Internal heating type drum dryer

A drum dryer, internal heating technology, applied in dryers, non-progressive dryers, drying, etc., can solve the problem that the drum materials cannot get heat energy, the heating area is limited, and the material drying of the drum dryer is affected Speed and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

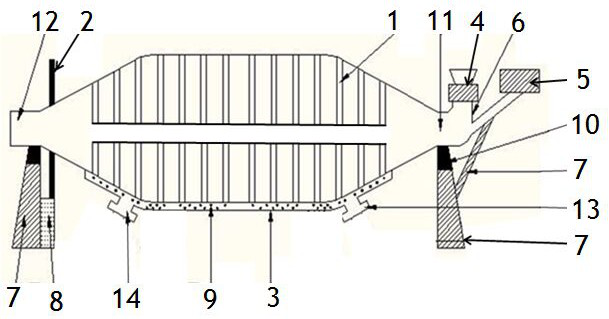

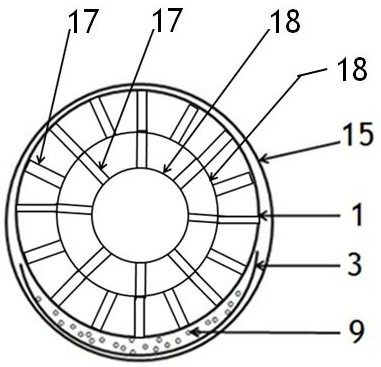

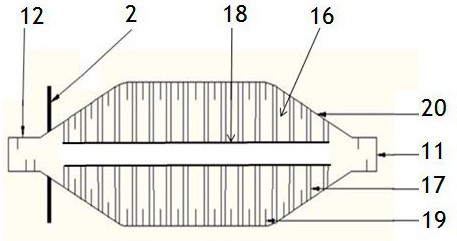

[0079] Such as figure 1 , figure 2 The internally heated tumble dryer shown includes a tumble drying bin 1, a gear ring 2, a heating tank 3, a feeding device 4, an exhaust device 5, a three-way device 6, a bracket 7, a driving device 8, and supporting wheels 10, Insulation layer 15.

[0080] The gear ring 2 is installed on the drum drying bin 1, and the gear ring 2 and the drum drying bin 1 are connected and fixed as a whole.

[0081] The supporting roller 10 is fixedly mounted on the bracket 7 .

[0082] The two ends of the drum drying bin 1 are provided with an inlet port 11 and an outlet port 12 .

[0083] The supporting wheels 10 on the support 7 support the drum drying bin 1 .

[0084] The driving device 8 is fixedly installed on the ground.

[0085] The driving device 8 is a hydraulic motor.

[0086] The heating tank 3 has a heat energy inlet 14 and a heat energy outlet 13; the appearance shape of the heating tank 3 is bathtub-shaped. The heating tank 3 is fixedl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com