Hot air drying machine with cooling section

A technology of hot air dryer and cooling section, which is applied in non-progressive dryers, dryers, and drying solid materials, etc., which can solve the problem that the dried materials cannot be cooled, the dried materials have dead angles, and heat exchange Low efficiency and other problems, to achieve the effect of enhancing cleanliness, shortening drying time, and ensuring material quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

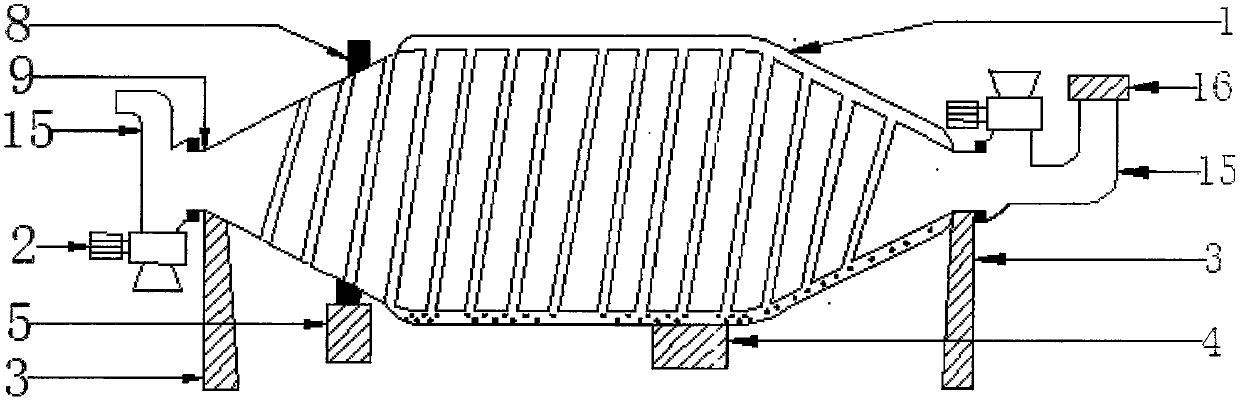

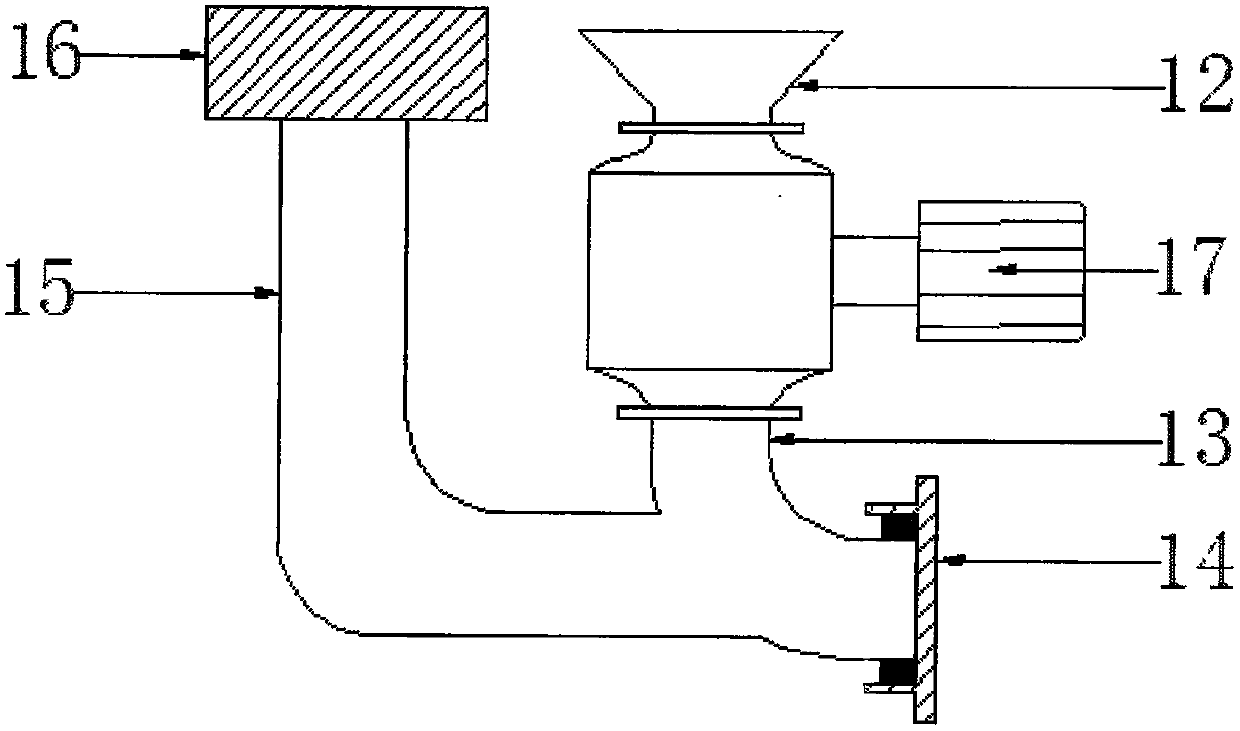

[0043] like figure 1 The shown hot air dryer with cooling section consists of drying chamber (1) with cooling section, vacuum feeding and discharging device (2), support (3), heating device (4), driving device (5), ventilation duct (15), blower fan (16) and track (8) form.

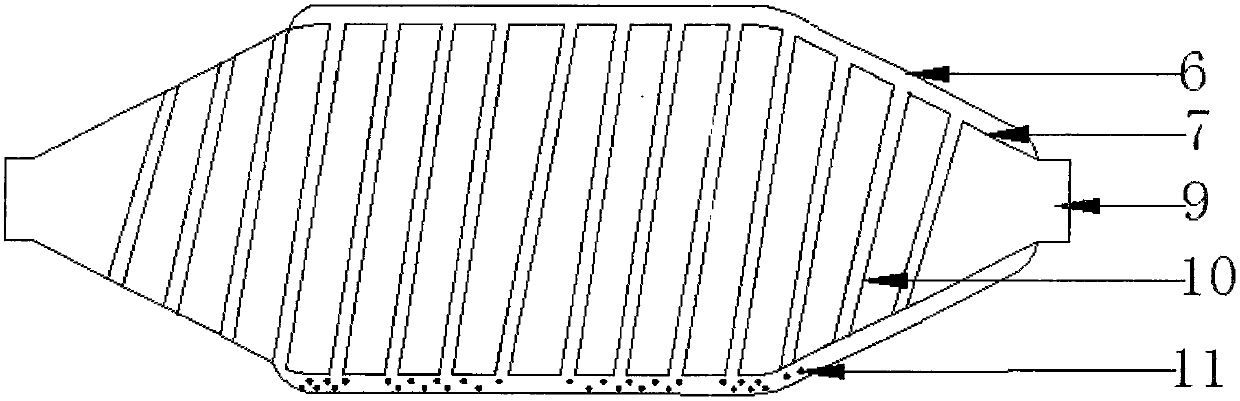

[0044] like figure 2 The shown drying chamber (1) with cooling section consists of an outer shell (6), an inner chamber (7), a heat-conducting working medium (11), and a cooling

[0045] The shell (6) is outside the inner chamber (7), and the inner cavity between the outer shell (6) and the inner chamber (7) is filled with a heat-conducting working medium (11).

[0046] The section of the inner chamber (7) with the shell (6) is a drying section; the section without the shell (6) on the inner chamber (7) is a cooling section.

[0047] The outer cover of the shell (6) has an insulating layer to keep warm, and the insulating layer and the shell (6) are not connected.

[0048] The inner bin (7) is compose...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com