Cylinder drying machine with cooling segment

A tumble dryer and cooling section technology, which is applied in dryers, drying, non-progressive dryers, etc., can solve the problems of small heat dissipation area, unusable, scrapped tumble dryers, etc., and achieve sealing effect. Good, guarantee the effect of negative pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

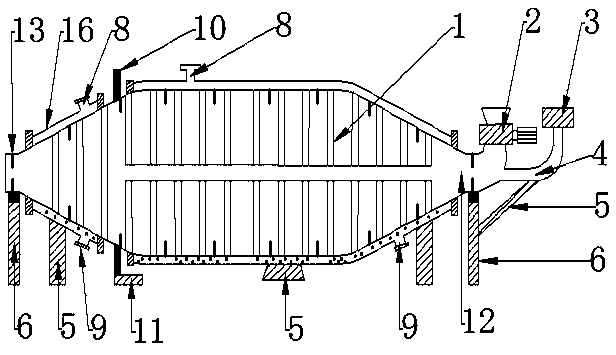

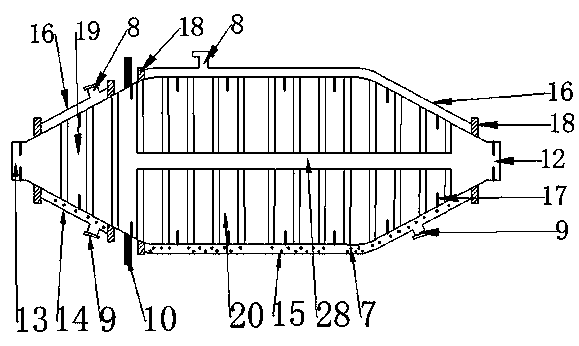

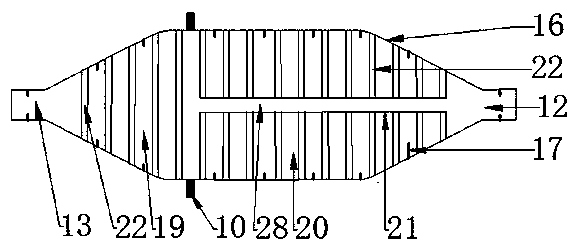

[0129] Such as figure 1 , figure 2 , Figure 6 A tumble dryer with a cooling section shown includes a tumble drying chamber (1), a discharge device (2), an exhaust device (3), a three-way pipe (4), a bracket (5), and a supporting wheel bracket (6), gear ring (10), driving device (11), sealing device (18).

[0130] The sealing device (18) is a dynamic sealing device.

[0131] The drum drying bin (1) has a material inlet (12) and a material outlet (13).

[0132] The supporting wheel bracket (6) includes a bracket and a supporting wheel.

[0133] 1. The supporting wheel is installed on the bracket.

[0134] 2. The supporting roller bracket (6) supports the drum drying bin (1); the supporting roller on the bracket of the supporting wheel bracket (6) supports the drum drying bin (1).

[0135] Such as figure 1 , Figure 6 The shown three-way pipeline (4) has a feed port (12), a discharge port (13), and an exhaust port (26).

[0136] The exhaust device (3) and the exhaust p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com