Heat pipe type three-cylinder dryer

A three-cylinder dryer and heat pipe technology, applied in dryers, drying, non-progressive dryers, etc., can solve the problems of insufficient total heat energy of the thermally conductive working medium, affecting the drying efficiency of materials, and limited heating area.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

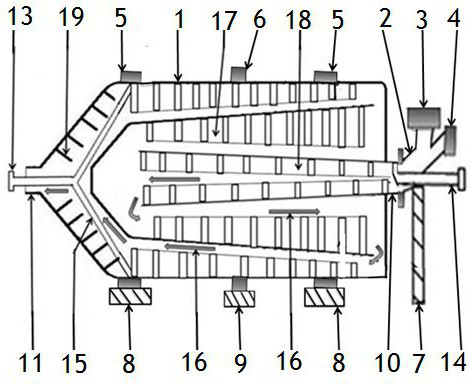

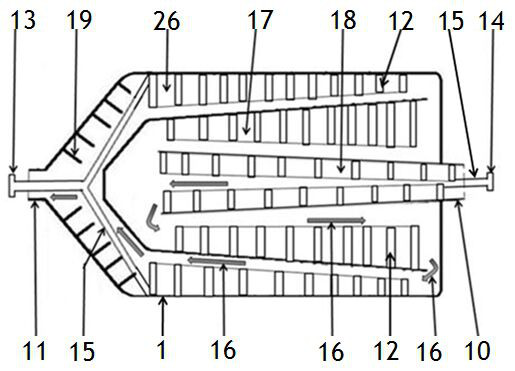

[0090] Such as figure 1 , figure 2 , image 3 The shown heat pipe three-cylinder dryer includes a heat pipe three-cylinder drying chamber 1, a tee joint device 2, a discharge device 3, an exhaust device 4, a raceway 5, a gear ring 6, a bracket 7, a supporting wheel 8, and a drive device9.

[0091] The outer diameter of the three-cylinder drying bin 1 of the heat pipe is 2800mm, and the length is 8000mm.

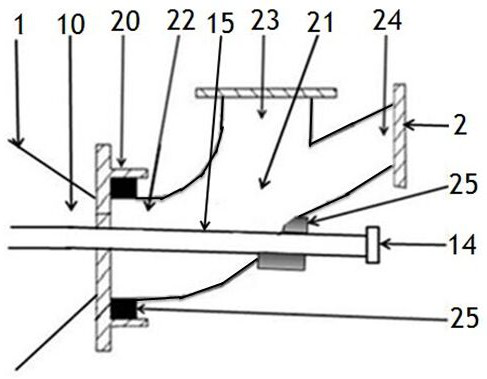

[0092] Such as image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 The shown heat pipe three-cylinder drying bin 1 includes a heating device 12, a three-cylinder drying bin, and a spiral blade 19; the heating device 12 is installed in the three-cylinder drying bin.

[0093] The three cylinder drying bins include an outer drum drying bin 26, a middle drum drying bin 17, and an inner drum drying bin 18.

[0094] The inner cylinder drying warehouse 18 at one end of the three cylinder drying warehouses of the heat pipe 1 has an inlet opening 10, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com