Heat pipe type three-cylinder vacuum dryer

A technology of heat pipe type and dryer, applied in dryers, non-progressive dryers, drying, etc., which can solve the problem of limited heating area, affecting the drying efficiency of materials in vacuum drying chambers, and insufficient total heat energy of heat-conducting working fluids And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

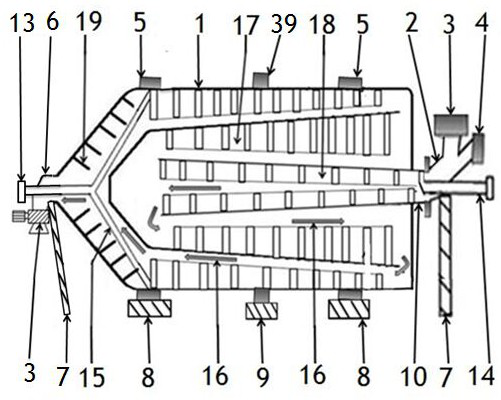

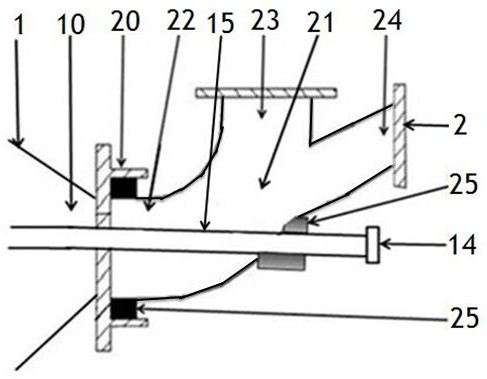

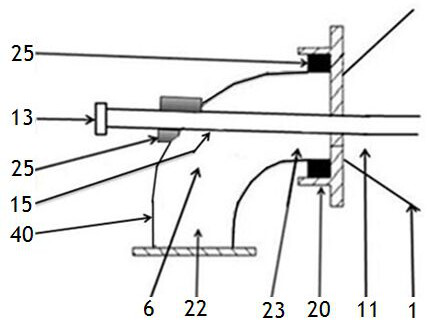

[0099] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 , Figure 8 , Figure 9 The heat pipe type three-cylinder vacuum dryer shown includes a vacuum drying chamber 1, a raceway 5, a gear ring 39, a tee joint device 2, a discharge device 3, a vacuum unit 4, an elbow device 6, a bracket 7, and supporting wheels 8. Driving device 9.

[0100] The outer diameter of the vacuum drying chamber 1 is 2800mm, and the length is 8000mm.

[0101] The vacuum drying bin 1 includes a heating device 12, a three-barrel drying bin, and a spiral blade 19; the heating device 12 is installed in a bin of the three-barrel drying bin.

[0102]The three cylinder drying bins include an outer drum drying bin 26, a middle drum drying bin 17, and an inner drum drying bin 18.

[0103] The vacuum drying chamber 1 has an inlet port 10 and an outlet port 11 .

[0104] A heating device 12 and a spiral blade 19 are installed in the outer cylinder drying chamber 26 of the three-cylinder d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com