Heat-pipe-type drum drying bin

A drum drying and heat pipe type technology, which is applied in the direction of drying solid materials, drying, dryers, etc., can solve the problems of materials not getting heat energy, limited heating area of heat-conducting working medium, and limited heat-conducting area, so as to improve heat conduction and heat reception speed effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

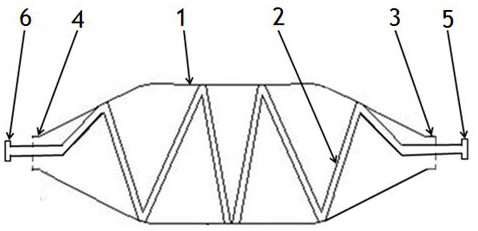

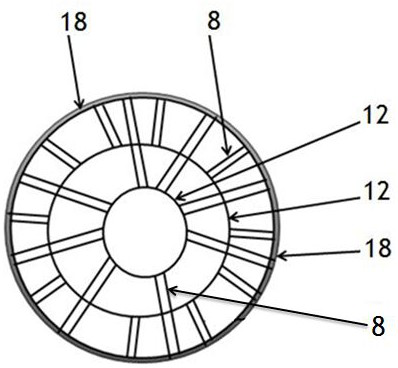

[0068] Such as figure 1 , figure 2 , image 3 The shown heat pipe type drum drying chamber includes a heat pipe heating device 2 and a drum drying chamber 1 .

[0069] The drum drying bin 1 is provided with a feed port 3 and a discharge port 4 .

[0070] The heat pipe heating device 2 is installed in the drum drying bin 1 .

[0071] The diameter of the drum drying bin 1 is 1580mm, and the length is 8000mm.

[0072] The material for making the bin body 18 of the drum drying bin 1 is a metal plate, and the thickness of the metal plate is 8 mm.

[0073] The diameter of the heat pipe heating device 2 is 1590mm, and the length is 9200mm.

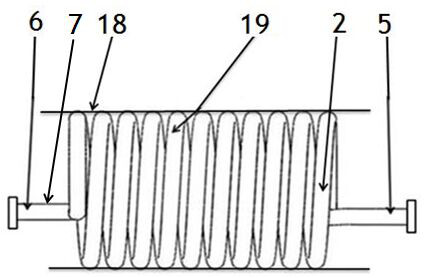

[0074] Such as figure 1 , image 3 , Figure 4 , Figure 5 The shown heat pipe heating device 2 includes a heating pipe 8 and a heat conducting pipe 7 .

[0075] The heat pipes 7 are arranged in a spiral shape.

[0076] The heat pipe 7 has a heat inlet 6 and a heat outlet 5; the diameter of the heat pipe 7 is 68mm, and the length of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com