Roller type hot air dryer

A hot air dryer, drum type technology, applied in dryers, drying, non-progressive dryers, etc., can solve the problems of difficult maintenance, increase a lot, and cannot be used, and achieve easy drying and good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

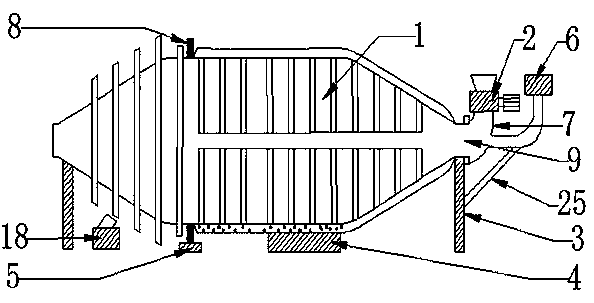

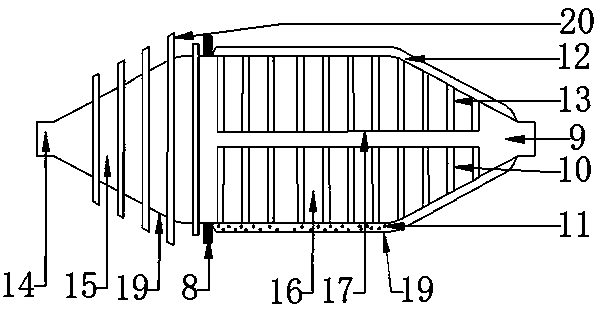

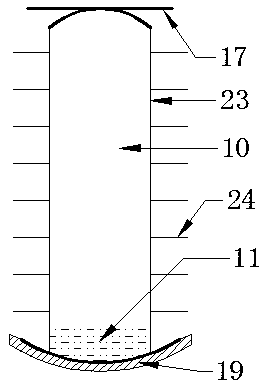

[0115] like figure 1 , figure 2 A drum type hot air dryer shown includes a drum drying chamber (1), a discharge device (2), a supporting wheel support (3), a heating device (4), a driving device (5), an exhaust device (6 ), tee pipe (7), gear ring (8), fan (18), sealing device (21), bracket (25).

[0116] The drum drying bin (1) has a material inlet (9) and a material outlet (14).

[0117] The supporting wheel bracket (3) includes a bracket and a supporting wheel.

[0118] 1. The supporting wheel is installed on the bracket.

[0119] 2. The roller bracket (3) supports the drum drying chamber (1).

[0120] like figure 1 , Figure 5 The three-way pipe (7) shown is a three-way metal pipe.

[0121] 1. There is an inlet (9), an outlet (14) and an exhaust outlet (22) on the three-way pipe (7).

[0122] There is a flange (26) on the feed port (9) of the tee pipe (7).

[0123] 1. One end of the unloading device (2) is fixedly connected to the flange (26) of the feed port (9)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com