Drum vacuum dryer

A drum vacuum and dryer technology, applied in dryers, drying, non-progressive dryers, etc., can solve problems such as low heat energy use efficiency, leakage of heat pipes, and inability to use, and achieve energy saving and reduction of waste heat utilization. row, avoid impact swing, ensure the effect of negative pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

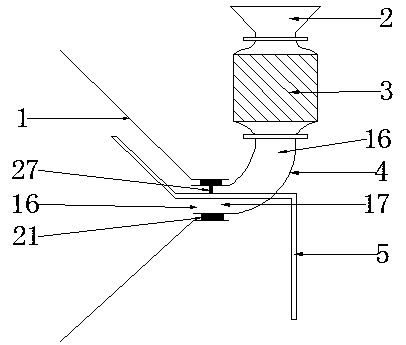

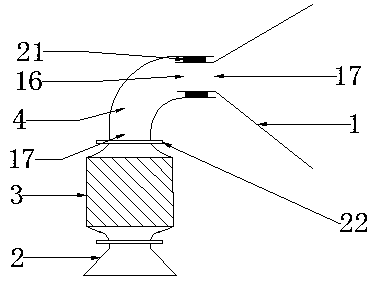

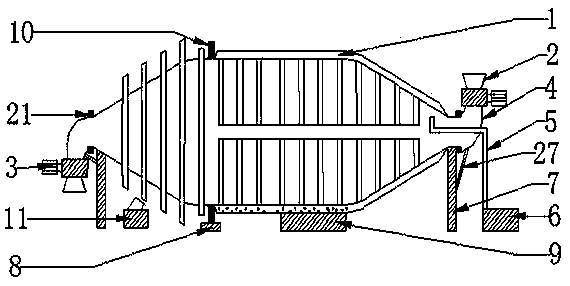

[0132] Such as figure 1 , figure 2 The drum vacuum dryer shown includes a vacuum drying chamber (1), a hopper (2), a discharge device (3), an elbow (4), an air duct (5), a vacuum unit (6), and a supporting wheel Support (7), driving device (8), heating device (9), gear ring (10), blower fan (11), sealing device (21), support (27).

[0133] The vacuum drying bin (1) has a feed inlet (16) and a feed outlet (17).

[0134] The supporting wheel bracket (7) includes a bracket and a supporting wheel.

[0135] 1. The supporting wheel is installed on the bracket.

[0136] 2. The support roller bracket (7) supports the vacuum drying chamber (1) and has a material inlet (16) and a material outlet (17).

[0137] Such as figure 1 , figure 2 , Figure 5 The shown elbow (4) is a metal elbow, and one end of the elbow (4) has a flange, and the other end does not have a flange to be a bare pipe.

[0138] The end of the elbow (4) without flange and the feed port (16) of the vacuum dryi...

Embodiment 2

[0220] The combined structure of the drum vacuum dryer shown in Embodiment 2 is the same as that described in Embodiment 1, and the similarities will not be repeated.

[0221] A drum vacuum dryer includes a vacuum drying chamber (1), a hopper (2), a discharge device (3), an elbow (4), an air duct (5), a vacuum unit (6), and a support wheel bracket (7 ), driving device (8), heating device (9), gear ring (10), fan (11), sealing device (21), bracket (27).

[0222] The vacuum drying bin (1) has a feed inlet (16) and a feed outlet (17).

[0223] The vacuum drying chamber (1) includes a heating chamber (12), a drying chamber (13), and a heat-conducting working fluid (15).

[0224] The heating chamber (12) is outside the drying chamber (13).

[0225] The drying bin (13) includes a bin body (26), a cooling standpipe, a heat pipe (14), a spiral blade, and a fixing strip (23).

[0226] The heat dissipation standpipe includes metal pipes (25) sealed at both ends, fins (24), and heat-c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com