Thermal tube type vacuum drier capable of utilizing afterheat

A vacuum dryer and vacuum unit technology, applied in non-progressive dryers, dryers, drying solid materials, etc., can solve the problems of low heat energy use efficiency, small heat dissipation area, unutilized heat energy, etc. High cost performance, high heat conversion efficiency, and the effect of shortening drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

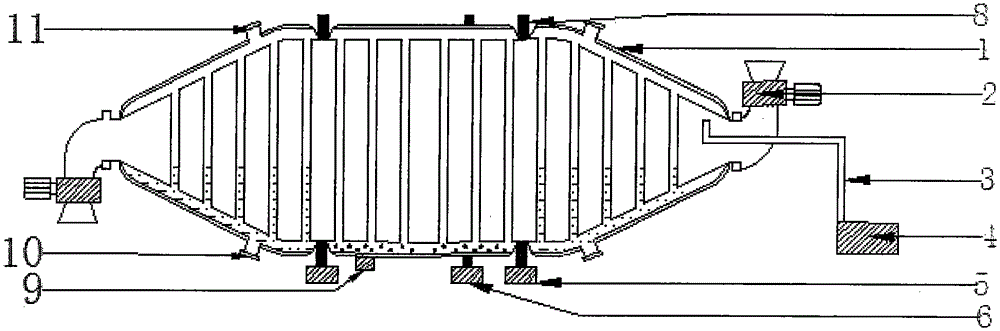

[0059] like figure 1 Shown is a heat pipe vacuum dryer (Type A) that can utilize waste heat, which consists of a heat pipe drying chamber (1) that can utilize waste heat, a vacuum feeding and discharging device (2), an air duct (3), and a vacuum unit (4) , a bracket (5), a driving device (6), a track (8) and a heating device (9).

[0060] like figure 1 , figure 2 The shown heat pipe drying chamber (1) that can utilize waste heat is composed of an outer shell (12), an inner chamber (13), a heat-conducting working medium (19) and a heat-conducting medium (18).

[0061] The inner bin (13) is composed of a bin body, a cooling standpipe (16) and spiral blades.

[0062] The interior of the inner chamber (13) is divided into a preheating section (22), a drying section (21) and a cooling section (20).

[0063] The outer casing (12) is respectively installed on the preheating section (22), the drying section (21) and the cooling section (20) of the inner chamber (13).

[0064] Th...

Embodiment 2

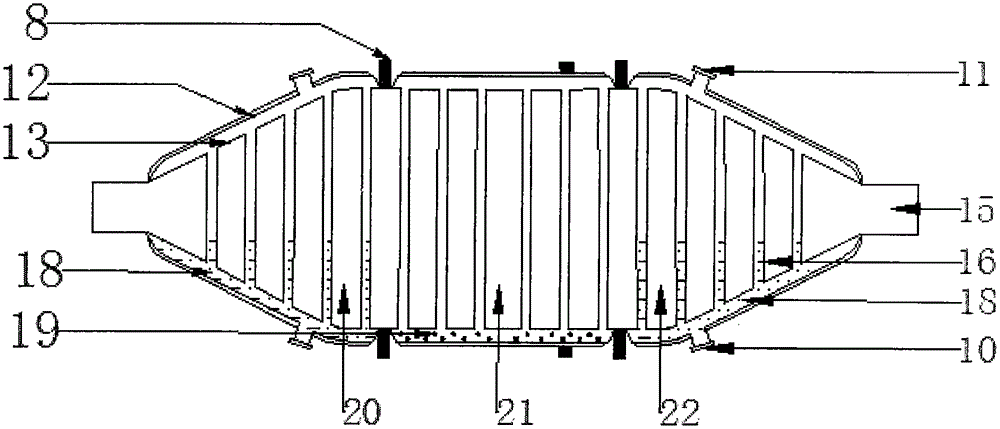

[0118] Such as Figure 4 Shown is a heat pipe vacuum dryer (Type B) that can utilize waste heat, which consists of a heat pipe drying chamber (1) that can utilize waste heat, a vacuum feeding and discharging device (2), an air duct (3), and a vacuum unit (4) , a support (5), a driving device (6), a track (8), and a heating device (9).

[0119] Such as Figure 4 A kind of heat pipe vacuum dryer (B type) that can utilize waste heat shown is the same as the combined structure of the heat pipe vacuum dryer (A type) that can utilize waste heat introduced in embodiment 1 and will not be repeated.

[0120] Such as Figure 5 The shown heat pipe drying chamber (1) that can utilize waste heat is composed of an outer shell (12), an inner chamber (13), a heat-conducting working medium (19) and a heat-conducting medium (18).

[0121] The interior of the inner warehouse (13) is divided into a drying section (21) and a cooling section (20); the drying section (21) and the cooling section ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com