Internal heating type roller vacuum drying machine

A drum vacuum and internal heating technology, which is applied in dryers, non-progressive dryers, drying, etc., can solve the problems of insufficient heat energy of heat-conducting working medium, limited heating area, and lack of heat energy for materials.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

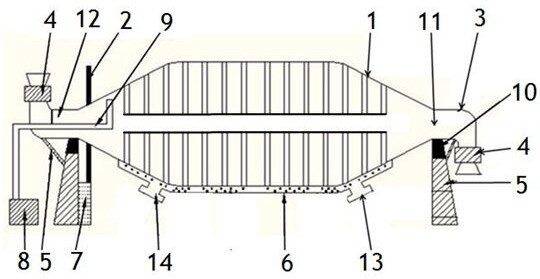

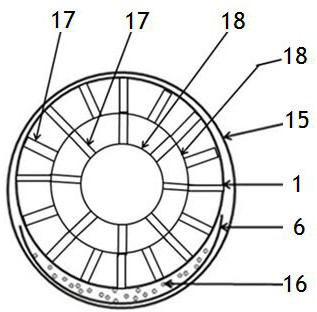

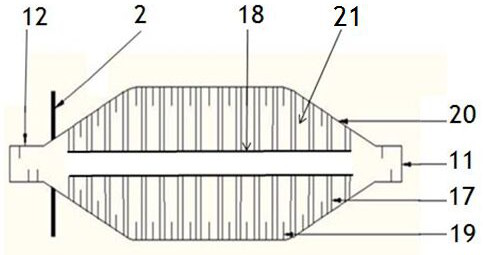

[0084] Such as figure 1 , figure 2 The shown internal heating drum vacuum dryer includes a drum drying chamber 1, a gear ring 2, an elbow device 3, a discharge device 4, a bracket 5, a heating tank 6, a driving device 7, a vacuum unit 8, an air duct 9, Insulation layer 15, support roller 10, hopper 25.

[0085] The gear ring 2 is installed on the drum drying bin 1, and the gear ring 2 and the drum drying bin 1 are connected and fixed as a whole.

[0086] The supporting roller 10 is fixedly mounted on the bracket 5 .

[0087] The supporting wheels 10 on the support 5 support the drum drying bin 1 .

[0088] The drive device 7 is fixedly installed on the ground. The driving wheels of the driving device 7 occlude and drive the gear teeth of the gear ring 2 on the drum drying bin 1 , and the gear ring 2 drives the drum drying bin 1 .

[0089] The drum drying bin 1 is driven by the driving device 7 , and the supporting wheels 10 of the drum drying bin 1 on the bracket 5 suppo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com