Roller vacuum drying machine with cooling section

A drum vacuum and cooling section technology, applied in the direction of dryers, drying, non-progressive dryers, etc., can solve the problems of large heat loss, etc., and achieve the effects of increasing firmness, avoiding impact and swing, and good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

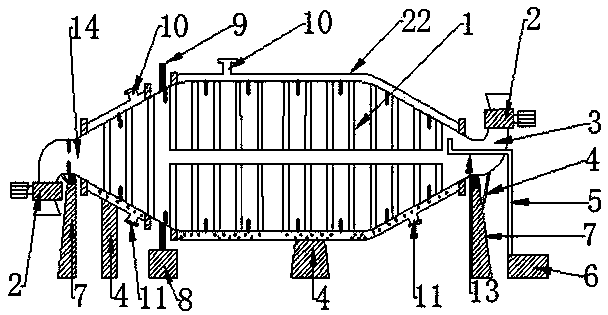

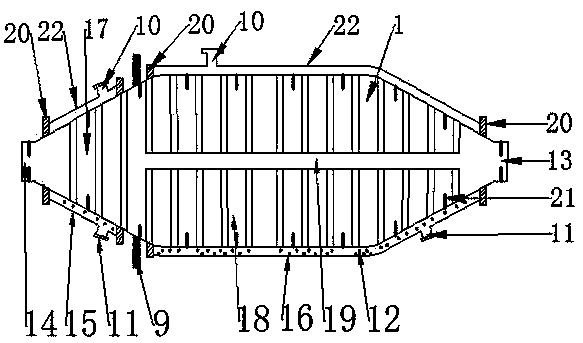

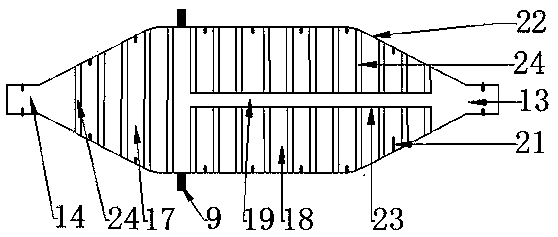

[0131] Such as figure 1 , figure 2 , Figure 6 , Figure 7 A drum vacuum dryer with a cooling section shown includes a drum drying chamber (1), a discharge device (2), an elbow (3), a bracket (4), an air duct (5), a vacuum unit (6 ), supporting wheel bracket (7), driving device (8), gear ring (9), sealing device (20), hopper (29).

[0132] The drum drying chamber (1) includes a heating chamber (16), a cooling chamber (15), a drying chamber (19), a sealing device (20), and a heat conducting medium (12).

[0133] The drum drying bin (1) has an inlet (13) and an outlet (14); the inlet (13) and outlet (14) on the drum drying bin (1) are also drying bins (19 ) feed port (13), discharge port (14).

[0134] Such as figure 1 Shown support roller support (7) comprises support, support roller.

[0135] 1. The supporting wheel is installed on the bracket.

[0136] 2. The roller support (7) supports the drying chamber (19) supporting the drum drying chamber (1).

[0137] The bra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com