Three-dimensional heating type two-cone vacuum drier

A vacuum dryer and three-dimensional heating technology, applied in non-progressive dryers, dryers, heating devices, etc., to achieve the effect of increasing the total amount of heat energy transmission, reducing the loss and optimizing the drying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

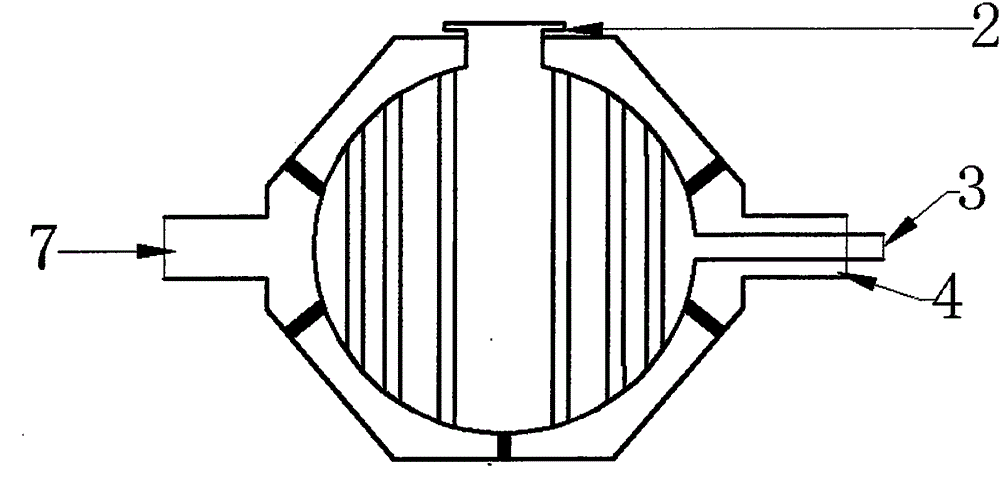

[0017] Such as figure 1 A three-dimensional heating type double-cone vacuum dryer shown is composed of a three-dimensional heating type vacuum drying chamber (1), a support (6), a vacuum unit (8), and a driving device (5).

[0018] The two ends of the three-dimensional heating vacuum drying chamber (1) are installed on the support (6).

[0019] The appearance shape of the three-dimensional heating vacuum drying chamber (1) is biconical.

[0020] The driving device (5) is installed on the bracket (6), and the driving device (5) drives the rotation movement of the three-dimensional heating vacuum drying chamber (1).

[0021] Such as figure 1 , figure 2 The shown three-dimensional heating vacuum drying chamber (1) has a heat-conducting medium inlet (7) and a heat-conducting medium outlet (4); the heat-conducting medium inlet (7) and the heat-conducting medium outlet (4) can be connected to a heating device.

[0022] The exhaust port (3) of the three-dimensional heating vacuu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com