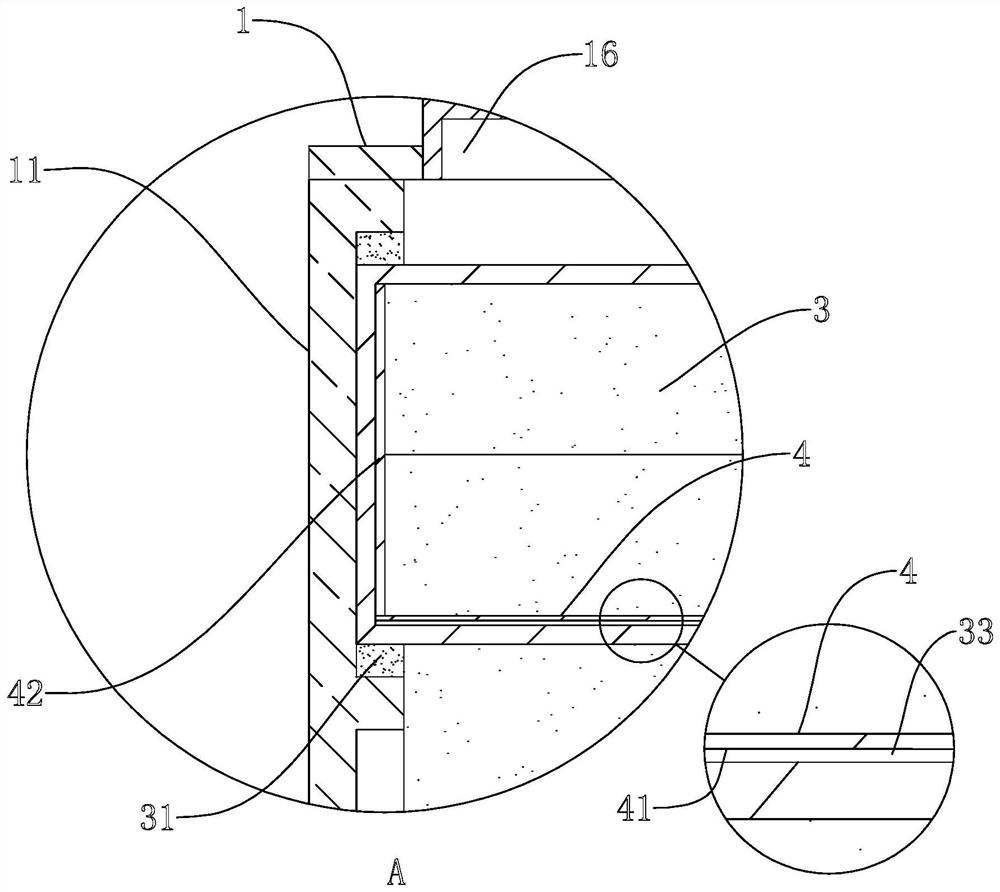

[0027] Embodiment, a drying device for tea processing, such as Figure 1 to Figure 6 As shown, it includes a main body 1 that is hollow inside and has openings at both left and right ends. The left open end of the main body 1 is provided with a left end plate 11, the right open end of the main body 1 is provided with a right end plate 12, and the right side of the right end plate 12 is provided with a rotating Motor 2, the left side of right end plate 12 is provided with first gear 21, and rotating motor 2 drives first gear 21 to rotate, and the left side of right end plate 12 is provided with at least two second gears 22 on the peripheral side of first gear 21, At least two second gears 22 are meshed with the first gear 21, and each second gear 22 is horizontally inserted with a rotating drum 3 with an opening on the right side. Specifically, the second gear 22 and the rotating drum 3 in this embodiment The quantity of tube 3 is six, certainly, also can be three or seven all ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com